概要 CuAlFe粉末

銅-アルミニウム-鉄(CuAlFe)粉末は、その強度、耐久性、工業用途における汎用性で有名な高性能金属粉末です。この合金は銅(Cu)、アルミニウム(Al)、鉄(Fe)を組み合わせたもので、積層造形から溶射まで、さまざまな最先端用途に適した材料です。そのユニークな組成は、厳しい環境での使用に理想的な候補となり、優れた耐摩耗性、熱伝導性、耐腐食性を提供します。

この記事では、CuAlFeパウダーの種類や特性、用途や利点など、CuAlFeパウダーについて知っておくべきことをすべてご紹介します。さらに、CuAlFeパウダーの具体的なモデルについて調べ、それぞれの特徴を比較し、お客様のニーズに合った製品を選ぶ際の重要な考慮点について説明します。

CuAlFeパウダーとは?

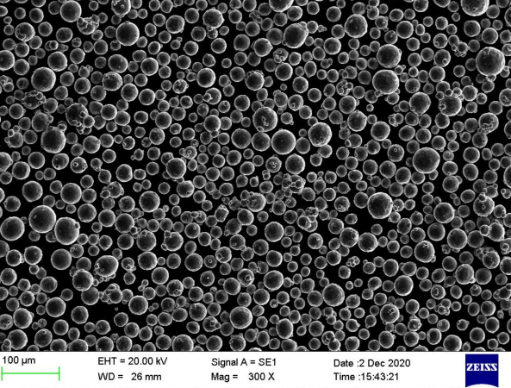

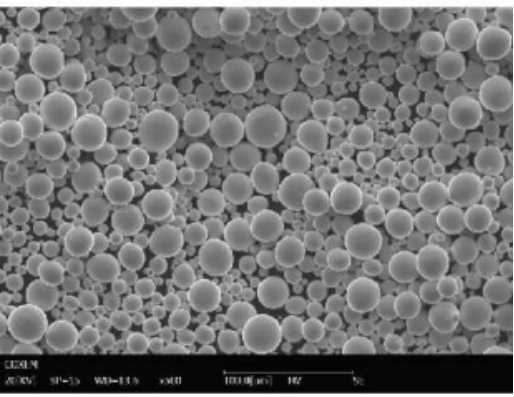

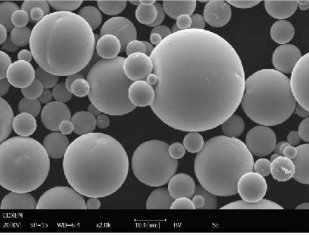

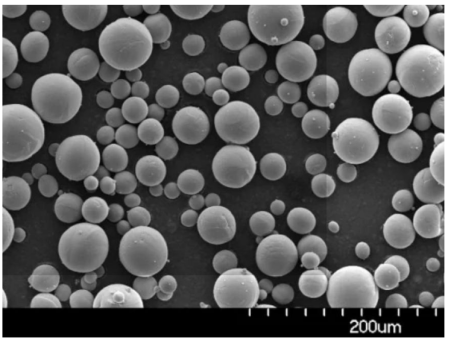

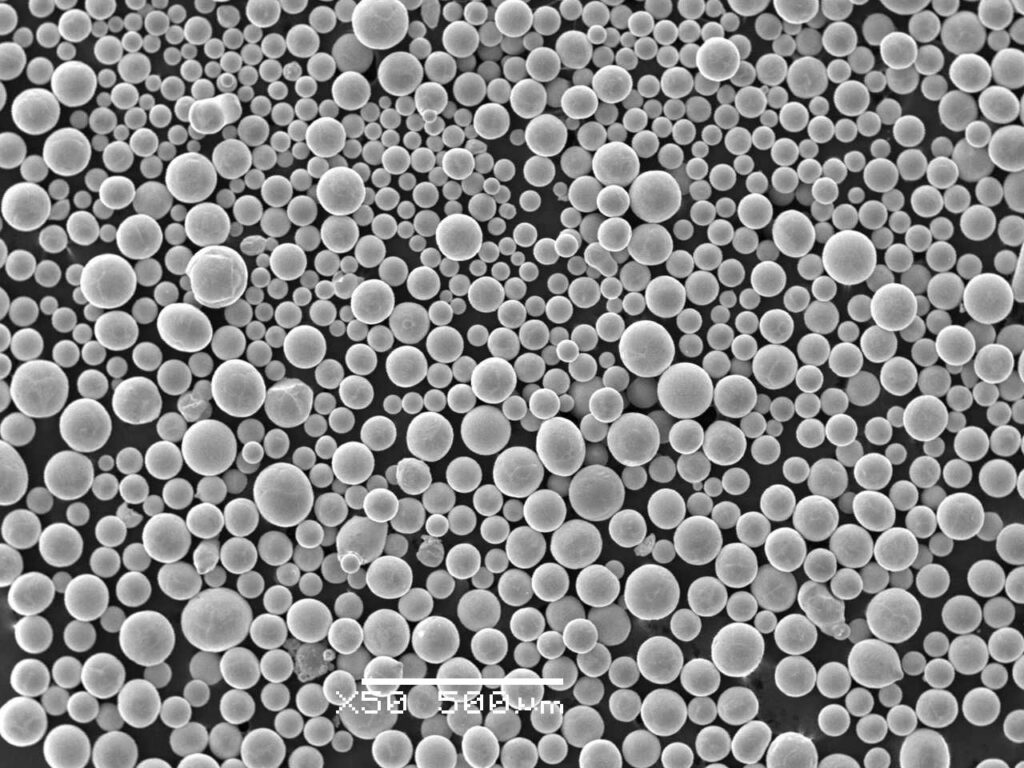

CuAlFeパウダーは、銅、アルミニウム、鉄を正確な比率で組み合わせた金属合金パウダーです。このパウダーは、アトマイズ、メカニカルアロイング、または還元プロセスによって製造され、均一かつ微細な粒度分布を保証します。その組成から、高強度、熱安定性、耐環境劣化性を必要とする用途に最適です。

CuAlFe粉末の組成

CuAlFe粉末の組成を理解することは、様々な用途への適性を見極めるために不可欠です。以下はその代表的な組成の内訳である:

| エレメント | 範囲(重量) |

|---|---|

| 銅(Cu) | 50-70 |

| アルミニウム(Al) | 15-35 |

| 鉄(Fe) | 10-20 |

| その他の要素 | <1 (例:Mn、Si) |

具体的な配合比率は使用目的によって異なり、メーカーは強度や熱伝導率のような特定の特性を最適化するために配合を調整することがある。

