1. Introduction: Why Silicon Oxide Powder is Vital in Modern Industry

Silicon oxide powder (SiO₂), also commonly referred to as silica powder, is a critical raw material in various industrial applications, from electronics and ceramics to coatings and 3D-Druck. Its exceptional thermal stability, mechanical strength, and dielectric properties make it indispensable across manufacturing sectors.

For B2B buyers including wholesalers, distributors, and large-scale manufacturers, sourcing high-purity, consistent-quality silicon oxide powder is crucial for ensuring product performance, regulatory compliance, and cost-efficiency.

Key Characteristics of Silicon Oxide Powder:

| Eigentum | Beschreibung |

|---|---|

| Chemische Formel | SiO₂ |

| Reinheitsbereich | 99.5% – 99.999% |

| Partikelgröße | 0.1μm to 100μm |

| Erscheinungsbild | White powder |

| Schmelzpunkt | ~1,710°C |

| Anwendungen | Electronics, paints, ceramics, metallurgy, 3D printing |

At Shanghai Truer Technology Co., Ltd, we understand the importance of quality and consistency. Our powder metallurgy division provides industry-grade silicon oxide powder optimized for advanced applications, with various particle size distributions and purity levels tailored to your needs.

🔗 Learn more about our powder metallurgy solutions on our PM-Pulver-Produkte seite.

2. Key Industrial Applications of Silicon Oxide Powder

Silicon oxide powder has a wide range of industrial use cases due to its insulating, abrasive, and chemical-resistant properties. Below are key B2B application areas:

2.1 Electronics & Semiconductors

- Used as an insulator in microelectronics and IC fabrication.

- Essential in producing optical fibers and semiconductors.

- Acts as a dielectric layer in capacitors and transistors.

2.2 Ceramics & Refractories

- Silicon oxide is a fundamental component in the production of high-temperature ceramics.

- Enhances strength and thermal resistance in refractory bricks used in furnaces and kilns.

2.3 Paints, Coatings, and Adhesives

- Acts as a matting agent and anti-caking agent.

- Improves scratch resistance and UV protection.

- Used in architectural and automotive coatings.

2.4 Rubber & Plastics

- Improves tensile strength and abrasion resistance in rubber compounds.

- Enhances durability and surface finish in plastic products.

2.5 Additive Manufacturing & 3D Printing

- Used as a binder or filler in metal and ceramic-based 3D printing.

- Enhances surface quality and strength of printed parts.

2.6 Metallurgy & Foundry Industry

- Used as a fluxing agent in metal processing.

- Improves flowability and mold release in foundry applications.

Key Industries Served:

- Elektronikfertigung

- Construction & Civil Engineering

- Automotive OEMs and Tier-1 Suppliers

- 3D Printing & Additive Manufacturing

- Chemical Processing Plants

- Luft- und Raumfahrt & Verteidigung

3. Types and Grades of Silicon Oxide Powder for B2B Buyers

Choosing the correct silicon oxide powder type is essential for industrial buyers aiming for specific performance outcomes and compliance standards.

