Introduction: Why Atomized Iron Powder Is Essential in Modern Manufacturing

Atomized iron powder is a foundational material in powder metallurgy (PM), additive manufacturing, magnetic materials, and a range of industrial applications. As industries increasingly shift toward precision manufacturing and lightweight components, the demand for high-purity, consistent, and scalable powder materials like atomized iron powder is rapidly growing.

What Is Atomized Iron Powder?

Atomized iron powder refers to fine iron particles produced through atomization processes—either water or gas—which break molten iron into droplets that solidify into powder form. This method ensures precise control over particle size, shape, and distribution, making it ideal for:

- Powder Metallurgy (PM) parts

- 3D-Druck and additive manufacturing

- Weichmagnetische Komponenten

- Diamond tools and cutting applications

- Sintered structural and automotive components

| Merkmal | Beschreibung |

|---|---|

| Reinheit | High-purity iron content, low oxygen/sulfur levels |

| Partikelgröße | Typically ranges from 20 to 200 μm |

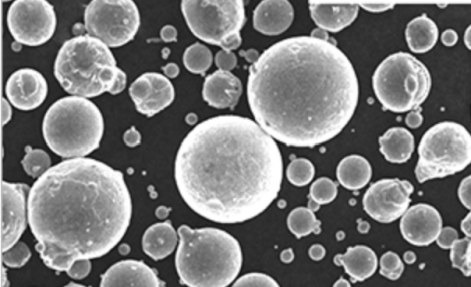

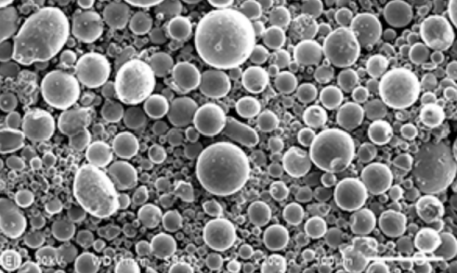

| Form | Spherical (gas) or irregular (water) |

| Fließfähigkeit | Critical for PM and AM applications |

| Komprimierbarkeit | High green strength for sintered parts |

Benefits for B2B Buyers and Manufacturers

- Konsistenz: Uniform particle size for consistent production quality

- Anpassungsfähigkeit: Tailored grades for specific industrial needs

- Kosten-Wirksamkeit: Efficient for high-volume production

- Nachhaltigkeit: Enables near-net-shape manufacturing, reducing waste

Whether you’re a PM component manufacturer, OEM supplier, oder 3D printing bureau, sourcing the right atomized iron powder can significantly impact your product performance and production efficiency.

Industrial Applications of Atomized Iron Powder

Atomized iron powder serves as a versatile base material across multiple high-value industries. Below are the primary industrial sectors utilizing this material:

1. Powder Metallurgy (PM)

Atomized iron powder is the backbone of the PM industry. Used in sintered structural parts, gears, pulleys, and bushings, its compressibility and sintering behavior make it ideal for:

- Komponenten für die Automobilindustrie

- Teile für industrielle Maschinen

- Haushaltsgeräte

| PM Applications | Benefits of Atomized Iron Powder |

|---|---|

| Gears & Bearings | High wear resistance & strength |

| Komponenten des Motors | Ausgezeichnete Wärmeleitfähigkeit |

| Brackets & Connectors | Close dimensional tolerances |

2. Additive Manufacturing (3D Printing)

With the rise of metal 3D printing, atomized iron powder—especially gas atomized—is gaining traction. Its spherical morphology provides superior flowability and layer adhesion in:

- Binder Jetting

- Selektives Laserschmelzen (SLM)

- Direct energy deposition (DED)

3. Soft Magnetic Applications

Iron powders are also engineered for magnetic properties, used in:

- Electromagnetic cores

- Transformers and inductors

- Electric motor components

High-purity, low-loss iron powder grades enable precise magnetic field control, meeting the demands of the electronics und automotive EV markets.

4. Diamond Tools and Cutting Applications

Atomized iron powder is used as a matrix material in diamond tools such as:

- Sägeblätter

- Bohrer

- Grinding wheels

It provides the necessary bonding strength and wear resistance to hold industrial diamonds in place under harsh conditions.

Types of Atomized Iron Powder: Water vs. Gas Atomization

Choosing the right atomization method is critical for your application. The two dominant production techniques—water atomization and gas atomization—yield powders with distinct characteristics.

