1. Einführung: Das Verständnis von F0008-Pulver in der Pulvermetallurgie

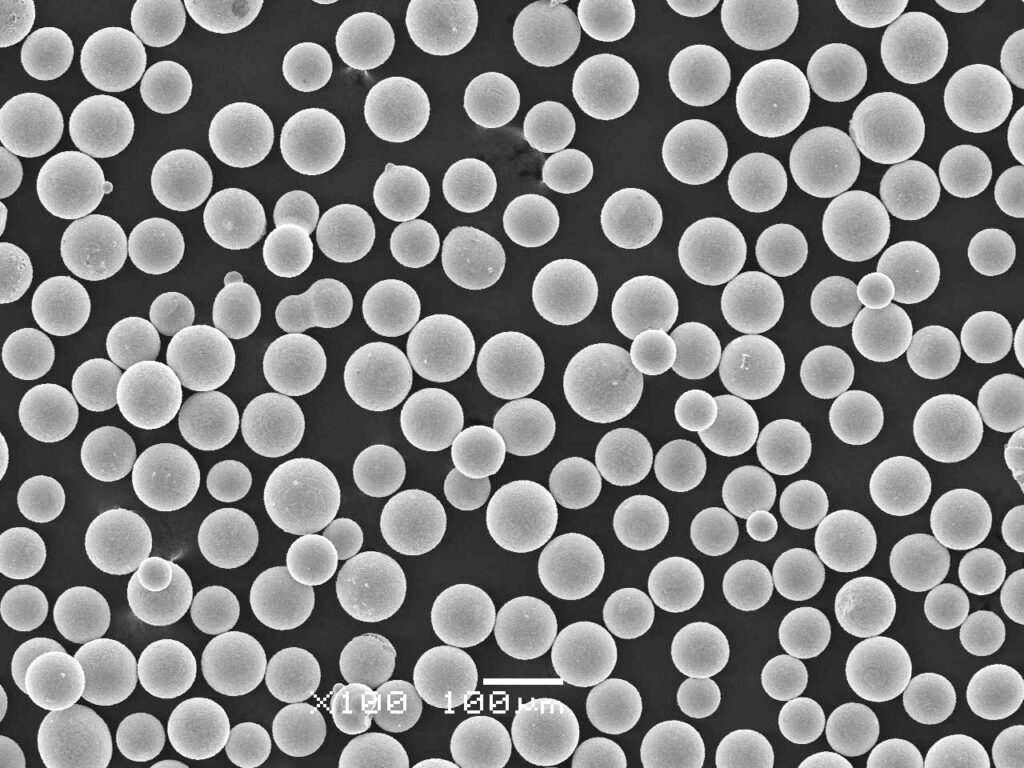

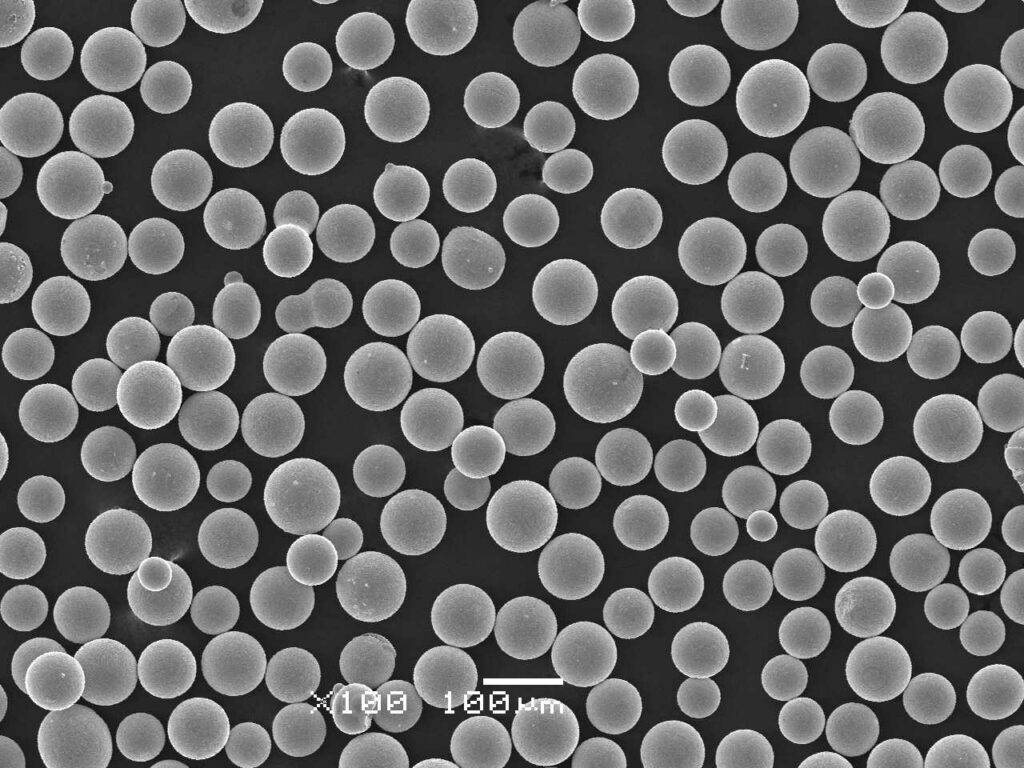

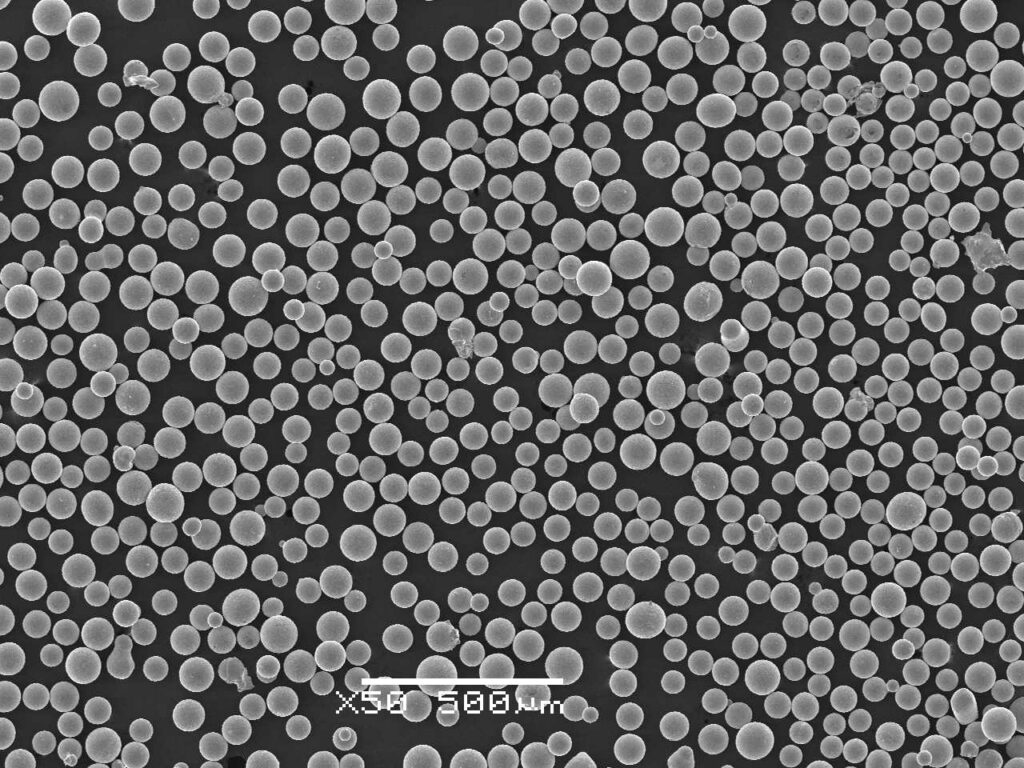

F0008-Pulver ist eine in der pulvermetallurgischen Industrie weit verbreitete Sorte, die als reines Eisenpulver mit einem Kohlenstoffgehalt von maximal 0,008 % klassifiziert ist. Es wird hauptsächlich durch Wasserverdüsung oder Eisenschwamm-Reduktionsverfahren hergestellt. F0008 ist bekannt für seine hohe Kompressibilität und hervorragende Maßgenauigkeit, wodurch es sich ideal für PM-Strukturteile eignet.

