1. Introduction: Why Aluminum Powder Matters in Manufacturing

Aluminum powder is one of the most widely used metal powders in industrial and manufacturing applications. From aerospace to automotive, electronics to pyrotechnics, its lightweight, high reactivity, and corrosion resistance make aluminum powder a critical raw material for a range of B2B applications.

For wholesale buyers, aluminum powder offers:

- Hohe thermische und elektrische Leitfähigkeit

- Low density and high strength-to-weight ratio

- Ausgezeichnete Korrosionsbeständigkeit

- Compatibility with additive manufacturing and powder metallurgy (PM)

As global industries move toward lightweight and energy-efficient solutions, the demand for high-purity, consistent-grade aluminum powder is on the rise. For suppliers and distributors, this creates a significant opportunity to cater to manufacturers seeking reliable and high-performance aluminum-based materials.

2. Industrial Applications of Aluminum Powder

Aluminum powder’s versatility makes it integral to many industrial sectors. Below are the key applications:

| Industrie | Application of Aluminum Powder |

|---|---|

| Luft- und Raumfahrt | Lightweight structural parts, fuel additives in solid rocket propellants |

| Automobilindustrie | Brake systems, anti-corrosion coatings, engine components |

| Additive Fertigung | Binder jetting, selective laser sintering (SLS) |

| Pulvermetallurgie (PM) | Sintered structural parts, bearings, gears |

| Paints & Coatings | Metallic finishes, reflective coatings |

| Pyrotechnik | Fireworks, explosives, flares |

| Chemische Industrie | Catalyst carriers, aluminothermic reactions |

Vorteile für B2B-Einkäufer:

- Ability to produce parts with complex geometries

- Enhanced material performance in demanding environments

- Cost-effective solutions for mass production

Especially in PM and additive manufacturing, aluminum powder enables high-volume production with minimal material waste—ideal for industries looking to reduce costs and improve sustainability.

