1. Introduction: Why AlMgSc Powder Is Gaining Attention in Advanced Manufacturing

AlMgSc powder—an aluminum-magnesium-scandium alloy—has become increasingly popular in high-performance industries such as aerospace, defense, and automotive. Its enhanced mechanical properties, lightweight composition, and compatibility with additive manufacturing (AM) technologies make it an ideal choice for OEMs, metal part manufacturers, and contract manufacturers.

Key Drivers of AlMgSc Powder Demand:

- ✔️ High strength-to-weight ratio

- ✔️ Excellent weldability and corrosion resistance

- ✔️ Improved printability for selective laser melting (SLM)

- ✔️ Suitable for thin-walled, complex structures

- ✔️ Enhanced fatigue and creep resistance

For B2B buyers, the demand for lightweight, high-performance materials has never been greater. AlMgSc powder fulfills this need, particularly in sectors that prioritize fuel efficiency, structural strength, and durability.

📌 Learn more about our powder metallurgy offerings on our PM-Pulver-Seite

2. Applications of AlMgSc Alloy Powder in Aerospace and Automotive Industries

AlMgSc powder’s unique combination of properties enables its use in multiple high-performance sectors. It is particularly valuable in applications where lightweight and high strength are critical.

Luft- und Raumfahrtanwendungen

- ✈️ Structural components for aircraft wings and fuselages

- 🚀 Satellite panels and structures in low-Earth orbit (LEO)

- 🛫 Load-bearing brackets and connectors

- 🔩 3D-printed custom aerospace parts using Direct Metal Laser Sintering (DMLS)

Automobilanwendungen

- 🚗 Lightweight chassis components

- 🛞 Wheel hubs and suspension parts in performance vehicles

- ⚙️ Heat exchangers and cooling systems

- 🧩 Complex geometries made via SLM or EBM for electric vehicles (EVs)

Additional Industrial Use Cases

- 🏗️ High-performance sports equipment

- 🛠️ Tooling inserts for high-speed manufacturing

- 📡 Defense and communication-grade enclosures

| Industrie | Anwendungsbereich | Benefit of AlMgSc Powder |

|---|---|---|

| Luft- und Raumfahrt | Strukturen von Luftfahrzeugen | Lightweight, high fatigue resistance |

| Automobilindustrie | EV performance parts | Thermal stability, reduced weight |

| Verteidigung | UAV components | Corrosion resistance, reliability |

| Konsumgüter | High-end sports gear | Customization, strength-to-weight ratio |

3. Key Properties of AlMgSc Powder That Benefit B2B Buyers

The versatility of AlMgSc powder in B2B applications lies in its superior materials science. This alloy combines aluminum’s lightness with magnesium’s strength and scandium’s exceptional grain refinement properties.

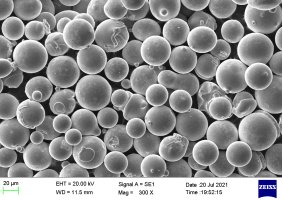

Physicochemical Properties

- 🔬 Particle Size Distribution: 15–45 µm or 20–63 µm (customizable)