Auf B2B-Märkten, insbesondere für Distributoren, Großhändler und Komponentenhersteller, bietet F0008-Pulver ein kostengünstiges Basismaterial mit gleichbleibender Leistung. Es ist in den MPIF-Normen (Metal Powder Industries Federation) enthalten und wird häufig als Referenzsorte für Qualität und Sinterverhalten verwendet.

Hauptmerkmale von F0008-Pulver:

| Merkmal | Spezifikation |

|---|---|

| Kohlenstoffgehalt | ≤ 0.008% |

| Partikelform | Unregelmäßig (wasserzerstäubt) |

| Durchflussmenge | ~25-30 s/50g |

| Scheinbare Dichte | ~2,90-3,00 g/cm³ |

| Komprimierbarkeit | Hoch |

| Typische Anwendungen | Strukturelle Teile, Buchsen |

F0008 ist besonders attraktiv für OEMs und Hersteller von PM-Teilen, die ein zuverlässiges, einfach zu formulierendes Basispulver suchen.

🔗 Möchten Sie technische Details erfahren oder F0008 bestellen? Besuchen Sie die F0008 Pulver Produktseite

2. Industrielle Anwendungen von F0008-Pulver

F0008-Pulver ist aufgrund seiner Reinheit, Formbarkeit und Kosteneffizienz ein grundlegender Rohstoff für eine Reihe von Branchen. Es wird in der Regel als Basispulver in Formulierungen verwendet und mit Legierungselementen wie Kupfer gemischt, Nickelund Graphit, um spezifische mechanische Anforderungen zu erfüllen.

Schlüsselindustrien, die F0008-Pulver verwenden:

- Automobilindustrie: Zahnräder, Ritzel, Riemenscheiben und Pleuelstangen

- Landwirtschaftliche Maschinen: Strukturelle Halterungen, Buchsen und Verschleißteile

- Unterhaltungselektronik: Magnetkerne, Wärmesenken

- Industrielle Ausrüstung: Kompressorteile, Ventilsitze, Nocken

- Werkzeuge und Hardware: Handwerkzeuge, Schlösser und Verschlüsse

Vorteile der Verwendung von F0008 in der industriellen Fertigung:

- Hohe Grünfestigkeit für verdichtete Teile

- Konstantes Sinterverhalten

- Kostengünstig im Vergleich zu legierten Pulvern

- Anpassungsfähig an verschiedene Sinterumgebungen (z. B. Wasserstoff, Stickstoff)

Beispielanwendungstabelle

| Anwendungsbereich | F0008 Beispiel für einen Anwendungsfall | Vorteile |

|---|---|---|

| Automobilindustrie | Zahnrad | Gleichmäßige Verschleißfestigkeit |

| Industrielle Maschinen | Pumpenhülse | Hohe Dimensionsstabilität |

| Elektronik | Magnetische Kerne | Geringe Wirbelstromverluste |

| Werkzeuge und Hardware | Teile des Schließmechanismus | Starke mechanische Eigenschaften |

3. Eigenschaften und technische Merkmale von F0008

Das Verständnis der technischen Eigenschaften von F0008 ist für B2B-Einkäufer von entscheidender Bedeutung, insbesondere für diejenigen, die an der Konstruktion von Bauteilen, Forschung und Entwicklung oder der Beschaffung beteiligt sind. Diese Pulversorte wird wegen ihrer ausgezeichneten Pressbarkeit und ihrer Fähigkeit, für eine verbesserte Leistung legiert oder gemischt zu werden, ausgewählt.

