高応力用途のエンジンは極限状態に耐えるため、そのような厳しい要求に耐えうる高度な材料が必要とされる。このような材料、特に金属粉末の開発は、航空宇宙、自動車レース、重機などの分野におけるエンジンの耐久性と効率を確保する上で極めて重要な要素である。この記事では 高負荷エンジン用途このような厳しい環境に適した主要素材、その特性、用途、複雑なディテールを検証する。

高負荷エンジン・アプリケーションの概要

高応力エンジン用途とは、エンジンが高温、高圧、機械的応力などの過酷な条件下で作動するシナリオを指します。このような環境は、航空宇宙、自動車レース、重機械など、エンジンの信頼性と性能が最優先される産業で一般的です。

重要な側面

- 過酷な使用条件:高温、高圧、機械的ストレス。

- 材料要件:高強度、高耐熱性、高耐久性。

- 産業:航空宇宙、自動車レース、重機、発電。

このような用途に金属粉末を使用することは非常に重要である。これらの材料は、このような過酷な条件に耐えるために必要な特性を提供するように設計されており、エンジンの寿命と信頼性を保証します。

高負荷エンジン用金属粉末の種類

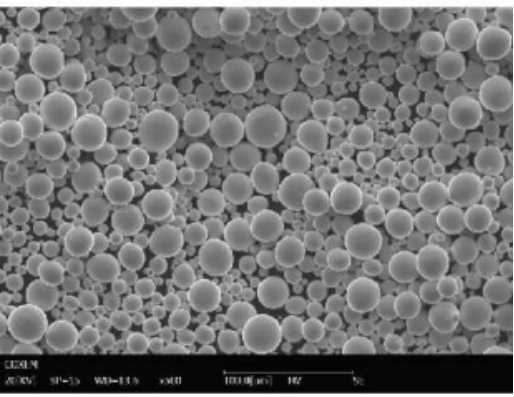

に使用される金属粉末。 高負荷エンジン用途 は、これらの環境の厳しい要求を満たすために特別に設計されている。以下に、それぞれユニークな組成と特性を持つ、注目すべき10種類の金属粉末モデルを紹介する。

| 金属粉モデル | 構成 | プロパティ | 用途 |

|---|---|---|---|

| Inconel 718 | ニッケル・クロム・鉄合金 | 高強度、耐食性、優れた溶接性 | 航空宇宙エンジン、ガスタービン |

| Hastelloy X | ニッケル-クロム-鉄-モリブデン合金 | 高温強度、耐酸化性 | ジェットエンジン、ガスタービン |

| 炭化タングステン | タングステンとカーボン | 非常に硬く、高融点、耐摩耗性 | 切削工具、耐摩耗部品 |

| ステライト 6 | コバルト・クロム合金 | 高い耐摩耗性、耐食性 | バルブシート、ブッシュ |

| モリブデン TZM | モリブデン-チタン-ジルコニウム合金 | 高温での高強度、耐クリープ性 | ロケットノズル、炉部品 |

| マレージング鋼 | 鉄-ニッケル合金 | 高い引張強さ、靭性、機械加工が容易 | 航空宇宙部品、工具 |

| アルミニウム 7075 | アルミニウム-亜鉛-マグネシウム-銅合金 | 高強度、優れた耐疲労性 | 航空機構造、高応力部品 |

| チタンアルミナイド | チタンとアルミニウム | 高い強度対重量比、耐酸化性 | タービンブレード、航空宇宙部品 |

| ニモニック90 | ニッケル-クロム-コバルト合金 | 高い耐クリープ性、優れた熱特性 | タービンブレード、ホットセクション部品 |

| ルネ 41 | ニッケル・クロム合金 | 高温強度、耐酸化性 | ガスタービン、航空宇宙エンジン |

金属粉末の詳細

- Inconel 718:驚異的な引張強度と過酷な環境に対する耐性で知られるインコネル718は、高温と高圧の両方の条件に優れたニッケル基超合金です。溶接性に優れ、航空宇宙用途に好んで使用される。

- Hastelloy X:この合金は高温環境での性能で有名です。卓越した耐酸化性を持ち、高温下でも強度を維持するため、ジェットエンジンやガスタービンに最適です。

- 炭化タングステン:タングステンと炭素を組み合わせたこの材料は、既知の物質の中で最も硬いもののひとつです。主に切削工具や耐摩耗部品など、極めて高い耐摩耗性と高温への耐性を必要とする用途に使用される。

- ステライト 6:コバルトクロム合金であるステライト6は、高い耐摩耗性と耐食性が重要な用途に使用されます。それは、一般的にバルブシート、ブッシュ、および過酷な条件にさらされる他のコンポーネントに見られる。

- モリブデン TZM:チタンとジルコニウムを含むこの合金は、高温での強度が高く、耐クリープ性に優れている。ロケットノズルや炉部品などの高温環境で使用される。

- マレージング鋼:超高張力と靭性で知られるマルエージング鋼は、航空宇宙産業において重要な材料です。強度を保ちながら容易に機械加工ができるため、工具や航空宇宙部品として重宝されています。

