1. What is GRCop-42 Powder and Why It Matters in Industry

GRCop-42 is a high-performance copper-based alloy powder developed for extreme environments, particularly in aerospace and advanced thermal applications. Comprising 90% copper, 6% chromium, and 4% niobium, GRCop-42 exhibits exceptional thermal conductivity, oxidation resistance, and mechanical strength at elevated temperatures.

B2B Relevance

- Wholesale demand: Increasing in aerospace and defense sectors.

- Industrial use: Ideal for additive manufacturing, thermal management systems, and rocket engine components.

- Distributors and OEMs: Seek this powder for its excellent balance of conductivity and strength.

Chemische Zusammensetzung

| Element | Zusammensetzung (%) |

|---|---|

| Cu | ~90.0 |

| Cr | ~6.0 |

| Nb | ~4.0 |

Industry-Specific Benefits

- High thermal conductivity for heat exchangers

- Stable mechanical properties at >700°C

- Excellent resistance to creep and oxidation

GRCop-42 is especially important in the emerging field of additive manufacturing (AM), where powder quality and performance directly impact part durability and reliability.

2. Applications of GRCop-42 Powder in Aerospace and Beyond

GRCop-42 is engineered specifically for high-heat, high-stress environments. It is extensively used in aerospace propulsion systems, but its utility spans several other industries as well.

Luft- und Raumfahrtanwendungen

- Rocket engine liners: Withstands extreme thermal cycles

- Combustion chambers: High oxidation resistance

- Nozzles and injectors: Maintains mechanical strength at high pressures

Andere industrielle Anwendungen

- Wärmemanagement-Systeme: Excellent for heat sinks and radiators

- 3D printing of copper-based parts: Ideal for laser powder bed fusion (LPBF)

- Elektronik: Used in high-frequency and high-heat environments

Additive Fertigung (AM)

GRCop-42 is compatible with:

- Laser Powder Bed Fusion (LPBF)

- Elektronenstrahlschmelzen (EBM)

- Gerichtete Energieabscheidung (DED)

