1. Introduction: What is CX Powder and Why It Matters in Manufacturing

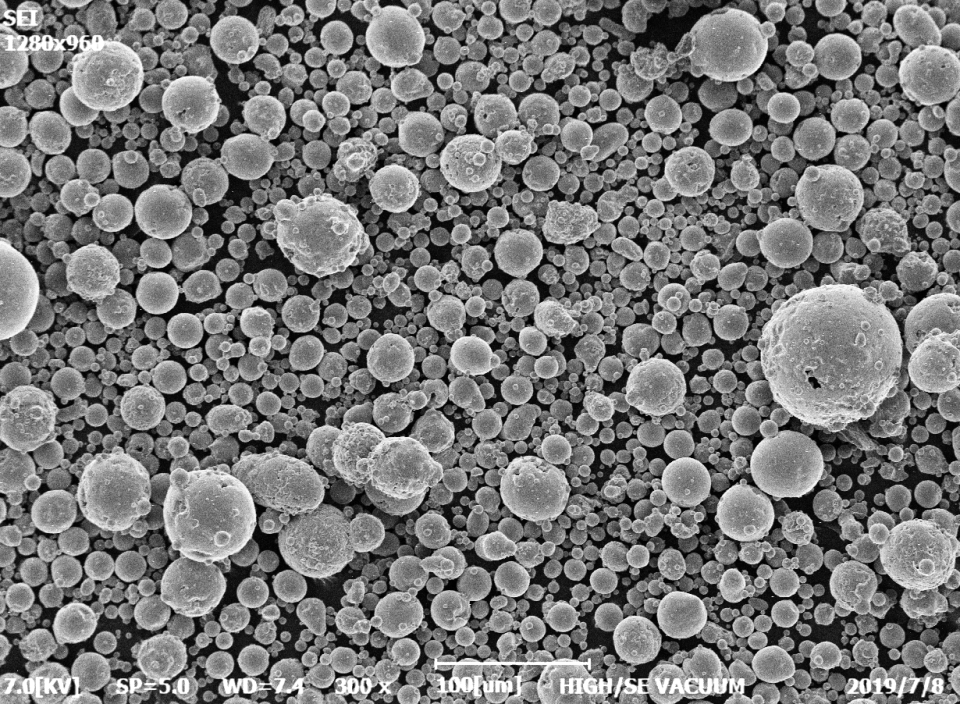

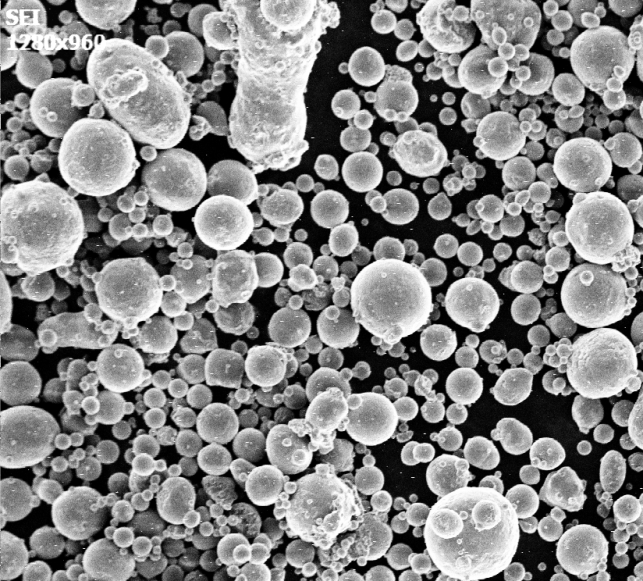

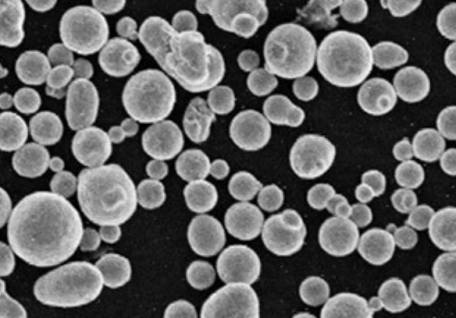

CX powder refers to a specialized category of powder metallurgy (PM) materials typically used for structural and functional industrial components. These powders are manufactured using advanced processes such as water atomization, gas atomization, or a combination of both, ensuring high purity, consistent particle size distribution, and optimized flow properties.