3.1 Based on Purity Levels

| Klasse | Reinheit | Anmeldung |

|---|---|---|

| Standard Grade | 99.5% | Construction, ceramics |

| High-Purity Grade | 99.9% | Electronics, optics |

| Ultra-High Purity | 99.99% – 99.999% | Semiconductor, aerospace |

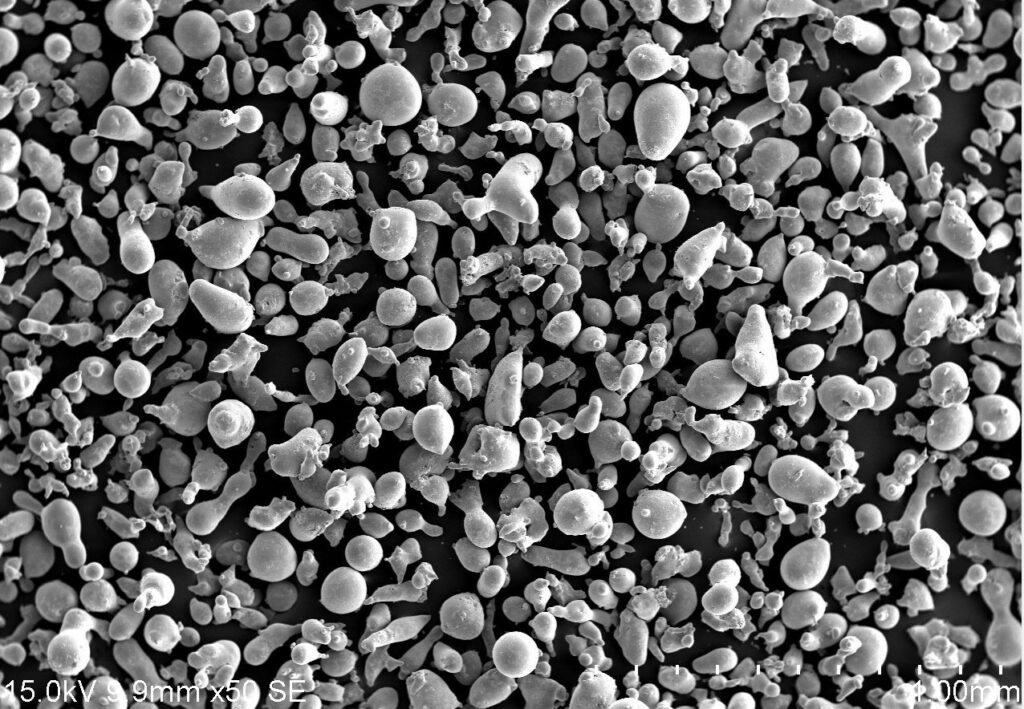

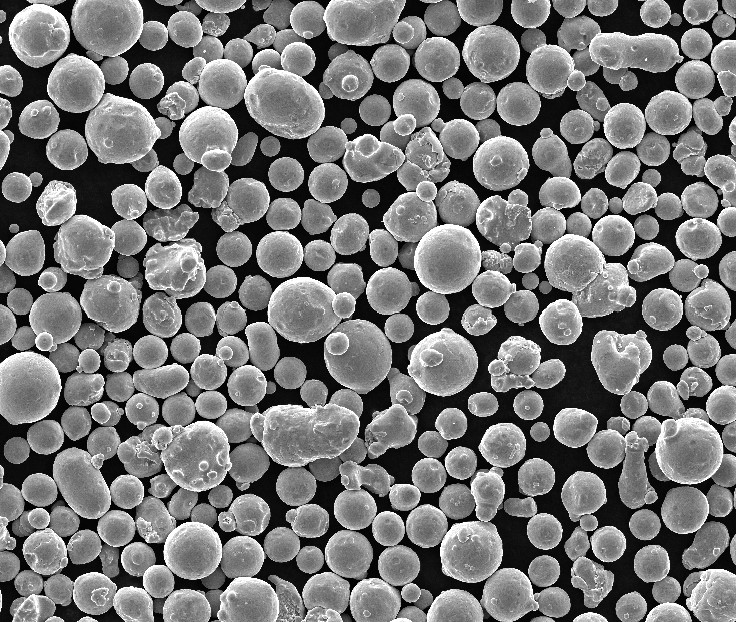

3.2 Based on Particle Size

| Typ | Größenbereich | Anmeldung |

|---|---|---|

| Micronized | 0.5μm – 10μm | Paints, plastics |

| Feines Puder | 10μm – 75μm | Ceramics, refractories |

| Grobes Pulver | 75μm – 100μm | Foundry, metallurgy |

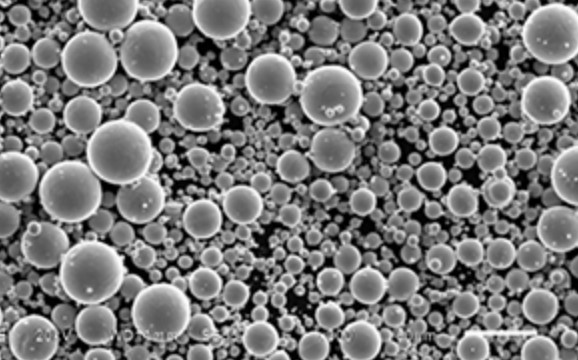

3.3 Based on Production Method

- Fumed Silica: Produced via flame hydrolysis; used in coatings and elastomers.

- Precipitated Silica: Produced via chemical precipitation; used in tires and rubber.

- Amorphous Silica: Used in pharmaceuticals and food-grade applications.

- Crystalline Silica: High hardness; used in abrasives and construction.

3.4 Custom Powder Metallurgy Grades by Shanghai Truer

Shanghai Truer Technology offers customized powder solutions, including:

- High-purity SiO₂ powders for additive manufacturing

- Tailored particle size distributions for specific B2B applications

- Blended powders for sintering, infiltration, or composite reinforcement

Explore our additive manufacturing capabilities and powders on our Über uns seite.

4. Global Market Trends and Growth Potential in the Silicon Oxide Sector

The global silicon oxide powder market has witnessed substantial growth in recent years, driven by advancements in electronics, additive manufacturing, and green construction materials. For B2B buyers, understanding these trends helps make informed procurement and investment decisions.

4.1 Market Size Overview

| Metrisch | 2023 | 2027 (Projected) | CAGR (2023–2027) |

|---|---|---|---|

| Global Market Value | $5.6 Billion | $8.2 Billion | 9.8% |

| Asien-Pazifik-Anteil | 42% | 46% | - |

| Key Growth Segments | Electronics, 3D Printing, Coatings | - | - |

4.2 Growth Drivers

- Electrification & Semiconductor Boom

Accelerated demand for chips and optical fibers is fueling high-purity silica consumption. - erweiterung des 3D-Drucks

