1. What is Rene Powder and Why It Matters in Industry

Rene powder is a high-performance, nickel-based superalloy powder used primarily in aerospace, energy, and high-temperature industrial applications. Known for its exceptional strength, creep resistance, and oxidation resistance at elevated temperatures, Rene powder is critical for manufacturing components that operate in extreme environments, such as turbine blades, combustion chambers, and aerospace engine components.

Key Properties of Rene Powder:

| Eigentum | Beschreibung |

|---|---|

| Zusammensetzung | Primarily nickel-based with additions of cobalt, chromium, tungsten, molybdenum, aluminum, and titanium |

| Schmelzpunkt | 1300–1400°C |

| Stärke | High tensile and yield strength at elevated temperatures |

| Resistance | Exceptional resistance to oxidation, corrosion, and thermal fatigue |

| Form | Available as atomized spherical powder for additive manufacturing and powder metallurgy |

Benefits for Industrial Buyers:

- Enables production of complex, high-temperature-resistant parts.

- Supports lightweighting strategies in aerospace.

- Enhances component lifecycle due to thermal fatigue resistance.

Target Industries Using Rene Powder:

- Aerospace (engine turbines, afterburners)

- Power generation (gas turbines, combustors)

- Automotive (turbochargers in motorsport)

- Defense & military applications

2. Industrial Applications of Rene Superalloy Powders

Rene powders are engineered for applications that demand high strength at elevated temperatures. Their performance capabilities make them indispensable across several industries:

Luft- und Raumfahrtindustrie:

- Turbine blades and vanes

- Afterburner components

- Jet engine disks

- Auspuffanlagen

Power Generation:

- Industrial gas turbines

- Combustor liners

- Transition ducts in turbines

Additive Manufacturing (Metal 3D Printing):

- Offers design freedom for complex geometries.

- Enables rapid prototyping and low-volume production of aerospace parts.

- Enhances material utilization and reduces waste.

Additive Manufacturing Use Case:

| Anmeldung | Nutzen Sie |

|---|---|

| Jet Engine Turbine Blade | High strength at 1100°C, oxidation resistance |

| Combustion Liner | Lightweight design, improved fuel efficiency |

| Turbine Disk | Resistance to creep and fatigue at high RPMs |

Sintering and Hot Isostatic Pressing (HIP):

Rene powder is also suited for powder metallurgy (PM) and HIP applications to create near-net shape or fully dense components with superior mechanical properties.

3. Types of Rene Powders: Rene 41, Rene 65, Rene 80 & More

There are several grades of Rene superalloys, each offering a unique combination of mechanical and thermal properties. Understanding these types is essential for B2B buyers, engineers, and procurement teams.

Common Rene Powder Grades:

| Legierung | Wesentliche Merkmale | Anwendungen |

|---|---|---|

| Rene 41 | Hochtemperaturfestigkeit, Korrosionsbeständigkeit | Turbine components, rocket engines |

| Rene 65 | Excellent creep resistance, weldability | Advanced jet engines |

| Rene 80 | Superior oxidation resistance | Turbine blades, vanes |

| Rene 108 | Higher temperature capacity | Advanced gas turbines |

| Rene N5 | Single crystal alloy; directional solidification | High-efficiency turbines |

Comparison Table:

