1. Introduction: What Is Diffusion-Alloyed Powder and Why It Matters

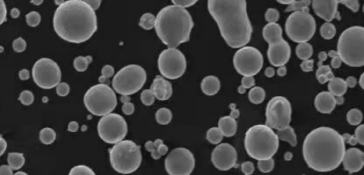

Diffusion-alloyed powder is a specialized powder metallurgy (PM) raw material where alloying elements are partially fused to the surface of iron powder particles through a high-temperature diffusion process. This method creates a hybrid powder with improved consistency, machinability, and mechanical properties, while still retaining the compressibility of premixed powders.

In the B2B manufacturing and metal fabrication world, diffusion-alloyed powders are vital for producing high-performance parts in industries such as:

- 자동차

- 항공우주

- 산업 기계

- 도구 및 다이

- 전자 제품

These powders are especially popular among OEMs, tier-one suppliers, and contract manufacturers due to their exceptional balance between performance and cost-efficiency.

주요 B2B 키워드:

- Diffusion-alloyed powder supplier

- Wholesale diffusion-alloyed powder

- PM powder distributor

- Powder metallurgy alloys

- Industrial metal powder bulk buy

2. Industrial Applications of Diffusion-Alloyed Powder

Diffusion-alloyed powders are engineered to improve strength, compressibility, and dimensional accuracy in sintered parts. These powders are widely used across several sectors:

자동차 산업

- 변속기 부품

- 기어 및 스프로킷

- 고강도 및 피로 저항

- 캠축 풀리

산업 기계

- Hydraulic system parts

- Bearing housings

- Structural supports

- 내마모성 부품

Power Tools & Hardware

- Drill components

- 절삭 공구 인서트

- 자동화된 PM 라인과 호환

전기 및 전자

- 자성 코어

- Heat-dissipating casings

- Connectors and terminals

| 산업 | 일반적인 구성 요소 | Benefits of Diffusion-Alloyed Powder |

|---|---|---|

| 자동차 | 기어, 스프로킷, 로드 | Increased strength, wear resistance |

| 산업 기계 | Housings, supports | Dimensional precision, durability |

| 도구 및 하드웨어 | Inserts, locks | 가공성, 내식성 |

| 전자 제품 | Terminals, casings | Thermal stability, conductivity |

Diffusion-alloyed powders such as FD-0208 are especially favored in automotive parts due to their excellent hardenability and fatigue resistance.

For a deeper look into Shanghai Truer’s diffusion-alloyed powder offerings, visit our PM 분말 제품 페이지.

3. 주요 특성 및 성능 이점

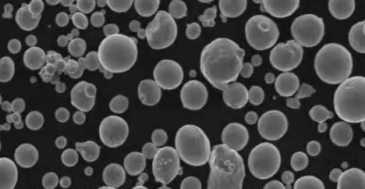

Diffusion-alloyed powders blend the advantages of both prealloyed and admixed powders. Below are the standout performance characteristics that make them ideal for bulk industrial applications:

기계적 특성

- 높은 그린 강도

- Enhanced sintered hardness

- 뛰어난 치수 안정성

열 속성

- Excellent sinterability at lower temperatures

- Reduced thermal distortion

- Improved thermal conductivity for specific applications

가공상의 이점

- Better compressibility than fully prealloyed powders

- Uniform alloy distribution

- Lower segregation during handling

Typical Grades Available at Shanghai Truer:

- FD-0208: Diffusion alloyed copper and nickel

- FD-0200: Basic iron-copper alloy

- FX-2008: High strength hybrid alloy

| 속성 | FD-0208 | FD-0200 | FX-2008 |

|---|---|---|---|

| 압축성 | 높음 | Medium | 높음 |

| Hardness (HB) | 80–100 | 60–80 | 100–120 |

| Sintered Density (g/cm³) | 6.8–7.2 | 6.5–6.9 | 7.0–7.3 |

| 인장 강도(MPa) | 600–800 | 350–500 | 750–900 |

These powders are especially suited for high-load components and applications where performance cannot be compromised.

If you’re interested in learning more about the technical capabilities and customizations available, reach out through our 연락처 페이지.

4. Market Trends and Demand in Powder Metallurgy

The global powder metallurgy (PM) market has been experiencing steady growth, driven by increasing demand for lightweight, high-strength components across industries like automotive, aerospace, and industrial automation. Diffusion-alloyed powders, in particular, are gaining traction due to their unique balance of mechanical performance and cost-efficiency.

주요 시장 동인:

- Electrification of vehicles (EVs) requiring precision parts

- Growth in industrial automation and robotics

- Reduced material waste compared to traditional machining

- Rising demand for sustainable and energy-efficient manufacturing processes

Diffusion-Alloyed Powder Market Trends:

- Increased demand in Asia-Pacific due to automotive and industrial expansion.

