1. Introduction: The Rise of Nickel Coated Aluminum Powder in Manufacturing

Nickel coated aluminum powder is an engineered metal powder product combining the lightweight characteristics of aluminum with the corrosion resistance and electrical conductivity of nickel. This hybrid material is increasingly becoming essential in powder metallurgy, additive manufacturing (3D-Druck), conductive composites, and electromagnetic interference (EMI) shielding applications.

In B2B sectors, especially in automotive, aerospace, electronics, and defense industries, demand for nickel coated aluminum powder is rising due to its high strength-to-weight ratio, electrical performance, and oxidation resistance.

Why B2B Buyers Care:

- ✅ Improved conductivity for EMI shielding materials

- ✅ Lightweight core ideal for aerospace and EV applications

- ✅ Enhanced corrosion resistance in harsh industrial environments

- ✅ Excellent compatibility with powder metallurgy (PM) and additive manufacturing processes

2. Industrial Applications of Nickel Coated Aluminum Powder

Nickel coated aluminum powders are used across various industrial domains that demand lightweight, conductive, and corrosion-resistant materials. Below is a breakdown of key application sectors and the specific benefits the powder offers.

| Industrie Sektor | Anmeldung | Benefits of Ni-Coated Al Powder |

|---|---|---|

| Electronics & Semiconductors | EMI shielding, conductive adhesives | High conductivity, oxidation stability |

| Automotive & EV | Leichte Strukturkomponenten | Corrosion resistance, weight reduction |

| Luft- und Raumfahrt | Fuel system components, shielding | High temp resistance, low density |

| Powder Metallurgy & Sintering | Additive in PM parts | Improved strength and wear resistance |

| 3D Printing (Additive Manufacturing) | Functional prototypes, metal parts | Uniform coating, sintering compatibility |

| Defense & Military | Radar-absorbing materials, armor | Electromagnetic absorption, durability |

Emerging Use Cases:

- Conductive inks and coatings

- Thermische Grenzflächenmaterialien

- Hybrid composites for wearable electronics

For advanced manufacturing buyers, particularly OEMs and tier-1 suppliers, sourcing high-quality nickel coated aluminum powder can significantly impact product performance and production cost-efficiency.

3. Key Properties and Technical Advantages

Nickel coated aluminum powder is designed to offer the best of both worlds — the lightness of aluminum and the functional advantages of nickel.

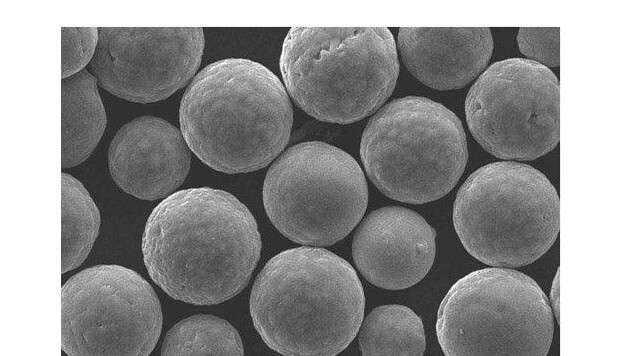

Physikalische & Chemische Eigenschaften

| Eigentum | Wertebereich |

|---|---|

| Partikelgrößenverteilung | 10–50 microns |

| Nickel Coating Thickness | 1–5 microns |

| Scheinbare Dichte | ~1.2–1.8 g/cm³ |

| Elektrische Leitfähigkeit | High (dependent on coating) |

| Korrosionsbeständigkeit | Excellent (due to Ni shell) |

| Oxidationsbeständigkeit | High (especially in humid conditions) |

| Wärmeleitfähigkeit | Mäßig bis hoch |

Vorteile für B2B-Einkäufer:

- Enhanced Sintering Behavior: Compatible with PM and AM processes

- Customizable Coating: Tailored Ni% for application-specific conductivity

- Stable Storage: Coating prevents rapid oxidation of aluminum core

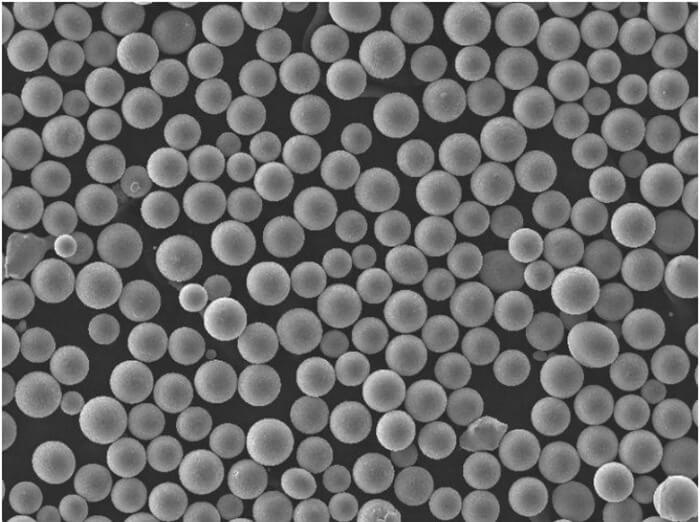

- Uniform Morphology: Spherical particles ensure consistent flowability

Integration with PM & AM Processes

Nickel coated aluminum powder is particularly suited for:

- Laser Powder Bed Fusion (LPBF)

- Binder Jetting and Sintering

- Cold Spray Processes

- Press and Sinter PM

Shanghai Truer Technology Co, Ltd. bietet high-performance PM powders including nickel coated aluminum options tailored for additive manufacturing and advanced PM parts production. Their integration of powder production and equipment ensures consistency and traceability across batches, which is crucial for B2B supply chains.

4. Market Trends and Growth Potential in B2B Sectors

The global demand for nickel coated aluminum powder is accelerating, driven by its applications in next-generation electronics, electric vehicles, and aerospace components. According to industry reports, the global market for metal-coated powders is expected to grow at a CAGR of over 6% through 2030, with Asia-Pacific leading the expansion.

Wichtige Markttreiber:

- 📈 Rise of Electric Vehicles: Lightweight conductive materials are needed for battery enclosures, shielding, and thermal management.

- 🛰️ Aerospace Innovations: Increasing adoption of additive manufacturing for lightweight parts boosts demand.

- 🧲 EMI Shielding Boom: 5G, IoT, and smart electronics require EMI-resistant materials.

- 🏭 Powder Metallurgy Growth: PM parts are used more widely in automotive, tools, and appliances.

- 🌍 Schwerpunkt Nachhaltigkeit: Nickel-coated aluminum’s recyclability and low weight reduce carbon footprint.

B2B Buyer Growth Segments:

| Segment | Opportunity for Distributors & OEMs |

|---|---|

| EV Component Manufacturing | High-volume, consistent powder quality |

| Aerospace Tier-1 Suppliers | Reliability, traceability, lightweight strength |

| Electronics OEMs | Conductive composites, inks, coatings |

| 3D Printing Service Bureaus | High-flowability powders for AM |

| Tooling Industry | Enhanced wear resistance and machinability |

B2B buyers increasingly prefer suppliers who can offer not just powders, but technical support, customization, and integrated solutions.

5. Choosing the Right Nickel Coated Aluminum Powder Supplier

Selecting a reliable supplier is crucial for maintaining product performance, safety, and cost-efficiency. Here are the key factors B2B buyers must evaluate when sourcing nickel coated aluminum powder:

✅ Checkliste zur Lieferantenbewertung:

| Kriterien | Why It Matters in B2B Procurement |

|---|---|

| Konsistenz des Pulvers | Ensures repeatability in AM/PM processes |

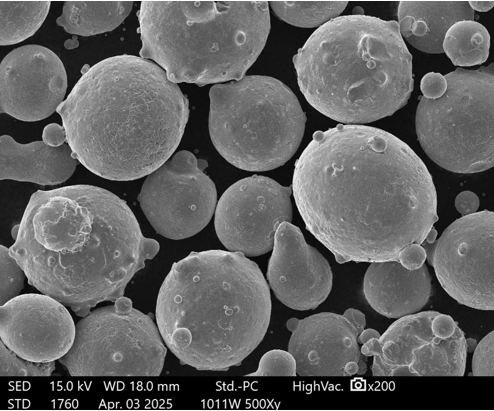

| Gleichmäßigkeit der Beschichtung | Impacts electrical/thermal performance |

| Anpassungsmöglichkeiten | Tailored properties for specific industries |

| Production Method Transparency | Water/gas atomized vs. electroless coating |

| Technische Unterstützung | Helps in process integration and troubleshooting |

| Zuverlässigkeit der Lieferkette | On-time delivery, especially for OEMs and factories |

| International Certifications | ISO, RoHS, REACH compliance for global trade |

Tip: Always request a technical data sheet (TDS) and recent batch sample before placing a large bulk order.

6. Top Global and Chinese Suppliers for Nickel Coated Aluminum Powder

The market is currently served by a mix of global giants and specialized Chinese manufacturers that offer cost-effective, high-quality alternatives. Below is a list of notable suppliers:

| Name des Lieferanten | Land | Zentrale Stärken |

|---|---|---|

| Hoganas AB | Schweden | Broad PM powder portfolio, global reach |

| Sandvik (now Alleima) | Schweden | Advanced metal powders for AM |

| Tekna (Arcam/GE Additive) | Kanada | Plasma atomized powders, high purity |

| Shanghai Truer Technology Co. Ltd. | China | Integrated powder production & AM solutions |

| CNPC-Pulver | China | Large-scale metal powder production |

| Changsha Huateng Metal Co., Ltd | China | Coated and uncoated aluminum powders |

Why More Buyers Are Turning to Chinese Suppliers:

- 🌏 Competitive pricing for bulk orders

- 🧪 Advanced lab and testing capabilities

- 📦 Scalable production for large B2B orders

- 🛠️ Customization based on particle size, coating thickness, and alloy content

- 🚚 Shorter lead times for APAC and EMEA markets

Many suppliers, including Shanghai Truer Technologie, combine powder production with additive manufacturing support equipment, offering an end-to-end solution for OEMs and industrial buyers.

7. Why More Buyers Are Sourcing from Chinese Manufacturers

China has emerged as a global leader in powder metallurgy and additive manufacturing material supply, especially for niche and advanced metal powders like nickel coated aluminum. Here’s why more B2B buyers are shifting their sourcing strategies:

Competitive Advantages of Chinese Suppliers:

- 🏭 Vertikale Integration: From raw material processing to finished powders and equipment

- ⚙️ Custom Engineering: Tailored powder morphology, PSD, and coating thickness

- 💲 Kosteneffizienz: Lower labor and energy costs result in competitive pricing

- 📈 Skalierbarkeit: High-volume manufacturing meets OEM-scale demand

- 🔬 R&D Investment: Ongoing innovation in powder surfaces, atomization techniques, and additive compatibility

Shanghai Truer Technology: A Case Study in Excellence

Established in 2009, Shanghai Truer Technology Co. Ltd. began its additive manufacturing division in 2019. The company is now recognized as one of the most professional powder metallurgy additive suppliers in China. They offer:

- ✅ Nickel coated aluminum powder with uniform, controllable coating

- ✅ PM bronze, PM steel, PM copper, and hybrid alloy powders

- ✅ Advanced lubricants and cutting agents for PM applications

- ✅ Full-chain additive solutions: powder + equipment + process consulting

By sourcing from Truer, B2B buyers benefit from technical support, reliable deliveries, and access to a wide range of PM-grade materials.

8. How to Order Wholesale Nickel Coated Aluminum Powder from China

For B2B buyers, especially OEMs, distributors, and e-commerce sellers, ordering nickel coated aluminum powder in bulk requires a systematic approach to ensure quality, regulatory compliance, and on-time delivery.