Additive manufacturing is increasingly using silicon oxide as a filler and structural enhancer. - Eco-Friendly Construction

Silica-based aerogels and insulation materials are gaining traction in green building projects. - Battery & Energy Storage

Used in lithium-silicon battery anodes for next-gen energy applications.

4.3 B2B Opportunities

- Long-term contracts with OEMs for silicon-based materials.

- Strategic sourcing agreements with Asian manufacturers.

- Private label partnerships for repackaging and distribution.

B2B buyers should monitor regional regulatory changes, technological innovations, and price fluctuations of raw materials to stay competitive.

5. Key Considerations When Choosing a Silicon Oxide Powder Supplier

Choosing the right supplier is critical to maintaining consistent product quality, meeting production deadlines, and staying compliant with industry standards. Here’s what wholesale buyers and distributors should evaluate:

5.1 Purity and Consistency

- Verify purity levels through independent lab reports (preferably ≥99.9% for electronics).

- Ensure consistent particle size distribution for repeatable performance.

5.2 Production Method

- Identify if the powder is water-atomized, gas-atomized, or precipitated.

- Assess whether particle morphology aligns with your application (spherical, flake, amorphous).

5.3 Supply Chain Strength

- Does the supplier offer stable lead times?

- Are they integrated with logistics partners for international shipping?

5.4 Certifications & Compliance

- ISO 9001, ISO 14001 (Environmental), RoHS, and REACH compliance.

- SDS and COA should be provided with each batch.

5.5 Technical Support & Customization

- Does the supplier offer technical consulting?

- Can they customize blend ratios, particle sizes, or packaging?

✅ Shanghai Truer Technology Co., Ltd excels in all these areas, offering full-spectrum powder metallurgy solutions, including silicon oxide powders with customizable specs and fast delivery options. Visit our Kontakt Seite to start a quote or technical consultation.

