1. Introduction to 17-4PH Powder in Industrial Manufacturing

17-4PH stainless steel powder, also known as UNS S17400 or Type 630, is one of the most widely used precipitation hardening stainless steel grades in the powder metallurgy and additive manufacturing industry. It is composed primarily of iron, chromium (approx. 15-17.5%), nickel (~3-5%), and copper with additions of niobium, providing a remarkable combination of high strength, corrosion resistance, and excellent mechanical properties at elevated temperatures.

For B2B buyers, particularly in the aerospace, automotive, energy, and tooling sectors, 17-4PH powder offers a cost-effective solution for producing complex, high-performance metal parts via metal injection molding (MIM), hot isostatic pressing (HIP), and selective laser melting (SLM).

Key Benefits for Industrial Use:

- Außergewöhnliche mechanische Festigkeit

- Good corrosion resistance in harsh environments

- Geeignet für Hochtemperaturanwendungen

- Excellent weldability and machinability

- Heat treatable to various hardness levels

This alloy is especially popular among OEMs, contract manufacturers, and additive manufacturing service providers seeking optimized performance without compromising ease of fabrication.

2. Applications of 17-4PH Powder in Engineering & Additive Manufacturing

17-4PH powder is renowned for its versatility and high-performance metrics across a wide range of industries. Here’s how different sectors utilize this material for mission-critical components:

Luft- und Raumfahrt

- Turbine engine components

- Strukturelle Klammern

- Fasteners and fittings

- Fuel system parts

Automobilindustrie

- Injection system housings

- Komponenten des Getriebes

- Gears and shafts

- Teile der Auspuffanlage

Medizinische Geräte

- Chirurgische Instrumente

- Orthopädische Implantate

- Dental components

Öl & Gas

- Valve bodies

- Werkzeuge für das Bohrloch

- Pumpengehäuse

Industrielle Ausrüstung

- Tooling inserts

- Pressure vessels

- Corrosive fluid connectors

Additive Manufacturing (3D-Druck)

- Lightweight, complex parts optimized for strength

- Conformal cooling channels in tooling applications

- Rapid prototyping with near-net-shape features

For more detailed information on industrial metal powders and their applications, visit our Powder Metallurgy Powders Page.

3. Properties, Composition & Grades of 17-4PH Stainless Steel Powder

17-4PH powder stands out due to its unique metallurgical makeup and the ability to be heat treated to various hardness levels. The powder is available in several particle size distributions tailored for applications like laser powder bed fusion (LPBF), binder jetting, and metal injection molding (MIM).

Chemical Composition (Typical %)

| Element | Reichweite (%) |

|---|---|

| Chrom | 15.0 – 17.5 |

| Nickel | 3.0 – 5.0 |

| Kupfer | 3.0 – 5.0 |

| Niobium + Tantalum | 0.15 – 0.45 |

| Mangan | ≤ 1.0 |

| Silizium | ≤ 1.0 |

| Kohlenstoff | ≤ 0.07 |

| Phosphor | ≤ 0.04 |

| Schwefel | ≤ 0.03 |

| Eisen | Waage |

Typical Mechanical Properties (After Aging)