| AM Technology | Compatibility Rating |

|---|---|

| LPBF | ★★★★★ |

| EBM | ★★★★☆ |

| DED | ★★★★☆ |

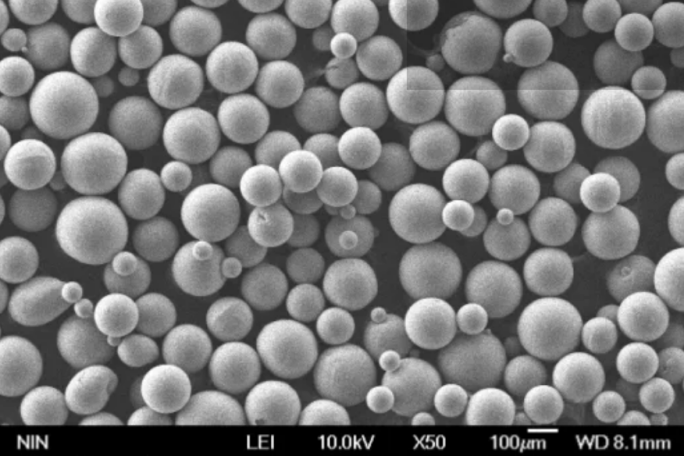

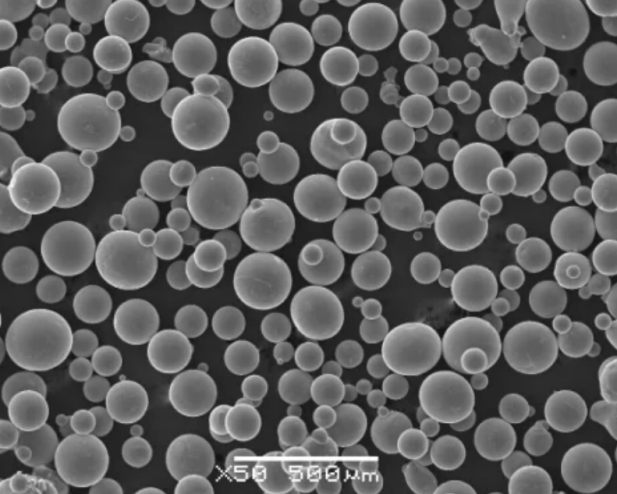

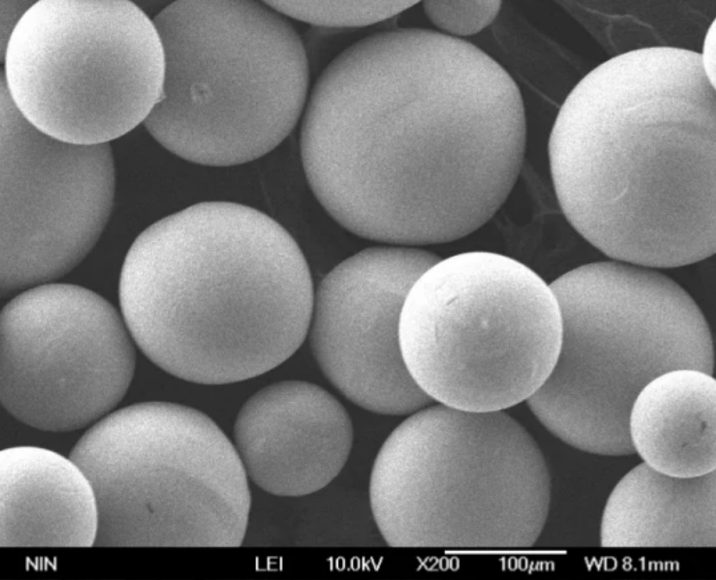

GRCop-42’s flowability, spherical morphology, and consistent particle size make it well-suited for advanced 3D-Druck Anwendungen.

3. Key Properties and Performance Benefits of GRCop-42 Alloy Powder

GRCop-42 is prized for its unique combination of thermal conductivity and mechanical strength at high temperatures. Industrial engineers and procurement managers look for these properties when evaluating powder suppliers for mission-critical parts.

Physikalische und mechanische Eigenschaften

| Eigentum | Wert |

|---|---|

| Dichte | 8,9 g/cm³ |

| Schmelzpunkt | ~1,083°C |

| Wärmeleitfähigkeit | >300 W/m·K |

| Yield Strength (at 500°C) | ~150 MPa |

| Kriechstromfestigkeit | Excellent at 700–800°C |

Eigenschaften des Pulvers

- Partikelgrößenverteilung: Optimized for LPBF

- Morphologie: Sphärisch

- Fließfähigkeit: High, reducing print defects

- Sauerstoffgehalt: Low, ensures high purity

Benefits for OEMs & Distributors

- Improved part reliability for end-users

- Lower lifecycle cost due to durability

- High performance in harsh environments

At Shanghai Truer Technology Co. Ltd., GRCop-42 powder can be custom-produced using advanced gas atomization methods to ensure uniformity and high purity. Truer’s strict quality control protocols make it a trusted partner for aerospace and industrial OEMs globally.

4. Current Market Trends for GRCop-42 Powder in B2B Supply Chains

As aerospace, defense, and advanced manufacturing industries continue to adopt additive manufacturing (AM), the demand for high-performance powders like GRCop-42 is rising rapidly. This trend is shaping the global powder metallurgy landscape and influencing sourcing strategies for OEMs, distributors, and contract manufacturers.

Key B2B Market Indicators

- Aerospace propulsion systems are expected to grow at a CAGR of 6.9% through 2027, driving demand for copper-based heat-resistant materials.

- Additive manufacturing materials market is projected to reach $23.33 billion by 2030, with copper alloys like GRCop-42 seeing significant adoption.

- Global interest in thermal management for EVs and high-performance computing also boosts GRCop-42 usage.

Top Sectors Driving Demand

| Industrie | Anwendungsbereich |

|---|---|

| Luft- und Raumfahrt | Rocket engines, nozzles, combustion chambers |

| Verteidigung | Missile propulsion, high-thermal military systems |

| Elektronik | High-frequency thermal dissipation components |

| Automotive (EV) | Battery cooling systems, electric motor casings |

| Additive Fertigung | High-conductivity 3D printed parts |

Challenges in the Supply Chain

- Limited number of high-purity manufacturers

- Inconsistent powder particle morphology from some sources

- High cost of Western-made GRCop-42 powders

These challenges have led many OEMs and industrial buyers to explore alternative sources in Asia, particularly China, where capabilities in powder atomization and quality assurance have dramatically improved.