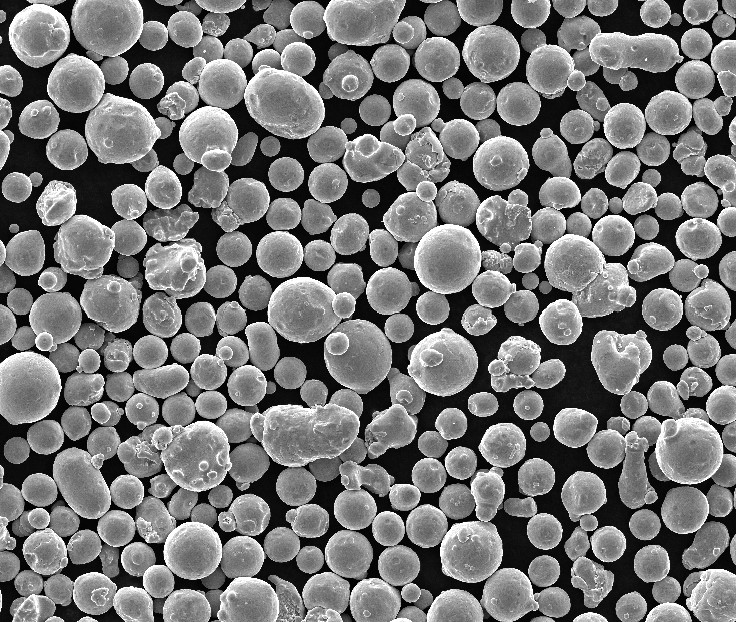

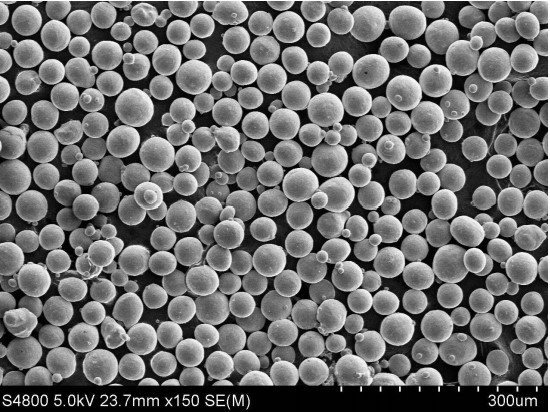

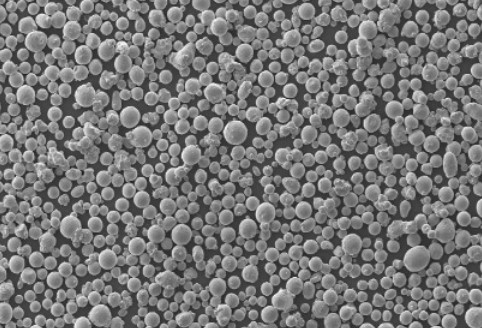

3. Types of Aluminum Powder and Their Properties

Different types of aluminum powders are produced for different industrial purposes. The selection depends on particle size, purity, shape, and production method. Below is a breakdown:

| Type of Aluminum Powder | Produktionsverfahren | Typische Verwendung | Partikelgröße | Reinheit |

|---|---|---|---|---|

| Atomized Aluminum Powder | Gas or Water Atomization | Additive Manufacturing, PM | 10-150 µm | 98–99.9% |

| Schuppenförmiges Aluminium-Pulver | Kugelmahlen | Paints, Coatings, Pyrotechnics | 5–50 µm | 98–99.5% |

| Granular Aluminum Powder | Crushing & Grinding | Metallurgy, Welding | 50–200 µm | 97–99% |

| Nano Aluminum Powder | Chemische Reduktion | High Reactivity Applications | <100 nm | >99% |

Key Selection Criteria for Wholesale Buyers:

- Spherical vs. flake shape depending on end-use

- Atomization method (gas atomized preferred for 3D-Druck)

- Consistent particle size distribution for uniform behavior

- Compatibility with lubricants and additives

Shanghai Truer Technology Co., Ltd offers high-quality aluminum and non-ferrous metal powders tailored for PM and additive manufacturing. Their powders are available in various grades and atomization methods, ensuring compatibility with different production environments. You can explore their full PM powder offerings here.

4. Global Market Trends in Aluminum Powder Supply

The global aluminum powder market is experiencing significant growth, driven by the rise of lightweight materials in manufacturing and the expansion of additive manufacturing technologies. Here are the key market trends every wholesale buyer and distributor should know:

🔍 Key Market Insights (2024–2029 Forecast):

| Metrisch | Wert |

|---|---|

| 2023 Marktgröße | USD 3.2 Billion |

| CAGR (2024-2029) | 6.4% |

| Leading Regions | Asia-Pacific, North America, Europe |

| Top Growth Industries | Aerospace, Automotive, 3D Printing |

🌍 What’s Driving Demand?

- Additive Manufacturing Boom: The adoption of 3D printing in aerospace and defense is increasing the demand for high-purity, gas-atomized aluminum powders.

- Lightweighting in Automotive: OEMs seek to reduce vehicle weight to meet emission standards, increasing the use of aluminum parts.

- Expansion im asiatisch-pazifischen Raum: China and India are ramping up production capacities, making Asia the largest and most cost-effective supplier region.

- Schwerpunkt Nachhaltigkeit: Aluminum is recyclable, making it an eco-friendly option aligned with global ESG goals.

For B2B buyers, understanding these trends is critical for long-term sourcing strategies. It’s clear that suppliers who can offer scalable production, high purity, and consistent quality will lead the market.