In the powder metallurgy and additive manufacturing (AM) sectors, CX powder is increasingly being adopted due to its:

- High sintering performance

- 뛰어난 기계적 강도

- Cost-efficiency for large-scale production

- Compatibility with multiple compacting processes

Manufacturers across sectors such as automotive, aerospace, electrical appliances, and tooling are leveraging CX powder to optimize part performance and reduce production costs.

Why CX Powder is Crucial in B2B Wholesale Supply Chains

For distributors, OEMs, and e-commerce sellers dealing in metal powders, CX powder offers:

- High demand from Tier-1 automotive and machinery suppliers

- Bulk procurement opportunities due to rising global usage

- Competitive edge in supplying advanced PM solutions

2. Applications of CX Powder in Industrial Sectors

CX powder’s versatility enables its use in a wide range of industrial applications. Below is a breakdown of the key sectors utilizing this powder:

| 산업 | 애플리케이션 | 혜택 |

|---|---|---|

| 자동차 | Gears, bushings, camshaft components | High wear resistance and mechanical integrity |

| 항공우주 | Structural brackets, seals | 무게 대비 강도가 높은 경량 |

| 전기 | Soft magnetic cores, switch components | High magnetic permeability |

| Tooling & Hardware | Cutting inserts, hand tools | Exceptional hardness and machinability |

| 소비자 가전 | Micro components, heat sinks | Excellent thermal conductivity and dimensional accuracy |

CX Powder Use Cases:

- Structural PM Parts: Used in high-load applications like transmission systems and engine parts.

- Magnetic Applications: CX powder with soft magnetic additives (e.g., QH-150) enhances magnetic performance in electrical components.

- Diamond Tool Bonding: Specialized diffusion CuSn-enhanced CX powders are ideal for cutting and grinding tools.

3. Key Properties and Use Cases of CX Powder

Understanding the properties of CX powder is crucial for engineers, procurement officers, and wholesale buyers. Here are the core characteristics:

물리적 및 기계적 특성

| 속성 | 값 범위 |

|---|---|

| 입자 크기 | 20–150 μm (customizable) |

| 겉보기 밀도 | 2.5-3.2 g/cm³ |

| 유동 속도(Hall) | 28-35 s/50g |

| 압축성 | Excellent under compacting pressures of 400–800 MPa |

| 경도(소결) | Up to 80 HRB depending on alloy |

Key Use Case Categories

- Precision Metal Parts: Ideal for compacted and sintered parts requiring tight tolerances.

- Soft Magnetic Components: Enhanced with additives like QHP-330 for transformer cores and inductors.

- Oil-Impregnated Bearings: High porosity and capillarity, especially when combined with phosphorus iron or bronze variants.

첨가제 호환성

CX powder is compatible with a range of additives provided by 상하이 트루어 기술 유한공사, such as:

- Lube-W & SUW-8000 lubricants: Ensure smooth compaction and ejection.

- Graphite TBC-400 & TBC-1000: Tailor sintering and mechanical properties.

- Cutting Agents (SME-100, TD-8): Improve machinability of sintered parts.

🔗 Explore our full line of PM powders including CX powder 여기에서.

4. Market Trends & Growth Potential for CX Powder

As global manufacturing shifts toward cost-effective, high-performance materials, CX powder is gaining rapid traction in multiple sectors. The global powder metallurgy market is projected to grow at a CAGR of over 7% from 2023 to 2030, and CX powder is a significant contributor to this growth due to its versatility and performance.

주요 성장 동력

- 자동차 경량화: CX powder helps produce lightweight yet strong components, supporting EV and hybrid vehicle production.

- Additive Manufacturing (AM) Adoption: CX powder’s compatibility with AM processes like binder jetting and selective laser sintering is expanding its applications.

- Asia-Pacific Expansion: With China and India scaling up manufacturing, the demand for PM materials like CX powder continues to rise.

Demand Forecast by Region (2024-2030)

| 지역 | 연평균 성장률(CAGR) % | Key Markets |

|---|---|---|

| 아시아 태평양 | 8.5% | Automotive, consumer goods |

| 북미 | 6.2% | 항공우주, 방위, 툴링 |

| 유럽 | 5.9% | Industrial machinery, EVs |

| 중동 | 4.5% | Oil & gas components |

| 라틴 아메리카 | 3.8% | Agricultural equipment |

Emerging Application Opportunities

- Green Energy: CX powder is used in magnetic cores for wind turbines and electric motors.

