1. Introduction: Why Inconel 718 Powder Matters in Modern Manufacturing

Inconel 718 powder is a nickel-based superalloy widely used in additive manufacturing and powder metallurgy (PM) processes. Known for its excellent corrosion resistance, mechanical strength, and heat resistance up to 700°C, Inconel 718 is the go-to material for critical components in aerospace, energy, automotive, and industrial tooling sectors.

Für B2B buyers, such as OEM manufacturers, aerospace part fabricators, and industrial component suppliers, sourcing high-purity, consistent Inconel 718 powder is mission-critical. The demand for Inconel 718 powder suppliers who offer bulk availability, custom particle size distributionund traceability certificates continues to rise.

Key Features of Inconel 718 Powder:

| Merkmal | Spezifikation |

|---|---|

| Basis-Zusammensetzung | Ni (50-55%), Cr (17-21%), Fe (Balance) |

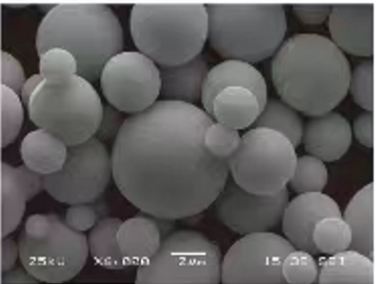

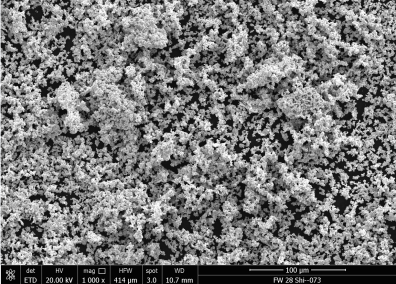

| Methoden der Pulverherstellung | Gas Atomization, Plasma Atomization |

| Partikelgrößenverteilung | D10–D90: 15–53 µm (AM Grade), 45–105 µm (PM Grade) |

| Schmelzbereich | 1260–1336°C |

| Dichte | 8,19 g/cm³ |

| Zugfestigkeit | Up to 1375 MPa (200 ksi) |

| Streckgrenze | Up to 1100 MPa (160 ksi) |

| Hitzebeständigkeit | Stable up to 700°C |

Inconel 718’s unique ability to maintain strength under extreme conditions makes it ideal for aerospace turbines, rocket engines, Kernreaktorenund oil & gas components.

2. Industrial Applications of Inconel 718 Powder

Inconel 718 powder is a preferred material in industries where high stress, pressure, and heat are a daily challenge. Its versatility allows it to be used across metal 3D-Druck, Heißisostatisches Pressen (HIP)und metal injection molding (MIM) Anwendungen.

Key Application Segments:

Luft- und Raumfahrt & Verteidigung

- Turbine blades and discs

- Jet engine components

- Aerospace fasteners

- Rocket motor casings

Energy & Power Generation

- Nuclear reactor vessels

- Wärmetauscher

- Gas turbine components

- Oil drilling tools

Automobilindustrie

- Räder für Turbolader

- Exhaust manifolds

- High-performance valve seats

Tooling & Molds

- Hot work tool inserts

- Injection molding tools

- Die casting dies

Why B2B Buyers Rely on Inconel 718

- Long lifecycle: Ideal for components with high replacement cost

- High fatigue resistance: Reduces failure in high-vibration environments

- Korrosionsbeständigkeit: Performs well in salt spray, acids, and oxidizing environments

- Superior weldability: Even in powder form, suitable for laser melting and DED processes

For industries using Additive Fertigung, Inconel 718 powder enables rapid prototyping, on-demand part productionund complex geometries that traditional machining can’t achieve.

3. Technical Properties and Performance Benefits

Understanding the material science behind Inconel 718 helps procurement managers, engineersund wholesale distributors make informed purchasing decisions.

