Spherical Iron Powder: Essential Guide for B2B Buyers

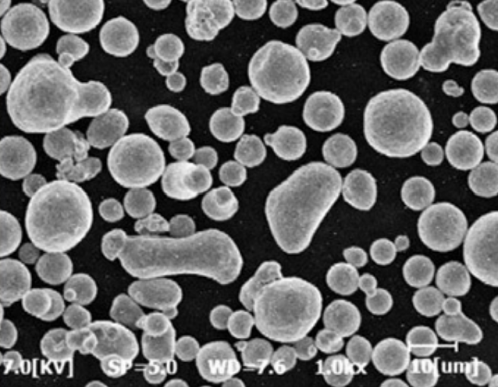

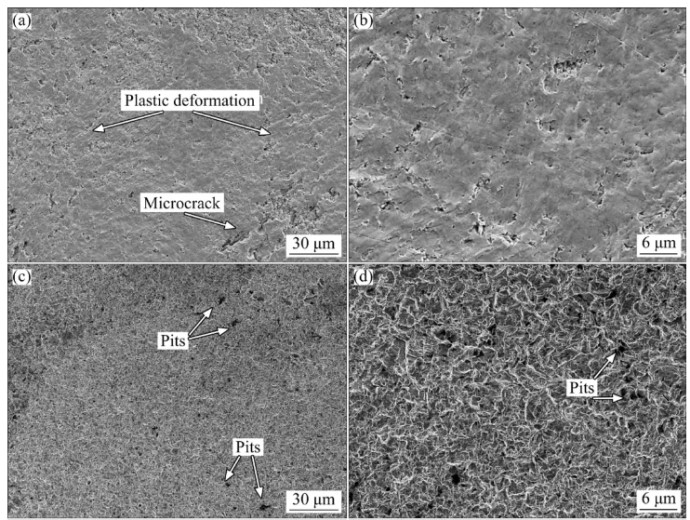

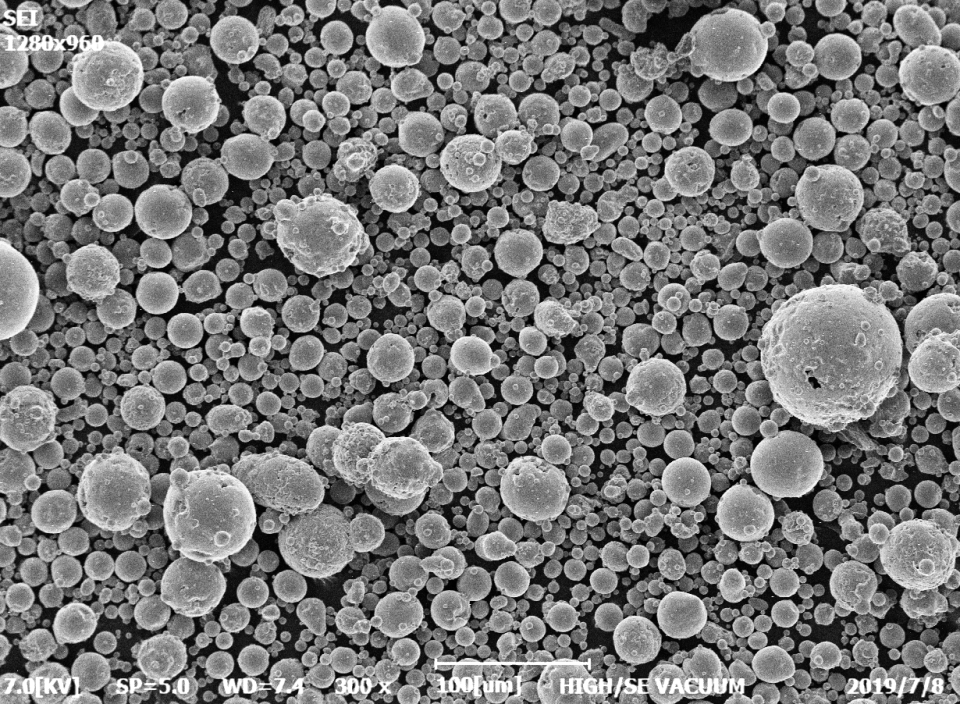

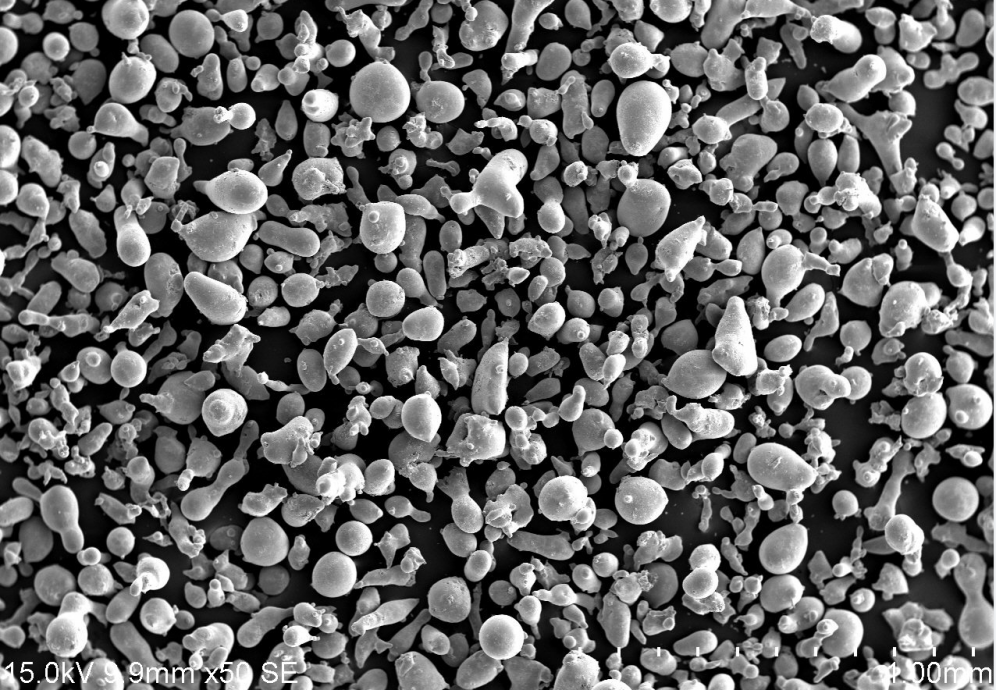

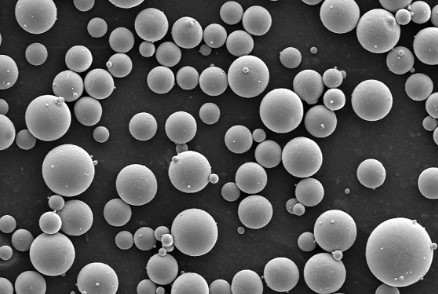

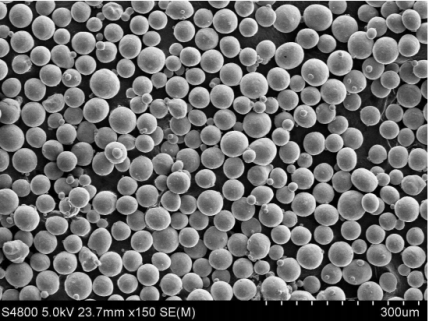

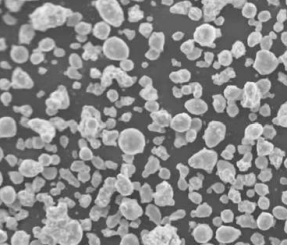

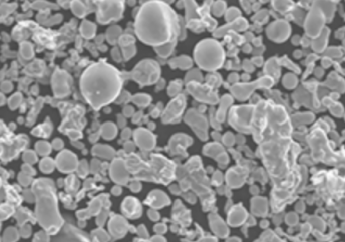

1. Introduction: Why Spherical Iron Powder Matters in Modern Manufacturing Spherical iron powder has become a cornerstone material in industries ranging from additive manufacturing and powder metallurgy (PM) to magnetic materials and soft magnetic composites. Its spherical morphology provides excellent flowability, uniform packing density, and exceptional sintering behavior—key factors for achieving high-quality finished parts. For […]

Spherical Iron Powder: Essential Guide for B2B Buyers Read More »