5. Key Factors When Choosing an Aluminum Powder Supplier

Selecting the right supplier for aluminum powder is crucial to ensure consistency, compliance, and cost-efficiency. Below are the main evaluation criteria for wholesale buyers, procurement managers, and OEMs:

🧾 Buyer’s Supplier Checklist:

| Faktor | Bedeutung | Warum es wichtig ist |

|---|---|---|

| Konsistente Partikelgröße | ⭐⭐⭐⭐⭐ | Ensures reliable performance in PM or AM processes |

| Reinheitsgrad | ⭐⭐⭐⭐ | Impacts conductivity, strength, and corrosion resistance |

| Zerstäubungsmethode | ⭐⭐⭐⭐⭐ | Gas atomization preferred for 3DP; water atomization for PM |

| Bulk Supply Capacity | ⭐⭐⭐⭐ | Critical for large-scale manufacturing |

| Vorlaufzeit der Lieferung | ⭐⭐⭐⭐ | Vermeidung von Produktionsverzögerungen |

| Compliance & Certifications | ⭐⭐⭐⭐⭐ | Especially important for aerospace, automotive, and defense |

| Anpassungsoptionen | ⭐⭐⭐ | Enables tailored solutions for specific applications |

| Technische Unterstützung | ⭐⭐⭐⭐ | Helps with troubleshooting and process optimization |

💡 Pro Tip: Look for suppliers that also offer additives, lubricants, and custom blends—this ensures compatibility across your entire production line.

Shanghai Truer Technology Co., Ltd checks all these boxes and more, offering full-stack powder metallurgy and additive manufacturing solutions. Their technical team collaborates closely with enterprise buyers to ensure the optimal aluminum powder specifications are met for your application. Learn more about Truer’s capabilities.

6. Top 5 Aluminum Powder Suppliers in Asia

Asia is a dominant region in aluminum powder production due to its cost-effective manufacturing and growing tech infrastructure. Below are the top B2B suppliers with a strong reputation for quality and bulk capacity:

| Anbieter | Land | Stärken | Globale Reichweite |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | Full PM & AM solutions, wide material range, custom R&D | 🌍🌍🌍 |

| Kymera International | China/US | High-purity atomized powders | 🌍🌍🌍🌍 |

| Toyo Aluminium K.K. | Japan | Flake aluminum powders for coatings | 🌍🌍 |

| Mepco | Indien | Industrial-grade aluminum powders for pyrotechnics & PM | 🌍🌍 |

| Nippon Atomized Metal Powders | Japan | High-quality gas atomized powders | 🌍🌍🌍 |

Why Shanghai Truer Stands Out for B2B Buyers:

- Offers both water and gas atomization options

- Access to hybrid alloy development for advanced applications

- Dedicated additives division for full PM system integration

- Proven track record in serving automotive, aerospace, and 3D printing sectors

Truer’s extensive experience and commitment to innovation make it one of Asia’s most reliable aluminum powder suppliers for global wholesale buyers. Check out their contact page to request samples or pricing.

7. Warum immer mehr Käufer sich an chinesische Hersteller wenden

In recent years, a significant shift has occurred in the global supply chain dynamics—more B2B buyers, wholesalers, and OEM manufacturers are sourcing aluminum powder directly from Chinese suppliers. This trend is driven by several critical factors:

💡 Strategic Advantages of Chinese Suppliers

| Faktor | Nutzen für Käufer |

|---|---|

| Kosteneffizienz | Lower production and labor costs translate to competitive pricing. |

| Fortschrittliche Fertigung | China has heavily invested in atomization and PM technologies. |

| Vielfältige Produktpalette | Suppliers like Shanghai Truer offer a wide variety of PM and AM powders. |

| Hohe Produktionskapazität | Large-scale facilities ensure bulk supply with short lead times. |

| Integration with Additives | Many Chinese suppliers provide integrated solutions (e.g., lubricants, cutting agents). |

📦 What Does This Mean for Distributors and OEMs?

- Better margins on resale or finished goods

- More flexibility for custom orders

- Faster iteration and prototyping cycles due to short lead times

- Access to next-gen materials for advanced applications

Shanghai Truer Technology Co., Ltd is a prime example of a Chinese supplier that aligns with these benefits. With over a decade of experience and a dedicated additive manufacturing division since 2019, Truer has positioned itself as a leader in aluminum powder production and PM solutions. Their ability to offer custom-engineered powders gives buyers a valuable edge in product development.