| Eigentum | Wert |

|---|---|

| Endgültige Zugfestigkeit | 1100–1300 MPa |

| Streckgrenze | 1000–1100 MPa |

| Härte (HRC) | 35–45 |

| Dehnung | 10–20% |

| Dichte | ~7.75 g/cm³ |

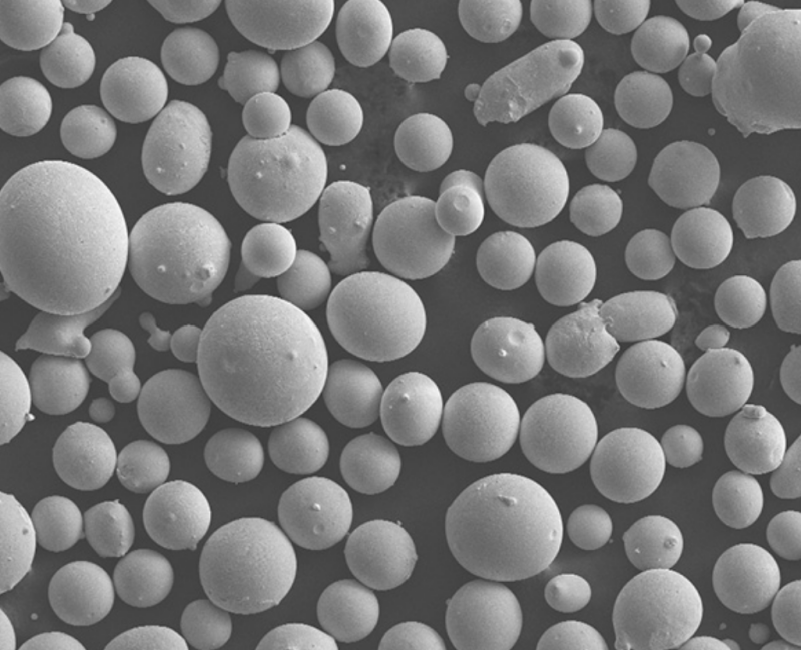

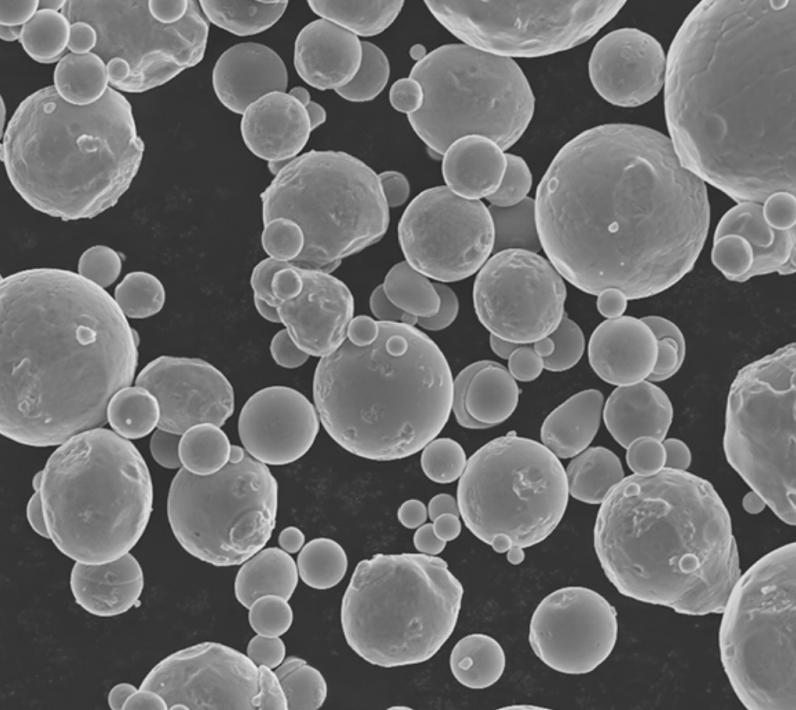

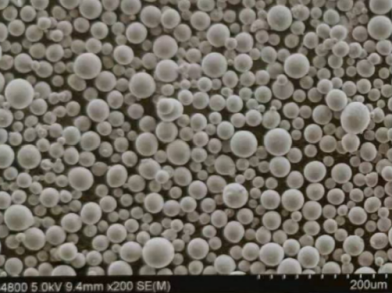

Available Grades & Particle Sizes

| Klasse | Methode der Anwendung | Partikelgrößenbereich |

|---|---|---|

| Zerstäubtes Gas | Additive Fertigung | 15–45 µm, 45–105 µm |

| Zerstäubtes Wasser | Press & Sinter, MIM | -150 mesh, -325 mesh |

| Sphärisch | Laser Sintering (SLM) | 20–63 µm |

Shanghai Truer Technology Co., Ltd. provides both gas atomized and water atomized 17-4PH powders, ensuring optimal particle morphology and flowability for different manufacturing techniques.

Why Industrial Buyers Choose 17-4PH Powder

- ✔️ Excellent combination of strength and corrosion resistance

- ✔️ Reliable performance in high-pressure and high-temperature environments

- ✔️ Availability in various particle sizes for AM, HIP, and MIM

- ✔️ Cost-effective alternative to titanium and high-nickel alloys

For more about our company’s history and powder metallurgy expertise, visit our Über uns Seite.

4. Market Trends and Demand Forecast for 17-4PH Powder

The global demand for 17-4PH stainless steel powder is experiencing steady growth, driven by its expanding applications in aerospace, medical, and additive manufacturing sectors. As industries move towards lightweight, high-strength components manufactured via powder metallurgy and 3D printing, 17-4PH offers an ideal material solution.

Wichtige Markttreiber

- Aerospace & Defense Growth: Rising aircraft production and MRO activities are boosting the use of 17-4PH for high-performance components.

- Additive Manufacturing Adoption: The shift to metal 3D printing in prototyping and end-use parts is fueling demand for spherical 17-4PH powder.

- Medical Device Manufacturing: Increased spending on surgical instruments and implants post-COVID has expanded medical-grade powder needs.