Wasserverdüstes Eisenpulver

Water atomization involves spraying high-pressure water onto molten iron, rapidly cooling and solidifying the droplets.

| Attribut | Zerstäubtes Wasser |

|---|---|

| Partikelform | Unregelmäßig |

| Fließfähigkeit | Mäßig |

| Komprimierbarkeit | Hoch |

| Kosten | Unter |

| Anwendungen | PM, structural parts, sintered bearings |

Vorteile:

- Kostengünstig für die Massenproduktion

- Ausgezeichnete Grünfestigkeit

- Breite Partikelgrößenverteilung

Common Grades by Shanghai Truer:

- CT-1000

- F-0000

- FC-0208

- FL-4605

These grades are widely used in structural components and general PM applications. Learn more about available PM powder grades here.

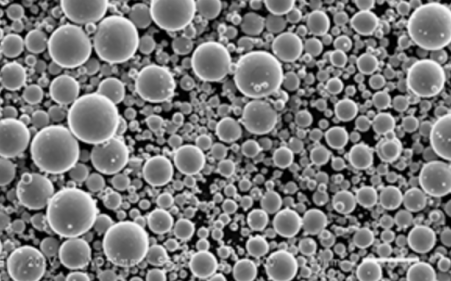

Gas Atomized Iron Powder

Gas atomization uses high-pressure inert gas (argon or nitrogen) to atomize molten iron, resulting in spherical particles.

| Attribut | Zerstäubtes Gas |

|---|---|

| Partikelform | Sphärisch |

| Fließfähigkeit | Ausgezeichnet |

| Reinheit | Höher |

| Kosten | Höher |

| Anwendungen | Additive manufacturing, magnetic parts, precision PM |

Vorteile:

- Superior flow and packing density

- Minimal contamination

- Ideal for 3D printing and magnetic applications

Specialty Grades by Shanghai Truer:

- SBF2218

- FN-5000

- FX-2008

These powders are engineered for additive manufacturing and high-precision PM parts.

Market Trends and Global Demand for Atomized Iron Powder

The global atomized iron powder market is experiencing unprecedented growth, driven by the expansion of industries such as automotive, additive manufacturing, and energy. As powder metallurgy (PM) and metal 3D printing technologies become more mainstream, the demand for high-quality iron powder continues to rise.

Global Market Overview

According to recent industry analysis, the global iron powder market is expected to reach over USD 8 billion by 2028, growing at a CAGR of 5.5%. Atomized iron powder, in particular, is a key contributor to this growth due to its essential role in sintered parts and additive manufacturing.

| Region | Market Share | Schlüsselindustrien |

|---|---|---|

| Asien-Pazifik | 45% | Automotive, Electronics |

| Nord-Amerika | 25% | Aerospace, 3D Printing |

| Europa | 20% | Industrial Machinery, Energy |

| Rest der Welt | 10% | Tools, Defense |

Die wichtigsten Wachstumstreiber

- Automobilbranche: Lightweight, complex-shaped sintered components reduce fuel consumption.

- Elektrofahrzeuge (EVs): Demand for soft magnetic components in motors and transformers.

- Additive Fertigung (AM): Rapid adoption in prototyping and small-batch production.

- Nachhaltige Produktion: PM and AM offer near-net-shape production, reducing waste.

Zu beobachtende Trends

- Shift Toward Gas Atomized Powder: Especially in 3D printing and high-precision parts.

- Increased Customization: Tailored particle sizes, compositions, and flow characteristics.

- Digital Supply Chain: Integration of online sourcing and digital catalogs for B2B buyers.

- China’s Dominance in Supply: Lower costs, technological advancements, and scalable production.

For industry professionals looking to capitalize on these trends, sourcing from a reliable, technically proficient supplier like Shanghai Truer Technology Co. Ltd. offers a distinct competitive edge.

Key Factors When Choosing a Reliable Atomized Iron Powder Supplier

Selecting the right supplier is a strategic decision that directly impacts your production efficiency, product quality, and long-term competitiveness. Here are the top criteria wholesale buyers and distributors should consider:

1. Qualität und Konsistenz des Pulvers

- Partikelgrößenverteilung: Essential for compressibility and flow in PM and AM processes.

- Reinheit: Low oxygen and sulfur content for better sintering and magnetic performance.

- Morphologie: Spherical particles for additive manufacturing, irregular for PM.

2. Produktionskapazitäten

- In-house water and gas atomization facilities

- Ability to produce in bulk or custom batches

- Proven track record in delivering consistent batches

Shanghai Truer uses both water and gas atomization techniques, offering flexibility for various industrial needs. Their powders meet international standards and are available in tailored particle sizes for specific applications.