Typische technische Eigenschaften von F0008-Pulver:

| Eigentum | Wertebereich |

|---|---|

| Kohlenstoffgehalt | ≤ 0.008% |

| Sauerstoffgehalt | 0.1% - 0.2% |

| Scheinbare Dichte | 2.90-3,00 g/cm³ |

| Durchflussmenge | 25-30 s/50g |

| Compressibility @ 450 MPa | ≥ 7,0 g/cm³ |

| Grüne Stärke | 15-25 MPa |

| Sintered Density (@1120°C) | 6.6-7,1 g/cm³ |

Vorteile für B2B-Einkäufer:

- Gleichmäßige Partikelgrößenverteilung für gleichbleibende Teilequalität

- Hervorragende Verdichtbarkeit, geringerer Pressenverschleiß

- Kompatibilität mit automatischen Verdichtungssystemen

- Flexibles Legieren mit Kupfer, Nickel oder Graphit

Gängige Legierungen, die mit F0008 gemischt sind:

- Cu-2%-Mischung für Verschleißfestigkeit

- Ni-2%-Mischung für erhöhte Zähigkeit

- Graphit 0,5%-1% für Stärke & Härte

📌 Erfahren Sie mehr über Pulvermetallurgie und Shanghai Truer’s firmenhintergrund im Bereich der additiven Fertigung und PM-Lösungen.

4. Globale Markttrends und Nachfrageprognose für F0008

Der globale Markt für Pulvermetallurgie (PM) wächst weiterhin stetig, angetrieben durch die Nachfrage aus den Bereichen Automobil, Industrie und Unterhaltungselektronik. F0008-Pulver, als eines der am häufigsten verwendeten Eisenpulver, spielt aufgrund seiner Vielseitigkeit, Kosteneffizienz und Leistung in Strukturbauteilen eine entscheidende Rolle bei diesem Wachstum.

🔍 Markteinblicke (2024-2030 Prognose)

| Region | Haupttreiber | CAGR (2024-2030) |

|---|---|---|

| Asien-Pazifik | Automotive & Maschinenbau, Kostenvorteile | 5.8% |

| Europa | Energieeffiziente Komponenten, EV-Nachfrage | 4.2% |

| Nord-Amerika | Luft- und Raumfahrt, Verteidigung und Konsumgüter | 3.9% |

| Naher Osten/Afrika | Entwicklung der Infrastruktur, wachsende industrielle Basis | 4.5% |

- Automobilbranche: Aufgrund der leichten, kostengünstigen PM-Teile ist F0008 nach wie vor der größte Anwender.

- Elektrofahrzeuge (EVs): Die steigende Nachfrage nach weichmagnetischen Komponenten fördert die Verwendung von F0008 in Motorkernen und Statoren.

- Grüne Produktion: Hohe Materialausnutzung und geringer Abfall machen F0008 für eine nachhaltige Produktion attraktiv.

📈 Nachfragetreiber für F0008

- Hohes Leistungs-/Kostenverhältnis

- Leicht legiert für verschiedene Anwendungen

- Zuverlässige Qualität von etablierten Lieferanten

- Kompatibilität mit Hochgeschwindigkeitsverdichtung und -sintern

🧭 Sind Sie an der Beschaffung von F0008 für Ihre Region interessiert? Entdecken Sie unser kontaktseite für den weltweiten Vertriebspartner-Support.

5. Wichtige Überlegungen bei der Beschaffung von F0008-Pulver

Für B2B-Einkäufer geht es bei der Beschaffung von F0008-Pulver um mehr als nur um eine Bestellung - sie müssen auch die Fähigkeiten des Lieferanten, die technische Konsistenz und das Preis-Leistungs-Verhältnis bewerten. Nachstehend finden Sie wichtige Kriterien, die Sie bei der Auswahl eines Lieferanten berücksichtigen sollten.

