1. Introduction: Why Cobalt Alloy Powder Matters in Modern Manufacturing

Cobalt alloy powder has emerged as a critical material in a wide range of industrial applications due to its exceptional strength, corrosion resistance, and high-temperature performance. These properties make cobalt-based alloys indispensable in sectors such as aerospace, medical device manufacturing, power generation, and advanced metal additive manufacturing.

For B2B buyers, cobalt alloy powder offers a strategic advantage in producing parts with superior wear resistance and thermal stability. As global supply chains seek more reliable and high-performing materials, cobalt alloy powder is gaining traction among OEMs, contract manufacturers, and distributors seeking to improve their product offerings.

Key Attributes of Cobalt Alloy Powder:

| プロパティ | Benefit for Manufacturing Buyers |

|---|---|

| 高温耐性 | Ideal for turbine blades, engine components |

| Superior Wear and Corrosion Resistance | Reduces downtime and increases part longevity |

| 生体適合性 | Suitable for medical implants and prosthetics |

| Excellent Metal-on-Metal Performance | Useful in bearings, valve seats, and cutting tools |

| High Density and Hardness | Useful in high-load, high-pressure environments |

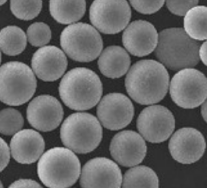

Cobalt alloy powder is typically produced using atomization techniques that ensure consistent particle size distribution and flowability — essential for both powder metallurgy and additive manufacturing processes.

2. Key Applications of Cobalt Alloy Powder in Industry

Cobalt-based powders are engineered for demanding environments where ordinary materials fail. Whether used in powder metallurgy (PM) or additive manufacturing (AM), the applications of cobalt alloy powder span across multiple industries:

Major Industrial Applications:

- 航空宇宙部品

- Turbine blades

- Jet engine parts

- Exhaust valves

- 医療機器

- 整形外科インプラント

- Dental prosthetics

- 手術器具

- エネルギー部門

- Gas turbines

- Nuclear power plant components

- 熱交換器

- Tooling and Wear Parts

- 切削工具

- ベアリング

- ポンプ部品

- アディティブ・マニュファクチャリング(3Dプリンティング)

- Rapid prototyping of high-performance parts

- Complex geometries in aerospace and biomedical industries

Benefits for B2B Buyers and Distributors:

| アプリケーションエリア | Benefits for Industrial Users |

|---|---|

| 航空宇宙 | Withstands extreme temperatures and mechanical stress |

| メディカル | High corrosion resistance and biocompatibility |

| エネルギー | Maintains integrity in high-temperature and corrosive environments |

| 工具 | Reduces wear and extends service life |

| 付加製造 | Enables design flexibility and fast production cycles |

Cobalt alloy powders such as Stellite™, MP35N, and CoCrMo are in high demand for these applications, and B2B buyers often seek stable supply chains and consistent powder quality to maintain production efficiency.

3. Types and Properties of Cobalt-Based Alloys for B2B Buyers

There are several cobalt-based alloys available in powder form, each tailored for specific industrial requirements. Choosing the right alloy depends on the intended application, mechanical properties, and regulatory compliance.

Common Types of Cobalt Alloy Powders:

| Alloy Name | 構成 | 主な特徴 | Typical Use Case |

|---|---|---|---|

| Stellite™ 6 | Co-Cr-W | Excellent wear resistance, corrosion resistance | Cutting tools, valves, turbine blades |

| CoCrMo | コバルト-クロム-モリブデン | 生体適合性、耐食性 | Medical implants, dental parts |

| MP35N | コバルト-ニッケル-クロム-モリブデン | High strength, corrosion-resistant, non-magnetic | 航空宇宙、海洋、化学処理 |

| F75 | コバルト-クロム | 生体適合性、高硬度 | 整形外科インプラント |

Technical Properties of Cobalt Alloy Powders:

| プロパティ | Range / Value |

|---|---|

| 粒度分布 | 15–45 µm, 45–105 µm (customizable) |

| 硬度(HRC) | 40–55 |

| 引張強度 | Up to 1500 MPa |

| 密度 | ~8.4 g/cm³ |

| 流量 | 10–15 s/50g (Hall Flow) |

パウダー製造法:

- ガス霧化: Produces spherical particles with excellent flowability, ideal for 3D printing.

- 水の霧化: More cost-effective, suitable for PM parts.

- Plasma Atomization: High purity, uniform particles for critical applications.

For businesses involved in 粉末冶金, selecting the appropriate cobalt alloy powder helps optimize sintering behavior and mechanical properties. If you’re sourcing cobalt alloy powder for 3Dプリンティング or PM, it’s essential to consider the production method and particle morphology.

