FeCoNiCrMn 분말 개요

FeCoNiCrMn 분말고엔트로피 합금(HEA)이라고도 불리는 이 금속 분말은 재료 과학의 혁신적인 발전을 상징합니다. 뛰어난 기계적, 화학적, 열적 특성으로 잘 알려진 이 금속 분말은 강도, 내식성, 다용도성이 요구되는 분야에 광범위하게 사용됩니다. FeCoNiCrMn을 포함한 HEA는 한두 가지 주요 원소가 주를 이루는 기존 합금과는 다른 독특한 다중 원소 설계로 인해 인기를 얻고 있습니다.

이 종합 가이드에서는 구성, 특성, 모델 및 응용 분야에 대해 자세히 살펴보면서 FeCoNiCrMn 분말에 대해 자세히 살펴봅니다. 또한 장점과 한계점, 주요 공급업체에 대해서도 설명하여 정보에 입각한 결정을 내릴 수 있도록 전체 그림을 제공합니다.

FeCoNiCrMn 파우더란?

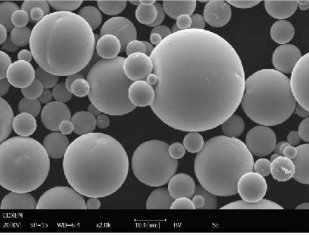

FeCoNiCrMn 분말은 철(Fe), 코발트(Co), 니켈(Ni), 크롬(Cr), 망간(Mn)을 거의 동일한 비율로 결합한 5원소 합금 분말입니다. 이 균형 잡힌 구성은 높은 엔트로피 특성의 기초를 형성하여 우수한 구조적 및 기능적 특성을 제공합니다.

주요 특징

- 높은 강도와 경도: 독특한 원자 배열로 인한 뛰어난 기계적 특성.

- 열 안정성: 고온 애플리케이션에 이상적입니다.

- 내식성: 산화 및 화학적 분해에 강합니다.

- 다용도성: 적층 제조, 항공우주 및 생물의학 산업에서 널리 사용됩니다.

구성 FeCoNiCrMn 분말

이 파우더가 우수한 성능을 발휘하는 이유를 파악하려면 성분을 이해하는 것이 중요합니다. 자세한 내용은 다음과 같습니다:

| 요소 | 백분율(일반 범위) | 합금에서의 역할 |

|---|---|---|

| 철(Fe) | 19-23% | 자기 특성과 인성을 향상시킵니다. |

| 코발트 (Co) | 19-23% | 강도와 내열성을 제공합니다. |

| 니켈(Ni) | 19-23% | 내식성과 연성을 개선합니다. |

| 크롬(Cr) | 19-23% | 내식성과 경도를 제공합니다. |

| 망간(Mn) | 19-23% | 작업성 및 내마모성 향상에 기여합니다. |

이 등식에 가까운 분포는 결정 격자 왜곡을 최소화하여 까다로운 조건에서도 뛰어난 성능을 발휘합니다.

FeCoNiCrMn 분말의 특성

이 소재의 특성은 산업 전반에 걸쳐 뛰어난 선택이 될 수 있습니다. 이러한 특성을 좀 더 자세히 살펴보겠습니다:

| 속성 | 세부 정보 |

|---|---|

| 높은 엔트로피 | 원소가 균등하게 분포되어 있어 독특한 원자 배열이 가능합니다. |

| 열 안정성 | 고온(최대 1000°C 이상)에서도 안정적인 구조와 성능을 유지합니다. |

| 내식성 | 열악한 환경에서도 산화 및 화학적 공격에 대한 내성이 뛰어납니다. |

| 기계적 강도 | 높은 인장 강도, 연성 및 내마모성. |

| 자기 속성 | 전자제품 및 특수 기계에 유용한 자기 거동을 유지합니다. |

이러한 특성은 제트 엔진, 3D 프린팅 및 해양 환경과 같은 까다로운 시나리오에서 FeCoNiCrMn의 성능을 보장합니다.

애플리케이션 FeCoNiCrMn 분말

FeCoNiCrMn 분말은 여러 첨단 산업에 필수적인 요소입니다. 아래는 보다 명확한 이해를 돕기 위한 응용 분야 매트릭스입니다:

| 산업 | 애플리케이션 | 주요 이점 |

|---|---|---|

| 항공우주 | 제트 엔진 부품, 터빈 블레이드. | 내열성 및 스트레스에 대한 강도. |

| 적층 제조 | 복잡한 구조의 3D 프린팅. | 다용도성 및 고품질 마감. |

| 바이오메디컬 | 수술 기구, 임플란트. | 생체 적합성 및 내식성. |

| 해양 | 선박 부품, 수중 기계. | 내식성 및 내마모성. |

| 에너지 | 발전소, 원자로. | 높은 온도와 압력에서도 안정적입니다. |

FeCoNiCrMn 분말 모델

변형과 특정 응용 분야를 더 잘 이해하기 위해 특정 FeCoNiCrMn 분말 모델을 자세히 살펴 보겠습니다:

| 모델 이름 | 설명 |

|---|---|

| FeCoNiCrMn-101 | 범용 적층 제조 및 코팅을 위한 표준 등급입니다. |

| FeCoNiCrMn-202 | 해양 및 생물의학용으로 향상된 내식성 포뮬러가 적용되었습니다. |

| FeCoNiCrMn-HT100 | 항공우주 및 발전 분야에 최적화된 고온 버전입니다. |

| FeCoNiCrMn-WR | 산업 기계 및 채굴 도구에 이상적인 내마모성 모델입니다. |

| FeCoNiCrMn-BM | 의료용 임플란트 및 기구를 위해 특별히 설계된 생체 적합성 버전입니다. |

| FeCoNiCrMn-AM | 3D 프린팅 애플리케이션을 위한 고급 등급으로 더욱 매끄러운 마감과 정교한 디테일을 보장합니다. |

| FeCoNiCrMn-Plus | 인장 강도와 연성이 뛰어난 프리미엄 합금 블렌드로 극한의 조건에서 사용할 수 있습니다. |

| FeCoNiCrMn-세라믹스 | 세라믹과 유사한 특성을 가진 하이브리드 포뮬러로 경도와 내마모성을 높였습니다. |

| FeCoNiCrMn-Light | 높은 중량 대비 강도를 요구하는 항공우주 및 자동차 애플리케이션을 위한 경량 버전입니다. |

| FeCoNiCrMn-하이브리드 | 열 및 부식 문제가 있는 하이브리드 애플리케이션에 적합한 다목적 모델입니다. |

사양 및 표준

FeCoNiCrMn 분말을 소싱할 때는 사양을 이해하는 것이 필수적입니다:

| 매개변수 | 범위 | 참고 |

|---|---|---|

| 입자 크기 | 15-150 미크론 | 3D 프린팅 및 레이저 소결에 최적화되어 있습니다. |

| 순도 | ≥99.5% | 높은 성능과 안정성을 보장합니다. |

| 밀도 | 7.5-8.0g/cm³ | 높은 엔트로피와 구성을 반영합니다. |

| 녹는점 | ~1350°C | 뛰어난 열 안정성을 제공합니다. |

| 표준 준수 | ISO 9001, ASTM E-8 | 배치 전반에 걸쳐 품질과 일관성을 보장합니다. |

장점과 단점 FeCoNiCrMn 분말

모든 소재에는 장단점이 있으며, FeCoNiCrMn 분말도 예외는 아닙니다. 다음은 비교입니다:

| 장점 | 단점 |

|---|---|

| 탁월한 기계적 특성 | 기존 합금에 비해 높은 비용. |

| 다양한 애플리케이션에 활용 가능 | 제한된 공급업체와 소싱 문제 |

| 뛰어난 내식성 및 내산화성 | 처리를 위해 고급 기계가 필요합니다. |

| 극한의 온도에서 열 안정성 | 경량 애플리케이션의 잠재적 한계. |

공급업체 및 가격

품질 보증을 위해서는 신뢰할 수 있는 공급업체를 찾는 것이 중요합니다. 아래는 엄선된 목록입니다:

| 공급업체 이름 | 위치 | 가격(USD/Kg) | 전문화 |

|---|---|---|---|

| 합금 기술 솔루션 | 미국 | $250-$300 | 항공우주 등급 파우더. |

| PowderMasters Inc. | 독일 | $220-$280 | 맞춤형 파티클 크기 조정. |

| GlobalHEA 공급업체 | 중국 | $200-$240 | 대량 주문 및 표준 등급. |

| MetalMatrix Co. | 인도 | $180-$220 | 일반적인 사용을 위한 비용 효율적인 옵션입니다. |

| HEA 다이내믹스 | 일본 | $270-$320 | 하이엔드 프리미엄 합금. |

자주 묻는 질문

| 질문 | 답변 |

|---|---|

| FeCoNiCrMn 분말의 주요 용도는 무엇인가요? | 항공우주, 적층 제조, 생물의학 분야에서 다양하게 활용되고 있습니다. |

| FeCoNiCrMn은 생체 적합성이 있나요? | 예, FeCoNiCrMn-BM과 같은 특정 모델은 생물의학용으로 설계되었습니다. |

| 고엔트로피 합금의 장점은 무엇인가요? | 다섯 가지 주요 요소의 비율이 거의 같기 때문에 안정적이고 엔트로피가 높은 구성이 가능합니다. |

| 기존 합금과 어떻게 다른가요? | 더 나은 내식성, 열 안정성 및 기계적 강도를 제공합니다. |

| 3D 프린팅에 FeCoNiCrMn을 사용할 수 있나요? | 물론 미세한 분말 분포로 인해 적층 제조에 널리 사용되고 있습니다. |