- Industrielle Automatisierung: Precision gears and shafts using MIM and HIP methods are increasingly adopting 17-4PH powder for strength and corrosion resistance.

Marktprognose (2024-2030)

| Region | CAGR (%) | Key Growth Sector |

|---|---|---|

| Nord-Amerika | 6.8% | Luft- und Raumfahrt & Verteidigung |

| Europa | 5.9% | Medical Devices & Automotive |

| Asien-Pazifik | 7.5% | Electronics & Industrial Tools |

| Naher Osten | 4.2% | Öl- und Gasexploration |

Explore our wide range of available stainless steel and prealloyed powders by visiting the PM-Pulver-Portfolio.

5. Key Considerations When Choosing a 17-4PH Powder Supplier

Selecting the right 17-4PH powder supplier is critical for ensuring consistent quality, traceability, and performance in your end products. For OEMs, tier-1 suppliers, and additive manufacturing service providers, here’s what to evaluate:

1. Powder Morphology & Flowability

- Spherical vs. Irregular Particles: Spherical powders offer better flow for 3D printing.

- Apparent & Tap Density: Affects filling and sintering behavior.

- Partikelgrößenverteilung (PSD): Tailored PSD improves layer uniformity in AM.

2. Material Certification & Quality Standards

Ensure your supplier offers:

- Full material traceability

- ISO 9001 oder AS9100 certification

- Konsistenz von Charge zu Charge

3. Manufacturing Method

- Zerstäubtes Gas: Ideal for LPBF and binder jetting.

- Zerstäubtes Wasser: More cost-effective, suitable for MIM and press-and-sinter.

- Hybride Zerstäubung: Offers balance of morphology and cost.

4. Supply Chain & Lead Time

- Local warehousing

- Rapid fulfillment

- Custom packaging options

5. Technical Support and R&D Collaboration

- Engineering assistance

- Application-specific formulations

- Entwicklung kundenspezifischer Legierungen

6. Top Global Suppliers of 17-4PH Powder for B2B Buyers

Here’s a comparative overview of some of the most reliable 17-4PH powder suppliers globally. These companies serve industries such as aerospace, oil & gas, medical, and heavy machinery.

| Name des Lieferanten | Region | Pulver Typ | Notable Strengths |

|---|---|---|---|

| Shanghai Truer Technology Co, Ltd. | China | Gas & Water Atomized | Custom blends, large portfolio, fast delivery |

| Zimmerer-Zusatzstoff | USA | Zerstäubtes Gas | Aerospace-grade powders, AS9100 certified |

| Sandvik Fischadler | Europa | Zerstäubtes Gas | High sphericity, AM-focused powders |

| Hoganas AB | Schweden | Zerstäubtes Wasser | Mass production, cost-effective |

| CNPC-Pulver | China | Zerstäubtes Gas | Competitive pricing, bulk B2B supply |

Shanghai Truer stands out as a one-stop supplier offering both powder production and additive manufacturing services. With a strong focus on powder metallurgy R&D, Truer supports customers with tailored solutions for diverse applications.

Learn more about Truer’s integrated capabilities and additive expertise on our Company Overview Page.

7. Why More OEMs Are Turning to Chinese 17-4PH Powder Manufacturers

In recent years, OEMs and global distributors have increasingly sourced 17-4PH powder from Chinese manufacturers due to competitive pricing, strong quality control, and advanced production capabilities.

Advantages of Chinese Suppliers

- Lower Cost per Kg: Particularly beneficial for high-volume buyers.

- Advanced Manufacturing Lines: Gas and water atomization at global standards.

- End-to-End-Dienste: Many suppliers offer post-processing or printing services.

- Schnelle Vorlaufzeiten: Shorter delivery cycles due to domestic production scalability.

Why Shanghai Truer is a Preferred Source

Shanghai Truer Technology Co., Ltd. has positioned itself as a leader in 17-4PH powder manufacturing by offering:

- ✔️ Full portfolio of PM stainless steel powders including 17-4PH

- ✔️ Water atomized, gas atomized, and hybrid production capabilities

- ✔️ Custom powder solutions for sintering, HIP, and 3D printing

- ✔️ Technical support from R&D to part performance validation

- ✔️ Global shipping and logistics support

Whether you’re an additive manufacturing bureau or a powder metallurgy component producer, Truer offers tailored supply agreements, competitive pricing, and unmatched powder quality.

Interested in working with us? Kontaktieren Sie uns heute to get a custom quote or technical consultation.

8. How to Order Wholesale 17-4PH Powder from Reliable Sources

For B2B buyers such as OEM manufacturers, industrial distributors, and additive manufacturing service providers, sourcing high-quality 17-4PH stainless steel powder efficiently and reliably is critical to maintaining production timelines and quality standards.

