الذوبان بالذوبان بالحث الكهربائي بالذوبان بالغاز الخامل (EIGA) هي عملية رائعة وتقنية للغاية تُستخدم في إنتاج مساحيق معدنية عالية الجودة. وتحظى هذه التقنية بتقدير خاص لقدرتها على إنتاج مساحيق ذات نقاء ممتاز، وتوزيع حجم جسيمات موحد، ومورفولوجيات جسيمات محددة، وهي أمور ضرورية في مختلف تطبيقات التصنيع المتقدمة. في هذا الدليل الشامل، سوف نتعمق في هذا الدليل الشامل في تعقيدات تقنية EIGA، ونستكشف نماذج محددة من مساحيق المعادن، ونقدم رؤى مفصلة حول خصائصها وتطبيقاتها ومزاياها.

نظرة عامة على الحث الكهربائي بالذوبان بالذوبان بالغاز الخامل بالحث الكهربائي

الذوبان بالحث الكهربائي بالذوبان بالغاز الخامل هي عملية تنطوي على ذوبان قطب كهربائي معدني باستخدام التسخين بالحث، يليها تفتيت المعدن المنصهر إلى جزيئات دقيقة باستخدام غاز خامل. وتحظى هذه الطريقة بتقدير كبير لإنتاج مساحيق خالية من التلوث، وهو أمر بالغ الأهمية في تطبيقات مثل التصنيع المضاف، ومسحوق المعادن، والسيراميك المتقدم.

الميزات الرئيسية لـ EIGA

- النقاء تقلل العملية من التلوث، مما يضمن الحصول على مساحيق معدنية عالية النقاء.

- التحكم في حجم الجسيمات: يسمح بالتحكم الدقيق في توزيع حجم الجسيمات.

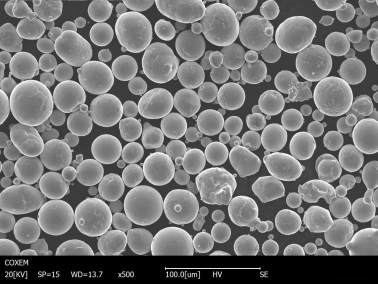

- الجسيمات الكروية: ينتج جسيمات كروية، مما يعزز قابلية التدفق وكثافة التعبئة.

- تعدد الاستخدامات: يمكن استخدامه مع مجموعة كبيرة من المعادن والسبائك.

تكوين مساحيق EIGA وخصائصها

يعد فهم تركيب مساحيق EIGA وخصائصها أمرًا ضروريًا لاختيار المادة المناسبة لتطبيقات محددة. نستكشف أدناه تركيبات وخصائص مختلف المساحيق المعدنية المنتجة باستخدام EIGA.

أنواع مساحيق EIGA وتركيباتها:

| المسحوق المعدني | التركيب | الخصائص |

|---|---|---|

| التيتانيوم (Ti-6Al-4V) | 90% التيتانيوم، 6% الألومنيوم، 4% الفاناديوم | متانة عالية وخفيفة الوزن ومقاومة للتآكل |

| سبائك النيكل (Inconel 718) | 50-55% نيكل، 17-21% كروم، 4.75-5.5% نيوبيوم، بالإضافة إلى الحديد، والموليبدينوم، والتيتانيوم | مقاومة درجات الحرارة العالية، ومقاومة التآكل |

| فولاذ مقاوم للصدأ (316L) | 16-18% كروم، 10-14% نيكل، 2-3% موليبدينوم، حديد التوازن | مقاومة للتآكل، وخصائص ميكانيكية جيدة |

| سبائك الكوبالت والكروم (CoCrMo) | 60-65% الكوبالت، 26-30% الكروم، 5-7% الموليبدينوم | مقاومة عالية للتآكل، متوافقة حيوياً |

| سبائك الألومنيوم (AlSi10Mg) | 85-901-90% ألومنيوم، 9-11% سيليكون، 0.2-0.4% مغنيسيوم | خفيفة الوزن وخصائص ميكانيكية جيدة وقابلة للصب |

| النحاس (النحاس) | >99% النحاس | توصيل كهربائي وحراري ممتاز |

| التنجستن (W) | >99% التنجستن | كثافة عالية جدًا ودرجة انصهار عالية |

| سبائك المغنيسيوم (AZ91D) | 90-93% المغنيسيوم، 8-9% الألومنيوم، 0.2-1% الزنك | خفيف الوزن وقابلية صب جيدة |

| فولاذ الأدوات (H13) | 0.32-0.45% الكربون، 4.75-5.5% الكروم، 1.1-1.75% الموليبدينوم، حديد التوازن | مقاومة عالية للتآكل، وصلابة جيدة |

| ألومينيد التيتانيوم (TiAl) | 45-48% التيتانيوم، 48-51% الألومنيوم | خفيف الوزن وقوي في درجات الحرارة العالية |