- 🌡️ Melting Point: ~620°C

- ⚖️ Density: 2.65 g/cm³

- 💥 Tensile Strength: >400 MPa

- 🔄 Elongation: 10–15%

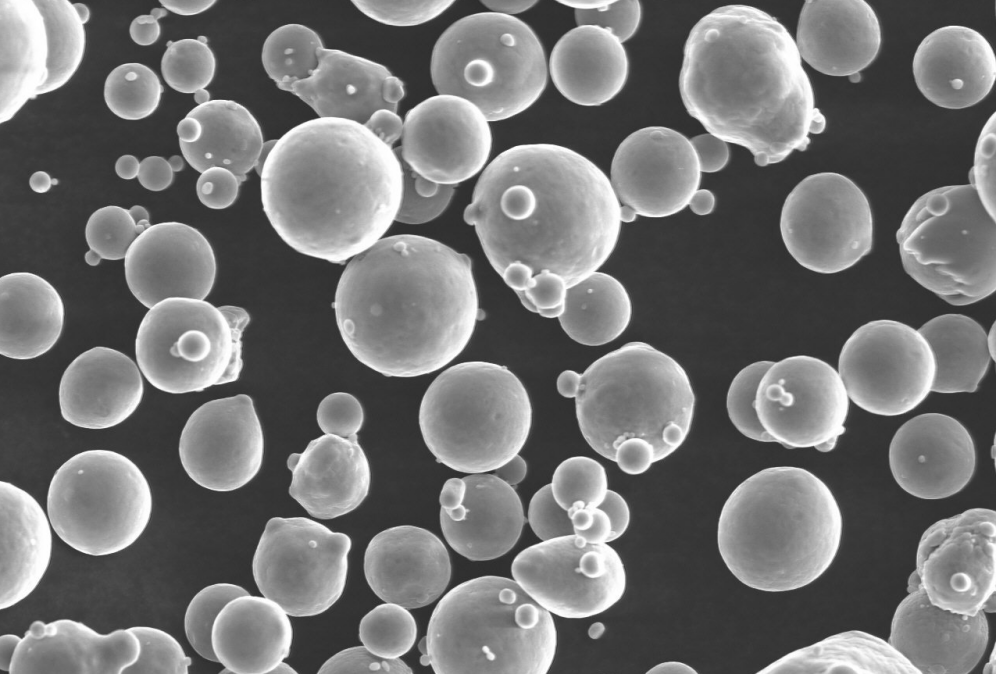

Eigenschaften des Pulvers

- ✅ High sphericity, ideal for laser powder bed fusion (LPBF)

- ✅ Low oxygen and moisture content

- ✅ Excellent flowability for uniform recoating

- ✅ Customizable alloy composition (Al-4Mg-0.6Sc-0.4Zr, etc.)

Benefits for Industrial Buyers

- 📦 Consistent build reliability for mass production

- 🧪 Less post-processing due to clean microstructures

- 🔩 Reduced cracking and porosity in final parts

- ⚙️ Compatible with existing aluminum alloy fusion parameters

| Eigentum | AlMgSc Powder Performance |

|---|---|

| Stärke | High, >400 MPa |

| Druckbarkeit | Excellent for SLM/LPBF |

| Oxidationsbeständigkeit | Very high due to scandium content |

| Mikrostruktur | Fine-grained, minimal defects |

| B2B Application Benefit | Ideal for precision-driven industries |

These properties make AlMgSc powder a valuable material for buyers that demand quality, consistency, and performance in their supply chain.

🧪 Explore the capabilities of Shanghai Truer Technologie in powder metallurgy and material science.

4. Market Trends and Growth Potential for AlMgSc Powder Supply

As industries push toward lightweight, high-strength materials for enhanced performance and sustainability, AlMgSc powder is emerging as a critical alloy in the global additive manufacturing (AM) and powder metallurgy (PM) market.

Die wichtigsten Wachstumstreiber:

- 🌍 Global shift toward electric vehicles (EVs) and lightweight aerospace components

- 🔬 Increased adoption of laser powder bed fusion (LPBF) and electron beam melting (EBM)

- 🏭 Expanding 3D-Druck capabilities in aerospace, defense, and automotive OEMs

- 📈 Rising demand for custom alloy powders with enhanced performance properties

Industry Forecasts:

| Metrisch | 2023 Value | 2028 Projection | CAGR (2023-2028) |

|---|---|---|---|

| Global AlMgSc Powder Market Size | $110 million | $320 million | ~24% |

| Aerospace AM Market Share | 42% of total usage | 50% of total usage | ~28% |

| China’s Share in Global Supply | 15% | 28% | ~31% |

Buyer Trends in B2B Market:

- ✅ Custom alloy compositions for niche applications

- ✅ Preference for tested, certified powder batches

- ✅ Consolidated sourcing from full-service suppliers

- ✅ Interest in low-oxygen, high-sphericity powder grades

AlMgSc powder has also gained traction in R&D institutes, defense agencies, and advanced medical equipment manufacturers, increasing the diversity of its application base.

📊 For more technical specifications and sourcing options, visit our PM-Pulver-Seite

5. How to Choose a Reliable AlMgSc Powder Supplier for Industrial Needs

For manufacturers, OEMs, and distributors, sourcing AlMgSc powder is not just about product availability—it’s about quality, consistency, and long-term reliability.

Key Criteria for Supplier Selection:

- ✅ Powder Quality & Consistency

- Sphärische Morphologie

- Low oxygen, nitrogen, and moisture content

- Enge Partikelgrößenverteilung

- ✅ Manufacturing Technology

- Gas atomization for high flowability

- Inert atmosphere processing

- Blending and sieving capabilities

- ✅ Certifications & Standards

- ISO 9001, AS9100 (for aerospace)

- Material test reports (MTRs)

- Batch-to-batch traceability

- ✅ Customization & Technical Support

- Tailored elemental compositions

- Application-specific alloy development

- Technische Beratung

- ✅ Logistics & Packaging

- Vacuum-sealed packaging

- Custom batch sizes for R&D or mass production

- Global shipping and compliance documentation

| Evaluation Area | Was zu beachten ist |

|---|---|

| Qualitätskontrolle | In-house testing, SEM/EDS, flowability reports |

| Zuverlässigkeit der Lieferkette | On-time delivery, large stock availability |

| Technische Unterstützung | Application engineers, metallurgy expertise |

| Personalisierung | Modified alloy ratios, special particle sizes |

| Zertifizierungen | ISO, aerospace-grade quality systems |

Choosing a supplier that offers both technical expertise and a robust supply chain can significantly reduce production risk and improve end-part performance.

