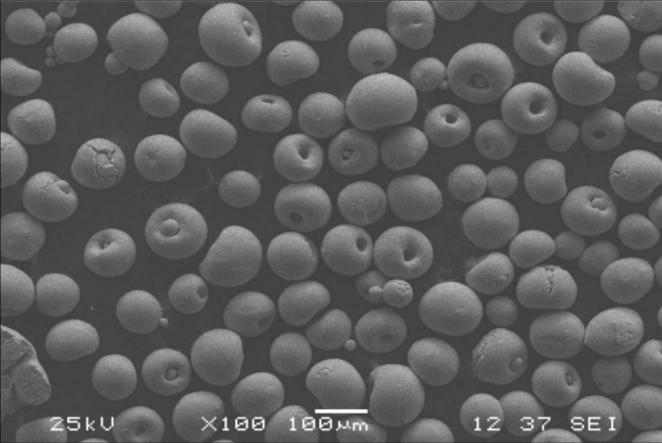

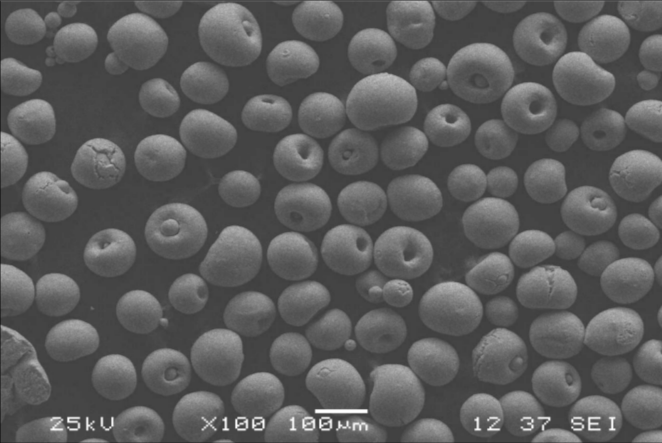

Überblick über reines Ta-Pulver

Tantal (Ta)-Pulver, oft bezeichnet als Reines Ta-Pulvertantal ist ein unverzichtbares Material für verschiedene High-Tech-Anwendungen. Tantal ist für seine hervorragende Korrosionsbeständigkeit, seinen hohen Schmelzpunkt und sein hervorragendes Verhältnis von Festigkeit zu Gewicht bekannt und spielt eine wichtige Rolle in der Elektronik, der Luft- und Raumfahrt, in medizinischen Geräten und vielem mehr. Aber was macht Pure Ta Powder so besonders unter anderen Metallpulvern? Lassen Sie uns in die Details eintauchen und seine Eigenschaften, Qualitäten und Verwendungszwecke erforschen und herausfinden, warum es ein unverzichtbares Material für die moderne Industrie ist.

Arten von reinem Ta-Pulver

Tantalpulver gibt es in verschiedenen Qualitäten und Spezifikationen, um den besonderen Anforderungen der verschiedenen Branchen gerecht zu werden. Nachstehend finden Sie eine beschreibende Liste der gängigen Modelle:

| Name des Modells | Beschreibung | Wichtige Anwendungen |

|---|---|---|

| Ta-200 | Hochreines Pulver (≥99,95%), ideal für die Herstellung von Kondensatoren. | Elektronik, Halbleiter |

| Ta-205 | Aufgrund seiner großen Partikelgröße ist es für Hochtemperaturlegierungen besonders geeignet. | Luft- und Raumfahrt, Turbinen |

| Ta-CX | Ultrafeines Pulver für die additive Fertigung und den 3D-Druck. | Medizinische Implantate, kundenspezifische Teile |

| Ta-NR | Knollenförmiges Pulver mit ausgezeichneter Fließfähigkeit für die Pulvermetallurgie. | Automobilindustrie, industrielle Komponenten |

| Ta-F2 | Schuppenförmiges Pulver mit vergrößerter Oberfläche, das in chemischen Anwendungen eingesetzt wird. | Chemische Verarbeitungsanlagen |

| Ta-SM | Super-Mikropulver für Oberflächenbeschichtungen. | Thermische Sprays, Schutzschichten |

| Ta-H1 | Hochdichtes Tantalpulver mit hervorragender elektrischer Leitfähigkeit. | Kondensatoren, Hochleistungselektronik |

| Ta-Aero | Für die Luft- und Raumfahrt geeignetes Pulver, das für extreme Umgebungen entwickelt wurde. | Raumfahrzeuge, Verteidigungsanwendungen |

| Ta-Med | Tantalpulver in medizinischer Qualität, biokompatibel und rein. | Medizinische Implantate, chirurgische Instrumente |

| Ta-AM | Optimiert für die additive Fertigung mit außergewöhnlichen Isotropieeigenschaften. | Prototyping, fortgeschrittene Fertigung |

Zusammensetzung der Reines Ta-Pulver

Reines Ta-Pulver besteht in erster Linie aus Tantal, mit Spuren von Verunreinigungen, die je nach Qualität variieren. Hier ist eine Aufschlüsselung:

| Komponente | Typischer Prozentsatz (%) |

|---|---|

| Tantal (Ta) | ≥99.9 |

| Sauerstoff (O) | ≤0.05 |

| Nitrogen (N) | ≤0.02 |

| Kohlenstoff (C) | ≤0.01 |

| Eisen (Fe) | ≤0.005 |

Eigenschaften und Merkmale von reinem Ta-Pulver

Reines Ta-Pulver weist einzigartige Eigenschaften auf, die es für spezielle Anwendungen wertvoll machen.

