1. Introduction: The Role of M2 Powder in Modern Manufacturing

M2 powder, derived from high-speed steel (HSS), is a critical material for industries requiring wear resistance, toughness, and high red hardness. As industries continue to shift toward precision, additive manufacturing (AM), and powder metallurgy (PM), M2 powder has emerged as a key input for manufacturers of cutting tools, dies, and advanced components.

For B2B stakeholders, especially in the sectors of tool manufacturing, automotive, aerospace, and industrial machinery, sourcing high-quality M2 powder in bulk can mean the difference between average performance and industry-leading output.

Why M2 Powder Matters for Wholesale Buyers

- Hohe Abriebfestigkeit: Ideal for cutting and drilling applications.

- Thermische Stabilität: Maintains hardness at elevated temperatures.

- Versatile Process Compatibility: Usable in PM, 3D-Druck, and metal injection molding.

- High Demand in B2B Supply Chains: Key component in tooling and die-making industries.

| Spezifikation | Wert |

|---|---|

| Material Composition | Fe, Mo, W, Cr, V, C |

| Härte (HRC) | 62–65 |

| Typische Anwendungen | Cutting tools, drills, punches, dies |

| Herstellungsmethoden | Atomization (gas/water), reduction |

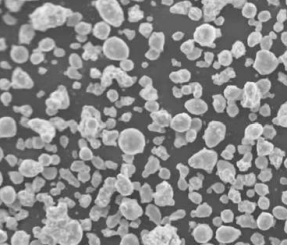

| Particle Size Options | 15–45μm, 45–105μm |

🔗 Erfahren Sie mehr über powder metallurgy solutions at Truer

2. Industrial Applications of M2 Powder

For industrial buyers, the value of M2 powder lies in its wide applicability across sectors that rely on high-speed tooling and components exposed to extreme conditions. Below are key industries that rely heavily on M2 powder:

A. Cutting Tool Manufacturing

M2 powder is a base material for producing:

- End mills

- Taps and dies

- Reamers

- Broaches

- Bohrer

These components require hardness and wear resistance — M2 powder delivers both.

B. Aerospace and Defense

High-performance parts like turbine blades and structural inserts benefit from the heat resistance and durability of M2 powder.

C. Additive Manufacturing (AM)

M2 powder is increasingly used in 3D printing and Direct Metal Laser Sintering (DMLS), offering:

- Flexibilität bei der Gestaltung

- Reduced waste

- Custom part geometries

D. Automotive Industry

M2 powder is used in:

- Valve seats

- Transmission tools

- Gear cutting

| Industrie | M2 Powder Application | Vorteile |

|---|---|---|

| Werkzeugbau | Drills, dies, cutters | High durability |

| Luft- und Raumfahrt | Custom parts via AM | Hitzebeständigkeit |

| Automobilindustrie | High-load components | Verschleißfestigkeit |

| Medizinische | Chirurgische Instrumente | Precision & strength |

3. Key Properties and Metallurgy of M2 Tool Steel Powder

Understanding the metallurgical properties of M2 powder is essential for B2B buyers evaluating suppliers. M2 is a tungsten-molybdenum high-speed steel known for its exceptional hardness and resistance to thermal degradation.

Chemical Composition of M2 Powder (%)

| Element | Content Range |

|---|---|

| Kohlenstoff (C) | 0.80–0.90 |

| Tungsten (W) | 5.50–6.75 |

| Molybdän (Mo) | 4.50–5.50 |

| Chrom (Cr) | 3.75–4.50 |

| Vanadium (V) | 1.75–2.20 |

| Eisen (Fe) | Waage |

Key Metallurgical Characteristics

- Red Hardness: Retains hardness up to 600°C.

- Verschleißfestigkeit: High due to carbide-forming elements.

- Zähigkeit: Better fracture resistance compared to other HSS grades.

- Grindability: Improved in powder form for finishing operations.

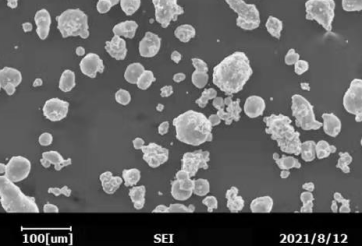

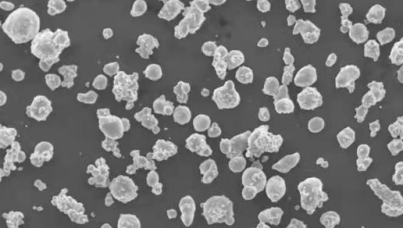

Types of Atomization Processes

| Prozess | Beschreibung | Vorteile |

|---|---|---|

| Gaszerstäubung | Inert gas used to break molten steel into powder | Spherical particles, high purity |

| Wasserzerstäubung | High-pressure water used | Cost-effective, irregular particles |

| Kombinierte Zerstäubung | Mix of water and gas methods | Balance of quality and cost |

At Shanghai Truer Technologie, M2 powder is produced via gas and hybrid atomization to meet stringent B2B manufacturing standards.