5. How to Select a Reliable GRCop-42 Powder Supplier

Choosing the right supplier for GRCop-42 powder is critical, especially for industries requiring consistent performance in extreme environments. OEMs, purchasing managers, and procurement teams must evaluate several criteria when sourcing this high-value material.

Key Selection Criteria

- Qualität und Konsistenz des Pulvers

- Partikelgrößenverteilung (PSD)

- Sphericity and morphology

- Oxygen content and purity

- Produktionskapazitäten

- Gas atomization expertise

- On-site testing and QA labs

- ISO and aerospace certifications

- Anpassungsoptionen

- Tailored PSD for different AM platforms

- Custom packaging for volume orders

- Zuverlässigkeit der Lieferkette

- Lead time and delivery consistency

- Global logistics support

- In-stock availability for large volumes

- Technische Unterstützung

- Application engineering expertise

- Material performance consulting

- Post-sale support and troubleshooting

Checklist for B2B Buyers

| Bewertungsfaktor | Warum es wichtig ist | Truer’s Offering |

|---|---|---|

| Zerstäubungsmethode | Ensures uniform powder morphology | Gas & hybrid |

| Qualitätszertifizierungen | Meets aerospace and AM standards | Verfügbar |

| On-Time Delivery | Reduces production delays | Proven record |

| Technical Consulting | Supports design and application optimization | Ja |

| Custom PSD & Packaging | Tailors powder to your process | Ja |

Shanghai Truer Technology Co., Ltd. fulfills all these criteria, offering premium-grade GRCop-42 powders with customizable specifications and strict quality control.

6. Top GRCop-42 Powder Manufacturers and Distributors Globally

Several companies worldwide produce GRCop-42 powder, but only a few offer the consistency, technical support, and B2B scalability needed for industrial applications.

Leading Global Suppliers

| Name des Unternehmens | Region | Stärken |

|---|---|---|

| Shanghai Truer Technologie | China | Custom PSD, high purity, advanced atomization |

| Praxair Oberflächentechnologien | USA | Aerospace-qualified powders, high cost |

| Tekna Fortgeschrittene Materialien | Kanada | Plasma atomized powders, limited volume production |

| Oerlikon Metco | Switzerland | Broad AM powder portfolio, limited GRCop-42 availability |

| AMETEK Specialty Metals | USA | Extensive copper alloy inventory |

Why Truer is Becoming a Preferred Choice

- Cost-effective sourcing without compromising quality

- Scalable production for bulk orders

- Flexible customization for different AM processes

- Fast-growing reputation among international B2B buyers

Truer’s growing presence in the global powder metallurgy market is supported by its extensive investment in R&D and its commitment to quality, making it a viable alternative to traditional Western suppliers.

Interested in sourcing GRCop-42 from a trusted Asian provider? Visit our homepage to explore our full product range and technical capabilities.

7. Why More Buyers are Turning to Chinese GRCop-42 Powder Sources

In the last five years, global B2B buyers—especially in aerospace, defense, and additive manufacturing—have increasingly sourced GRCop-42 powders from Chinese manufacturers. Several factors contribute to this shift, including cost competitiveness, improved powder quality, and scalable production capabilities.

Hauptgründe für die Verschiebung

- Konkurrenzfähige Preisgestaltung

- Western suppliers often price GRCop-42 at a premium due to brand reputation and certification overhead.

- Chinese manufacturers offer comparable quality at significantly lower costs, especially for bulk orders.

- High-Quality Atomization Technology

- The latest gas and hybrid atomization methods ensure tight particle size distribution and high powder sphericity.

- Kürzere Vorlaufzeiten

- Improved logistics networks and domestic capacity help reduce delivery timelines.

- Flexible Customization

- Tailoring PSD and packaging to specific AM technologies (LPBF, DED, etc.) is easier with Chinese suppliers who have agile production lines.

