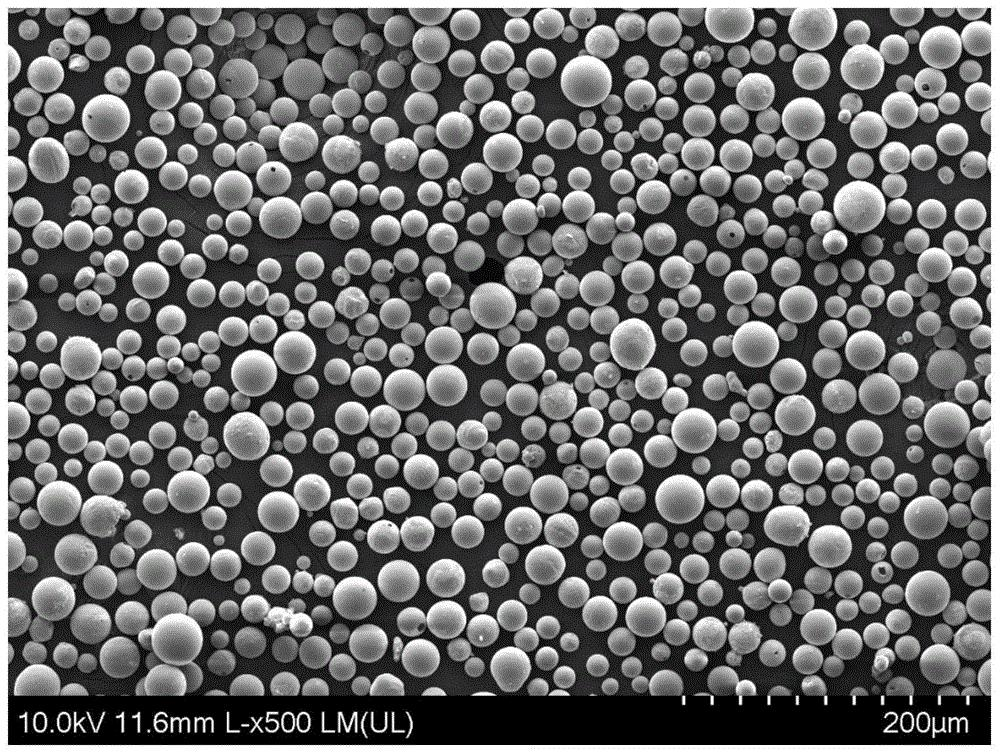

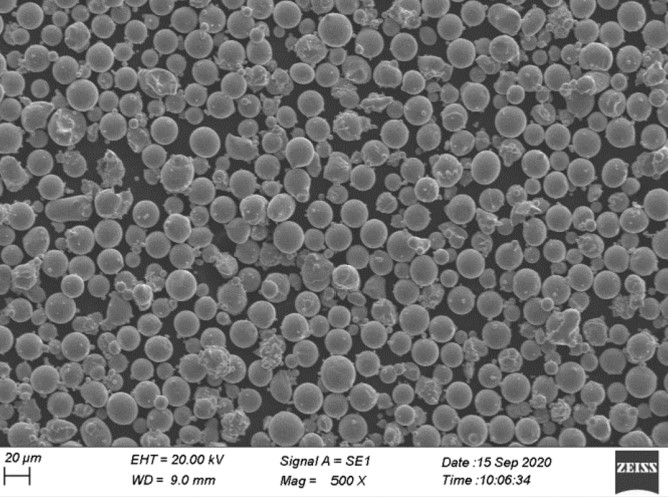

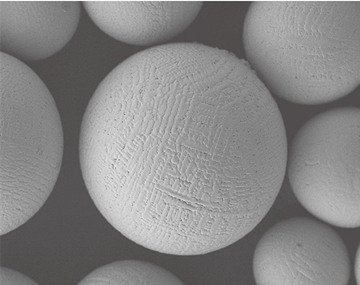

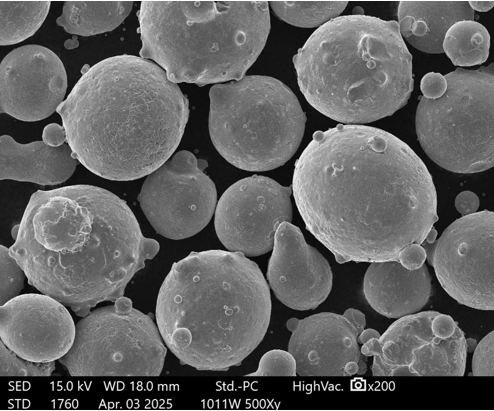

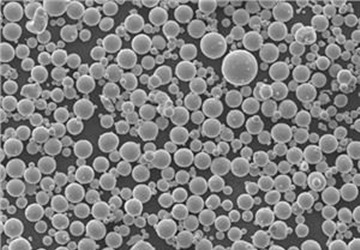

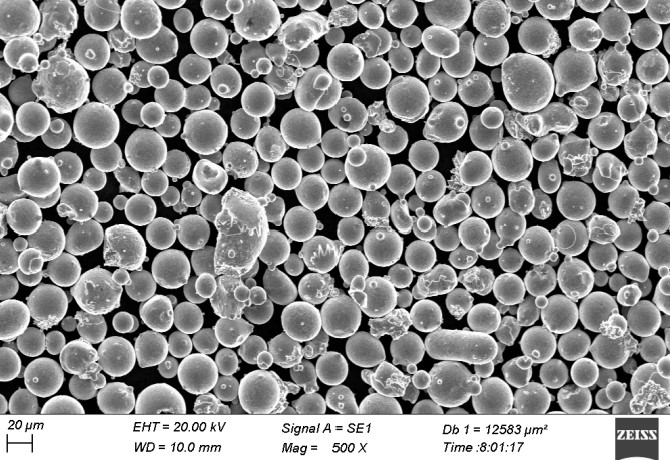

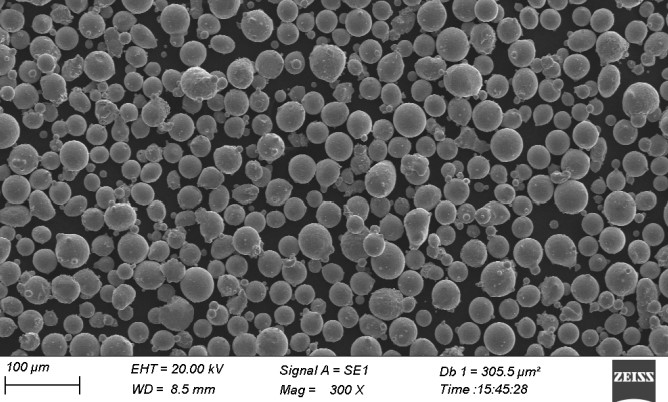

TiC Powder

TiC Powder TiC powder, or Titanium Carbide powder, is a gray, metallic, extremely hard material known for its exceptional wear resistance, high melting point, excellent corrosion resistance, and good thermal and electrical conductivity. It is used in manufacturing wear-resistant materials, cutting tools, abrasives, high-temperature components, and cermets. It is also used in the coatings and thermal spraying industries […]