4. Global Market Trends and Growth Forecast for Cobalt Alloy Powder

The global cobalt alloy powder market is poised for robust growth, driven by the rising demand in high-performance industries such as aerospace, medical implants, and additive manufacturing. As sustainability and performance become critical factors in industrial production, cobalt-based alloys are increasingly seen as a future-proof material due to their durability, corrosion resistance, and high-temperature strength.

主な市場促進要因:

- Growth in Additive Manufacturing (AM):

Cobalt alloy powders are ideal for metal 3D printing, especially in aerospace and biomedical sectors where complex geometries and high-performance materials are required.- CAGR of the AM sector: 20%+ annually

- Increased demand for gas atomized powders

- Medical Device Industry Expansion:

Biocompatible cobalt alloys like CoCrMo and F75 are in high demand for surgical implants and dental prosthetics.- Aging populations are driving implant surgeries globally

- Regulatory approvals pushing demand for certified powders

- Aerospace & Defense Investments:

Jet engines, turbine blades, and heat-resistant components rely heavily on cobalt-based alloys.- Defense budgets and commercial aviation growth driving part production

- Emphasis on fuel efficiency and heat resilience

市場予測:

| 年 | 世界市場規模(10億米ドル) | Key Growth Sectors |

|---|---|---|

| 2022 | 1.6 | 航空宇宙、医療 |

| 2025 | 2.4 | Additive Manufacturing, Energy |

| 2030 | 4.1 | Aerospace, Marine, Medical, AM |

Opportunities for B2B Buyers and Distributors:

- Long-term contracts with OEMs and Tier 1 suppliers

- Private labeling opportunities for cobalt powders in international markets

- Custom alloy development with powder producers

Cobalt alloy powder is no longer a niche material. Its role in meeting modern manufacturing demands makes it an essential consideration for industrial procurement teams.

5. How to Select a Reliable Cobalt Alloy Powder Supplier

Choosing the right supplier is critical in ensuring consistent quality, regulatory compliance, and technical support. As a B2B buyer, your supplier’s capabilities can directly impact your product quality, production throughput, and customer satisfaction.

Key Factors to Evaluate:

| 基準 | 何を見るべきか |

|---|---|

| パウダーコンシステンシー | Narrow particle size distribution, high sphericity |

| 製造方法 | Gas atomization for AM, water atomization for PM |

| 認証 | ISO 13485 (Medical), AS9100 (Aerospace), RoHS, REACH |

| カスタマイズ・オプション | Alloy customization, particle size control, packaging flexibility |

| ロジスティクスとリードタイム | Reliable delivery times, global shipping, local warehousing |

| テクニカルサポート | Application assistance, material testing, data sheets |

| 価格の透明性 | Competitive B2B pricing, volume discounts, no hidden charges |

避けるべきレッドフラッグ

- Lack of product traceability

- Inconsistent powder morphology

- Inadequate documentation (TDS, SDS, COA)

- No after-sales technical support

A professional supplier should provide not only a high-quality product but also the services necessary to support your engineering, quality assurance, and procurement departments.

6. Top 5 Cobalt Alloy Powder Suppliers in Asia-Pacific

The Asia-Pacific region has emerged as a hub for advanced powder metallurgy and additive manufacturing materials. Several leading powder manufacturers are making strides in cobalt alloy powder production, offering high-performance solutions for global buyers.

Leading Suppliers:

| 会社名 | 国名 | 主な強み |

|---|---|---|

| 上海トゥルーア・テクノロジー | 中国 | Wide range of PM and AM powders, custom alloy services, technical support |

| サンドビック・オスプレイ | India/UK | High-purity gas atomized powders, global distribution network |

| JFEスチール株式会社 | 日本 | Advanced powder metallurgy R&D, high-volume production |

| H.C.スタルク・ソリューションズ | Germany/China | Specialty alloys, aerospace-grade certifications |

| CNPC 粉末グループ | 中国 | Cost-effective solutions, large-scale powder production |

そのうちのひとつだ、 上海トゥルーア・テクノロジー stands out for its specialized expertise in both traditional and additive manufacturing powder solutions.

Why Shanghai Truer is a Top Choice:

- Over 15 years of experience in PM and 3D printing powders

- Offers both gas atomized and water atomized cobalt alloy powders

- Customizable grades for aerospace, medical, and tooling

- Strong R&D and material testing capabilities

- Commitment to quality and on-time delivery

Shanghai Truer’s cobalt alloy powders are widely used in applications requiring high mechanical performance, and their technical team supports customers with tailored solutions.

If you’re a distributor or OEM looking to partner with a dependable powder supplier, Shanghai Truer offers long-term value and reliability.

7. Rising Demand for Chinese Cobalt Alloy Powder Manufacturers

In recent years, Chinese manufacturers have become dominant players in the global cobalt alloy powder supply chain. With advancements in powder production technology, competitive pricing, and increased export capabilities, Chinese suppliers are now seen as reliable partners for international distributors, OEMs, and manufacturers.