| Eigentum | Einzelheiten |

|---|---|

| Dichte | 16.6 g/cm³ |

| Schmelzpunkt | 3017°C |

| Elektrische Leitfähigkeit | Hervorragend geeignet für elektronische Bauteile. |

| Korrosionsbeständigkeit | Hochgradig säurebeständig, insbesondere gegen Flusssäure. |

| Thermische Stabilität | Behält seine Integrität auch bei hohen Temperaturen bei. |

| Verarbeitbarkeit | Verformbar und dehnbar, ermöglicht verschiedene Verarbeitungsmethoden. |

| Biokompatibilität | Inert und sicher für medizinische Implantate. |

Anwendungen von reinem Ta-Pulver

Reines Ta-Pulver findet aufgrund seiner vielseitigen Eigenschaften in verschiedenen Branchen Anwendung:

| Industrie | Spezifische Anwendungen |

|---|---|

| Elektronik | Kondensatoren, Dünnschichtwiderstände, Leiterplatten. |

| Luft- und Raumfahrt | Hochtemperaturlegierungen, Triebwerkskomponenten, Schutzbeschichtungen. |

| Medizinische | Knochenimplantate, chirurgische Instrumente, biokompatible Beschichtungen. |

| Chemische Verarbeitung | Korrosionsbeständige Ausrüstung für Chemieanlagen. |

| 3D-Druck | Fortschrittliche Herstellung komplexer, leichter Strukturen. |

Spezifikationen, Größen und Normen

Reines Ta-Pulver ist in verschiedenen Größen und Qualitäten erhältlich, um den Anforderungen der Industrie gerecht zu werden.

| Spezifikation | Einzelheiten |

|---|---|

| Partikelgröße | 1-150 µm |

| Reinheitsgrade | ≥99.95% |

| Normen | ASTM B708, ISO 9001:2015 |

| Verpackung | 1 kg, 5 kg, 25 kg versiegelte Behälter. |

Lieferanten und Preisangaben

| Name des Lieferanten | Land | Preisspanne (USD/kg) | Spezialisierung |

|---|---|---|---|

| H.C. Starck | Deutschland | $500-$800 | Hochreine Tantal-Pulver. |

| Global Advanced Metals | USA | $450-$750 | Pulver für die Elektronik. |

| JX Nippon Bergbau | Japan | $600-$900 | Pulver für die Medizin und die Luft- und Raumfahrt. |

| Zhuzhou Zementiertes Hartmetall | China | $300-$600 | Kostengünstige Industriepulver. |

Vorteile und Beschränkungen von Reines Ta-Pulver

| Aspekt | Vorteile | Beschränkungen |

|---|---|---|

| Reinheit | Der hohe Reinheitsgrad gewährleistet eine gleichbleibende Leistung. | Höhere Kosten im Vergleich zu alternativen Materialien. |

| Korrosionsbeständigkeit | Unerreichte Beständigkeit in sauren Umgebungen. | Begrenzte Verfügbarkeit aufgrund geopolitischer Faktoren. |

| Duktilität | Lässt sich leicht zu komplexen Strukturen formen. | Spröde bei extrem niedrigen Temperaturen. |

| Anwendungen | Vielseitig einsetzbar für verschiedene Branchen. | Erfordert eine spezielle Handhabung und Verarbeitung. |

Warum sollten Sie sich für reines Ta-Pulver entscheiden?

Wenn Sie nach einem Material suchen, das Festigkeit, Flexibilität und Korrosionsbeständigkeit vereint, ist Pure Ta Powder ein starker Kandidat. Stellen Sie sich eine Düsentriebwerksturbine vor, die bei glühenden Temperaturen arbeitet, oder einen Herzschrittmacher, der im menschlichen Körper einwandfrei funktioniert. Beide sind für ihre außergewöhnliche Leistung auf Tantal angewiesen. Seine einzigartigen Eigenschaften machen es in kritischen Industrien unersetzlich, trotz der höheren Kosten und des begrenzten Angebots.

FAQs

| Frage | Antwort |

|---|---|

| Wie hoch ist der Schmelzpunkt von Pure Ta Powder? | Tantal schmilzt bei 3017°C und ist daher für Hochtemperaturanwendungen geeignet. |

| Kann reines Ta-Pulver für den 3D-Druck verwendet werden? | Ja, bestimmte Sorten wie Ta-AM und Ta-CX sind für die additive Fertigung konzipiert. |

| Warum wird Tantal für medizinische Implantate bevorzugt? | Seine Biokompatibilität gewährleistet, dass es im menschlichen Körper nicht zu unerwünschten Reaktionen kommt. |

| Ist Pure Ta Powder recycelbar? | Ja, Tantal kann zurückgewonnen und wiederverwendet werden, ohne dass sich seine Eigenschaften verschlechtern. |

| Welche Branchen profitieren am meisten von Tantal? | Die Elektronik-, Luft- und Raumfahrt-, Medizin- und Chemieindustrie sind in hohem Maße von ihr abhängig. |

Schlussfolgerung

Reines Ta-Pulver ist ein Eckpfeiler der modernen Materialwissenschaft. Seine Fähigkeit, unter extremen Bedingungen zu arbeiten und dabei stabil und korrosionsbeständig zu bleiben, macht es für verschiedene Branchen von unschätzbarem Wert.