✅ Qualität & Zertifizierung

- Einhaltung von ISO 9001, ISO 14001 und IATF 16949

- Konformität mit MPIF- und ASTM-Normen

- Konsistenz des Kohlenstoff- und Sauerstoffgehalts von Charge zu Charge

✅ Produktionskapazitäten

- Zerstäubungsmethode (Wasser, Reduktion, Gas)

- Jährliche Kapazität und Skalierbarkeit

- Verfügbarkeit von kundenspezifischen Mischungen mit Cu, Ni oder Graphit

✅ Logistik & Lieferkette

- Vorlaufzeit und Bestandsverfügbarkeit

- Exportbereitschaft und Dokumentation

- Regionale Lagerhaltung und JIT-Lieferoptionen

✅ Technische Unterstützung

- Anwendungstechnische Dienstleistungen

- Beratung zur Sinterung

- Legierungsanpassung und Prüflaboratorien

Vergleichstabelle: Lokale vs. globale Beschaffung

| Kriterien | Lokaler Lieferant (Inland) | Globaler Anbieter (Asien/China) |

|---|---|---|

| Kosten pro kg | Hoch | Konkurrenzfähig |

| Vorlaufzeit | Kürzer (falls vorrätig) | Mittel (mit geplanter Logistik) |

| Produktanpassung | Begrenzt | Hoch |

| Technische Unterstützung | Variabel | Verfügbar mit R&D-Labors |

🔎 Suchen Sie einen zuverlässigen, kundenspezifischen F0008-Lieferanten? Besuchen Sie die PM-Pulver-Seite um das umfangreiche Angebot von Shanghai Truer zu erkunden.

6. Die besten F0008-Pulver-Lieferanten in Asien

Asien hat sich als führende Region für die großvolumige und kostengünstige Produktion von F0008-Pulver erwiesen. Die folgenden Lieferanten haben sich einen guten Ruf für Qualität, Konsistenz und Exportfähigkeit erworben.

🏆 Top 5 F0008-Pulver Lieferanten (Asien)

| Name des Unternehmens | Land | Spezialität | Zertifizierungen |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | Komplettes Spektrum an PM-Pulvern + Additivlösungen | ISO 9001, CE, RoHS |

| Hoganas China | China/Schweden | Weltweit führend bei eisenhaltigen Pulvern | IATF 16949, ISO 14001 |

| Pometon S.p.A | Indien/Italien | Wasserverdüstes Eisen- und Kupferpulver | ISO 9001, REICHWEITE |

| JFE Steel Corporation | Japan | Hochwertige reduzierte Eisenpulver | JIS, ISO 9001 |

| CNPC-Pulver-Gruppe | China | Wasser- und gaszerstäubte Pulver für PM & AM | ISO 9001, SGS |

Shanghai Truer Technology auf einen Blick

Shanghai Truer Technology Co., Ltd. wurde 2009 gegründet und ist seit 2019 im Bereich der additiven Fertigung tätig. Das Unternehmen ist spezialisiert auf die Herstellung und Lieferung von Hochleistungs-PM-Pulvern wie F0008, F0000, FC-0208 und legierten Sorten. Truer ist bekannt für:

- Moderne Produktionslinien für die Wasser- und Gaszerstäubung

- Kundenspezifische Mischungen aus Cu, Ni, C und Schmiermitteln für PM-Teile

- Interne Forschung und Entwicklung für die Entwicklung von Additiven und Schmierstoffen

- End-to-End-PM-Lösungen einschließlich Ausrüstung, Pulver und technischer Unterstützung

🌐 Erfahren Sie mehr über den Auftrag und die Innovation von Shanghai Truer auf deren Über uns Seite

7. Warum immer mehr Käufer auf chinesische F0008-Hersteller umsteigen

In den letzten zehn Jahren haben sich chinesische Hersteller rasch zu weltweit führenden Unternehmen in der Pulvermetallurgie entwickelt. Insbesondere für F0008-Pulver bietet China ein einzigartiges Wertversprechen: hochwertige Produktion gepaart mit wettbewerbsfähigen Preisen und reaktionsschnellen Lieferketten.