| Eigentum | Rene 41 | Rene 65 | Rene 80 | Rene N5 |

|---|---|---|---|---|

| Max Temp (°C) | 980 | 1050 | 1100 | 1150 |

| Streckgrenze | Hoch | Sehr hoch | Hoch | Ultra High |

| Schweißeignung | Gut | Ausgezeichnet | Mäßig | Niedrig |

| AM Compatibility | Ausgezeichnet | Ausgezeichnet | Gut | Begrenzt |

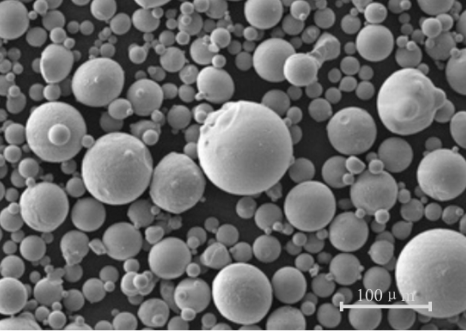

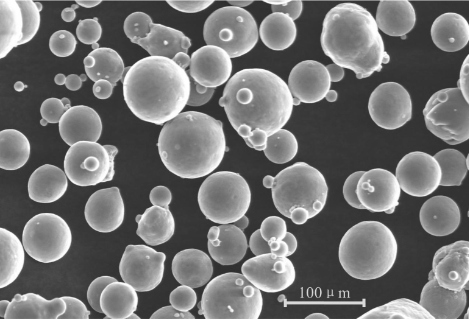

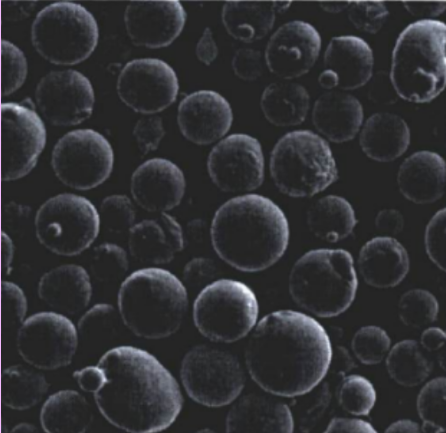

Methoden der Pulverherstellung:

- Gas Atomization (Preferred for AM)

- Plasma-Zerstäubung

- Electrode Induction Melting Gas Atomization (EIGA)

- Vacuum Induction Melting (VIM)

Shanghai Truer Technology offers Rene-based high-performance alloy powders using gas atomization and blended atomization methods, ensuring high purity, spherical morphology, and superior flowability for advanced manufacturing.

To explore other metal powders from Shanghai Truer Technology, visit their PM Powder solutions page.

4. Global Market Trends for Rene Powder in Aerospace & Energy

The demand for Rene powder has grown significantly in recent years, driven by the global expansion of the aerospace and energy industries. As both sectors push the limits of performance and heat tolerance, the need for advanced superalloys like Rene continues to rise.

Wichtige Markttreiber:

- Aerospace Expansion: Global air traffic is expected to grow by 4.3% annually until 2035, increasing demand for high-performance turbine components.

- Energy Sector Modernization: Natural gas turbines and combined-cycle plants require materials that endure extreme heat and stress.

- Additive Manufacturing Growth: Metal 3D-Druck is becoming more mainstream for manufacturing aerospace parts, and Rene powder is one of the preferred materials.

Market Size and Growth:

| Jahr | Global Rene Powder Market (USD) | CAGR |

|---|---|---|

| 2022 | $450 Million | – |

| 2023 | $520 Million | 15.5% |

| 2026 (Projected) | $780 Million | 14–16% |

Geographical Demand:

- Nord-Amerika: Major aerospace OEMs and defense contractors

- Europa: Turbine and aircraft engine manufacturers

- Asien-Pazifik: Rising demand from China and India’s aerospace and energy sectors

Industry Trends:

- Increased use of gas atomized superalloy powders for laser powder bed fusion (LPBF)

- Shift from casting to Additive Fertigung for turbine blade production

- Growing interest in single-crystal Rene alloys for advanced jet engines

5. How to Choose a Reliable Rene Powder Supplier

Choosing the right Rene powder supplier is critical for maintaining quality, performance, and compliance in aerospace and energy applications. Below are the key criteria wholesale buyers and procurement managers should consider.