- Customization of powder blends for specific mechanical properties.

- Shift from premix to diffusion-alloyed grades for better consistency and reduced segregation.

- Use of advanced atomization technologies to improve quality and purity.

| 지역 | Growth Trend | 수요를 주도하는 주요 산업 |

|---|---|---|

| 북미 | Steady | Automotive, Aerospace, Defense |

| 유럽 | 보통 | Automotive, Green Energy |

| 아시아 태평양 | Rapid | Automotive, Industrial Automation |

| 라틴 아메리카 | 신규 | Mining Equipment, Tools Manufacturing |

According to industry reports, the global PM market is projected to reach USD 12 billion by 2028, with diffusion-alloyed powders comprising a growing share. This presents a significant opportunity for B2B buyers looking to source high-performance powders at scale.

5. How to Choose the Right Diffusion-Alloyed Powder Supplier

Sourcing the right diffusion-alloyed powder supplier is critical for manufacturers focused on quality, consistency, and cost management. Below are the key factors to consider when evaluating suppliers:

1. Technical Expertise & Certifications

- ISO 9001 certification and quality control systems

- In-house R&D and testing labs for custom powder development

- Long-standing experience in powder metallurgy and additive manufacturing

2. Product Range & Availability

- Availability of standard grades like FD-0208, FD-0200, FX-2008

- Customizable alloy compositions and particle size distributions

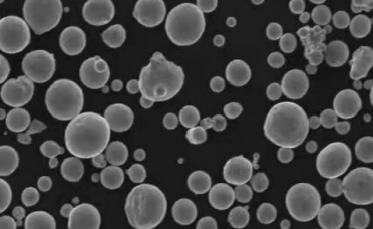

- Multiple production methods (water atomized, gas atomized)

3. Manufacturing Capabilities

- Advanced atomization technologies

- Strict consistency in powder particle distribution

- Clean production environments to avoid contamination

4. Logistics & Support

- 글로벌 배송 능력

- Technical support for part design and sintering optimization

- Local warehousing or distribution networks

| Supplier Feature | B2B 구매자를 위한 중요성 |

|---|---|

| ISO/TS Certifications | Ensures quality and reliability |

| Custom Powder Solutions | Matches specific part performance needs |

| Volume Flexibility | Supports both small batches and bulk orders |

| 경쟁력 있는 가격 | Better cost per unit for high-volume buyers |

For example, Shanghai Truer Technology Co., Ltd. has over 15 years of experience and offers both standard and custom diffusion-alloyed powders for global buyers. Learn more about our company’s background 여기에서.

6. Top Suppliers of Diffusion-Alloyed Powders Worldwide

When sourcing diffusion-alloyed powders, it’s essential to know which suppliers offer the best combination of quality, customization, and global support. Here’s a list of some of the most recognized suppliers in the industry:

| 공급업체 이름 | 지역 | Notable Products | 강점 |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | 중국 | FD-0208, FX-2008, FD-0200 | Customization, full PM solutions |

| 호가나스 AB | 스웨덴 | Astaloy, Distaloy grades | 글로벌 입지, 첨단 R&D |

| 리오틴토 금속 분말 | 캐나다 | ATOMET, FL Series | High purity, automotive focus |

| GKN 회가나에스 | 미국 | Ancorsteel grades | Long-standing reputation, innovation |

| 키메라 인터내셔널 | 미국 | 특수 합금 분말 | Diverse PM product lines |

Why Shanghai Truer is a Top Choice in China:

- Offers a wide range of diffusion-alloyed powders including FD-0208 and FX-2008

- Integrates powder manufacturing with additive manufacturing services

- Provides tailored solutions for diamond tools, oil-impregnated bearings, and soft magnetic parts

- Supplies both water atomized and hybrid atomization powders

Shanghai Truer is not only a manufacturer but also one of the most professional additive suppliers in China’s powder metallurgy industry—supporting OEMs, tier-one suppliers, and global distributors.

To view our full list of diffusion-alloyed and PM powders, head over to our PM 분말 카탈로그.

7. Why More Buyers Are Switching to Chinese Powder Metallurgy Suppliers

Global supply chains are undergoing a transformation, and more B2B buyers—including manufacturers, distributors, and e-commerce sellers—are sourcing directly from Chinese powder metallurgy suppliers. The reasons for this shift are rooted in cost-efficiency, scalability, and innovation.