Mechanical Properties (Heat Treated Condition)

| Eigentum | Wert |

|---|---|

| Zugfestigkeit | 1375 MPa (200 ksi) |

| Streckgrenze | 1100 MPa (160 ksi) |

| Dehnung beim Bruch | 12–20% |

| Härte (Rockwell C) | 32–44 HRC |

| Operating Temp Range | -252°C to 700°C |

| Stress Rupture Strength | 700 MPa at 650°C for 1000hrs |

Thermal and Chemical Properties

| Eigentum | Spezifikation |

|---|---|

| Wärmeleitfähigkeit | 11.4 W/m·K at 21°C |

| Specific Heat Capacity | 435 J/kg·K |

| Oxidationsbeständigkeit | Excellent up to 980°C |

| Korrosionsbeständigkeit | Excellent in acids & seawater |

Performance Advantages

- Maintains mechanical integrity at high temperatures

- Excellent weldability and resistance to post-weld cracking

- Stable microstructure after multiple heat cycles

- Low thermal expansion for dimensional stability

Whether you’re sourcing for powder bed fusion (PBF), direct energy deposition (DED), oder binder jetting, Inconel 718 powder offers the performance reliability required for mission-critical applications.

To explore more powder metallurgy (PM) options beyond Inconel 718, check out our PM-Pulver-Seite for a full list of available grades and specifications.

4. Market Trends & Demand Forecast for Inconel 718 Powder

In recent years, Inconel 718 powder has seen a sharp increase in industrial demand, largely driven by the growth of additive manufacturing and the global aerospace recovery post-COVID. As manufacturers seek to reduce material waste, improve part performance, and optimize supply chains, Inconel 718 has emerged as a preferred alloy for high-temperature and high-load applications.

Global Inconel 718 Powder Market Overview

| Metrisch | 2023 Value | 2028 Projection | CAGR (2023-2028) |

|---|---|---|---|

| Marktgröße (USD) | 1,2 Mrd. Dollar | $2.1 Billion | 10.2% |

| Additive Manufacturing Share | 38% | 52% | High growth |

| Top Regions | North America, EU, China |

Wichtige Markttreiber

- Aerospace recovery: Airlines are ramping up production of next-gen engines, increasing demand for superalloys.

- Defense spending: Governments are investing in missile and aircraft development.

- Industrial 3D printing: Widespread adoption across aerospace, oil & gas, and automotive sectors.

- Localized manufacturing: Geopolitical tensions are encouraging domestic part production using AM.

B2B Buying Trends

- Shift toward long-term supply contracts with powder manufacturers

- Increasing demand for customized PSD (Particle Size Distribution)

- Präferenz für ISO-certified suppliers with traceable batch data

- Growing interest in Chinesische Anbieter for cost competitiveness

5. How to Choose the Right Inconel 718 Powder Supplier

Choosing the right Inconel 718 powder supplier is critical for ensuring consistent part performance, compliance with industry standards, and timely delivery. Here are the top criteria B2B buyers should consider:

Key Selection Criteria

| Faktor | Buyer Considerations |

|---|---|

| Reinheit des Pulvers | Look for 99.9%+ purity and low oxygen/sulfur levels |

| Partikelgrößenverteilung | PSD ranges from 15–53 µm (AM) or 45–105 µm (PM) |

| Zertifizierung | ISO 9001, AS9100, Nadcap if applicable |

| Produktionsverfahren | Gas Atomization preferred for AM; Water Atomized for PM |

| Konsistenz der Chargen | Consistent morphology and flowability are critical |

| Logistics & Delivery | Fast lead times and global shipping capabilities |

| Personalisierung | Ability to provide tailored blends or surface treatments |

| Technische Unterstützung | On-site metallurgical support and documentation |

Questions to Ask Potential Suppliers

- Do you offer customized PSD for different AM machines?

- What is your typical lead time for bulk orders?

- Can you provide CoA (Certificate of Analysis) and traceability?

- Do you offer R&D support or prototyping services?

- Wie wird die Konsistenz von Charge zu Charge sichergestellt?

When evaluating suppliers, it’s recommended to request a sample batch, review their test report, and assess their responsiveness to B2B inquiries.