خصائص مساحيق EIGA:

| الخصائص | الوصف |

|---|---|

| مورفولوجيا الجسيمات | كروي الشكل، مما يعزز قابلية التدفق وكثافة التعبئة |

| النقاء | مرتفع، بسبب الجو الغازي الخامل الذي يمنع الأكسدة والتلوث |

| توزيع حجم الجسيمات | ضيقة ويمكن التحكم فيها، وهي ضرورية لعمليات التصنيع الدقيقة |

| الكثافة | كثافة صنبور وكثافة حجمية عالية، مفيدة لتقنيات دمج المسحوق القاعي |

| مساحة السطح | يتم التحكم فيها لتحسين عمليات التلبيد والصهر |

تطبيقات مساحيق EIGA

وتجد مساحيق EIGA تطبيقات في مختلف الصناعات، ويستفيد كل منها من الخصائص الفريدة لهذه المساحيق المعدنية عالية الجودة. فيما يلي جدول مفصل يعرض التطبيقات المختلفة.

تطبيقات واستخدامات مساحيق EIGA:

| الصناعة | طلب | المزايا |

|---|---|---|

| الفضاء | شفرات التوربينات، والمكونات الهيكلية | نسبة عالية من القوة إلى الوزن ومقاومة درجات الحرارة |

| الطبية | الغرسات والأطراف الاصطناعية وتطبيقات طب الأسنان | التوافق الحيوي ومقاومة التآكل والتآكل |

| السيارات | مكونات المحرك، المبادلات الحرارية | خفيف الوزن وعالي الأداء |

| الإلكترونيات | الأحبار الموصلة والمشتتات الحرارية | توصيل كهربائي ممتاز |

| الطاقة | خلايا الوقود ومكونات البطارية | كفاءة عالية وموثوقية عالية |

| التصنيع الإضافي | الطباعة ثلاثية الأبعاد للأشكال الهندسية المعقدة | مرونة التصميم، وتقليل نفايات المواد |

| تعدين المساحيق | الأجزاء الملبدة والمحامل | كثافة عالية وبنية مجهرية موحدة |

| الطلاءات | طلاءات الرش الحراري، الطلاءات المقاومة للتآكل | خصائص السطح المحسّنة والمتانة |

المواصفات والأحجام والدرجات والمعايير

عند اختيار مساحيق EIGA لتطبيقات محددة، من الضروري فهم المواصفات والأحجام والدرجات والمعايير المرتبطة بهذه المواد.

مواصفات ومعايير مساحيق EIGA:

| المسحوق المعدني | نطاق حجم الجسيمات (ميكرومتر) | الدرجات القياسية | المعايير ذات الصلة |

|---|---|---|---|

| Ti-6Al-4V | 15-45, 45-90 | الصف الخامس | ASTM F2924 |

| انكونيل 718 | 15-45, 45-106 | AMS 5662 | AMS 5662، ASTM B637، AMS 5662، ASTM B637 |

| فولاذ مقاوم للصدأ 316L | 15-45, 45-106 | ASTM F138 | أستم A276، F138 |

| CoCrMo | 15-45, 45-106 | ASTM F75 | ASTM F75 |

| AlSi10 ملغ | 15-45, 45-106 | EN AC-43400 | EN 1706 |

| النحاس | 15-45, 45-106 | OFHC | ASTM B216 |

| التنغستن | 15-45, 45-106 | دبليو 1، دبليو 2 | ASTM B777 |

| المغنيسيوم AZ91D | 15-45, 45-106 | ASTM B93/B93M | ASTM B93/B93M |

| فولاذ الأدوات H13 | 15-45, 45-106 | ASTM A681 | ASTM A681 |

| ألومينيد التيتانيوم | 15-45, 45-106 | مخصص | الأيزو 5832-3 ISO 5832-3 |

تفاصيل الموردين والأسعار

يعد تحديد الموردين ذوي السمعة الطيبة وفهم تفاصيل التسعير أمرًا حيويًا للحصول على مساحيق EIGA عالية الجودة. فيما يلي جدول يوضح بعض الموردين الرئيسيين والأسعار الإرشادية.