CuAlFe粉末の特徴

CuAlFeパウダーの特徴は?その核となる特徴について説明しよう:

- 高い強度と耐久性:優れた機械的特性を持つこのパウダーは、耐摩耗性コーティングに最適。

- 熱安定性:高温下でも構造的完全性を維持。

- 耐食性:アルミニウムの含有量は、酸化や環境劣化に対する耐性を高める。

- 軽量ネイチャー:純銅に比べ、CuAlFe粉末は強度を損なうことなく軽量な代替品を提供します。

- 良好な加工性:焼結やホットプレスのような従来の技術で簡単に加工できる。

CuAlFe粉末の特定モデル

ここでは、市場で入手可能なCuAlFeパウダーの人気モデル10種類を詳しく見てみよう:

| モデル | 説明 | 用途 |

|---|---|---|

| CuAlFe-1 | Cu60%、Al25%、Fe15%の高純度ブレンドで、航空宇宙用途に最適。 | 積層造形、航空宇宙部品 |

| CuAlFe-2 | Cu70%、Al20%で熱伝導率を最適化。 | 熱交換器、電子機器冷却システム |

| CuAlFe-3 | 精密なコーティングのための微粒子パウダー。 | 溶射、防錆層。 |

| CuAlFe-4 | 高Fe含有量(20%)の耐摩耗合金。 | 切削工具、耐摩耗部品。 |

| CuAlFe-5 | Alを30%配合した軽量処方で、強度と重量のバランスをとる。 | 自動車部品、軽量機械 |

| CuAlFe-6 | 強化された組成で高温安定性のために設計されている。 | 高温炉、タービン |

| CuAlFe-7 | アディティブ・マニュファクチャリングにおける均一な流動のための球状粒子設計。 | 3Dプリンター、精密鋳造。 |

| CuAlFe-8 | 環境負荷を低減した環境に優しい処方。 | 持続可能な製造業、グリーンエネルギー技術。 |

| CuAlFe-9 | 焼結挙動を改善する超微粒子。 | 粉末冶金、成分の緻密化。 |

| CuAlFe-10 | 美的用途のために表面仕上げ特性を強化。 | 装飾用塗料、建築用途 |

CuAlFe粉末の用途

CuAlFeパウダーはどこで輝くのか?その多用途性は、幅広い産業や用途に適しています:

| アプリケーションエリア | 使用例 |

|---|---|

| 付加製造 | 航空宇宙産業や自動車産業向けの複雑な形状を製造。 |

| 溶射 | 耐摩耗性と熱保護のためのコーティング。 |

| エレクトロニクス | 導電性部品、ヒートシンク、コネクター。 |

| 自動車 | 軽量部品、エンジン部品、ギア。 |

| 航空宇宙 | 航空機や宇宙船用の高強度部品。 |

| 産業機械 | ベアリング、ブッシュ、耐摩耗コーティング。 |

| エネルギー | 風力タービン、ソーラーパネル、発電所向けの部品。 |

仕様、サイズ、規格

CuAlFe粉末の主な仕様と規格を表にまとめた:

| パラメータ | 詳細 |

|---|---|

| 粒子径範囲 | 10-100ミクロン(用途に応じて調整可能)。 |

| 純度 | ほとんどのモデルで99%。 |

| 規格遵守 | 喘息B212、ISO9001、DIN EN 10204。 |

| 梱包サイズ | 1kg、5kg、25kg、およびカスタム・バルク包装。 |

| 粉体の形態 | 製造工程により、球状、不規則、樹枝状などの形状がある。 |

の利点 CuAlFe粉末

- 強化された強さ:CuAlFeパウダーは、要求の厳しい用途に卓越した強度と耐久性を提供します。

- 軽量:アルミニウムは軽量化に貢献し、航空宇宙や自動車用途に最適。

- コスト効率:チタンのような高価な合金に代わる、費用対効果の高い選択肢を提供。

- 熱性能:放熱性に優れ、電子部品に最適。

- エコフレンドリー:持続可能性を念頭に置いて設計されたモデルもある。

の限界 CuAlFe粉末

CuAlFeパウダーは素晴らしいが、欠点がないわけではない:

- 限定的な耐食性:いくつかの素材よりは良いが、腐食性の高い環境では純アルミニウムやステンレス鋼にはかなわないかもしれない。

- 加工の課題:最適な結果を得るためには、正確な機器と技術が必要。

- コスト変動:原料価格や加工方法によって変動する可能性がある。

長所と短所の比較

| アスペクト | 長所 | 短所 |

|---|---|---|

| 強度と耐久性 | 優れた機械的特性。 | 特殊な後処理が必要な場合がある。 |

| 熱特性 | 放熱のための高い導電性。 | 超高温環境には不向き。 |

| 耐食性 | アルミニウムを強化した中程度の耐性。 | 極端な腐食環境には適さない。 |

| 汎用性 | 業界を問わず適用可能。 | 演奏は編成によって異なる場合がある。 |

サプライヤーと価格

| サプライヤー | 製品範囲 | 平均価格(USD/kg) | 連絡先の詳細 |

|---|---|---|---|

| パウダーテック | CuAlFe-1からCuAlFe-10のモデル。 | $50-$80 | www.powdertech.com |

| アロイワークス | 特注配合も可能。 | $45-$75 | [email protected] |

| メタルフォーム・ソリューション | 包装済み粉末とバルク粉末。 | $55-$90 | www.metalformsolutions.com |

| 工業用合金株式会社 | 高純度CuAlFe粉末。 | $60-$85 | [email protected] |

よくある質問

| 質問 | 回答 |

|---|---|

| どのような産業でCuAlFe粉末がよく使用されていますか? | 航空宇宙、自動車、エレクトロニクス、エネルギー分野。 |

| CuAlFeパウダーはどのようにして作られるのか? | 通常、アトマイズまたはメカニカルアロイングプロセスによって製造される。 |

| CuAlFeパウダーは再利用できますか? | そう、管理された条件下では、積層造形で使われなかった粉末はリサイクルできることが多い。 |

| CuAlFeパウダーは環境に優しいか? | 環境に配慮した設計で、環境への影響を低減しているモデルもある。 |

| どのような粒径がありますか? | 一般的なサイズは10~100ミクロンで、用途によって異なる。 |