- 3D 프린팅: Especially when paired with gas atomization, CX powder is suitable for high-resolution AM parts.

🔗 Learn more about how CX powder fits into the future of metal manufacturing on our company homepage.

5. How to Choose the Right CX Powder Supplier

For B2B buyers, selecting a CX powder supplier is a strategic decision that impacts quality, consistency, and cost-efficiency. Here’s what to consider:

Key Selection Criteria

- Powder Production Method: Ensure the supplier offers water, gas, or hybrid atomized powder options based on your application.

- Powder Grades Available: Look for multiple grades such as FD-0208, FL-4605, and CT-1000 for flexibility in application.

- Additive Integration: Opt for suppliers that provide compatible additives like lubricants, graphite, and cutting agents.

- Quality Assurance: ISO certifications, in-house lab testing, and traceability are essential.

- Lead Time & Inventory Management: Short lead times and robust logistics make a huge difference in bulk orders.

Supplier Comparison Checklist

| 요인 | 중요성 | 상하이 트루어 | 경쟁업체 A | 경쟁업체 B |

|---|---|---|---|---|

| Multiple Atomization Methods | ★★★★★ | ✅ | ❌ | ❌ |

| Additive Portfolio | ★★★★★ | ✅ | ✅ | ❌ |

| Custom Grade Development | ★★★★☆ | ✅ | ❌ | ❌ |

| Bulk Order Capacity | ★★★★★ | ✅ | ✅ | ✅ |

| 기술 지원 | ★★★★☆ | ✅ | ❌ | ❌ |

6. Top 5 CX Powder Suppliers in Asia

Asia is home to several high-quality CX powder manufacturers. Below are the top five suppliers based on product range, customer support, and international reach:

| 공급업체 이름 | 국가 | 전문화 | 웹사이트 |

|---|---|---|---|

| 상하이 트루어 기술 유한공사 | 중국 | Additive solutions, multiple PM grades, hybrid atomization | 방문 |

| MolyWorks Materials | 중국 | AM-focused CX powder, gas atomization | N/A |

| Hitachi Powdered Metals | 일본 | High-performance PM powders for automotive sector | N/A |

| JFE 스틸 코퍼레이션 | 일본 | Structural and magnetic PM powders | N/A |

| Hoganas AB (Asia Division) | 중국 | Broad PM portfolio and global distribution | N/A |

상하이 트루어가 돋보이는 이유

- Established in 2009, additive business since 2019

- Offers both traditional PM and advanced AM powders

- Full additive portfolio for customized powder behavior

- Supplies to industries including automotive, tooling, electronics, and 3D printing

🔗 Want to learn more? Visit our 연락처 페이지 to discuss your CX powder needs with a specialist.

7. Why More Manufacturers Are Switching to Chinese CX Powder Sources

China has emerged as a global leader in powder metallurgy, and CX powder is no exception. Here’s why global buyers are increasingly sourcing from Chinese manufacturers like Shanghai Truer:

1. 비용 효율성

- 2024년 12월 18일 (수) 15:41:54 +0000

- Lower shipping and production costs

- Economies of scale for large-volume buyers

2. 기술 발전

- Use of hybrid atomization (water + gas) enhances powder quality

- Customizable powder grades for niche applications

3. 통합 첨가제 솔루션

- Chinese suppliers offer a one-stop shop for base powder and process additives

- Reduces supplier dependency and logistic complexity

4. Supply Chain Resilience

- Robust domestic infrastructure supports fast turnaround

- Strategic stockpiling and logistics planning mitigate global disruptions

5. Compliance & Certification

- Most top-tier Chinese suppliers have ISO 9001, RoHS, and REACH certifications

- Active R&D support for emerging applications like EVs and AM

🔗 Discover the full range of powder metallurgy solutions from Shanghai Truer on our PM 파우더 페이지.

8. Why Choose Shanghai Truer as Your CX Powder Partner

When it comes to sourcing high-quality CX powder in bulk, Shanghai Truer Technology Co., Ltd stands out as a trusted and innovative partner. With over a decade of experience in powder metallurgy and a strong foothold in additive manufacturing since 2019, Truer delivers comprehensive powder solutions tailored for industrial-scale applications.

