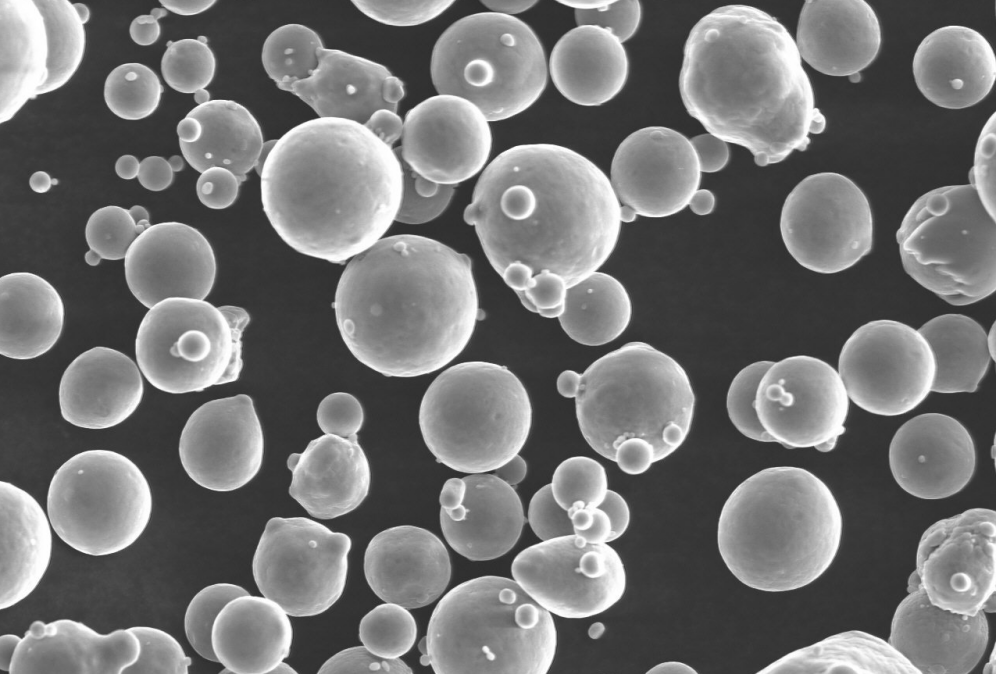

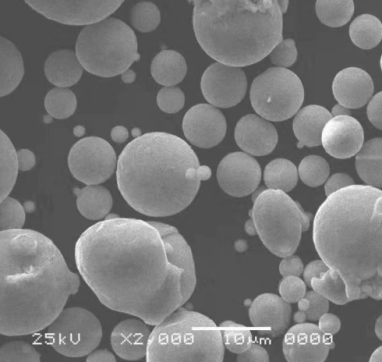

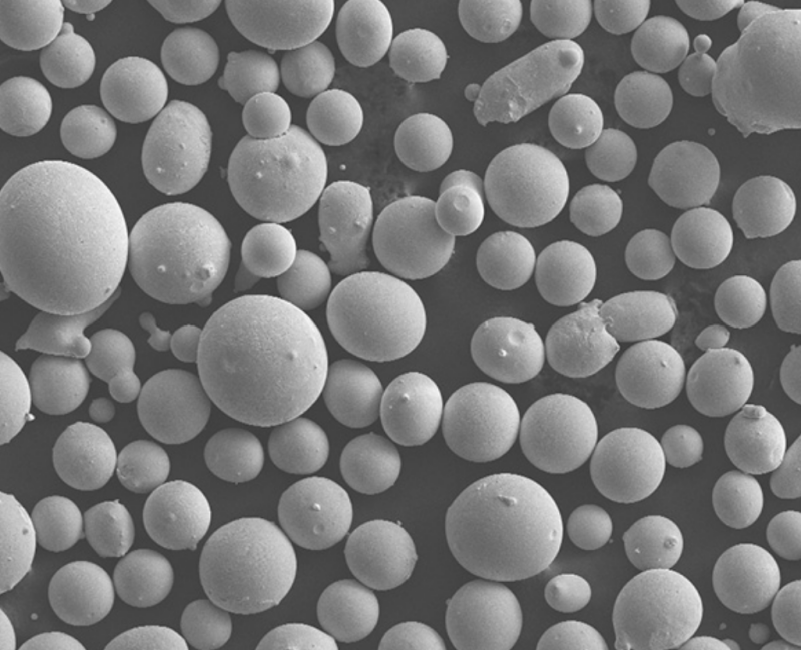

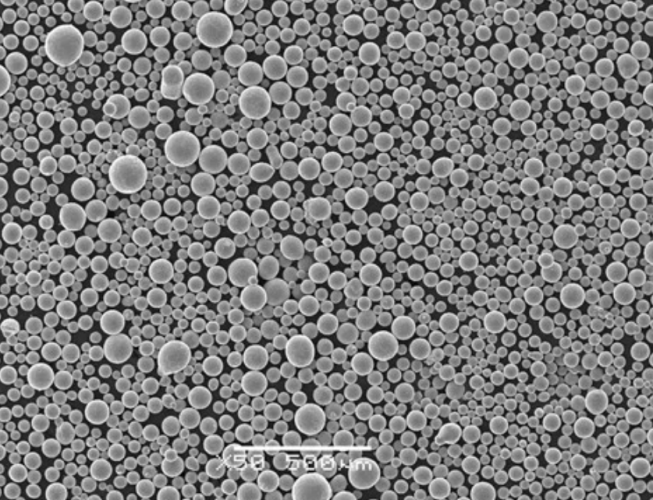

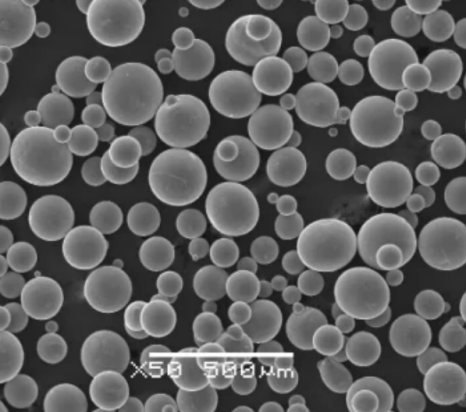

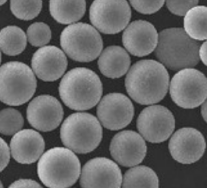

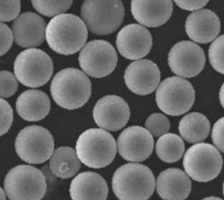

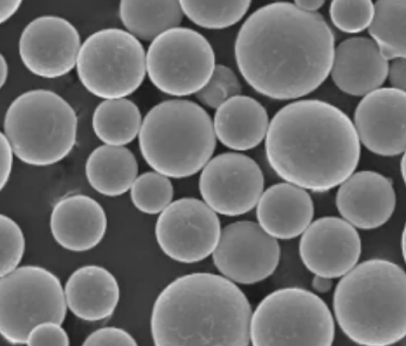

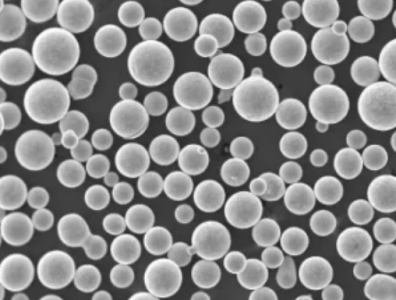

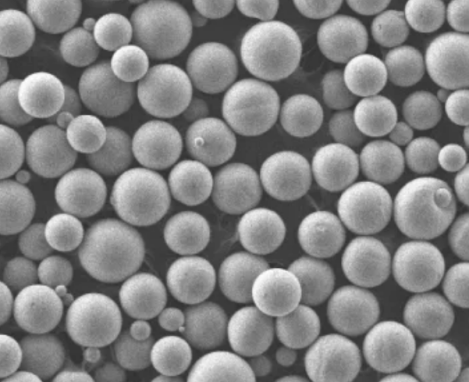

Atomised SS-410L Powder for Industrial Applications

1. Introduction: Why SS-410L Powder Is Crucial in Modern Manufacturing In the evolving landscape of additive manufacturing (AM) and powder metallurgy (PM), stainless steel powders like SS-410L are gaining significant traction among OEMs, e-commerce sellers, and industrial component manufacturers. SS-410L, a martensitic stainless steel with low carbon content, offers a balance between corrosion resistance, mechanical […]

Atomised SS-410L Powder for Industrial Applications Read More »