3. Technische Unterstützung & Anpassung

- Application-specific powder formulations

- Material certifications and batch traceability

- On-site technical consultation and R&D support

Truer provides value-added services beyond powder supply. Their Truer Additives Division offers technical support for PM lubricants, cutting agents, and sintering additives—making them a one-stop solution for powder metallurgy requirements.

4. Delivery & Logistics

- Globale Versandmöglichkeiten

- Secure, moisture-proof packaging

- Reliable lead times and inventory management

5. Pricing & Payment Terms

- Wettbewerbsfähige Preise für Großaufträge

- Flexible payment terms for long-term partners

- Transparent cost structures with no hidden fees

Top 5 Atomized Iron Powder Suppliers Globally

Here’s a curated list of the leading suppliers of atomized iron powder for B2B buyers, based on product portfolio, global reach, and industrial reputation.

| Anbieter | Land | Stärken | Website |

|---|---|---|---|

| Hoganas AB | Schweden | High-quality, global network | www.hoganas.com |

| Shanghai Truer Technology Co. Ltd. | China | Water & gas atomized powders, PM additives | am-material.de |

| Rio Tinto Metall-Pulver | Kanada | Large-scale production, automotive focus | www.qmp-powders.com |

| JFE Steel Corporation | Japan | Precision powders, high-tech applications | www.jfe-steel.co.jp |

| GKN Hoeganaes | USA | Advanced PM solutions, R&D-driven | www.gknpm.com |

Warum Shanghai Truer sich abhebt

- Bewährtes Fachwissen: Founded in 2009, Additive Manufacturing division launched in 2019.

- Vollständige vertikale Integration: From powder production to custom additive solutions.

- Diverse Powder Portfolio: Including pre-alloyed, hybrid, and diffusion-alloyed grades.

- Domestic and Export Clients: Trusted by both Chinese and international manufacturers.

They offer various PM iron powder grades including:

- F-0000: Pure iron powder

- FC-0208: Copper steel

- FL-4605: Diffusion alloyed steel

- FN-0205: Nickel steel

- FD-0208: High-density sintering

You can explore the full product list and specifications on their PM-Pulver-Seite.

Why More Buyers Are Turning to Chinese Atomized Iron Powder Manufacturers

In recent years, Chinese manufacturers have emerged as global leaders in the atomized iron powder supply chain. Here’s why:

Cost-Competitive Production

- Lower labor and production costs

- Economies of scale for large-volume orders

- High material utilization and waste reduction

Technologische Fortschritte

- Adoption of modern atomization technologies

- Integration of AI and automation in powder classification

- Stringent in-house quality control systems

Flexible MOQ and Customization

- Ability to fulfill both small and large orders

- Customized alloy compositions and particle sizes

- Fast turnaround for prototyping and development projects

Strategic Location & Logistics

- Proximity to major seaports and logistics hubs

- Strong export infrastructure

- Reliable delivery timelines

Case Example: Shanghai Truer

Shanghai Truer Technology exemplifies the strengths of Chinese suppliers. Their commitment to quality, innovation, and B2B customer support has earned them a strong reputation across Asia, Europe, and North America.

They also offer specialized PM additives like:

- Lube-W: High-performance lubricant

- SUW-8000: Advanced PM formulation enhancer

- QHP-330: New-generation soft magnetic additive

For customized inquiries, visit their Kontakt Seite and get in touch with their technical team.

Why Choose Shanghai Truer Technology as Your Powder Supplier

When it comes to sourcing atomized iron powder in bulk, selecting a trustworthy and technically proficient supplier is critical. Shanghai Truer Technology Co., Ltd. has positioned itself as one of the most reliable and innovative powder metallurgy suppliers in China—and increasingly, on the global stage.

Überblick über das Unternehmen

Founded in 2009, Shanghai Truer entered the additive manufacturing space in 2019, bringing over a decade of expertise in metallurgy into the rapidly evolving 3D printing and PM sectors. The company integrates:

- Powder production (water & gas atomized)

- PM additives and lubricants

- Customized material solutions

- Equipment and services for 3D printing powder making

Their extensive product line and in-house R&D position them as more than just a supplier—they are a strategic partner for manufacturers worldwide. Learn more about their corporate mission and capabilities on the Über uns Seite.

Key Advantages for B2B Buyers

1. Complete Powder Metallurgy Ecosystem

Shanghai Truer is not limited to just supplying powder. They provide a comprehensive solution for PM and AM manufacturers, including:

- Lubricants (e.g., SUW-5000B, Lube-W)

- Cutting agents (e.g., SME-100, TD-8)

- Magnetic additives (e.g., QH-150)

- Graphite additives (e.g., TBC-400, TBC-1000)

This allows clients to streamline their supply chain and ensure chemical and physical compatibility of materials.