🚀 Hauptgründe, warum B2B-Einkäufer chinesische F0008-Lieferanten bevorzugen

- Kosteneffizienz

- Der chinesische F0008 kostet in der Regel 15-30 % weniger als westliche Pendants

- Niedrigere Produktions- und Arbeitskosten, die direkt an die Käufer weitergegeben werden

- Skalierbare Produktionskapazität

- Hochvolumige Produktion gewährleistet Konsistenz auch für große OEMs und Händler

- Kürzere Durchlaufzeiten durch automatisierte Linien und umfangreiche Lagerbestände

- Fortschrittliche Technologie

- Einsatz von Gas- und Wasserzerstäubung, CIP (Cold Isostatic Pressing) und Hybrid-Mischverfahren

- Integration von AI- und QC-Automatisierungssystemen für eine bessere Partikelkontrolle

- Anpassung & Flexibilität

- Maßgeschneiderte Zusammensetzungen mit Zusatzstoffen (Cu, Ni, Graphit) auf Anfrage erhältlich

- Unterstützung für Nischenanwendungen: weichmagnetische, gesinterte Lager, komplexe Legierungen

- Konform & Exportfähig

- ISO-zertifizierte Produktionsstätten

- Vertrautheit mit internationaler Logistik, Dokumentation und Zoll

📦 Vorteile von Logistik und Fulfillment

| Merkmal | Beschreibung |

|---|---|

| Regionale Lagerhaltung | Inventarisierungszentren in Asien, EU und NA |

| OEM-Verpackungsoptionen | Kundenspezifisches Verpacken, Palettieren, Vakuumversiegeln |

| Unterstützung der Dokumentation | CO, MSDS, RoHS, REACH, Zollformulare |

| Multimodaler Versand | Schiff, Flugzeug, Bahn je nach Dringlichkeit |

Das chinesische F0008-Ökosystem ist so konzipiert, dass es sowohl Großhändler als auch Nischen-B2B-Käufer unterstützt, die maßgeschneiderte Leistung bei geringeren Kosten suchen.

🏭 Neugierig, wie Shanghai Truer große B2B-Aufträge abwickelt? Erkunden Sie unser Kontakt Seite zur Unterstützung der Logistik und Auftragsplanung.

8. Warum sollten Sie Shanghai Truer Technology als Ihren F0008-Lieferanten wählen?

Shanghai Truer Technology Co., Ltd ist einer der fortschrittlichsten und zuverlässigsten Lieferanten von F0008-Pulver in China. Mit über einem Jahrzehnt Erfahrung in der Pulvermetallurgie und einer spezialisierten Abteilung für additive Fertigung ist Truer mehr als nur ein Lieferant - es ist ein strategischer Partner für B2B-Käufer.

🧬 Was Shanghai Truer auszeichnet

| Merkmal | Shanghai Truer Advantage |

|---|---|

| Erfahrung in der Industrie | Gegründet im Jahr 2009, PM-Geschäft seit 2019 |

| Produktpalette | F0008, F0000, FC-0208, FD-0200, FL-4605, PM-Bronze, PM-Edelstahl, CuSn |

| Produktionsmethoden | Wasserzerstäubung, Gaszerstäubung, Reduktion, Hybridzerstäubung |

| Additives Fachwissen | Schmiermittel (Lube-W, SUW-8000), sulfidfreie Schneidmittel, Graphit, weichmagnetische Pulver |

| Zertifizierungen | ISO 9001, CE, RoHS, vollständige QC-Dokumentation |

| Anpassungsmöglichkeiten | Cu-, Ni-, Graphit-Legierungen; sinterfähige Mischungen |

| Globale Reichweite | Kunden in Nordamerika, Europa und Südostasien |

🌐 Integrierte Lösungen für die Pulvermetallurgie

- Hochreine Grundpulver wie F0008 mit engen Toleranzvorgaben

- Vorgemischte Formulierungen mit verbesserter Sinterleistung

- Eigene Entwicklung von Additiven zur Verbesserung der Grünfestigkeit und Bearbeitbarkeit