Key Advantages of Chinese PM Suppliers

- 비용 효율적인 프로덕션

Lower labor and material costs allow for highly competitive pricing—especially important for wholesale and high-volume buyers. - Advanced Manufacturing Technologies

Many Chinese manufacturers, like Shanghai Truer, have invested in advanced atomization and processing technologies, offering high-quality diffusion-alloyed powders that rival global brands. - 맞춤화 및 유연성

Chinese suppliers are often more agile in developing custom powder formulations tailored to specific B2B applications, including automotive, aerospace, and industrial components. - 통합 공급망

With access to raw materials, logistics hubs, and technical resources, Chinese PM suppliers can fulfill large orders quickly and reliably.

| Benefits for B2B Buyers | 설명 |

|---|---|

| 경쟁력 있는 가격 | Lower cost per kilogram for bulk orders |

| Technical Customization | Powder blends tailored to your application |

| Fast Turnaround Times | Shorter lead times for global shipments |

| 확장 가능한 생산 | Easily ramp up from trial batch to mass production |

Example: Why Shanghai Truer Is Leading the Shift

Shanghai Truer Technology Co., Ltd. exemplifies the strengths of Chinese PM suppliers:

- 14+ years in materials science and metallurgy

- Full integration of 3D 프린팅 powder equipment, PM powders, and additive solutions

- Offers diffusion-alloyed grades such as FD-0208, FX-2008, and FD-0200

- Provides lubricants, cutting agents, graphite additions, and sintering additives for full PM solutions

To explore how Shanghai Truer supports international buyers, visit our 홈페이지.

8. Why Choose Shanghai Truer as Your Powder Metallurgy Partner

Shanghai Truer Technology Co., Ltd. is more than just a materials supplier—it’s a strategic partner for global B2B companies looking to scale their powder metallurgy operations.

트루어를 차별화하는 요소

- ✅ 포괄적인 제품 라인

From PM iron, copper, and steel powders to diffusion-alloyed and prealloyed grades, Truer covers all your base material needs. - ✅ 고급 생산 방법

Offers water atomization, gas atomization, and hybrid atomization to meet diverse technical requirements. - ✅ Turnkey Support for Manufacturers

Truer assists with application engineering, prototyping, powder selection, and performance testing. - ✅ Trusted by Global OEMs and Distributors

Exporting to North America, Europe, and Southeast Asia with excellent customer satisfaction and quality control.

Featured Diffusion-Alloyed Products

| 제품명 | Composition Type | 일반적인 애플리케이션 |

|---|---|---|

| FD-0208 | Fe-Cu-Ni (diffused) | Gears, sprockets, structural parts |

| FX-2008 | Fe-Cu-Ni-Mo (hybrid) | High-strength automotive parts |

| FD-0200 | Fe-Cu (diffused) | General-purpose PM parts |

Additional Products from Truer

- 윤활제: Lube-W, SUW-5000B

- Cutting Agents: SME-100 (sulfur-free), TD-8 (composite)

- Graphite Additives: QHP-330, TBC-400, TBC-1000

- Soft Magnetic Additives: QH-150

Whether you’re a component manufacturer, PM distributor, or OEM, Truer provides tailored support combined with technical expertise.

📩 For direct quotes or sample requests, 여기에서 문의하십시오..

9. FAQs: Buying Wholesale Diffusion-Alloyed Powder

Q1: What is the minimum order quantity (MOQ) for diffusion-alloyed powders at Shanghai Truer?

A: Our standard MOQ is 500 kg. However, for first-time buyers or R&D purposes, we can support smaller trial batches.

Q2: Can I request custom alloy compositions or particle size distributions?

A: Yes. Shanghai Truer specializes in customized powder solutions to meet specific performance or production requirements.

Q3: What quality certifications does Truer hold?

A: We operate under ISO 9001 quality management systems and offer full batch traceability and third-party testing on request.

Q4: Which atomization methods are available?

A: We offer water atomized, gas atomized, and hybrid (water + gas) powders to meet different applications and price points.

Q5: Do you export internationally?

A: Yes. We have a strong global logistics network and regularly ship to North America, Europe, Southeast Asia, and the Middle East.

에 습기 방지재와 오염 방지를 위한 진공 밀봉과 함께 포장됩니다.

A: You can start by visiting our PM 파우더 페이지 and submitting an inquiry through the contact form. A representative will get in touch within 24 hours.

Q7: What industries benefit most from diffusion-alloyed powders?

A: Automotive, aerospace, industrial machinery, tool manufacturing, and electronics.

Q8: Can diffusion-alloyed powders be used in additive manufacturing (3D printing)?

A: While primarily used in PM parts, Truer also offers additive-grade powders. Contact us to learn more about our AM solutions.

✅ Internal Anchor Text Links Used in This Article:

By choosing Shanghai Truer as your diffusion-alloyed powder supplier, you’re partnering with a trusted, innovative, and globally recognized leader in powder metallurgy.

📞 Ready to source high-performance diffusion-alloyed powders in bulk? 오늘 저희에게 연락하십시오 for quotes, samples, or technical consultations.