1. Qualität und Konsistenz des Pulvers

- Sphärische Morphologie for excellent flowability

- Niedriger Sauerstoffgehalt (<0.05%) for high-performance applications

- Atomization method (gas > water for Rene superalloys)

2. Certification and Compliance

- ISO 9001:2015, AS9100 for aerospace quality standards

- Material certifications and traceability

- Compliance with REACH and RoHS

3. Technical Support & R&D Capabilities

- Ability to customize powder size distribution

- Metallurgical support for additive manufacturing

- In-house lab testing: particle size analysis, SEM, XRF

4. Logistics & Supply Chain

- Consistent lead times

- Globale Versandmöglichkeiten

- Inventory management and reorder systems

Checkliste zur Lieferantenbewertung:

| Kriterien | Bedeutung | Anmerkungen |

|---|---|---|

| Reinheit des Pulvers | ★★★★★ | Critical for high-temp parts |

| Fließfähigkeit | ★★★★☆ | Affects AM and PM processes |

| Zertifizierungen | ★★★★★ | Required for aerospace |

| Personalisierung | ★★★★☆ | Needed for specific AM specs |

| Support Services | ★★★★☆ | Helpful for new applications |

| Lieferzeiten | ★★★★☆ | Impacts production cycles |

For a supplier that checks all these boxes, Shanghai Truer Technology stands out as one of the most reliable sources in Asia.

6. Top 5 Rene Powder Suppliers Globally

To help buyers compare and assess options, here are the top global Rene powder manufacturers based on product range, quality, and B2B support.

| Anbieter | Region | Stärken | Produktionsverfahren |

|---|---|---|---|

| ATI-Spezialmaterialien | USA | Wide alloy range, aerospace certified | VIM + Gas Atomization |

| Zimmerer-Zusatzstoff | USA/UK | AM-focused Rene powders | Gaszerstäubung |

| AP&C (GE-Zusatzstoff) | Kanada | High-quality spherical powders | Plasma-Zerstäubung |

| Shanghai Truer Technologie | China | Custom powders, competitive pricing | Gas & Hybrid Atomization |

| Sino-Euro-Materialien | China | Regional supply, low MOQ | Water & Gas Atomization |

Why Shanghai Truer Technology is Competitive:

- Established since 2009, with a dedicated additive manufacturing division since 2019.

- Angebote custom alloy development und tailor-made particle size distributions.

- Provides Rene powder through gas atomization and hybrid methods, ensuring high sphericity und excellent flowability.

- Supplies both standard and niche PM powders for high-performance applications.

You can learn more about Shanghai Truer Technology’s company background and mission here.

7. Why More Buyers Are Turning to Chinese Rene Powder Sources

In recent years, more global buyers—including aerospace OEMs, turbine manufacturers, and AM service providers—have begun sourcing Rene powder from Chinese suppliers. This trend is driven by several competitive advantages.

Key Benefits:

- Kosteneffizienz: Chinese suppliers offer significantly lower prices due to optimized manufacturing and local raw material sourcing.

- Rapid Customization: Faster new alloy development cycles, especially for AM powders.

- Improved Quality Control: Many Chinese firms now operate with ISO 9001 and even AS9100 certifications.

- Kürzere Vorlaufzeiten: Local sourcing for Asia-Pacific buyers and reduced shipping times for global customers.

Case Study: Shanghai Truer Technology

Shanghai Truer has helped numerous international clients replace high-cost OEM powders with equivalent or superior custom Rene powders at a fraction of the cost.

Was Shanghai Truer auszeichnet:

- Multimodal atomization: Offers both gas atomized and hybrid water-gas atomized Rene powders.

- Powder metallurgy expertise: Over a decade of experience in PM and additive powder supply.

- End-to-end solutions: From powder production to additive consulting and application support.

For inquiries or bulk orders, you can contact Shanghai Truer Technology here.

8. How to Order Wholesale Rene Powder from Shanghai Truer

Ordering Rene powder in bulk for aerospace, energy, or additive manufacturing applications requires a supplier who understands both the technical requirements and the logistics of global B2B transactions. Shanghai Truer Technology offers a seamless procurement process tailored to engineering teams, procurement departments, and OEM manufacturers.

Step-by-Step Wholesale Ordering Process:

- Anfrage einreichen

- Besuchen Sie die kontaktseite or email Truer’s sales team.

