アディティブ・マニュファクチャリング(AM)マシンの魅力的な世界へようこそ!この驚くべき装置は、製品の創造、設計、製造方法に革命をもたらしています。金属、プラスチック、セラミックなどの材料を使い、デジタルモデルから直接、層ごとに物体を作ることができることを想像してみてください。SFのように聞こえるだろうか?しかし、それは今まさに起こっているのです!

この記事では、その複雑さについて掘り下げていく。 AM機その用途や利点、そしてもちろん、その魔法を支える金属粉に焦点を当てます。使用される金属粉末の種類、組成、特性、その他多くのことを探求します。さあ、シートベルトを締めて、AMマシンの世界を巡る魅力的な旅に出かけよう。

AMマシンの概要

アディティブ・マニュファクチャリング(Additive Manufacturing)は、一般に3Dプリンティングとして知られ、材料を層ごとに追加してオブジェクトを作成する。材料を削る(切断、穴あけなど)ことが多い従来の製造方法とは異なり、AMは精度と効率がすべてである。これらの機械は、航空宇宙、自動車、ヘルスケア、消費財など、さまざまな業界で使用されている。

AMマシンとは?

AMマシンは、デジタル設計を使用して物理的な物体を層ごとに構築する高度な装置である。金属、ポリマー、セラミックなど、さまざまな素材を扱うことができる。これらの機械は、従来の製造方法では不可能な複雑な形状を作り出すことができる。

AMマシンの仕組み

AMマシンは、単純でありながら洗練されたプロセスに従う:

- デザイン:コンピュータ支援設計(CAD)ソフトウェアを使用して3Dモデルを作成します。

- スライシング:モデルは薄いレイヤーにスライスされる。

- 印刷:機械は、デジタル設計図に従って、レイヤーごとに材料を追加していく。

- 後処理:研磨や熱処理など、必要な処理を施して印刷物を仕上げる。

AMマシンの利点

- 複雑な幾何学:伝統的な手法では実現できない複雑なデザインを生み出す。

- 材料効率:減法的製造に比べ無駄が少ない。

- カスタマイズ:パーソナライズされた製品のデザインを簡単に変更できます。

- スピード:ラピッドプロトタイピングと生産

AMマシンの種類

それぞれユニークな機能と用途を持つ、さまざまな種類のAMマシンを見てみよう。

1.ステレオリソグラフィー(SLA)

SLAは、レーザーを使って液状の樹脂を硬化させ、固形の物体を作ります。滑らかな表面で詳細なプロトタイプを作成するのに理想的です。

2.選択的レーザー焼結(SLS)

SLSは、レーザーで粉末材料を溶融する。様々な素材から耐久性のある機能的な部品を製造するのに適している。

3.溶融堆積モデリング(FDM)

FDMは、熱可塑性フィラメントを溶かして押し出し、造形物を作ります。ホビーや工業用途に人気があります。

4.ダイレクトメタルレーザー焼結(DMLS)

DMLSはレーザーを使って金属粉末を焼結し、丈夫で複雑な金属部品を作る。航空宇宙産業や医療産業で広く利用されている。

5.電子ビーム溶解(EBM)

EBMは電子ビームを使用して金属粉末を溶融する。高強度、高温の用途に最適。

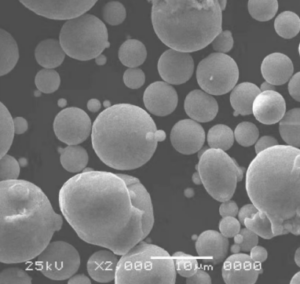

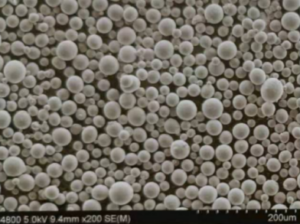

AMマシン用金属粉末

金属粉末は、特に高い強度と精度が要求される産業において、多くのAMプロセスの中心となっています。ここでは、AMに使用される主な金属粉末をご紹介します:

1.チタン合金 (Ti-6Al-4V)

説明:チタン合金は、高強度、軽量、優れた耐食性で知られています。

用途:航空宇宙、医療用インプラント、自動車。

プロパティ:高い強度対重量比、生体適合性、優れた耐疲労性。

2.ステンレススチール(316L)