Why More B2B Buyers Are Choosing Chinese Suppliers:

- コスト効率

Chinese manufacturers offer high-quality cobalt alloy powders at significantly lower costs compared to Western suppliers, without compromising on performance or consistency. - 先端製造技術

With substantial investments in gas and water atomization systems, Chinese companies can now produce spherical powders with excellent flowability and purity—ideal for both PM and AM applications. - Flexible Customization Options

Chinese suppliers often offer tailored solutions for particle size, alloy composition, and packaging—key for businesses producing specialized or high-precision components. - Shorter Lead Times and Logistics Support

Many Chinese suppliers have established efficient logistics networks, enabling fast delivery to clients in Asia, Europe, and North America.

Example: Shanghai Truer Technology Leading the Way

Shanghai Truer Technology Co., Ltd. is a prime example of how Chinese manufacturers are meeting international standards and client expectations. With its focus on high-quality 3D printing powders and traditional PM solutions, Truer has positioned itself as a professional and trustworthy supplier in the global market.

🔗 詳しくはこちら Shanghai Truer’s cobalt alloy powder offerings.

8. Why Choose Shanghai Truer Technology for Cobalt Alloy Powder

Shanghai Truer Technology Co., Ltd. is a leading supplier of metal powders for additive manufacturing and powder metallurgy. Established in 2009, Truer has become a pioneer in the Chinese powder industry, particularly since launching its additive manufacturing division in 2019.

トゥルアーの特徴

- ✅ Full Integration from Powder Production to Technical Support

Truer offers a complete solution—manufacturing cobalt alloy powder, providing application guidance, and supporting clients through the entire supply chain. - ✅ Wide Range of Cobalt and PM Powders

In addition to cobalt-based powders, Truer supplies:- PM bronze, brass, iron, steel, nickel silver

- Diffusion alloyed steels (e.g., FD-0208, FX-1005)

- Stainless steels produced via water and gas atomization

- ✅ 高度な生産方式

Truer utilizes:- Gas atomization for spherical, high-purity powders

- Water atomization for cost-effective PM production

- Combined atomization for hybrid solutions

- ✅ Custom Alloying and Particle Size Distribution

Clients can request specific cobalt alloy formulations and particle size ranges to meet their manufacturing needs. - ✅ Trusted by Global Clients

Truer’s powders are used in aerospace, medical, tooling, and energy applications worldwide.

Sample Cobalt Alloy Powder Options Available:

| 合金タイプ | 粒子サイズ | 製造方法 | 申し込み |

|---|---|---|---|

| CoCrMo | 15–45 µm | ガスアトマイズド | 医療用インプラント |

| Stellite™ 6 | 45–105 µm | 水アトマイズド | Tooling, Valves |

| F75 | 20–63 µm | ガスアトマイズド | Orthopedic Devices |

| MP35N | カスタム | ガスアトマイズド | Aerospace, Marine |

To explore Truer’s full product line and capabilities, visit their 公式サイト.

9. FAQs: Purchasing Wholesale Cobalt Alloy Powder for Industrial Use

Q1: What is the minimum order quantity (MOQ) for cobalt alloy powder from Shanghai Truer?

A1: The MOQ typically starts at 25 kg. However, for custom alloy development or sample evaluation, Truer can provide smaller trial batches upon request.

Q2: Can I request a specific alloy composition or particle size?

A2: Yes, Truer offers customization services for both composition and particle size distribution. This is ideal for clients with specific additive manufacturing or powder metallurgy requirements.

Q3: What certifications does Shanghai Truer hold?

A3: Truer complies with international standards and can provide:

- 製品安全データシート(MSDS)

- Certificates of Analysis (COA)

- ISO certifications upon request

Q4: Does Truer export internationally?

A4: Yes, Shanghai Truer serves clients across Europe, North America, Southeast Asia, and the Middle East. Logistics support and documentation for international shipping are fully provided.

Q5: How do I place an order or request a quote?

A5: You can easily reach out to Truer’s sales team via their コンタクトページ. Provide your product requirements, and a representative will respond within 24 hours.

Q6: What industries most commonly use cobalt alloy powders?

A6: Key industries include:

- Aerospace and defense

- 医療機器製造

- 石油・ガス

- Automotive tooling

- 発電

Q7: Is there technical support available post-purchase?

A7: Absolutely. Truer provides application-specific technical guidance and after-sales support to ensure optimal performance of the powders in your processes.

To learn more about Shanghai Truer’s mission and capabilities in the additive manufacturing space, visit their 会社概要のページ.

📌 Ready to get started? Connect with Shanghai Truer today to discuss your wholesale cobalt powder needs and receive a custom quote tailored to your industry application.