- Provide the following info:

- Desired Rene alloy grade (e.g., Rene 41, Rene 65)

- Required particle size distribution (e.g., 15–45 μm for LPBF)

- Estimated order volume (kg or tons)

- Intended application (AM, PM, HIP, etc.)

- Erhalten Sie technische Beratung

- Truer’s metallurgical engineers will assess your requirements and propose:

- Pulverspezifikationen

- Atomization method (gas, hybrid, etc.)

- Surface treatment or sieving options

- Truer’s metallurgical engineers will assess your requirements and propose:

- Quotation and Sample Testing

- Competitive pricing based on volume and specifications

- Optional 1–5 kg sample for performance testing

- Place Wholesale Order

- Flexible MOQ for B2B clients

- OEM labeling and packaging options available

- Versand und Lieferung

- Global shipping via air or sea

- Lead time: 7–15 working days depending on volume and customization

Payment & Support Options:

| Merkmal | Beschreibung |

|---|---|

| Zahlungsbedingungen | 30% deposit, 70% before delivery (negotiable for long-term clients) |

| Versand | EXW, FOB, CIF, DDP available |

| Unterstützung | Post-sale technical support, reordering assistance |

Bulk Packaging Options:

| Verpackungsart | Volumen | Material |

|---|---|---|

| Aluminum Foil Bags | 5-10 kg | Vacuum-sealed |

| Stahltrommeln | 25–50 kg | Inert gas backfilled |

| Custom OEM | Up to 200 kg | Palletized drums |

To start the conversation, contact Truer’s sales engineer here.

9. FAQs: Common Questions About Buying Rene Powder

Q1: Which Rene powder grade is best for additive manufacturing?

A: Rene 41 and Rene 65 are commonly used in LPBF and DMLS due to their excellent printability, oxidation resistance, and mechanical performance. Truer can supply both in spherical form, optimized for 3D printing.

Q2: What’s the difference between gas atomized and hybrid atomized powder?

A: Gas atomized powders are highly spherical, flow well, and are ideal for AM. Hybrid atomization (gas + water) offers a balance of cost and performance, suitable for PM and HIP applications. Truer offers both.

Q3: Does Truer offer custom particle size distributions?

A: Yes. Truer can tailor PSDs from 0–150 μm to meet specific needs for binder jetting, LPBF, or MIM. Popular ranges include:

- 15–45 μm for LPBF

- 45–105 μm for EBM

- 0–25 μm for MIM

Q4: Are your Rene powders certified?

A: All powders come with full material certification, including:

- Chemical composition (ICP, XRF)

- Particle size distribution (laser diffraction)

- Morphology (SEM)

- Flowability and apparent density testing

Additionally, Truer is ISO 9001 certified and compliant with international aerospace material standards.

Q5: Can I get a sample for testing?

A: Absolutely. Sample quantities (1–5 kg) are available for evaluation before placing a bulk order. Standard turnaround for samples is 3–5 business days.

Q6: Do you offer other high-temperature or specialty alloys?

A: Yes. In addition to Rene alloys, Truer also supplies:

- PM Inconel 718, 625

- PM Cobalt alloys (e.g., MP35N)

- PM Titanium alloys (e.g., Ti-6Al-4V)

- Stainless steel powders and bronze powders

You can explore the full portfolio on Truer’s produktseite.

🔚 Final Thoughts: Why Truer is the Smart Choice for Rene Powder

Shanghai Truer Technology has become a trusted name in the powder metallurgy and additive manufacturing space thanks to its:

- Strong technical foundation: Over a decade of experience in PM and AM powder development

- Advanced atomization capabilities: Gas, water, and hybrid atomization for tailored performance

- Global B2B focus: Serving aerospace, energy, defense, and advanced manufacturing clients worldwide

- Full-service support: From material selection to logistics and post-sale engineering

Whether you’re an aerospace OEM, a turbine component manufacturer, or an AM service provider, Truer offers a complete solution for Rene powder sourcing. With competitive pricing, reliable quality, and responsive support, they are redefining the value equation in high-performance alloy powder supply.