For more information about Shanghai Truer Technology’s powder specifications and services, visit the Über uns Seite to understand our capabilities and certifications.

6. Top Global Suppliers of Inconel 718 Powder

Below is a curated list of high-quality Inconel 718 powder suppliers for B2B buyers, based on reliability, global reach, and powder quality.

Top 5 Inconel 718 Powder Suppliers (Global)

| Name des Unternehmens | Land | Pulver Typ | Anmerkungen |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | PM & AM grade | Wide inventory, custom blends, ISO-certified |

| Zimmerer-Zusatzstoff | USA | Zerstäubtes Gas | AS9100 certified, high-end aerospace focus |

| Hoganas AB | Schweden | PM grade | Strong PM presence, global footprint |

| EOS GmbH | Deutschland | Zerstäubtes Gas | Machine + powder ecosystem, AM focused |

| Sandvik Fischadler | UK | Zerstäubtes Gas | Advanced powder metallurgy solutions |

Why Shanghai Truer Technology Co., Ltd Stands Out:

- Bietet sowohl water atomized and gas atomized Inconel 718 powders

- Supplies both PM grade und AM grade Pulver

- Custom blends for 4600 steel, FN5000, FD-0208, etc.

- Strong in-house metallurgical R&D support

- Flexibel MOQ options for bulk and trial orders

- Over a decade of experience in powder metallurgy and additive materials

- Seamless ordering through Kontakt Seite

7. Warum immer mehr Käufer sich an chinesische Hersteller wenden

Chinese manufacturers have emerged as strategic sourcing partners for Inconel 718 powder due to advancements in manufacturing technology, cost-efficiency, and faster delivery timelines.

Advantages of Sourcing Inconel 718 from China

- Konkurrenzfähige Preisgestaltung: Chinese suppliers offer 15–30% lower prices without compromising quality.

- Advanced Infrastructure: Modern gas atomization and water atomization facilities.

- Quick Scalability: Ability to handle both small and large production runs.

- Anpassungsfähigkeit: Tailored PSD, prealloyed blends, and surface coatings.

- Globale Logistik: Experience in exporting to EU, NA, and Southeast Asia.

Risk Mitigation Tips for B2B Buyers

- Choose ISO-certified Chinese suppliers with export experience.

- Request full documentation (CoA, MSDS, RoHS compliance).

- Opt for suppliers with English-speaking technical teams.

- Use suppliers with established online presence and product catalogs.

Shanghai Truer Technology is a trusted name in China’s powder metallurgy sector, known for reliability, innovation, and excellent after-sales service. With over 15 years in the industry and a focus on additive manufacturing since 2019, Truer is the preferred supplier for many domestic and international enterprises.

8. How to Order Wholesale Inconel 718 Powder from Truer

For B2B buyers, especially manufacturers, distributors, and e-commerce suppliers, ordering Inconel 718 powder in bulk requires a structured procurement process to ensure product consistency, certification compliance, and timely delivery.

Shanghai Truer Technology Co., Ltd offers a streamlined wholesale ordering process tailored to the needs of international buyers. Here’s how you can place a bulk order efficiently.

Schritt-für-Schritt-Bestellprozess

| Schritt | Beschreibung |

|---|---|

| 1. Anfrage Einreichung | Besuchen Sie die Kontakt Seite and fill out the RFQ form with your quantity, PSD requirements, and delivery location. |

| 2. Technische Konsultation | Truer’s team will respond within 24 hours to confirm specs like powder morphology, particle size range, and alloy composition. |

| 3. Quotation & MOQ | A formal quotation including unit price, lead time, MOQ (as low as 10kg for trials), and logistics cost will be sent. |

| 4. Musterzulassung (fakultativ) | For first-time buyers, a 1–2kg sample can be shipped for quality testing. |

| 5. Bestätigung der Bestellung | Upon sample approval or direct confirmation, a purchase agreement is issued. |

| 6. Produktion & Qualitätskontrolle | Powders are manufactured or sourced from inventory, then tested and certified (ISO, RoHS, CoA). |

| 7. Logistik und Versand | Orders are shipped via air, sea, or express courier depending on urgency. Truer provides tracking and customs documentation. |

| 8. After-Sales-Unterstützung | Full technical support is available post-purchase, including repeat orders and R&D collaboration. |