6. Top 5 Trusted Silicon Oxide Powder Suppliers in Asia

Asia is home to some of the most advanced powder metallurgy and material technology companies. Here are 5 reliable suppliers known for their consistency and innovation in silicon oxide powder production:

| Anbieter | Land | Wesentliche Merkmale | Industry Focus |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | Custom PM powders, atomization tech, 3D printing integration | Automotive, AM, Electronics |

| Tosoh Corporation | Japan | High-purity silica, extensive R&D | Semiconductors, Optical |

| Evonik Industries | Germany (Asia Division) | Fumed silica, advanced composites | Coatings, Plastics |

| Jinan Yuxing Chemicals | China | Precipitated silica, bulk supply | Rubber, Plastics |

| Admatechs Co., Ltd | Japan | Spherical silica, thermal conductivity solutions | Electronics, Ceramics |

Shanghai Truer stands out by offering not only silicon oxide powder, but also value-added services including powder blending, technical guidance, and additive development tailored for PM and AM applications.

Why B2B Buyers Prefer Truer:

- Over 14 years of powder metallurgy expertise

- In-house development of additive solutions for PM industries

- Fast prototyping and OEM support

- Combined water + gas atomization capability for precision powders

🔗 Discover more about our company’s mission and innovation on the Über Shanghai Truer seite.

7. Why More Buyers Are Switching to Direct-from-Manufacturer Sources

The traditional distribution model often involves multiple layers of handling, which can increase costs, limit customization, and delay delivery. Today, more B2B buyers are moving toward sourcing silicon oxide powder directly from manufacturers like Shanghai Truer.

7.1 Benefits of Direct Sourcing

- Kostenvorteil

Elimination of distributor markups reduces procurement costs by 10–30%. - Schnellere Vorlaufzeiten

Direct communication with production units allows for quicker order processing and delivery. - Flexibilität bei der Anpassung

Tailored particle sizes, purities, and packaging are more feasible with manufacturers. - Better Technical Collaboration

Manufacturers can offer R&D support, testing, and product optimization.

7.2 Case Example: Truer’s Direct Supply Model

Shanghai Truer provides seamless direct supply services via its digital platform and dedicated customer service teams. Clients can:

- Request samples

- Get real-time updates on order progress

- Access technical documentation

- Get support with international certifications

This approach is especially beneficial for:

- International distributors seeking private-label options

- OEMs with specialized material requirements

- Research institutions needing consistent quality for their formulations

🔗 Browse our product offerings and initiate a wholesale inquiry on the PM-Pulver Produkte Seite.

8. Why Choose Shanghai Truer Technology as Your Silicon Oxide Powder Partner

Shanghai Truer Technology Co., Ltd is not just a manufacturer — we’re a complete solution provider in the powder metallurgy (PM) and additive manufacturing (AM) space. With over 14 years in the industry and a dedicated additive manufacturing division launched in 2019, Truer has become a go-to supplier for companies seeking consistency, innovation, and technical support in their powder sourcing.

8.1 What Makes Truer Different?

| Value Proposition | Einzelheiten |

|---|---|

| ✅ Industry Expertise | Established in 2009, with deep PM knowledge and global customer base |

| ✅ Customization | Tailored particle size, purity, and surface treatment options |

| ✅ Advanced Equipment | In-house water atomization, gas atomization, and hybrid tech |

| ✅ Technische Unterstützung | End-to-end consulting, OEM support, and documentation |

| ✅ Wide Product Range | From silicon oxide to PM steel, bronze, nickel, and soft magnetic materials |

8.2 Silicon Oxide Powder at Truer

Shanghai Truer provides high-purity silicon oxide powder suitable for:

- Ceramics and refractories

- 3D printing applications

- Coatings and adhesives

- Advanced electronics

- Metallurgical flux and foundry applications

Each batch is quality tested and can be customized for:

- Purity: Up to 99.999%

- Particle size: From <1μm fine powder to 100μm coarse powder

- Packaging: 25kg bags, 500kg super sacks, or custom formats

Truer also offers composite material solutions by blending silicon oxide with other performance-enhancing additives depending on your industry needs.