Shanghai Truer Technology Co., Ltd simplifies this process with a customer-centric, full-service model tailored to global buyers.

Schritt-für-Schritt-Bestellverfahren mit Truer

| Schritt | Beschreibung | Key Considerations |

|---|---|---|

| 1️⃣ Inquiry | Contact sales via Truer's Kontaktseite | Include specs, volume, timeline |

| 2️⃣ Technical Consultation | Discuss powder grade, coating % and PSD (particle size distribution) | Custom formulation available |

| 3️⃣ Sample Request (Optional) | Request 100g–1kg batch for initial testing | TDS and SDS provided |

| 4️⃣ Quotation & Contract | Receive formal quote (EXW/FOB/CIF/DDP) | MOQ, lead time, payment terms |

| 5️⃣ Production & Quality Check | Powder produced, tested, and certified | ISO, SGS, RoHS, REACH documentation |

| 6️⃣ Shipping & Delivery | Air or sea freight arranged based on urgency | Tracked logistics, customs support |

| 7️⃣ After-Sales Support | Technical advice on powder use and storage | Reordering and scaling support |

Customization Options Available

- 📏 Particle size: 10–50μm or tailored ranges

- 🧲 Nickel coating thickness: 1–5 microns

- 🔄 Morphology: Spherical or irregular

- 🧪 Additives: Optional alloying or sintering aids

Shanghai Truer also offers OEM packaging and labeling for distributors and e-commerce sellers. Their manufacturing and export expertise makes them a reliable partner for long-term collaboration.

9. FAQs: Buying Nickel Coated Aluminum Powder in Bulk

Below are some of the most frequently asked questions from B2B buyers when sourcing nickel coated aluminum powder:

Q1: What’s the difference between electroless and electrolytic nickel coating?

- Electroless nickel plating creates a uniform coating without using electricity, ideal for ensuring even thickness across irregular particles.

- Electrolytic plating may result in uneven surfaces and is less preferred for powder metallurgy applications.

Shanghai Truer uses advanced electroless coating methods to ensure high uniformity and repeatability.

Q2: Can I order small quantities (less than 100kg) for prototyping?

Yes. Truer accepts pilot orders for R&D and prototyping. Minimum order quantities (MOQ) can be as low as 10kg for specialized projects.

Q3: Is the powder safe to handle and ship internationally?

Yes. Nickel coated aluminum powder is shipped with full documentation including:

- Sicherheitsdatenblatt (SDS)

- Technical Data Sheet (TDS)

- Material Certificate

- Compliance with RoHS, REACH, and ISO standards

Q4: How should the powder be stored?

- Store in sealed, moisture-proof containers

- Avoid exposure to high humidity and open air

- Recommended storage temperature: 15–25°C

Q5: What makes Truer different from other Chinese suppliers?

- In-house powder manufacturing and quality control

- Integrated solutions: powders, lubricants, and PM additives

- Rapid prototyping and custom formulations

- Responsive customer service in English and Chinese

- Trusted by global OEMs and distributors in over 30 countries

Final Thoughts: A Strategic Choice for Forward-Thinking Buyers

Nickel coated aluminum powder is no longer a niche material — it’s a vital component in modern manufacturing where weight, conductivity, and corrosion resistance matter.

For OEMs, industrial buyers, and distributors looking to:

- Improve product performance

- Reduce production costs

- Gain access to custom formulations

- Ensure reliable supply chain support

…Shanghai Truer Technology Co., Ltd is a proven B2B partner that delivers both material consistency and technical excellence.

✅ With over a decade of powder metallurgy experience

✅ A robust product portfolio that includes PM bronze, PM steel, and nickel alloy powders

✅ And full in-house capabilities from R&D to export logistics

Truer is not just a supplier — it’s your strategic partner in high-performance metal powders.

🟢 Ready to get started? Contact us here to request a quote or sample today.