6. Top Global Suppliers of AlMgSc Powder for Wholesale and Distribution

Several companies have established themselves as reliable suppliers of AlMgSc powder, catering to industrial clients worldwide. These suppliers use advanced gas atomization or hybrid production methods to ensure quality and consistency.

Top 5 AlMgSc Powder Suppliers (2024)

| Name des Lieferanten | Region | Zentrale Stärken |

|---|---|---|

| Shanghai Truer Technologie | China | Broad alloy range, custom formulation, ISO-certified |

| AP&C (GE-Zusatzstoff) | Kanada | Aerospace-grade powders, gas atomized |

| TLS Technik | Deutschland | R&D-focused, specialty aluminum alloys |

| Tekna | Kanada | Nanopowder expertise, scalable production |

| Equispheres | Kanada | Uniform particle morphology, AM-optimized powders |

Warum Shanghai Truer sich auszeichnet:

Shanghai Truer Technology Co., Ltd is a leading manufacturer and supplier of high-performance metal powders—including AlMgSc—tailored for additive manufacturing and powder metallurgy. Since entering the AM industry in 2019, Truer has developed a comprehensive ecosystem of powder production, equipment, and technical support.

✅ In-house gas atomization technology

✅ Custom alloy development for B2B clients

✅ Strong logistics for global distribution

✅ Technical expertise in PM and AM applications

Truer offers grades suitable for aerospace, automotive, and defense applications and supports customer R&D with expert metallurgical consultation.

📞 For inquiries or bulk orders, connect with us via our Kontakt Seite

7. Why More B2B Buyers Are Sourcing AlMgSc Powder from China

China has rapidly become a strategic supply hub for AM powders, including niche alloys like AlMgSc. This shift is driven by advancements in domestic powder metallurgy capabilities and competitive pricing.

Key Reasons:

- 🏭 Mature supply chain for rare earth elements like scandium

- 📉 Lower production costs without sacrificing quality

- ⚙️ Scalable manufacturing infrastructure

- 🚢 Efficient logistics and global shipping networks

Chinese suppliers like Shanghai Truer are now offering:

- Custom AlMgSc compositions with tight tolerances

- Globally competitive pricing for wholesale buyers

- ISO-certified processes and QC systems

- Fast turnaround times for prototyping and mass orders

Cost Comparison Table (Indicative):

| Region | Preis (pro kg) | Vorlaufzeit | Personalisierung | Zertifizierungen |

|---|---|---|---|---|

| China | $420–$550 | 2-3 Wochen | Hoch | ISO 9001 |

| Europa | $600–$750 | 4-6 Wochen | Mittel | ISO, AS9100 |

| Nord-Amerika | $700–$850 | 4-8 Wochen | Mittel | ISO, AS9100 |

As B2B buyers seek both performance and value, sourcing from China becomes increasingly attractive—especially when working with experienced partners like Truer.

🌐 Discover more about Truer’s capabilities and infrastructure on our Über uns Seite

8. Why Choose Shanghai Truer Technology as Your AlMgSc Powder Supplier

Shanghai Truer Technology Co., Ltd is not just a powder supplier—it is a full-solution partner for B2B customers in additive manufacturing (AM) and powder metallurgy (PM). Since its establishment in 2009 and AM business expansion in 2019, Truer has become one of China’s most reliable and innovative metallic powder providers.

What Makes Truer a Preferred Choice for Wholesale Buyers:

✅ In-House Powder Production Capabilities

Truer manufactures AlMgSc powder using advanced gas atomization techniques, ensuring:

- High sphericity and low oxygen content

- Controlled particle size distribution (D10–D90)

- Repeatable quality with full batch traceability

✅ Custom Alloy Formulations

Truer works closely with engineering teams and R&D departments to develop customized AlMgSc compositions, such as:

- Al-4Mg-0.6Sc-0.4Zr

- Al-3.5Mg-0.7Sc optimized for SLM and EBM

- Tailored blends for unique mechanical or thermal demands

✅ Technical Expertise & Support

Truer’s powder metallurgy division is staffed with trained metallurgists and AM specialists. Services include:

- Application consultation

- Powder selection for specific AM platforms

- Post-processing guidance

✅ Full-Service B2B Support

Truer provides end-to-end service for enterprise customers:

- Custom packaging (vacuum-sealed, nitrogen-filled)

