Guide to Soft Magnetic Powder for Industrial Applications

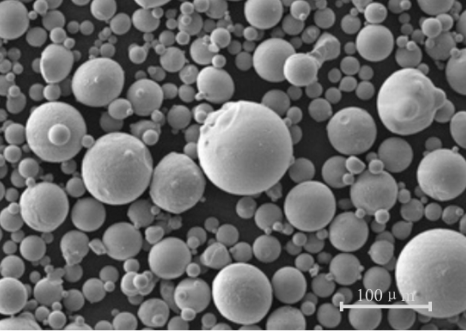

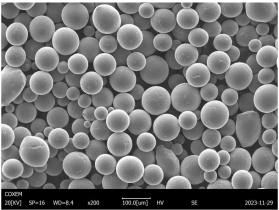

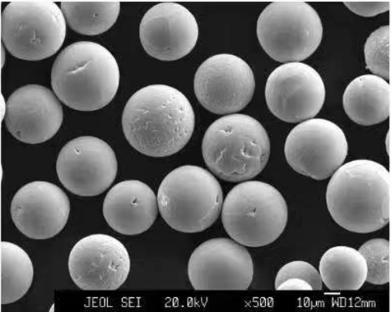

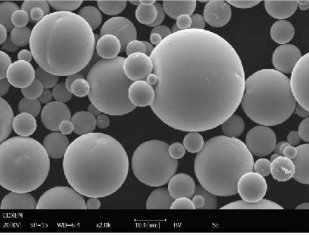

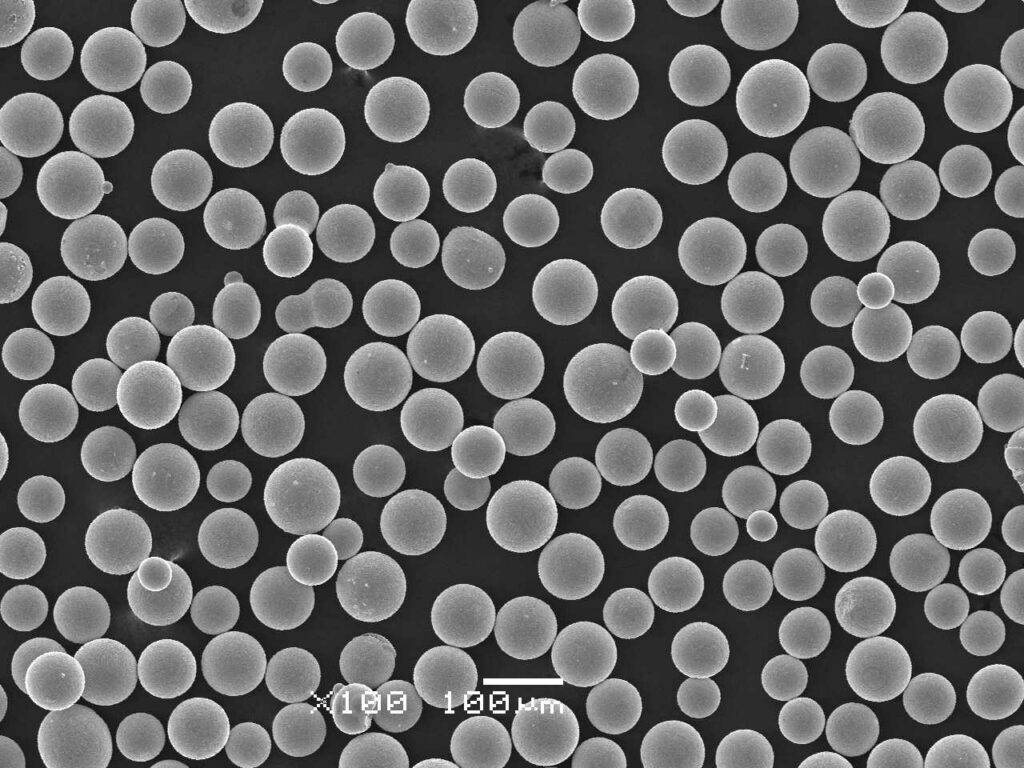

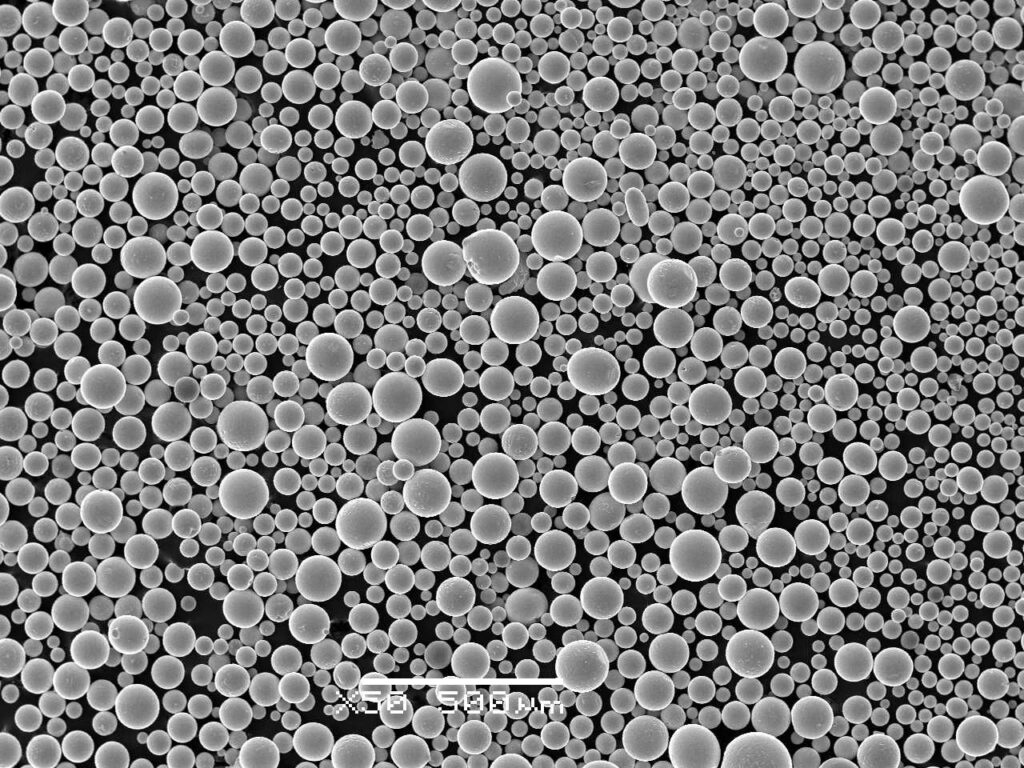

1. Introduction: The Role of Soft Magnetic Powder in Modern Industry Soft magnetic powders are increasingly critical in the development of high-efficiency electrical and electronic components. These powders, primarily made from iron or iron alloys, are known for their ability to magnetize and demagnetize easily, making them ideal for use in high-frequency and low-loss electromagnetic […]

Guide to Soft Magnetic Powder for Industrial Applications Read More »