1. Introduction: Why Bronze Powder is Vital in Modern Manufacturing

Bronze powder—a finely ground mixture of copper and tin—has become indispensable in various manufacturing sectors, from powder metallurgy (PM) to additive manufacturing (AM). For B2B buyers, bronze powder offers unmatched versatility, corrosion resistance, and thermal conductivity. Its applications range from automotive parts and bushings to decorative coatings and 3D-Druck components.

In bulk procurement, bronze powder is especially valuable due to:

- Cost-efficiency for high-volume production

- Compatibility with pressing and sintering processes

- Enhanced recyclability and sustainability

For industrial buyers, sourcing high-quality bronze powder in bulk ensures consistent performance and reduces operational downtime.

2. Industrial Applications of Bronze Powder

Bronze powder is used extensively across multiple sectors. Below is a breakdown of key industries and how they utilize bronze powder:

| Industrie | Anmeldung | Vorteile |

|---|---|---|

| Automobilindustrie | Bearings, bushings, brake pads | Wear resistance, self-lubrication |

| Luft- und Raumfahrt | Lightweight structural parts | Hohes Festigkeits-Gewichts-Verhältnis |

| Elektrisch | Leitfähige Komponenten | Ausgezeichnete elektrische Leitfähigkeit |

| Additive Fertigung | 3D printed parts | Precision, surface finish |

| Werkzeugbau | Diamond tool bonding | Thermische Stabilität |

| Öl & Gas | Gesinterte Filter | Corrosion resistance under pressure |

Key Benefits for B2B Buyers

- Konsistente Partikelgrößenverteilung

- High bulk density for compaction

- Excellent sintering performance

- Customizability for specific applications

Shanghai Truer Technology Co., Ltd, a leading Chinese supplier, offers a wide range of bronze powders suitable for all these applications. Their powders are manufactured using water atomization, ensuring high purity and optimal performance. Learn more about their PM bronze powder offerings on the PM-Pulver Produktseite.

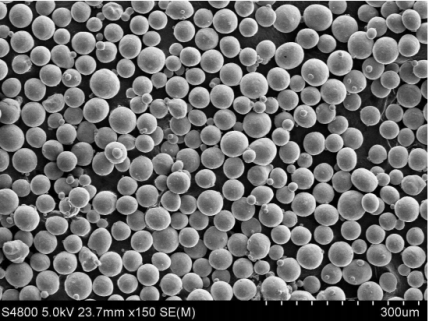

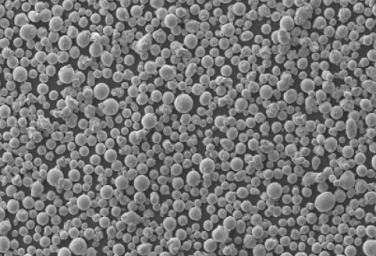

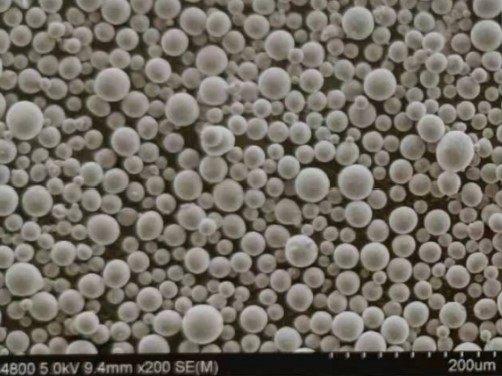

3. Types of Bronze Powder & Their Properties

Bronze powders vary by composition, particle size, and production method. Below is a comparison of the most common types:

| Typ | Zusammensetzung | Produktionsverfahren | Typische Verwendung |

|---|---|---|---|

| Standard Bronze Powder | Cu-Sn Alloy (90/10, 85/15, etc.) | Zerstäubtes Wasser | General PM applications |

| Pre-Alloyed Bronze | Homogeneous Cu-Sn | Zerstäubtes Gas | High-performance sintering |

| Diffusion Alloyed Bronze | Cu matrix with Sn diffused | Reduction/Combined Atomization | Diamond tools, oil-impregnated bearings |

| Fine Bronze Powder | Micron-scale | Carbonyl Process | 3D printing, decorative finishes |

Properties of Bronze Powder

- Particle Size: 20–150 μm (customizable)

- Apparent Density: 2.5–4.5 g/cm³

- Flow Rate: 15–30 s/50g (Hall Flow)

- Oxygen Content: < 0.5%

For example, Shanghai Truer provides both standard and custom bronze powder grades suitable for sintered metal parts and additive manufacturing. Their diffusion CuSn powder is especially popular in producing sintered bearings and diamond tools—two of the most demanding use cases.

If you’re new to the company, you can read more about their legacy and technological capabilities by visiting their Über uns Seite.

4. Global Market Trends and Growth Projections

The global bronze powder market is on a steady growth trajectory, driven by increased demand for powder metallurgy components, rising adoption of additive manufacturing, and evolving applications in the automotive, aerospace, and electronics sectors.