4. Global Market Trends for M2 Powder in B2B Trade

The global demand for M2 high-speed steel powder is steadily growing, driven by advancements in precision engineering, tool manufacturing, and additive manufacturing. For B2B buyers, understanding these trends is essential for strategic sourcing and long-term planning.

A. Market Drivers

- Rise in Additive Manufacturing (AM): Industries such as aerospace and medical are adopting AM, increasing the need for high-performance powders like M2.

- Growth of Automotive and Tooling Sectors: Expanding vehicle production and the increasing demand for automated machining tools are boosting M2 powder consumption.

- Shift from Conventional to Powder Metallurgy: PM and 3D printing reduce material waste and improve design flexibility, leading to more M2 powder usage.

B. Key Regions for Supply and Demand

| Region | Trend | Wichtigste Einsicht |

|---|---|---|

| Nord-Amerika | High adoption of AM | Strong demand from aerospace & defense |

| Europa | Sustainability-focused | PM adoption for green manufacturing |

| Asien-Pazifik | Low-cost manufacturing hub | China leads in M2 powder production |

| Naher Osten | Emerging market | Infrastructure growth driving tooling needs |

C. Evolving Buyer Needs

- Personalisierung: Buyers want tailored particle sizes and purity levels.

- Rückverfolgbarkeit: Certifications and quality control documents are non-negotiable.

- Stabilität der Lieferkette: Buyers prefer suppliers with in-house production capabilities to avoid delays.

📌 Explore our full PM powder offerings tailored for global distributors and manufacturers.

5. How to Choose Reliable M2 Powder Suppliers

When sourcing M2 powder in bulk, choosing a reliable supplier can directly affect production quality and lead times. Here are key decision-making criteria for wholesale buyers and industrial procurement teams.

A. Quality Standards and Certifications

Look for suppliers compliant with:

- ISO 9001: Quality Management Systems

- ISO 14001: Environmental Management

- Material certifications (e.g., ASTM, DIN standards)

B. Produktionskapazitäten

Evaluate the supplier’s:

- Atomization methods (gas, water, hybrid)

- In-house testing (particle size analysis, chemical composition)

- Chargenkonsistenz und Wiederholbarkeit

C. Supply Chain and Logistics

- Globale Versandmöglichkeiten

- Inventory availability and lead time

- Custom packaging for bulk orders

D. Technical Support

- Pre-sales consultation

- Post-sales application support

- Entwicklung kundenspezifischer Legierungen

| Kriterien | Warum es wichtig ist | What to Ask |

|---|---|---|

| Zertifizierungen | Ensure quality and traceability | Do you provide mill test reports (MTR)? |

| Produktionsverfahren | Affects particle shape and purity | What atomization method is used? |

| MOQ & Vorlaufzeit | Influences procurement planning | What’s your minimum order quantity? |

| Personalisierung | Enables application-specific use | Can you tailor particle size or blend? |

6. Top M2 Powder Manufacturers and Distributors Worldwide

Several global players dominate the M2 powder market, each offering varying degrees of product customization, pricing, and logistics support. Below is a comparison of leading suppliers for B2B buyers.

A. Top Global Suppliers

| Unternehmen | Region | Zentrale Stärken |

|---|---|---|

| Hoganas AB | Schweden | Large product portfolio, global reach |

| Tischlertechnik | USA | High-performance alloys, aerospace focus |

| Sandvik AB | Schweden | Advanced metallurgy, AM solutions |

| Shanghai Truer Technologie | China | Competitive pricing, wide PM portfolio |

| Daido-Stahl | Japan | Precision tooling, consistent quality |

B. What Sets Shanghai Truer Apart

Shanghai Truer Technology Co., Ltd, established in 2009, expanded into additive manufacturing in 2019 and has since become a trusted supplier of high-quality M2 and other PM powders for industrial applications. Here’s what makes them a top choice:

- Diverse PM Product Line: Offers PM M2 powder along with PM bronze, PM steel, PM stainless steel, and more.

- Advanced Atomization Capabilities: Gas, water, and hybrid atomization.

- Customized Solutions: Particle size and formulation tailored to customer needs.

- In-House Technical Expertise: Decades of experience in metallurgy and powder formulation.

- Cost-Effective for International Buyers: Competitive pricing without compromising on quality.

🧭 Learn more about Shanghai Truer Technology’s history and capabilities

7. Why Buyers Are Switching to Chinese M2 Powder Suppliers

In the past decade, more global distributors and industrial buyers have turned to Chinese suppliers for high-performance metal powders. Here’s why M2 powder from China, especially from companies like Shanghai Truer, is becoming the preferred choice.

