電極誘導溶解 不活性ガスアトマイゼーション (EIGA)は、高品質の金属粉末の製造に使用される魅力的で高度な技術プロセスである。この技術は、優れた純度、均一な粒度分布、特定の粒子形態を持つ粉末を製造する能力で特に評価されています。この広範なガイドでは、EIGAの複雑さを掘り下げ、特定の金属粉末モデルを探求し、その特性、用途、利点に関する詳細な洞察を提供します。

電極誘導溶解不活性ガスアトマイゼーションの概要

電極誘導溶融不活性ガスアトマイゼーションは、誘導加熱による金属電極の溶融と、不活性ガスによる溶融金属の微粒子化を伴うプロセスです。この方法は、添加剤製造、粉末冶金、先端セラミックなどの用途で重要な、汚染のない粉末を製造することで高く評価されています。

EIGAの主な特徴:

- 純粋さ: このプロセスはコンタミネーションを最小限に抑え、高純度の金属粉末を確保する。

- 粒子径コントロール: 粒度分布の精密なコントロールが可能。

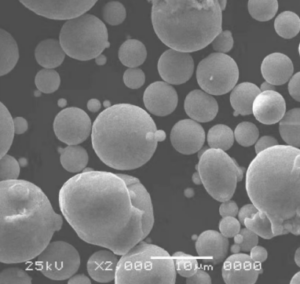

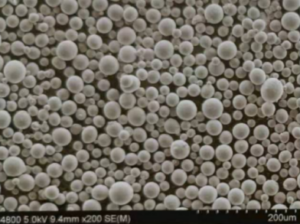

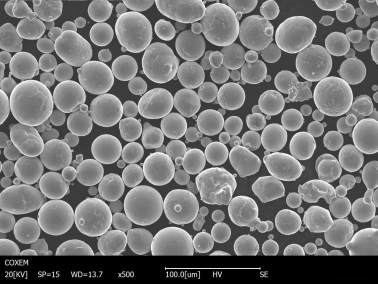

- 球状の粒子: 球状粒子を生成し、流動性と充填密度を高める。

- 汎用性がある: さまざまな金属や合金に使用できる。

EIGA粉末の組成と特性

EIGA粉末の組成と特性を理解することは、特定の用途に適した材料を選択するために不可欠です。以下では、EIGAを使用して製造された様々な金属粉末の組成と特性についてご紹介します。

EIGA粉末の種類と組成:

| 金属粉 | 構成 | プロパティ |

|---|---|---|

| チタン(Ti-6Al-4V) | チタン90%、アルミニウム6%、バナジウム4 | 高強度、軽量、耐食性 |

| ニッケル合金(インコネル718) | ニッケル50~55%、クロム17~21%、ニオブ4.75~5.5%、その他鉄、モリブデン、チタン | 耐高温性、耐食性 |

| ステンレススチール(316L) | 16-18%クロム、10-14%ニッケル、2-3%モリブデン、バランス鉄 | 耐食性、優れた機械的特性 |

| コバルトクロム合金(CoCrMo) | コバルト60~65%、クロム26~30%、モリブデン5~7 | 高い耐摩耗性、生体適合性 |

| アルミニウム合金 (AlSi10Mg) | アルミニウム85~90%、シリコン9~11%、マグネシウム0.2~0.4 | 軽量、良好な機械的特性、キャスタブル |

| 銅(Cu) | 99%銅 | 優れた電気伝導性と熱伝導性 |

| タングステン(W) | タングステン99 | 非常に高密度、高融点 |

| マグネシウム合金(AZ91D) | マグネシウム90~93%、アルミニウム8~9%、亜鉛0.2~1 | 軽量、良好なキャスタビリティー |

| 工具鋼(H13) | 0.32-0.45% 炭素、4.75-5.5% クロム、1.1-1.75% モリブデン、バランス 鉄 | 高い耐摩耗性、優れた靭性 |

| チタンアルミナイド(TiAl) | チタン45~48%、アルミニウム48~51 | 軽量、高温強度 |

EIGAパウダーの特徴:

| 特徴 | 説明 |

|---|---|

| 粒子の形態学 | 球状で流動性と充填密度を高める |

| 純度 | 不活性ガス雰囲気により、酸化やコンタミネーションを防止するため、高い。 |

| 粒度分布 | 精密な製造工程に不可欠な、狭く制御可能な構造 |

| 密度 | タップ密度とバルク密度が高く、粉末床溶融技術に有利 |

| 表面積 | 焼結および溶解プロセスを最適化するように制御される。 |

EIGAパウダーの用途

EIGAパウダーは様々な産業分野で使用されており、それぞれがこの高品質金属パウダーのユニークな特性を活用しています。下記は様々な用途を紹介した詳細な表です。

EIGAパウダーの用途と使用法:

| 産業 | 申し込み | メリット |

|---|---|---|

| 航空宇宙 | タービンブレード、構造部品 | 高い強度対重量比、耐熱性 |

| メディカル | インプラント、補綴、歯科用途 | 生体適合性、耐食性 |

| 自動車 | エンジン部品、熱交換器 | 軽量、高性能 |

| エレクトロニクス | 導電性インク、ヒートシンク | 優れた導電性 |

| エネルギー | 燃料電池、バッテリー部品 | 高効率、信頼性 |

| 付加製造 | 複雑な形状の3Dプリント | 設計の柔軟性、材料の無駄の削減 |

| 粉末冶金 | 焼結部品、ベアリング | 高密度、均一な微細構造 |

| コーティング | 溶射皮膜、耐摩耗皮膜 | 表面特性、耐久性の向上 |

仕様、サイズ、等級、規格

特定の用途にEIGAパウダーを選択する場合、これらの材料に関連する仕様、サイズ、グレード、規格を理解することが極めて重要です。

EIGA粉末の仕様と規格:

| 金属粉 | 粒子径範囲 (µm) | 標準グレード | 関連規格 |

|---|---|---|---|

| Ti-6Al-4V | 15-45, 45-90 | グレード5 | ASTM F2924 |

| Inconel 718 | 15-45, 45-106 | AMS 5662 | AMS5662、ASM B637 |

| 316Lステンレス鋼 | 15-45, 45-106 | ASTM F138 | A276, F138 |

| CoCrMo | 15-45, 45-106 | ASTM F75 | ASTM F75 |

| AlSi10Mg | 15-45, 45-106 | EN AC-43400 | EN 1706 |

| 銅 | 15-45, 45-106 | OFHC | ASTM B216 |

| タングステン | 15-45, 45-106 | W1, W2 | ASTM B777 |

| AZ91D マグネシウム | 15-45, 45-106 | ASTM B93/B93M | ASTM B93/B93M |

| H13工具鋼 | 15-45, 45-106 | ASTM A681 | ASTM A681 |

| チタンアルミナイド | 15-45, 45-106 | カスタム | ISO 5832-3 |

サプライヤーと価格詳細

高品質のEIGAパウダーを調達するには、信頼できるサプライヤーを特定し、価格設定の詳細を理解することが不可欠です。以下の表は、主なサプライヤーの概要と参考価格です。

EIGAパウダーのサプライヤーと価格:

| サプライヤー | 金属粉 | 価格帯(米ドル/kg) | 連絡先 |

|---|---|---|---|

| プラクセア・サーフェス・テクノロジー | Ti-6Al-4V | $200 – $300 | Praxair ウェブサイト |

| カーペンター添加剤 | Inconel 718 | $150 – $250 | カーペンター・アディティブ ウェブサイト |

| GKNホエガネス | 316Lステンレス鋼 | $100 – $200 | GKN ホエガネス ウェブサイト |

| HCスタルク・ソリューションズ | CoCrMo | $200 – $300 | HCスタルク・ソリューションズ ウェブサイト |

| エッカート・アメリカ | AlSi10Mg | $50 – $100 | ECKARTウェブサイト |

| AMETEK 特殊金属製品 | 銅 | $50 – $100 | アメテックSMPウェブサイト |

| アドバンスド・パウダー&コーティング社 | タングステン | $300 – $500 | アドバンスド・パウダー&コーティング ウェブサイト |

| 中欧先進材料 | AZ91D マグネシウム | $50 – $100 | 中諾ウェブサイト |

| ケナメタル | H13工具鋼 | $100 – $200 | ケナメタルウェブサイト |

| ATIメタルズ | チタンアルミナイド | $300 – $500 | ATI金属ウェブサイト |

EIGAパウダーの長所と短所を比較する

EIGAパウダーの利点と限界を評価することは、特定の用途について十分な情報を得た上で決定することに役立ちます。

EIGA粉末の利点と限界:

| メリット | 説明 |

|---|---|

| 高純度 | EIGAはコンタミネーションを最小限に抑え、高純度の粉末を製造する。 |

| 均一な粒子径 | 粒度分布の精密なコントロールが可能。 |

| 球状粒子 | 積層造形に重要な流動性と充填密度を高める。 |

| 多様な素材 | 様々な金属や合金から粉末を製造できる。 |

| 低酸素 | 不活性ガス雰囲気は酸化を抑え、材料の完全性を維持する。 |

| 制限 | 説明 |

|---|---|

| コスト | EIGAパウダーは、他の方法に比べて高価な場合がある。 |

| 複雑さ | このプロセスには高度な設備と専門知識が必要だ。 |

| 生産量 | 一回のバッチで生産できる粉末の量に制限がある場合がある。 |

| エネルギー消費 | 誘導溶解のため、高いエネルギーが必要。 |

詳細な洞察と実例

チタン(Ti-6Al-4V)とインコネル718の比較:

チタンTi-6Al-4Vとインコネル718は、高性能アプリケーションに使用される2つの著名な金属粉末です。Ti-6Al-4Vは、その高い強度重量比と耐食性で知られ、航空宇宙や生物医学分野で広く使用されています。対照的に、高温強度と耐酸化性に優れたインコネル718は、過酷な環境で使用される航空宇宙部品に好まれている。両者を比較すると、Ti-6Al-4Vは軽量で重量が重視される用途に適しているのに対し、インコネル718は高温条件下で優れた性能を発揮する。

ステンレス鋼316Lとアルミニウム合金(AlSi10Mg)の比較:

ステンレス鋼316Lとアルミニウム合金AlSi10Mgは、積層造形で一般的に使用されます。316Lは耐食性と機械的特性で好まれ、医療および海洋用途に最適です。一方、軽量で鋳造可能なAlSi10Mgは、軽量化が重要な自動車および航空宇宙用途に最適です。316Lは耐久性に優れ、AlSi10Mgは軽量化を実現する。

医療用コバルトクロム合金(CoCrMo):

コバルトクロム合金(CoCrMo)は、その高い耐摩耗性と生体適合性により、医療用途、特にインプラントや人工関節に広く使用されています。この合金は、劣化することなく体内の過酷な環境に耐えることができるため、長期的なインプラントに最適です。さらに、その機械的特性は耐荷重用途に適しており、医療機器の信頼性と寿命を保証します。

よくある質問

| 質問 | 回答 |

|---|---|

| 電極誘導溶解不活性ガスアトマイズとは? | EIGAは、誘導加熱で金属電極を溶かし、不活性ガスで溶融金属を微粒子化するプロセスである。 |

| EIGAで加工できる金属は? | チタン、ニッケル、ステンレス鋼、コバルトクロム、アルミニウム、銅、タングステン、マグネシウム、工具鋼、チタンアルミナイドなど、幅広い金属と合金。 |

| EIGAパウダーを使うメリットは何ですか? | EIGAパウダーは、高純度、均一な粒子径、球状モルフォロジー、低酸素含有量を提供し、高度な製造アプリケーションに最適です。 |

| EIGAは他の粉体製造法と比べてどうですか? | EIGAは、ガスアトマイゼーションや水アトマイゼーションのような方法と比較して、優れた純度と粒子制御を提供するが、より高価で複雑になる可能性がある。 |

| EIGAパウダーの一般的な用途は? | 用途としては、航空宇宙部品、医療用インプラント、自動車部品、電子機器、エネルギー・システム、積層造形、粉末冶金、コーティングなどがある。 |

| EIGAパウダーを選ぶ際、どのような要素を考慮すべきでしょうか? | 主な要因としては、特定の用途要件、希望する材料特性、粒度分布、純度、コストなどが挙げられる。 |

| EIGAパウダーは積層造形に使用できますか? | はい、EIGAパウダーは粒度分布が制御され、純度が高いため、積層造形に非常に適しています。 |

| EIGAパウダーの一般的な粒度範囲は? | 粒子径は通常15~106ミクロンで、用途や要件によって異なる。 |

| EIGAパウダーの使用に制限はありますか? | 制限事項としては、コストが高いこと、プロセスが複雑であること、生産量が限られていること、エネルギー消費が大きいことなどが挙げられる。 |

| EIGAのパウダーはどこで購入できますか? | 評判の良いサプライヤーには、Praxair Surface Technologies、Carpenter Additive、GKN Hoeganaes、HC Starck Solutions、ECKART America、AMETEK Specialty Metal Products、Advanced Powder & Coatings Ltd.、Zhongnuo Advanced Material、Kennametal、ATI Metalsなどがある。 |

結論

電極誘導溶解 不活性ガスアトマイゼーション は、高品質の金属粉末の製造において極めて重要な役割を果たす最先端技術である。卓越した純度、正確な粒度分布、球状の形態を持つ粉末を製造するその能力は、航空宇宙、医療、積層造形などの先端製造分野で不可欠なものとなっています。EIGAパウダーの組成、特性、用途、利点を理解することで、産業界はこの技術を活用し、製品の優れたパフォーマンスとイノベーションを実現することができます。

技術者、研究者、製造者のいずれであっても、この包括的なガイドは、EIGAパウダーの複雑さを理解し、特定のニーズに対して十分な情報に基づいた決定を下すために必要な知識と洞察を提供します。