الموردون وأسعار مساحيق EIGA:

| المورد | المسحوق المعدني | نطاق السعر (دولار/كجم) | معلومات الاتصال |

|---|---|---|---|

| براكسير للتقنيات السطحية | Ti-6Al-4V | $200 – $300 | موقع براكسير الإلكتروني |

| مضافات النجار | انكونيل 718 | $150 – $250 | الموقع الإلكتروني لمضافات النجار |

| GKN Hoeganaes | فولاذ مقاوم للصدأ 316L | $100 – $200 | الموقع الإلكتروني لشركة GKN Hoeganaes |

| شركة إتش سي ستارك سوليوشنز | CoCrMo | $200 – $300 | الموقع الإلكتروني لشركة إتش سي ستارك سوليوشنز |

| إيكارت أمريكا | AlSi10 ملغ | $50 – $100 | موقع ECKART الإلكتروني |

| المنتجات المعدنية المتخصصة AMETEK | النحاس | $50 – $100 | موقع AMETEK SMP الإلكتروني |

| شركة Advanced Powder & Coatings Ltd. | التنغستن | $300 – $500 | موقع شركة Advanced Powder & Coatings الإلكتروني |

| مواد زونغنو المتقدمة | المغنيسيوم AZ91D | $50 – $100 | موقع Zhongnuo الإلكتروني |

| كيناميتال | فولاذ الأدوات H13 | $100 – $200 | موقع كيناميتال الإلكتروني |

| معادن ATI | ألومينيد التيتانيوم | $300 – $500 | موقع ATI Metals الإلكتروني |

مقارنة إيجابيات مساحيق EIGA وسلبياتها

يساعد تقييم مزايا وقيود مساحيق EIGA في اتخاذ قرارات مستنيرة لتطبيقات محددة.

مزايا وقيود مساحيق EIGA:

| الميزة | الوصف |

|---|---|

| عالية النقاء | تقلل EIGA من التلوث، وتنتج مساحيق عالية النقاء. |

| حجم الجسيمات المنتظم | يسمح بالتحكم الدقيق في توزيع حجم الجسيمات. |

| الجسيمات الكروية | يعزّز قابلية التدفق وكثافة التعبئة، وهو أمر بالغ الأهمية للتصنيع الإضافي. |

| مجموعة مواد متعددة الاستخدامات | يمكن إنتاج مساحيق من مجموعة واسعة من المعادن والسبائك. |

| انخفاض محتوى الأكسجين | يقلل جو الغاز الخامل من الأكسدة، مما يحافظ على سلامة المواد. |

| التقييد | الوصف |

|---|---|

| التكلفة | يمكن أن تكون مساحيق EIGA أكثر تكلفة مقارنة بالطرق الأخرى. |

| التعقيد | تتطلب العملية معدات وخبرات متطورة. |

| حجم الإنتاج | قد تكون محدودة في حجم المسحوق الذي يمكن إنتاجه في دفعة واحدة. |

| استهلاك الطاقة | متطلبات طاقة عالية بسبب الذوبان بالحث الحثي. |

رؤى وأمثلة مفصلة

التيتانيوم (Ti-6Al-4V) مقابل Inconel 718:

يعد التيتانيوم Ti-6Al-4V و Inconel 718 مساحيق معدنية بارزة تستخدم في التطبيقات عالية الأداء. يُستخدم Ti-6Al-4V، المعروف بنسبة قوته العالية إلى وزنه ومقاومته للتآكل، على نطاق واسع في مجالات الطيران والطب الحيوي. وعلى النقيض من ذلك، يُفضل استخدام إنكونيل 718، بفضل قوته الفائقة في درجات الحرارة العالية ومقاومته للأكسدة، في مكونات الطيران التي تعمل في البيئات القاسية. عند المقارنة بين الاثنين، فإن Ti-6Al-4V أخف وزنًا وأكثر ملاءمة للتطبيقات الحساسة للوزن، في حين أن Inconel 718 يقدم أداءً أفضل في ظروف درجات الحرارة العالية.

الفولاذ المقاوم للصدأ 316L مقابل سبائك الألومنيوم (AlSi10Mg):

يشيع استخدام الفولاذ المقاوم للصدأ 316L وسبائك الألومنيوم AlSi10Mg في التصنيع المضاف. ويُفضّل استخدام 316L لمقاومته للتآكل وخصائصه الميكانيكية، مما يجعله مثاليًا للتطبيقات الطبية والبحرية. من ناحية أخرى، تُعدّ سبائك AlSi10Mg، كونها خفيفة الوزن وقابلة للسبك، ممتازة لتطبيقات السيارات والفضاء حيث يكون تقليل الوزن أمرًا بالغ الأهمية. وغالبًا ما يتلخص الاختيار بين هذه المواد في متطلبات الاستخدام المحددة، حيث يوفر 316L المتانة بينما يوفر AlSi10Mg توفيرًا في الوزن.