A. Cost-Performance Advantage

- Niedrigere Produktionskosten

- Strong R&D ecosystem

- High-volume capacity for bulk orders

B. Quality Matching Global Standards

- Many Chinese suppliers now meet or exceed ASTM and ISO standards.

- Continuous investment in high-end atomization and testing equipment.

C. Shorter Lead Times and Flexible MOQs

- Fast turnaround for custom orders

- Scalable from prototype batches to full-volume production

D. Government Support and Export Infrastructure

- Favorable policies for metallurgy and AM industries

- Established logistics chains for easier global exports

Case Study: Shanghai Truer’s Global B2B Reach

A European cutting tool manufacturer recently switched to Shanghai Truer for its M2 powder supply and reported:

- 18% cost savings

- 25% improvement in delivery speed

- Equivalent or better hardness and wear resistance compared to previous supplier

8. How to Order Wholesale M2 Powder from Shanghai Truer

For B2B buyers, especially procurement managers, distributors, and OEMs, streamlining the ordering process is essential to avoid delays and ensure quality consistency. Shanghai Truer Technology offers a professional, transparent, and highly customizable wholesale ordering experience for M2 powder and other PM materials.

Schritt-für-Schritt-Bestellprozess

- Erste Anfrage

- Fill out the contact form on the official kontaktseite

- Share your requirements: grade, particle size, quantity, usage scenario

- Technische Konsultation

- Truer’s in-house engineers review your application

- Recommend the best M2 powder type and particle size distribution

- Provide technical data sheets (TDS) and material safety data sheets (MSDS)

- Quotation and Pricing

- FOB/CIF/DDP terms available

- Bulk pricing tiers and MOQ flexibility

- Custom packaging and labeling options for OEM buyers

- Probenprüfung (optional)

- Sample M2 powder can be shipped for lab analysis or prototype testing

- Reports on morphology, composition, and flowability available

- Production and Delivery

- Lead time: 7–15 working days depending on volume

- Shipping via air (DHL/FedEx) or sea freight with full export documentation

- Real-time tracking and logistics support

MOQ and Packaging Options

| Art der Bestellung | MOQ | Verpackung |

|---|---|---|

| Sample | 1–5 kg | Vacuum-sealed aluminum foil bags |

| Pilot Batch | 25–100 kg | Sealed PE bags in steel drums |

| Full Production | 500+ kg | Custom drums or ISO-certified containers |

Zahlungsbedingungen

- TT, LC, PayPal (for small orders)

- Net 30/60 terms for long-term B2B clients

- Multicurrency invoicing: USD, EUR, RMB

Support Services for Distributors

- White-label packaging available

- Technical brochures and marketing materials

- After-sales support for application troubleshooting

📦 Start sourcing your M2 powder today via Shanghai Truer's Kontaktseite

9. FAQs: Buying and Using M2 Powder in Bulk

Here are answers to common questions asked by industrial buyers, distributors, and procurement professionals when sourcing M2 powder from international suppliers.

Q1: What is the standard grade of M2 HSS powder available?

A: Truer supplies M2 powder that complies with international standards such as ASTM A600, DIN 1.3343, and JIS SKH9. Custom chemical compositions are also available upon request.

Q2: What particle size ranges are available?

A: Standard mesh sizes include:

- 15–45μm for AM and MIM

- 45–105μm for hot isostatic pressing (HIP) and PM parts

- Custom sieving available for precision requirements

Q3: What atomization methods are used?

A: Shanghai Truer uses:

- Gaszerstäubung for spherical, high-purity particles

- Wasserzerstäubung for cost-effective production

- Hybrid atomization for balanced performance and price

Q4: Can I order mixed PM powders for different tooling applications?

A: Yes. Truer offers a complete range of PM materials including:

- PM bronze, brass, nickel silver

- PM stainless steel and pre-alloyed steels

- Special additives like graphite, lubricants, and cutting agents

📌 Browse the full PM Pulverkatalog hier

Q5: Is technical support available for new applications?

A: Absolutely. Truer’s Powder Metallurgy Additives Division offers:

- On-site and virtual consultation

- Kundenspezifische Pulverentwicklung

- Application testing and optimization

Final Thoughts: Partnering with Truer for M2 Powder Supply

If your business depends on high-performance tooling materials, selecting the right M2 powder supplier is critical. Shanghai Truer Technology Co., Ltd stands out in the global market with:

- Over a decade of PM experience and deep industry knowledge

- Full-spectrum powder solutions including M2, stainless steel, and specialty blends

- Customized offerings tailored to your production methods and end-use applications

With a proven track record, global logistics support, and competitive pricing, Truer is the ideal partner for B2B buyers looking to scale their operations without compromising on quality.

🔗 Learn more about the company and its powder metallurgy vision by visiting the Über uns Seite