Key Market Stats:

| Metrisch | Wert |

|---|---|

| Global Market Size (2023) | USD 480 Million |

| Projected CAGR (2024–2030) | 6.8% |

| Major Markets | China, USA, Germany, Japan, India |

| Top Application Segments | Automotive (35%), Electronics (20%), Additive Manufacturing (15%) |

Emerging Trends:

- Shift Toward Pre-Alloyed Powders: Pre-alloyed bronze powders offer better homogeneity and sintering efficiency, making them ideal for high-performance applications.

- Increased Customization Demand: OEMs and part manufacturers require tailored bronze powder compositions for specific end-use performance.

- Nachhaltigkeit Push: Eco-conscious manufacturers are favoring recyclable and low-emission powder materials.

B2B buyers are increasingly seeking long-term partnerships with reliable suppliers who can offer not only standardized bronze powders but also custom blends for niche applications.

5. Key Factors to Consider When Choosing a Bronze Powder Supplier

Selecting the right bronze powder supplier is critical for maintaining product quality, reducing lead times, and optimizing production efficiency. Here are the most important factors wholesale buyers, manufacturers, and distributors should consider:

1. Produktqualität & Konsistenz

- Does the supplier offer tight control over particle size distribution?

- Are the powders standardized under ISO or ASTM specifications?

- Are lab reports and material data sheets provided?

2. Produktionskapazitäten

- Availability of water atomization, gas atomization, and reduction processes

- Capacity to supply large-scale, recurring orders

- Ability to produce customized compositions (e.g., Cu-Sn ratios)

3. Technical Support & R&D

- Is there a technical team available for material consultation?

- Do they assist with application development or prototyping?

4. Supply Chain and Logistics

- How fast is their lead time?

- Do they support international shipping and export documentation?

- Are they experienced in customs handling for bulk powder shipments?

5. Regulatory Compliance & Safety

- Compliance with RoHS, REACH, or other regional regulations

- Safe packaging and MSDS availability

One supplier that ticks all these boxes is Shanghai Truer Technology Co. Ltd.. With over a decade of experience in powder metallurgy and additive manufacturing materials, Truer ensures that its bronze powders meet the highest industry standards.

6. Top 5 Bronze Powder Suppliers in Asia

Asia is at the forefront of bronze powder manufacturing, with China, Japan, and India being the leading producers. Below are some of the most reputable suppliers:

| Name des Unternehmens | Land | Stärke | Website |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | Wide product range, custom blends, advanced atomization | am-material.de |

| Fukuda Metallfolie und -pulver | Japan | High-purity powders for electronics | K.A. |

| Jinhua Huaxi Powder Metallurgy | China | Cost-effective PM powders | K.A. |

| Hoganas India Pvt. Ltd | Indien | Global presence, automotive-grade powders | K.A. |

| CNPC-Pulver | China | Strong R&D, export-ready | K.A. |

Why Shanghai Truer Leads the Pack:

- Offers both water and gas atomized bronze powders

- Capable of producing diffusion CuSn powders for diamond tools

- Supplies to over 30 countries globally

- Customizable grades like CT-1000, CZ-1000, FD-20Cu, and more

- Professional additive division for tailored PM applications

For businesses looking for a reliable supply of bronze powders, Shanghai Truer provides not just materials but also technical expertise and global logistics.

7. Why More Buyers Are Switching to Chinese Bronze Powder Manufacturers

In recent years, a significant shift has occurred in the global sourcing of bronze powders: more buyers are moving their procurement to China. Here’s why:

1. Konkurrenzfähige Preisgestaltung

Chinese suppliers like Truer offer lower per-kilo costs due to:

- Größenvorteile

- Local sourcing of raw materials

- Efficient manufacturing processes

2. Wide Product Range

Unlike some Western suppliers that specialize in only a few compositions, Chinese manufacturers provide:

- Standard bronze powders (e.g., 90/10, 85/15)

- Diffusion alloyed and pre-alloyed powders

- Custom formulations for specific industries

3. Flexible MOQ and Logistics

- Small batch orders available for testing

- Scalable to large volumes for automotive and industrial production

- Support for international shipping and documentation

4. Innovation and R&D

- Investment in combined atomization (water + gas)

- Development of application-specific additives

- Collaboration with global OEMs

5. End-to-End Solutions

Leading Chinese manufacturers like Truer offer more than just powders. They also provide:

- Lubricants (Lube-W, SUW-5000B)

- Cutting agents (SME-100, TD-8)

- Soft magnetic additives (QH-150)

- Graphite blends (TBC-400, TBC-1000)

For a complete list of powder metallurgy additives, visit the Truer PM Powder Section.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Bronze Powder Partner

For B2B buyers, choosing a supplier isn’t just about price—it’s about long-term reliability, technical support, and product consistency. Shanghai Truer Technology Co., Ltd, founded in 2009, has become one of China’s most trusted partners in the powder metallurgy and additive manufacturing sectors.