سبائك الكوبالت والكروم (CoCrMo) للتطبيقات الطبية:

تُستخدم سبيكة الكوبالت والكروم (CoCrMo) على نطاق واسع في التطبيقات الطبية، خاصةً في الغرسات والأطراف الصناعية، نظرًا لمقاومتها العالية للتآكل وتوافقها الحيوي. إن قدرة السبيكة على تحمل بيئة الجسم القاسية دون أن تتحلل تجعلها الخيار الأفضل للغرسات طويلة الأمد. بالإضافة إلى ذلك، فإن خواصها الميكانيكية مناسبة تماماً للتطبيقات الحاملة، مما يضمن الموثوقية وطول العمر في الأجهزة الطبية.

التعليمات

| سؤال | الإجابة |

|---|---|

| ما هو ذوبان الغاز الخامل بالذوبان بالحث الكهربائي؟ | EIGA هي عملية تنطوي على صهر قطب كهربائي معدني باستخدام التسخين بالحث وتذرية المعدن المنصهر إلى جسيمات دقيقة باستخدام غاز خامل. |

| ما هي المعادن التي يمكن معالجتها باستخدام EIGA؟ | مجموعة كبيرة من المعادن والسبائك، بما في ذلك التيتانيوم والنيكل والفولاذ المقاوم للصدأ والكوبالت والكروم والألومنيوم والنحاس والتنغستن والمغنيسيوم وفولاذ الأدوات وألومينيوم التيتانيوم. |

| ما هي فوائد استخدام مساحيق EIGA؟ | توفر مساحيق EIGA درجة نقاء عالية وحجم جسيمات موحد ومورفولوجيا كروية ومحتوى منخفض من الأكسجين، مما يجعلها مثالية لتطبيقات التصنيع المتقدمة. |

| كيف يمكن مقارنة EIGA بطرق إنتاج المساحيق الأخرى؟ | توفر EIGA نقاءً فائقًا وتحكمًا في الجسيمات مقارنةً بطرق مثل الانحلال الغازي أو الانحلال المائي، على الرغم من أنها قد تكون أكثر تكلفة وتعقيدًا. |

| ما هي التطبيقات الشائعة لمساحيق EIGA؟ | تشمل التطبيقات مكونات الطيران، والزراعات الطبية، وقطع غيار السيارات، والإلكترونيات، وأنظمة الطاقة، والتصنيع المضاف، ومسحوق المعادن، والطلاء. |

| ما العوامل التي يجب أخذها في الاعتبار عند اختيار مساحيق EIGA؟ | وتشمل العوامل الرئيسية متطلبات التطبيق المحددة، وخصائص المواد المطلوبة، وتوزيع حجم الجسيمات، والنقاء، والتكلفة. |

| هل يمكن استخدام مساحيق EIGA في التصنيع المضاف؟ | نعم، تعد مساحيق EIGA مناسبة للغاية للتصنيع الإضافي نظرًا لتوزيع حجم الجسيمات المتحكم فيه ونقاوتها العالية، مما يعزز جودة الأجزاء المطبوعة. |

| ما هو نطاق حجم الجسيمات النموذجي لمساحيق EIGA؟ | وتتراوح أحجام الجسيمات عادةً من 15 إلى 106 ميكرون، حسب الاستخدام والمتطلبات. |

| هل هناك أي قيود على استخدام مساحيق EIGA؟ | تشمل القيود ارتفاع التكاليف وتعقيد العملية ومحدودية حجم الإنتاج وارتفاع استهلاك الطاقة. |

| أين يمكنني شراء مساحيق EIGA؟ | ومن بين الموردين ذوي السمعة الطيبة براكسير سيرفيس تكنولوجيز، وكاربنتر للإضافات، وجي كي إن هوجانز، وإتش سي ستارك سوليوشنز، وإيكارت أمريكا، وأميتيك سبيشالتي ميتال سبيشالتي ميتالز، وأدفانسد باودر آند كوتنغز المحدودة، وجونغنو أدفانسد ماتيريديتال وكيناميتال وأتي ميتالز. |

خاتمة

الذوبان بالذوبان بالحث الكهربائي بالذوبان بالغاز الخامل هي تقنية متطورة تؤدي دورًا محوريًا في إنتاج مساحيق معدنية عالية الجودة. كما أن قدرتها على إنتاج مساحيق ذات نقاء استثنائي وتوزيع دقيق لحجم الجسيمات ومورفولوجيا كروية تجعلها لا غنى عنها في قطاعات التصنيع المتقدمة مثل الفضاء والطب والتصنيع الإضافي. من خلال فهم تركيبة مساحيق EIGA وخصائصها وتطبيقاتها ومزاياها، يمكن للصناعات الاستفادة من هذه التقنية لتحقيق أداء فائق وابتكار في منتجاتها.

سواءً كنت مهندسًا أو باحثًا أو مصنعًا، يوفر هذا الدليل الشامل المعرفة والرؤى اللازمة للتغلب على تعقيدات مساحيق EIGA واتخاذ قرارات مستنيرة لاحتياجاتك الخاصة.