To explore their full portfolio of materials including PM aluminum and hybrid low-alloy powders, visit their PM-Pulver Produktseite.

8. Why Choose Shanghai Truer Technology Co., Ltd for Aluminum Powder

Shanghai Truer Technology Co., Ltd is not just another metal powder manufacturer—they are a comprehensive solution provider in the powder metallurgy and additive manufacturing ecosystem.

🏭 Company Overview at a Glance:

- 📍 Founded in 2009, additive manufacturing division started in 2019

- 🧪 Offers both standard and custom PM/AM aluminum powders

- ⚙️ Supplies full range of PM additives and lubricants

- 🌍 Serves global OEMs, distributors, and 3D printing service providers

📋 What Sets Truer Apart:

| Merkmal | Truer Advantage |

|---|---|

| Interne Zerstäubung | Offers water, gas, and hybrid atomization methods |

| Wide Powder Selection | PM aluminum, PM bronze, PM nickel silver, and more |

| Additives Fachwissen | Provides lubricants (Lube-W, SUW-5000B), cutting agents, and soft magnetic materials |

| Kundenspezifische Formulierungen | Tailored grade development for unique industrial needs |

| Sicherung der Qualität | Strict QC protocols with consistent batch testing |

| Globale Unterstützung | Responsive technical assistance and export documentation |

🔗 Integrated B2B Services:

- OEM consultation for material selection

- Full documentation (RoHS, REACH, MSDS)

- Volume-based pricing for bulk buyers

- Worldwide shipping and logistics support

To learn more about the company’s mission, values, and technical capabilities, visit their Über uns Seite.

9. FAQs: Common Questions About Buying Bulk Aluminum Powder

Below are frequently asked questions from distributors, procurement teams, and industrial buyers regarding aluminum powder sourcing:

Q1: What is the minimum order quantity (MOQ) for bulk aluminum powder?

A: MOQ varies based on the grade and production method. Truer typically offers MOQs starting at 100 kg, with volume discounts for larger orders.

Q2: Can I request a custom particle size distribution?

A: Yes. Truer provides customized particle size ranges for specific applications such as binder jetting, SLS, or PM sintering.

Q3: How do I ensure the powder is compatible with my manufacturing process?

A: Truer offers technical consultation to help you select the right grade, atomization type, and additives to match your production environment.

Q4: What are the packaging options?

A: Aluminum powder is available in sealed aluminum foil bags, drums, or vacuum packaging, depending on quantity and reactivity. Custom packaging is available upon request.

Q5: How can I order samples for testing?

A: You can request samples directly through Truer’s Kontakt Seite. They typically provide sample quantities for evaluation before committing to large orders.

Q6: Are Truer’s powders suitable for additive manufacturing?

A: Absolutely. Truer offers gas-atomized aluminum powders with high sphericity and purity, suitable for SLS, SLM, and binder jetting applications.

Q7: How fast is the delivery?

A: Domestic orders ship within 3–5 business days. International orders typically ship within 7–14 business days, depending on customs and shipping method.

🔚 Conclusion: Partner with Truer for Reliable Aluminum Powder Supply

Aluminum powder’s role in modern manufacturing continues to grow across industries—from aerospace components to high-performance 3D printed parts. For B2B buyers, the key to success lies in sourcing high-quality, consistent, and application-specific powder from a trustworthy supplier.

Shanghai Truer Technology Co., Ltd delivers on all fronts:

✅ Full control over powder production methods

✅ Broad portfolio of aluminum and alloy powders

✅ Integrated additive and lubricant solutions

✅ Global logistics and technical support

Whether you’re an OEM, distributor, or 3D printing service provider, Truer offers the technology, expertise, and reliability you need to scale your operations.

👉 Ready to source high-quality aluminum powder? Contact Truer today for a quote or sample.