- Government and Industry Support

- China has heavily invested in additive manufacturing and powder metallurgy as part of its “Made in China 2025” initiative, promoting innovation and quality standards.

Comparison Table: Western vs. Chinese GRCop-42 Suppliers

| Kriterien | Westliche Zulieferer | Chinesische Anbieter (z. B. Truer) |

|---|---|---|

| Preis pro kg (lose) | $900–$1,200 | $600–$800 |

| Custom PSD available | Begrenzt | Ja |

| Lead time (bulk orders) | 4-6 Wochen | 2-3 Wochen |

| Technische Unterstützung | Verfügbar | Verfügbar |

| Additive manufacturing use | Ja | Ja |

| Minimum order quantity | Oft hoch | Flexibel |

Chinese suppliers like Shanghai Truer Technology Co. Ltd. have proven that they can meet or exceed global standards with their advanced powder metallurgy solutions, making them an increasingly preferred option for global buyers.

8. Why Choose Shanghai Truer Technology as Your Powder Supplier

Shanghai Truer Technology Co., Ltd, established in 2009, has become one of China’s most trusted names in additive manufacturing and powder metallurgy. Since launching its 3D printing powder business in 2019, Truer has developed a strong reputation for producing high-performance powders—including GRCop-42—for industrial applications.

Was zeichnet Truer aus?

- ✅ Integrated R&D and Manufacturing

Full control over powder production from atomization to final QA. - ✅ Advanced Atomization Equipment

Gas, water, and hybrid atomization techniques tailored to material demands. - ✅ Strict Quality Control

Every batch of GRCop-42 undergoes comprehensive testing for purity, PSD, and flowability. - ✅ Custom Powder Solutions

Truer tailors powder characteristics to your AM platform (LPBF, DED, EBM). - ✅ Global B2B Support

With extensive export experience, Truer supports distributors, OEMs, and contract manufacturers worldwide.

GRCop-42 Powder Overview from Truer

| Attribut | Spezifikation |

|---|---|

| Partikelgrößenbereich | 15–53 μm (customizable) |

| Morphologie | Sphärisch |

| Produktionsverfahren | Gas atomization (hybrid available) |

| Reinheit | ≥ 99.9% |

| Sauerstoffgehalt | ≤ 0.05% |

| Verpackungs-Optionen | 5kg, 10kg, 25kg, vacuum-sealed |

| Zertifizierungen | ISO 9001, RoHS, Reach-compliant |

Industries Served

- Luft- und Raumfahrt & Verteidigung

- Automotive (EV thermal systems)

- Electronics and 5G infrastructure

- Industrial additive manufacturing

To explore Truer’s full product line including copper-based PM powders, visit the PM-Pulver Produktseite.

9. FAQs: Common Questions About Buying GRCop-42 Powder in Bulk

Q1: Can GRCop-42 powder be used in all 3D printing technologies?

A: GRCop-42 is ideal for laser powder bed fusion (LPBF) and directed energy deposition (DED). Truer can customize the powder’s PSD and flow characteristics to match your AM process.

Q2: What is the typical lead time for a 25kg order?

A: For in-stock products, Truer can ship within 5–7 business days. Custom orders may require 2–3 weeks.

Q3: How does Truer ensure powder quality?

A: Every batch undergoes strict quality control protocols including:

- Laser diffraction PSD analysis

- SEM morphology inspection

- Oxygen/nitrogen content analysis

- Flowability and tap density testing

Q4: Is there a minimum order quantity?

A: Truer supports flexible MOQs to accommodate both small-scale prototyping and large-scale production.

Q5: How do I get a quote or start an order?

A: You can request a quotation or place an order directly via the Kontakt Seite.

Ready to Source High-Performance GRCop-42 Powder?

Shanghai Truer Technology is your trusted partner for additive manufacturing powders, offering world-class GRCop-42 for aerospace, defense, and industrial use. Learn more about our capabilities and request a customized quote through our company homepage.

Internal Anchor Links Recap:

This concludes the full guide on sourcing and using GRCop-42 powder for B2B applications. Stay ahead of your competition with better materials, reliable sourcing, and a proven supply chain partner—Shanghai Truer Technology.