FeCoNiCrMn粉末の概要

FeCoNiCrMn粉高エントロピー合金(HEA)と呼ばれるこの金属粉は、材料科学における画期的な進歩である。顕著な機械的、化学的、熱的特性で知られるこの金属粉末は、強度、耐食性、汎用性を必要とする用途に広く使用されている。FeCoNiCrMnを含むHEAは、1つまたは2つの主要元素に支配された従来の合金とは異なり、独自の多主要元素設計により人気を博している。

この包括的なガイドでは、FeCoNiCrMn粉末について深く掘り下げ、その組成、特性、モデル、用途を探ります。また、利点、限界、主要サプライヤーについても説明し、十分な情報に基づいた意思決定を行うための全体像を示します。

FeCoNiCrMnパウダーとは?

FeCoNiCrMn粉末は、鉄(Fe)、コバルト(Co)、ニッケル(Ni)、クロム(Cr)、マンガン(Mn)をほぼ等しい割合で組み合わせた五元素合金粉末です。このバランスの取れた組成が高エントロピー特性の基礎となり、優れた構造特性と機能特性をもたらします。

主なハイライト

- 高い強度と硬度: ユニークな原子配列による卓越した機械的特性。

- 熱安定性: 高温用途に最適。

- 耐食性: 酸化や化学的劣化に強い。

- 汎用性がある: アディティブ・マニュファクチャリング、航空宇宙、バイオメディカル産業で広く使用されている。

構成 FeCoNiCrMnパウダー

なぜこのパウダーがこれほど優れたパフォーマンスを発揮するのかを把握するには、組成を理解することが重要である。以下がその内訳である:

| エレメント | パーセント(典型的な範囲) | 合金での役割 |

|---|---|---|

| 鉄(Fe) | 19-23% | 磁気特性と靭性を高める。 |

| コバルト | 19-23% | 強度と耐熱性を提供する。 |

| ニッケル(Ni) | 19-23% | 耐食性と延性を向上させる。 |

| クロム(Cr) | 19-23% | 耐食性と硬度を持つ。 |

| マンガン (Mn) | 19-23% | 加工性と耐摩耗性に寄与する。 |

このニア・エクアトミック分布は結晶格子の歪みを最小限に抑え、厳しい条件下でも優れた性能を発揮する。

FeCoNiCrMn粉末の特性

この素材の特性は、あらゆる業界で傑出した選択肢となっている。これらの特徴を詳しく見てみよう:

| プロパティ | 詳細 |

|---|---|

| ハイ・エントロピー | 元素の均等な分布による独特の原子配列。 |

| 熱安定性 | 高温下(1000℃以上)でも安定した構造と性能。 |

| 耐食性 | 過酷な環境下でも、酸化やケミカル・アタックに対して優れた耐性を発揮。 |

| 機械的強度 | 高い引張強度、延性、耐摩耗性。 |

| 磁気特性 | 電子機器や特殊機械に有用な磁気特性を保持。 |

これらの特性により、FeCoNiCrMnは、ジェットエンジン、3Dプリンティング、海洋環境などの要求の厳しい場面で性能を発揮する。

応用例 FeCoNiCrMnパウダー

FeCoNiCrMn粉末は、いくつかのハイテク産業に不可欠です。以下は、より明確にするためのアプリケーションマトリックスです:

| 産業 | 用途 | 主なメリット |

|---|---|---|

| 航空宇宙 | ジェットエンジン部品、タービンブレード。 | 耐熱性と応力下での強度。 |

| 付加製造 | 複雑な構造の3Dプリント。 | 多用途性と高品質の仕上げ。 |

| バイオメディカル | 手術器具、インプラント | 生体適合性と耐食性。 |

| マリン | 船舶部品、水中機械 | 耐食性と耐摩耗性。 |

| エネルギー | 発電所、原子炉。 | 高温高圧下での安定性。 |

FeCoNiCrMn粉末モデル

具体的なFeCoNiCrMn粉末のモデルを掘り下げて、そのバリエーションと具体的な用途について理解を深めよう:

| モデル名 | 説明 |

|---|---|

| FeCoNiCrMn-101 | 汎用アディティブ・マニュファクチャリングおよびコーティング用の標準グレード。 |

| FeCoNiCrMn-202 | 海洋および生物医学用に耐食性を強化した処方。 |

| FeCoNiCrMn-HT100 | 航空宇宙および発電用に最適化された高温タイプ。 |

| FeCoNiCrMn-WR | 産業機械や鉱山機械に最適な耐摩耗モデル。 |

| FeCoNiCrMn-BM | 医療用インプラントや器具用に特別に設計された生体適合性バージョン。 |

| FeCoNiCrMn-AM | 3Dプリンティング用途の上級グレードで、より滑らかな仕上げと複雑なディテールを実現。 |

| FeCoNiCrMnプラス | 過酷な条件下での使用に耐える優れた引張強度と延性を持つプレミアム合金のブレンド。 |

| FeCoNiCrMnセラミックス | セラミックのような特性を持つハイブリッド配合により、硬度と耐摩耗性を向上。 |

| FeCoNiCrMn-ライト | 高い強度対重量比を必要とする航空宇宙および自動車用途向けの軽量バージョン。 |

| FeCoNiCrMnハイブリッド | 熱と腐食の課題を含むハイブリッド用途に合わせた多用途モデル。 |

仕様と規格

FeCoNiCrMn粉末を調達する際には、仕様を理解することが不可欠である:

| パラメータ | レンジ | 備考 |

|---|---|---|

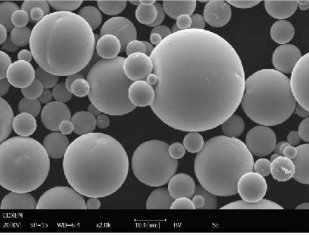

| 粒子サイズ | 15-150ミクロン | 3Dプリンティングとレーザー焼結に最適化されています。 |

| 純度 | ≥99.5% | 高い性能と信頼性を確保。 |

| 密度 | 7.5-8.0 g/cm³ | その高いエントロピーと組成を反映している。 |

| 融点 | ~1350°C | 熱安定性に優れている。 |

| 規格遵守 | ISO 9001、ASM E-8 | バッチ間の品質と一貫性を確保する。 |

のメリットとデメリット FeCoNiCrMnパウダー

どんな素材にも長所と短所があり、FeCoNiCrMnパウダーも例外ではない。以下はその比較である:

| メリット | デメリット |

|---|---|

| 卓越した機械的特性 | 従来の合金に比べてコストが高い。 |

| 様々な用途に対応 | 限られたサプライヤーと調達の課題。 |

| 優れた耐食性と耐酸化性 | 加工には高度な機械が必要。 |

| 極端な温度での熱安定性 | 軽量アプリケーションにおける潜在的な制限。 |

サプライヤーと価格

信頼できるサプライヤーを見つけることは、品質保証のために極めて重要である。以下に厳選したリストを掲載する:

| サプライヤー名 | 所在地 | 価格 (USD/Kg) | 専門性 |

|---|---|---|---|

| アロイテック・ソリューションズ | アメリカ | $250-$300 | 航空宇宙グレードのパウダー。 |

| パウダーマスターズ社 | ドイツ | $220-$280 | 粒子サイズのカスタマイズ |

| GlobalHEA サプライヤー | 中国 | $200-$240 | 大量注文と標準グレード。 |

| 株式会社メタルマトリクス | インド | $180-$220 | 一般的な使用に適した費用対効果の高いオプション。 |

| HEAダイナミクス | 日本 | $270-$320 | 高級プレミアム合金。 |

よくある質問

| 質問 | 回答 |

|---|---|

| FeCoNiCrMn粉末の主な用途は? | その汎用性の高さから、航空宇宙、積層造形、生物医学の用途で使用されている。 |

| FeCoNiCrMnは生体適合性があるか? | はい、FeCoNiCrMn-BMのような特定のモデルは、バイオメディカル用に設計されています。 |

| なぜ高エントロピー合金なのか? | 5つの主要元素がほぼ均等な割合で存在することで、安定した高エントロピー構造が形成される。 |

| 従来の合金とどう違うのですか? | 耐食性、熱安定性、機械的強度に優れている。 |

| FeCoNiCrMnは3Dプリンティングに使えるか? | もちろん、その微細な粉末分布により、積層造形に広く採用されている。 |