🔗 Learn more about our advanced materials and services on the Haupt-Website.

9. How to Order Wholesale Silicon Oxide Powder from Shanghai Truer

Ordering from Shanghai Truer is a streamlined experience designed for industrial buyers, procurement teams, and sourcing agents.

9.1 Step-by-Step Ordering Process

| Schritt | Beschreibung |

|---|---|

| 1. Produkt-Anfrage | Submit your RFQ through our Kontakt-Formular oder E-Mail |

| 2. Technical Alignment | Share required specs (purity, particle size, quantity, etc.) |

| 3. Sample Request | Request samples for lab testing and application validation |

| 4. Quotation | Receive a formal quotation including Incoterms, lead time, and payment terms |

| 5. Purchase Order | Issue PO and confirm logistics preferences (EXW, FOB, CIF) |

| 6. Production & QA | Batch production begins with full quality assurance checks |

| 7. Shipping & Documentation | Receive COA, SDS, and shipping documents with your order |

9.2 Payment & Delivery Options

- Accepted Payment Methods: T/T, L/C, or secure international wire transfer

- Lead Time: 7–14 days for standard orders; 15–30 days for custom specs

- Shipping: Sea freight, air cargo, or courier depending on volume and urgency

9.3 After-Sales Support

- Technical consultation for integration into your production

- Documentation support for customs and compliance

- Ongoing collaboration for material optimization

Need a custom grade for a new product line? Our R&D team will work with you to develop a solution that meets your exact requirements.

🔗 Ready to get started? Reach out via our Kontakt Seite for a personalized quote.

10. FAQs: Everything You Need to Know About Buying Wholesale Silicon Oxide Powder

Q1. What purity levels are available in your silicon oxide powder?

We offer various grades ranging from 99.5% to 99.999% purity. Our standard offering is 99.9% high-purity grade suitable for most industrial applications.

Q2. Can you provide documentation such as COA and SDS?

Yes. Every batch is shipped with a Certificate of Analysis (COA) and Safety Data Sheet (SDS) to ensure transparency and compliance.

Q3. Do you offer technical assistance with product integration?

Absolutely. Our team can help with application guidance, testing protocols, and compatibility with other PM materials.

Q4. What is the minimum order quantity (MOQ)?

Our standard MOQ is 25kg, but we offer flexibility for R&D or pilot-scale orders. For wholesale buyers, we recommend 500kg+ for optimal pricing.

Q5. How do you ensure consistency in particle size and purity?

We utilize advanced atomization technologies and quality assurance protocols, including laser diffraction particle size analysis and ICP-MS purity testing.

Q6. Can I request a custom particle size distribution?

Yes. We offer particle size customization based on your processing method — whether it’s for sintering, injection molding, or coating.

Q7. Do you ship internationally?

Yes. We have clients across North America, Europe, Southeast Asia, and the Middle East. We can handle all necessary export documentation and logistics.

Q8. What industries do you typically serve?

We serve electronics, ceramics, coatings, additive manufacturing, metallurgy, and more. Our clients range from Fortune 500 OEMs to regional distributors.

Q9. Is silicon oxide powder available as part of composite blends?

Yes. We can supply it as part of composite or pre-mixed powders with copper, nickel, or iron base materials for specific PM or AM applications.

Q10. Where can I learn more about your full product line?

🔗 Besuchen Sie unsere PM-Pulver Seite to explore all available powder metallurgy products.

By choosing Shanghai Truer Technology as your silicon oxide powder supplier, you’re partnering with one of China’s most trusted names in powder metallurgy innovation. Our commitment to quality, customization, and technical support ensures your business stays ahead in a competitive market.

Ready to start your next procurement project?

📩 Contact us now for samples, a quote, or a technical discussion.