Shanghai Truer와 협력할 때의 주요 장점

| 기능 | B2B 구매자를 위한 혜택 |

|---|---|

| Wide Powder Portfolio | Over 15 types of PM powders including CX, bronze, nickel silver, brass, steel, and more |

| Custom Atomization Methods | Water, gas, and hybrid atomization for application-specific properties |

| 통합 첨가제 솔루션 | Lubricants, graphite, cutting agents, and magnetic additives for enhanced performance |

| Custom Grade Development | Engineers work directly with clients to develop or modify powder characteristics |

| Consistent Quality Control | In-house testing, ISO-certified processes, and traceability ensure reliability |

| Rapid Turnaround & Logistics | Efficient supply chain for both domestic and international shipping |

Shanghai Truer’s CX Powder Highlights

- Grades Available: FD-0208, FL-4605, FD-0200, CT-1000, F-0000, and more

- Common Use Cases: Structural automotive parts, cutting tools, sintered bearings, AM prototyping

- 소결 기어 Works seamlessly with Truer’s additives like Lube-W, QH-150, TBC-400, and SME-100

🔗 Learn more about our company’s mission, innovation, and team at our 회사 소개 페이지.

9. How to Order Wholesale CX Powder from Shanghai Truer

Ordering CX powder from Shanghai Truer is designed to be straightforward and scalable for B2B clients, whether you’re a distributor, OEM, or e-commerce seller.

단계별 도매 주문 프로세스

- Initial Consultation

- Contact Truer’s sales team via phone or the 문의 페이지

- Discuss your application, quantity requirements, and grade preferences

- Technical Support & Material Matching

- Truer’s engineers will recommend the best CX powder grade and compatible additives

- Provide sample specs or request a test batch

- Quotation & Lead Time Confirmation

- Receive a customized quotation including pricing, delivery timeline, and MOQ

- Confirm order quantity (from 100 kg to several tons)

- 생산 및 품질 관리

- Powder is atomized, blended, and tested according to your specs

- Certificates of Analysis (CoA) provided

- 포장 및 배송

- Available in sealed drums, vacuum packs, or bulk containers

- Global logistics support for air, sea, or rail transport

- 판매 후 지원

- 지속적인 기술 지원

- Re-order options with priority lead time

Documents Required for B2B Orders

- Company registration or VAT certificate

- Import/export license (for international orders)

- Purchase Order (PO) and technical data sheet (if applicable)

🔗 For a custom quote or bulk order inquiry, visit our Contact Truer page.

10. FAQs: Everything You Need to Know About Buying CX Powder Wholesale

Here are some of the most frequently asked questions by wholesale buyers and industrial procurement teams about CX powder:

Q1: What’s the minimum order quantity (MOQ) for CX powder?

A: The typical MOQ is 100 kg. However, for special grades or trial batches, smaller quantities may be arranged.

Q2: Can I request a custom CX powder grade?

A: Yes. Shanghai Truer offers custom blending and alloying services. Share your technical requirements and our team will provide a tailored solution.

Q3: What packaging options are available?

A: CX powder is supplied in sealed 25 kg drums, 1-ton bulk bags, or vacuum-sealed aluminum packs for sensitive grades.

Q4: Is Truer’s CX powder suitable for 3D 프린팅?

A: Absolutely. Gas-atomized or hybrid-atomized CX powder grades are optimized for additive manufacturing methods like binder jetting and laser sintering.

Q5: Can I combine CX powder with Truer’s additives?

A: Yes, and it’s recommended. Truer offers a full range of lubricants (e.g. Lube-W), graphite (TBC-400), and cutting agents (SME-100) that enhance the performance of CX powder in sintered parts.

🔗 Browse our full selection of CX and other PM powders on the PM 분말 제품 페이지를 방문하십시오..

With its consistent quality, extensive product range, and engineering support, Shanghai Truer is your go-to supplier for wholesale CX powder. Whether you’re in automotive, tooling, or additive manufacturing, our team is ready to help you optimize your material sourcing strategy.

Ready to request a quote or start a trial batch?

🔗 오늘 저희에게 연락하십시오 and let’s build your next-generation components together.