Here’s a step-by-step guide to ordering 17-4PH powder wholesale from Shanghai Truer Technology Co., Ltd., one of China’s most trusted powder metallurgy suppliers.

🧾 Step-by-Step Wholesale Ordering Process

| Schritt | Beschreibung |

|---|---|

| 1. Produkt-Anfrage | Contact Truer’s sales team via Kontakt-Formular or email with your powder specifications, quantity needs, and application. |

| 2. Technische Konsultation | Truer’s technical team will help identify the optimal particle size, atomization method (gas or water), and packaging based on your application (SLM, MIM, HIP, etc.). |

| 3. Quote & Sample Request | Receive a detailed quotation including MOQ, delivery time, and Incoterms. Sample powder (0.5–5kg) is available for testing. |

| 4. Sample Testing & Validation | Conduct internal testing for flowability, density, and sintering behavior. Truer can also provide full batch COA and SDS. |

| 5. Purchase Order (PO) | Once testing is approved, submit your PO. Truer accepts bulk orders starting from 50kg up to several tons. |

| 6. Production & Quality Control | Powder is atomized, sieved, and packed under inert gas with full traceability and quality inspection. |

| 7. Versand & Lieferung | Orders are shipped globally by sea, air, or express courier with export documentation. Delivery time ranges from 7 to 21 days based on location. |

📦 Available Packaging Options

- Sealed Metal Drums: 25kg, 50kg

- Vacuum Bags/Pouches: 5kg, 10kg

- Custom Bulk Packaging: Available on request

🤝 Value-Added Services from Truer

- OEM labeling and custom branding

- Entwicklung kundenspezifischer Legierungen

- Technical support for additive manufacturing process optimization

- On-site or remote powder metallurgy consultation

For complete powder listings and grades, visit our PM-Pulver-Portfolio.

9. FAQs: Everything You Need to Know About Buying 17-4PH Powder Wholesale

Here are some of the most frequent questions we receive from industrial buyers, procurement teams, and engineering managers:

❓ What is the minimum order quantity (MOQ) for 17-4PH powder?

📌 MOQ is typically 50kg for commercial orders. For R&D purposes, smaller samples (1–5kg) are available.

❓ What is the difference between gas-atomized and water-atomized 17-4PH powder?

| Merkmal | Zerstäubtes Gas | Zerstäubtes Wasser |

|---|---|---|

| Partikelform | Sphärisch | Unregelmäßig |

| Fließfähigkeit | Ausgezeichnet | Mäßig |

| Anmeldung | AM (SLM, L-PBF), Binder Jet | MIM, Press & Sinter |

| Kosten | Höher | Unter |

Gas atomized powder is preferred for additive manufacturing due to its flowability and packing density, while water atomized powder is ideal for conventional powder metallurgy.

❓ Can you provide material certification and testing data?

📌 Yes, all shipments include a Certificate of Analysis (COA), Material Safety Data Sheet (MSDS), and internal quality inspection reports. Custom testing (e.g., SEM, PSD, tap density) is available on request.

❓ What is the delivery time for international orders?

📌 Delivery typically takes:

- Asia: 5–7 working days

- Europe: 10–14 working days

- North America: 12–21 working days

Expedited shipping via air freight is available.

❓ Can I request a custom particle size distribution?

📌 Yes. Truer can tailor the PSD to match your specific process — whether that’s <15µm for binder jetting, 20–45µm for SLM, or -325 mesh for MIM.

❓ How does Truer ensure powder quality and consistency?

📌 Truer uses advanced atomization technology, multi-stage sieving, and inert gas packaging. Every batch undergoes:

- SEM morphology analysis

- Chemical composition validation (ICP-OES)

- Flowability and apparent density testing

- Oxygen/nitrogen/hydrogen content analysis

For more insights into our quality control and powder solutions, explore our About Page.

✅ Summary: Why Shanghai Truer is the Smart Choice for B2B Buyers

Shanghai Truer Technology Co., Ltd. has emerged as a premier supplier of 17-4PH stainless steel powder thanks to its:

- 🔬 Dual atomization capabilities (gas & water)

- 🧪 In-house testing and material R&D

- 🌐 Global logistics and B2B fulfillment expertise

- 🧰 Full spectrum of PM powders and additive manufacturing support

- 🤝 Proven reliability with OEMs and distributors worldwide

Whether you’re sourcing 17-4PH powder for aerospace components or MIM parts, Truer combines technical expertise with cost-effective manufacturing to help you succeed.

👉 Ready to start your order or need technical advice? Kontaktieren Sie uns heute for a consultation or quotation.