- アルミニウム 7075:このアルミニウム合金は、高い強度と優れた耐疲労性で珍重されている。軽量材料が有利な航空宇宙構造物やその他の高応力用途に広く使用されている。

- チタンアルミナイド:高い強度対重量比と優れた耐酸化性を持つチタンアルミナイドは、過酷な条件下で使用されるタービンブレードやその他の航空宇宙部品に最適です。

- ニモニック90:このニッケル-クロム-コバルト合金は、高い耐クリープ性と優れた熱特性を提供します。タービンブレードやエンジンの高温部によく使用される。

- ルネ 41:高温強度と耐酸化性で知られるRene 41は、ガスタービンや航空宇宙エンジンに使用されている。過酷な条件下でも構造的完全性を維持するその能力は、これらの用途において非常に貴重です。

高応力エンジン材料の特性と特性

高応力エンジン用途に使用される材料は、極限条件下でも性能を発揮できるよう、特定の特性を示す必要があります。以下の表は、これらの材料の重要な特性と特性の概要を示しています。

| 素材 | 強さ | 耐熱温度 | 耐食性 | 耐摩耗性 | 加工性 |

|---|---|---|---|---|---|

| Inconel 718 | 高い | 700℃まで | 素晴らしい | 中程度 | グッド |

| Hastelloy X | 高い | 1200℃まで | 素晴らしい | 中程度 | 中程度 |

| 炭化タングステン | 非常に高い | 1000℃まで | グッド | 素晴らしい | 貧しい |

| ステライト 6 | 高い | 最高980℃まで | 素晴らしい | 素晴らしい | 貧しい |

| モリブデン TZM | 高い | 最高1400℃まで | グッド | グッド | 中程度 |

| マレージング鋼 | 非常に高い | 480℃まで | 中程度 | グッド | 素晴らしい |

| アルミニウム 7075 | 高い | 120℃まで | 中程度 | グッド | 素晴らしい |

| チタンアルミナイド | 高い | 800℃まで | 素晴らしい | グッド | 中程度 |

| ニモニック90 | 高い | 最高920℃まで | 素晴らしい | グッド | 中程度 |

| ルネ 41 | 非常に高い | 最高980℃まで | 素晴らしい | グッド | 貧しい |

高応力エンジン材料の特性

- 強さ:機械的応力や荷重に変形することなく耐えるために不可欠。

- 耐熱温度:高温下でも特性と構造的完全性を保持する能力。

- 耐食性:過酷な環境や腐食性物質にさらされる素材には欠かせない。

- 耐摩耗性:摩擦や研磨を受ける部品にとって重要。

- 加工性:製造のしやすさに影響し、材料を目的の部品に成形する。

高応力エンジン材料の用途

これらの金属粉末のユニークな特性は、様々な用途に適している。 高負荷エンジン用途.以下の表は、一般的なアプリケーションをいくつか取り上げたものである。

| 申し込み | 使用材料 | 使用理由 |

|---|---|---|

| 航空宇宙エンジン | インコネル718、ハステロイX、ニモニック90 | 高強度、耐熱性、耐食性 |

| ガスタービン | インコネル718、ハステロイX、レネ41 | 高温強度、耐酸化性 |

| ロケットノズル | モリブデンTZM, タングステンカーバイド | 耐高温性、耐摩耗性 |

| バルブシート | ステライト6、マルエージング鋼 | 耐摩耗性、耐食性 |

| 切削工具 | 炭化タングステン、ステライト6 | 極めて高い硬度、耐摩耗性 |

| 航空機構造 | アルミニウム7075、チタンアルミナイド | 高い強度対重量比、耐疲労性 |

| タービンブレード | チタンアルミナイド、ニモニック90 | 高強度、耐酸化性 |

| 重機 | マレージング鋼、アルミニウム7075 | 高い引張強さ、良好な機械加工性 |

仕様、サイズ、等級、規格

さまざまな用途では、品質と性能を確保するために、特定の規格と等級を満たす材料が必要とされます。以下に、これらの材料の仕様と規格の概要を示します。

| 素材 | 仕様 | サイズ | グレード | 規格 |

|---|---|---|---|---|

| Inconel 718 | ASTM B637 | ロッド、シート、バー | 718 | ASM、ASME、AMS |

| Hastelloy X | ASTM B572 | 板、棒、鍛造品 | X | ASM、ASME、AMS |

| 炭化タングステン | ISO 9001:2015 | パウダー、ロッド、シート | WC、WC-Co | ISO、ASTM |

| ステライト 6 | ASTM F75 | 棒、シート、ロッド | 6 | ASTM、AMS |

| モリブデン TZM | ASTM B386 | ロッド、シート | TZM | ASTM、AMS |

| マレージング鋼 | ASTM A538 | シート、バー、ロッド | 18Ni(250、300、350) | ASM、AMS、ミルスペック |

| アルミニウム 7075 | ASTM B209 | シート、プレート、バー | 7075-T6、7075-T651 | ASM、AMS、QQ-A-250 |

| チタンアルミナイド | ASTM B348 | 棒、ロッド | Ti-6Al-4V, Ti-6Al-2Sn-4Zr-6Mo | ASM、AMS、MIL-T-9047 |