Was zeichnet Shanghai Truer aus?

| Merkmal | Nutzen für B2B-Einkäufer |

|---|---|

| 15+ Years of Industry Experience | Proven expertise in PM and 3D printing powder |

| In-House R&D & Testing Lab | Custom powder development and quality assurance |

| Multiple Atomization Technologies | Water, gas, and hybrid atomization ensure flexibility |

| Extensive Product Portfolio | From basic Cu-Sn blends to diffusion CuSn and specialty grades |

| Globale Exportfähigkeit | Ships to 30+ countries with complete documentation |

| Additive Solutions Division | One-stop shop for PM additives, lubricants, and graphite |

Powder Grades Available from Truer:

- Standard Bronze: CT-1000, CZ-1000

- Diffusion Bronze: FD-20Cu

- Hybrid Low-Alloy: FD-0208, FX-2008

- Custom Formulations: Based on Cu-Sn ratios and application specs

Truer also provides a full suite of PM additives such as:

- Schmiermittel: Lube-W, SUW-5000B, SUW-8000

- Schneidmittel: SME-100 (schwefelfrei), TD-8

- Magnetic Additives: QH-150

- Graphit: TBC-400, TBC-1000

This allows buyers to consolidate their supply chain and reduce vendor complexity.

Want to learn more about Shanghai Truer’s capabilities and history? Visit their detailed Über uns Seite.

9. How to Order Wholesale Bronze Powder from Truer

Ordering bronze powder from Shanghai Truer is designed to be quick, transparent, and buyer-friendly. Whether you’re sourcing for sintered parts, 3D printing, or diamond tools, Truer provides a streamlined procurement process that ensures timely delivery and technical support.

Step-by-Step Ordering Workflow:

- Erste Anfrage

- Contact Truer through their official Kontakt-Formular

- Provide details including powder grade, application, quantity, and special requirements

- Technische Konsultation

- Truer’s team will recommend the best-fit powder or develop a custom blend

- Material Data Sheets and test samples can be provided

- Angebot & Vorlaufzeit

- Receive formal quotation including pricing, MOQ, and delivery timeline

- Confirm international shipping options and INCOTERMS

- Order Placement

- Submit Purchase Order (PO)

- Initial deposit or full payment via bank transfer or LC

- Produktion & Qualitätskontrolle

- Bronze powders are produced under tight QA/QC protocols

- Inspection reports and COAs are included

- Verpackung & Versand

- Secure packaging (bags, drums, or totes)

- Shipped via air or sea freight depending on urgency

- After-Sales-Unterstützung

- Technical feedback loop for application performance

- Reordering assistance and stocking options available

Flexible Order Options:

- MOQ: As low as 25kg for new customers

- Bulk Orders: Up to several tons for OEMs and large-scale production

- Sample Testing: Available for R&D and prototyping

Truer’s international logistics experience ensures smooth customs clearance and timely delivery worldwide. For product specifications and to start your order, browse the full PM Powder Product List.

10. FAQs: Common Questions About Buying Wholesale Bronze Powder

To help B2B buyers make informed decisions, here are some frequently asked questions about sourcing bronze powder:

Q1: What’s the difference between pre-alloyed and diffusion bronze powders?

- Pre-Alloyed: Copper and tin are melted and atomized together, offering better homogeneity.

- Diffusionslegiert: Tin is diffused onto copper particles post-atomization. Ideal for applications like diamond tools or sintered bearings.

Q2: What are typical particle sizes available?

- Particle sizes range from 20μm to 150μm.

- Custom ranges can be produced based on compaction and sintering requirements.

Q3: What is the standard packaging?

- 25kg bags, 1-ton super sacks, or steel drums depending on volume and shipping method.

Q4: Can I request a custom Cu-Sn ratio?

- Yes. Truer can develop customized copper-tin compositions tailored to your specific application.

Q5: Is technical support available after purchase?

- Absolutely. Truer provides full technical support, including sintering guidance, additive selection, and troubleshooting.

Q6: Do Truer powders meet international quality standards?

- Yes. Truer follows ISO and ASTM standards and provides COAs, MSDS, and full traceability for each batch.

Q7: How long is the lead time for bulk orders?

- Typically 7–21 days depending on the order size and production schedule.

For any additional questions or to request a free consultation, you can directly contact Truer here.

Internal Anchor Text Links Summary:

| Ankertext | URL |

|---|---|

| PM bronze powder offerings | https://am-material.com/pm-powder/ |

| Über uns Seite | https://am-material.com/about/ |

| Shanghai Truer | https://am-material.com/ |

| PM Powder Product List | https://am-material.com/pm-powder/ |

| contact Truer here | https://am-material.com/contact-us/ |

By partnering with a trusted supplier like Shanghai Truer Technology Co., Ltd, you gain access to a full ecosystem of powder metallurgy solutions—from bronze powder to additives and technical support. Whether you’re a distributor, OEM, or e-commerce seller, Truer is equipped to meet your production needs efficiently and reliably.