- Fast and reliable logistics to global destinations

- Detailed material test reports (MTRs) with every batch

- Flexible MOQs for both R&D and mass production

✅ Industry Certifications

- ISO 9001:2015 zertifiziert

- Compliance with aerospace and automotive standards

- Internal quality audits and QC checkpoints

| Merkmal | Nutzen für B2B-Einkäufer |

|---|---|

| In-house atomization | Reliable and repeatable powder quality |

| Entwicklung kundenspezifischer Legierungen | Application-specific solutions |

| Technische Beratung | Reduced trial-and-error in production |

| Globale Logistik | On-time delivery and inventory planning |

| Certifications & testing | Confidence in compliance and performance |

🔧 Learn more about Truer’s full powder catalog on our PM-Pulver-Seite

9. How to Order Wholesale AlMgSc Powder from Shanghai Truer

Ordering high-quality AlMgSc powder from Shanghai Truer is a seamless process tailored for B2B customers across industries. Whether you’re a procurement manager, R&D engineer, or OEM production lead, Truer provides a responsive and transparent ordering system.

Schritt-für-Schritt-Bestellverfahren:

- 📩 Inquiry & Consultation

- Besuchen Sie die Kontakt Seite or email Truer directly

- Share your technical requirements: alloy composition, particle size, quantity, application

- Receive technical consultation and product match suggestions

- 📄 Quotation & Sample Request

- Truer provides a formal quote based on your specifications

- Samples (typically 0.5–1 kg) can be shipped for validation/testing

- Material test reports (MTRs), COAs, and SDS documents included

- 🧾 Order Confirmation

- Finalize order quantity, packaging format, and delivery terms (EXW, FOB, CIF)

- Sign purchase agreement and issue PO

- Payment via bank transfer, LC, or agreed terms

- 📦 Production & Shipping

- Powder is produced or drawn from available stock

- Packaged in vacuum-sealed containers with nitrogen protection

- Global shipping via FedEx, DHL, or freight forwarder

- 📋 Post-Sales Support

- Receive post-delivery technical support

- Assistance with powder performance, printing parameters, or reordering

- Option to schedule regular deliveries or sign supply agreements

| Schritt | Action Required by B2B Customer | Truer’s Role |

|---|---|---|

| Anfrage | Submit needs and specs | Offer consultation and recommendations |

| Angebot | Review and approve sample/quote | Provide MTRs, pricing, and delivery ETA |

| Bestätigung der Bestellung | Confirm PO and payment terms | Schedule production and packaging |

| Fulfillment | Receive shipment and inspect quality | Deliver with documentation and support |

| After-Sales | Contact for tech help or reorder | Continuous support and optimization |

📬 Ready to place an order? Start by filling out our quick form on the Kontakt Seite

10. FAQs: Common Questions About Buying AlMgSc Powder in Bulk

Below are the most frequently asked questions from wholesale buyers, procurement teams, and industrial users regarding AlMgSc alloy powder.

📌 What is the typical composition of AlMgSc powder?

Most commonly, AlMgSc powder includes 3–5% magnesium, 0.4–0.7% scandium, and a small percentage of zirconium (0.2–0.5%) to enhance grain refinement. Custom ratios are available on request.

📌 Is AlMgSc compatible with laser-based 3D printing systems?

Yes. AlMgSc powder is optimized for SLM, LPBF, and EBM machines. It offers excellent flowability, laser absorption, and layer fusion properties.

📌 Can I order custom particle size distributions?

Absolutely. Truer provides standard PSDs (15–45 µm, 20–63 µm) and can tailor distribution based on machine compatibility or performance requirements.

📌 Do you ship internationally?

Yes. Truer exports globally and supports all major INCOTERMS (EXW, FOB, CIF). Vacuum-sealed packaging ensures powder integrity during transit.

📌 What is the minimum order quantity (MOQ)?

MOQ is flexible depending on the application. For R&D or prototyping, orders can start from 1 kg. For mass production, Truer supports bulk orders starting at 25 kg or more.

📌 Are quality certifications provided?

Yes. Every batch is delivered with a Material Test Report (MTR), Certificate of Analysis (COA), and relevant safety documentation.

📌 Can you assist with choosing the right alloy?

Definitely. Truer’s technical team provides consulting and alloy selection based on your application, print technology, and mechanical requirements.

📌 How can I trust the quality of the powder?

Truer conducts strict internal testing (SEM, EDS, flow rate, oxidation level) and complies with ISO 9001:2015. You can request a sample batch for testing before full-scale ordering.

🤝 For technical questions or custom requests, connect with Truer via the Kontakt Seite

By combining Shanghai Truer’s proven capabilities with the high-performance characteristics of AlMgSc powder, your enterprise gains a competitive edge in manufacturing innovation, supply chain efficiency, and product excellence.