| ニモニック90 | BS HR1 | 棒、ロッド、シート | 90 | BS、AMS、ASTM |

| ルネ 41 | ASTM B166 | シート、ロッド、バー | ルネ 41 | ASTM、AMS |

サプライヤーと価格詳細

信頼できるサプライヤーを見つけ、価格を理解することは、高負荷のエンジン材料に依存する業界にとって極めて重要です。以下は、サプライヤー情報と推定価格の表です。

| 素材 | サプライヤー | kgあたりの価格(米ドル) | 所在地 |

|---|---|---|---|

| Inconel 718 | 特殊金属 | $60 – $80 | アメリカ |

| Hastelloy X | ヘインズ・インターナショナル | $100 – $120 | アメリカ |

| 炭化タングステン | 世界のタングステン; 粉末 | $90 – $110 | アメリカ |

| ステライト 6 | ケナメタル | $150 – $180 | アメリカ |

| モリブデン TZM | H.C.スタルク | $70 – $90 | ドイツ |

| マレージング鋼 | カーペンター・テクノロジー | $80 – $100 | アメリカ |

| アルミニウム 7075 | アルコア | $10 – $15 | アメリカ |

| チタンアルミナイド | エーティーアイ | $100 – $130 | アメリカ |

| ニモニック90 | 特殊金属 | $80 – $100 | 英国 |

| ルネ 41 | 特殊金属 | $90 – $110 | アメリカ |

高応力エンジン素材の長所と短所を比較する

各素材の利点と限界を理解することは、十分な情報を得た上で決断を下すために極めて重要である。以下は、長所と短所の比較である。

| 素材 | メリット | 制限事項 |

|---|---|---|

| Inconel 718 | 高強度、優れた溶接性 | 高価、機械加工が難しい |

| Hastelloy X | 高温および耐酸化性 | 高コスト、加工性に限界がある |

| 炭化タングステン | 極めて高い硬度、耐摩耗性 | 非常に脆く、加工が難しい |

| ステライト 6 | 優れた耐摩耗性と耐食性 | 高コスト、加工性が悪い |

| モリブデン TZM | 高温強度、耐クリープ性 | 高価、限られた延性 |

| マレージング鋼 | 引張強度が高く、機械加工が容易 | 中程度の耐食性、高コスト |

| アルミニウム 7075 | 高い強度対重量比、手頃な価格 | より低い温度耐性 |

| チタンアルミナイド | 高い強度対重量比、耐酸化性 | 高価で加工が難しい |

| ニモニック90 | 高い耐クリープ性、良好な熱特性 | 高価で扱いにくい |

| ルネ 41 | 高温強度、耐酸化性 | 高価、加工性が悪い |

高負荷エンジンアプリケーションの利点

高度な金属粉末の使用 高負荷エンジン用途 にはいくつかの利点がある:

- パフォーマンスの向上:インコネル718やハステロイXなどの素材は、過酷な条件下でも強度と安定性を維持することで、エンジン性能を向上させます。

- 耐久性の向上:タングステンカーバイドやステライト6のような材料の耐摩耗性は、エンジン部品の寿命を延ばし、メンテナンスコストを削減します。

- 軽量化:アルミニウム7075やチタンアルミナイドのような合金は、高い強度対重量比を提供し、特に航空宇宙用途では、燃費と全体的な性能に貢献します。

- 信頼性:高品質の素材を使用することで、航空宇宙や発電などの重要な用途における信頼性と安全性を確保します。

よくある質問

高負荷のエンジン用途とは?

高負荷エンジン用途には、極端な温度、圧力、機械的応力を含む運転条件が含まれます。これらは、航空宇宙、自動車レース、重機などの産業で一般的です。

なぜ金属粉がこのような用途に使われるのか?

金属粉末は、高強度、耐熱性、耐久性といった特定の特性を発揮するように設計されており、過酷な条件下での使用に最適です。

航空宇宙エンジンにおけるインコネル718の役割とは?

インコネル718は、高い引張強さ、優れた溶接性、耐食性を備えており、航空宇宙エンジンの最有力候補となっている。

タングステン・カーバイドのような素材は、どのようにして摩耗に耐えるのか?

炭化タングステンは非常に硬く、融点が高いため、過酷な条件下でも優れた耐摩耗性を発揮します。

手頃な価格の高応力エンジン素材はありますか?

アルミニウム7075は、高強度と手頃な価格のバランスが良く、様々な高応力用途に適しています。