2. Wide Powder Selection

They offer a broad range of iron-based powders suitable for various industrial applications. Some of their most popular atomized iron powder grades include:

| Klasse | Merkmale | Anmeldung |

|---|---|---|

| F-0000 | Pure iron, high compressibility | Strukturelle PM-Teile |

| FL-4605 | Diffusion alloyed, high strength | Automotive gears |

| FC-0208 | Iron-copper blend | Bearings, electrical contacts |

| FN-0205 | Nickel alloyed | High-performance PM parts |

| FD-0208 | High-density sintering | Precision automotive components |

For a detailed overview of available grades and specifications, visit the PM Powder catalog.

3. Dual Atomization Capabilities

Unlike many suppliers who specialize in either water or gas atomization, Shanghai Truer operates both systems, offering:

- Wasserverdüstes Eisenpulver: Cost-effective, suitable for conventional PM

- Gas Atomized Iron Powder: Spherical, high-purity, ideal for additive manufacturing

4. Robust Quality Control

Each batch of powder undergoes rigorous testing for:

- Partikelgrößenverteilung

- Flow rate and apparent density

- Chemical composition (O, N, S, C levels)

- Morphology analysis via SEM

5. Global Client Support

With a growing international customer base, Truer offers multilingual sales, technical assistance, and documentation support. Whether you’re based in North America, Europe, or Southeast Asia, their logistics and export teams ensure timely and compliant delivery.

How to Order Wholesale Atomized Iron Powder from China

If you’re a distributor, OEM, or industrial buyer looking to source atomized iron powder in bulk, here’s a step-by-step guide to streamline your purchasing process from China—specifically from Shanghai Truer Technology.

Schritt 1: Definieren Sie Ihre Anforderungen

Before reaching out, gather the following information:

- Required grade (e.g., FC-0208, FL-4605)

- Partikelgrößenverteilung (e.g., 45–150 μm)

- Menge (kg/tons per month or year)

- Intended Anmeldung (e.g., sintered gears, laser printing)

- Any custom specifications (e.g., flow rate, oxygen content)

Step 2: Contact the Supplier

You can initiate your inquiry by visiting the Kontakt Seite and filling out the request form.

Include:

- Business name and contact details

- Technical requirements

- Preferred incoterms (e.g., FOB Shanghai, CIF)

- Target price (if applicable)

You can also email directly or schedule a video call with their technical sales team for more complex inquiries.

Step 3: Receive Technical Data & Quotation

Truer will provide:

- TDS (Technical Data Sheets)

- COA (Certificate of Analysis)

- Price quotation (including shipping options)

- Lead time and MOQ details

Step 4: Approve Samples (Optional)

For large or recurring orders, it’s recommended to request a sample batch for internal testing. Truer can ship small samples (1–5 kg) via air freight to expedite the evaluation process.

Step 5: Place Order & Arrange Payment

Once satisfied with the samples and quote:

- Confirm the purchase order (PO)

- Proceed with payment (T/T, LC, or other agreed terms)

- Truer handles packaging, export documentation, and shipment

Step 6: Post-Sale Technical Support

After delivery, Truer’s technical team remains available for:

- Prozess-Optimierung

- Fehlersuche

- Reordering and inventory planning

FAQs: Common Questions About Buying Atomized Iron Powder in Bulk

Here are some of the most frequently asked questions from B2B buyers and distributors:

1. What is the difference between water atomized and gas atomized iron powder?

| Merkmal | Zerstäubtes Wasser | Zerstäubtes Gas |

|---|---|---|

| Form | Unregelmäßig | Sphärisch |

| Fließfähigkeit | Mäßig | Ausgezeichnet |

| Kosten | Unter | Höher |

| Best Use | PM parts | Additive Fertigung |

2. What are the minimum order quantities (MOQ)?

- MOQ generally starts at 100kg, but custom MOQs can be negotiated based on the project scope and frequency of orders.

3. Can I request a custom alloy composition?

Yes. Truer supports custom alloy formulations und tailored particle size distributions, especially for R&D and high-performance applications.

4. How long is the lead time?

Standard lead time:

- Stocked grades: 2–3 business days

- Benutzerdefinierte Noten: 10–15 business days

- Export shipping: 7–25 days depending on region

5. Are the powders certified?

Yes. Truer provides:

- ISO-compliant quality documentation

- COA and RoHS reports

- Third-party material certifications upon request

By choosing Shanghai Truer Technology as your atomized iron powder supplier, you gain a competitive edge in pricing, quality, and technical innovation. To begin your sourcing journey, browse their Homepage or reach out via their kontaktseite heute.