- Beratung zu Sinterzyklen, Verdichtungsdruck und Bauteilgestaltung

🧪 Ausgewählte Produkte von Truer

| Pulver Typ | Beschreibung | Anwendungsfälle |

|---|---|---|

| F0008 Eisenpulver | Geringer Kohlenstoffgehalt, hohe Kompressibilität | Strukturelle Teile, Buchsen |

| FX-2008 | Hochdichtes, diffusionslegiertes Eisen | Anwendungen mit hoher Belastung |

| FD-0208 | Cu-Ni vorlegiertes Stahlpulver | Kfz-Getriebe, Nocken |

| SUW-8000 Schmiermittel | Hochtemperatur-PM-Schmierstoff mit geringem Rückstand | PM Teil Produktion |

| QHP-330 Graphit | Stabiler Graphit zum Legieren | Erhöhung der Festigkeit und Härte |

🔗 Entdecken Sie die gesamte PM-Produktpalette auf der PM-Pulver-Seite, einschließlich F0008 und legierte Sorten.

9. FAQs: Was B2B-Einkäufer über F0008-Pulver wissen sollten

Q1: Welchen Normen entspricht das F0008-Pulver?

F0008 entspricht den MPIF- und ASTM-Normen. Shanghai Truer liefert auch interne Qualitätsdaten, einschließlich Partikelgrößenanalyse, Durchflussrate und Schüttdichteberichte.

F2: Kann F0008 für bestimmte Anwendungen angepasst werden?

Ja. F0008 kann mit Kupfer, Nickel, Graphit oder Schmiermitteln gemischt werden, um Ihre mechanischen Anforderungen zu erfüllen. Truer bietet kundenspezifische Formulierungen in Absprache mit Ihrem technischen Team.

F3: Wie gewährleistet Shanghai Truer die Qualitätskontrolle?

Truer verwendet fortschrittliche QC-Systeme, einschließlich Laserbeugung, SEM-Analyse und chemische Analyse auf Chargenebene. Jede Lieferung wird von einem COA (Certificate of Analysis) begleitet.

Q4: Wie hoch ist die Mindestbestellmenge (MOQ) für internationale Käufer?

Die Mindestbestellmengen können je nach Region und Logistik variieren, beginnen aber in der Regel bei 500 kg. Bei größeren Bestellungen sind kundenspezifische Verpackungen und Mengenrabatte möglich.

F5: Kann ich Muster anfordern, bevor ich eine Großbestellung aufgebe?

Auf jeden Fall. Truer stellt kostenlose Muster (normalerweise 1-2 kg) für Tests und Sinterversuche zur Verfügung. Wenden Sie sich an das Vertriebsteam, um den Versand und die Dokumentation zu organisieren.

F6: Wie lange dauert der Versand bei internationalen Bestellungen?

- Asien: 5-10 Tage

- Europa: 15-20 Tage

- Nordamerika: 20-30 Tage

Für dringende Bestellungen sind auch Luftfrachtoptionen verfügbar.

📩 Möchten Sie eine Bestellung aufgeben oder ein Angebot anfordern? Kontaktieren Sie uns über unser Kontakt-Formular

✅ Zusammenfassung der verwendeten internen Links:

| Verwendeter Anchor-Text | URL Verknüpft mit |

|---|---|

| F0008 Pulver Produktseite | https://am-material.com/pm-powder/ |

| firmenhintergrund | https://am-material.com/about/ |

| kontaktseite | https://am-material.com/contact-us/ |

| PM-Pulver-Seite | https://am-material.com/pm-powder/ |

| Kontakt-Formular | https://am-material.com/contact-us/ |

Anhand dieses Leitfadens können Großabnehmer, Hersteller von PM-Komponenten und industrielle Händler fundierte Entscheidungen über die Beschaffung von F0008-Pulver treffen. Shanghai Truer zeichnet sich als vertrauenswürdiger Partner aus, der konsistente Qualität, technische Unterstützung und globale Erfüllung für alle Ihre Bedürfnisse in der Pulvermetallurgie bietet.