Wholesale Packaging Options

| Verpackungsart | Volumen | Anwendungsfall |

|---|---|---|

| Sealed Aluminum Foil Bags | 1–5 kg | Lab use, R&D, prototyping |

| Anti-Static Plastic Barrels | 10–50 kg | Small-batch production |

| Steel Drums with Vacuum Seal | 100–500 kg | Large-scale manufacturing |

Payment & Shipping Terms

- Akzeptierte Zahlungen: T/T, L/C at sight, PayPal (for samples)

- Vorlaufzeit: 7–14 days for stock items, 21–30 days for custom production

- FOB Ports: Shanghai, Ningbo

- Incoterms Supported: EXW, FOB, CIF, DDP

For more information about Truer’s full product range, including PM powders and additives, visit our Homepage.

9. FAQs: Common Questions About Buying Inconel 718 Powder in Bulk

Q1: What’s the difference between water atomized and gas atomized Inconel 718 powder?

- Zerstäubtes Wasser: Cost-effective, suitable for PM applications, larger particle size, excellent for press-and-sinter.

- Zerstäubtes Gas: High sphericity, low oxygen content, ideal for additive manufacturing processes like SLM and EBM.

Truer offers both types depending on your application. You can explore powder options on our PM-Pulver-Seite.

Q2: Can I request a custom particle size distribution (PSD)?

Yes. Truer can tailor the PSD to fit your AM machine or sintering process:

- 15–45µm for laser powder bed fusion

- 45–105µm for metal injection molding and PM

- Custom PSD for binder jetting or DED applications

Q3: What certifications does Truer provide with the powder?

Each batch comes with:

- Certificate of Analysis (CoA)

- Sicherheitsdatenblatt (MSDS)

- ISO 9001:2015 Compliance

- Optional: RoHS, Reach, and SGS report upon request

Q4: Was ist die Mindestbestellmenge (MOQ)?

- MOQ for standard Inconel 718 powder: 10kg

- MOQ for custom PSD or blends: 25–50kg

- Sample orders: 1–2kg available for evaluation

Q5: Does Truer support international shipping and customs documentation?

Absolutely. Truer has experience exporting to over 30 countries. We provide:

- Commercial invoice

- Packing list

- Certificate of origin (if needed)

- Harmonized code declaration

- MSDS and CoA for customs clearance

F6: Kann ich Ihr Werk besuchen oder eine Videoinspektion anfordern?

Yes, Truer welcomes factory audits and third-party inspections. For international clients, we can also arrange:

- Live video factory tour

- Batch-specific video inspection

- Quality assurance demonstrations

To arrange a visit or virtual tour, submit your request through our Kontakt Seite.

Q7: What are other powders Truer provides?

In addition to Inconel 718, Truer offers:

- PM 4200 steel, FD-0208, FX-2008

- PM stainless steel, bronze, brass, and copper-steel

- Diffusion alloyed and hybrid low-alloy powders

- Specialty additives like QH-150 soft magnetic powders and TBC-1000 graphite

You can view the full list on our PM Powder catalog page.

By trusting Shanghai Truer Technology Co., Ltd as your Inconel 718 powder supplier, you’re aligning with one of China’s most advanced and reliable powder metallurgy providers.

We invite you to explore our full range of products, services, and technical capabilities by visiting our Über uns Seite.

✅ Internal Links Summary (Anchor Texts):

- PM-Pulver-Seite — for full powder specs

- Über uns Seite — to learn about Truer’s history and capabilities

- Kontakt Seite — to start a quote or technical inquiry

- Homepage — for a full overview of products and services

- PM Powder catalog page — linked again for product comparison

Stay competitive. Source smarter. Choose Truer.

For RFQs or technical consultation, contact us now and experience the Truer difference.