説明:耐食性と強度で知られる万能合金。

用途:医療機器、食品加工、化学工業

プロパティ:高強度、耐食性、良好な延性。

3.インコネル (IN625)

説明:高温強度と耐食性に優れたニッケルクロム超合金。

用途:航空宇宙、発電、海洋産業。

プロパティ:高温、耐酸化性、高強度。

4.アルミニウム合金 (AlSi10Mg)

説明:軽量で強靭なアルミニウム合金は、優れた熱特性を必要とする部品に最適です。

用途:自動車、航空宇宙、家電。

プロパティ:高い強度対重量比、良好な熱伝導性、耐食性。

5.工具鋼(H13)

説明:硬度と耐摩耗性で知られる。

用途:工具、金型、金型

プロパティ:高硬度、耐摩耗性、熱安定性。

6.コバルトクロム(CoCr)

説明:耐摩耗性と生体適合性で知られる超合金。

用途:医療用インプラント、歯科補綴物、航空宇宙。

プロパティ:高い耐摩耗性、優れた生体適合性、高い強度。

7.銅合金 (CuCr1Zr)

説明:銅合金はその熱伝導性と電気伝導性で評価されている。

用途:電気部品、熱交換器、ロケットエンジン部品。

プロパティ:高い熱伝導性と電気伝導性、良好な強度。

8.マルエージング鋼 (1.2709)

説明:靭性と寸法安定性に優れた高強度鋼。

用途:航空宇宙、工具、高性能エンジニアリング。

プロパティ:高強度、高靭性、優れた溶接性。

9.ニッケル合金(ハステロイX)

説明:耐酸化性と高温強度で知られる。

用途:航空宇宙、化学処理、産業用ガスタービン。

プロパティ:高温強度、耐酸化性、耐食性。

10.炭化タングステン(WC-Co)

説明:非常に硬く、耐摩耗性があり、厳しい環境で使用される。

用途:切削工具、耐摩耗部品、鉱山機械。

プロパティ:高硬度、優れた耐摩耗性、高熱伝導性。

金属粉末の組成と特性

ここでは、これらの金属粉末の組成と特性について詳しく見てみよう:

| 金属粉 | 構成 | プロパティ |

|---|---|---|

| チタン合金 | Ti、Al、V | 高い強度対重量比、生体適合性 |

| ステンレス鋼 | Fe、Cr、Ni、Mo | 耐食性、優れた延性 |

| インコネル | Ni、Cr、Mo、Nb | 高温強度、耐酸化性 |

| アルミニウム合金 | Al、Si、Mg | 軽量、熱伝導性、耐食性 |

| 工具鋼 | Fe、C、Cr、Mo | 硬度、耐摩耗性、熱安定性 |

| コバルト・クロム | Co、Cr、Mo | 耐摩耗性、生体適合性 |

| 銅合金 | Cu、Cr、Zr | 熱伝導性、電気伝導性、強度 |

| マレージング鋼 | Fe、Ni、Co、Mo | 高強度、靭性、溶接性 |

| ニッケル合金 | Ni、Cr、Mo、Fe | 耐酸化性、高温強度 |

| 炭化タングステン | WC、Co | 硬度、耐摩耗性、熱伝導性 |

AMにおける金属粉末の用途

AMにおける金属粉末の多用途性は、様々な産業における幅広い用途を可能にする:

| 産業 | 用途 |

|---|---|

| 航空宇宙 | エンジン部品、構造部品、熱交換器 |

| メディカル | インプラント、補綴物、手術器具 |

| 自動車 | 軽量部品、エンジン部品、カスタム部品 |

| エレクトロニクス | ヒートシンク、コネクタ、ハウジング |

| 工具 | 金型、切削工具 |

| エネルギー | タービンブレード、熱交換器、発電部品 |

| 消費財 | ジュエリー、アイウェア、カスタムデザイン製品 |

仕様、サイズ、等級、規格

AM用の金属粉末を選択する際には、その仕様、サイズ、グレード、規格を考慮することが極めて重要である:

| 金属粉 | 仕様 | サイズ | グレード | 規格 |

|---|---|---|---|---|

| チタン合金 | ASMB348、AMS4999 | 15-45µm、45-106µm | Ti-6Al-4V ELI | ASTM F2924、ISO 5832-3 |

| ステンレス鋼 | アストレムA276、アストレムF138 | 10~50μm、20~63μm | 316L、17-4 PH | ASTM F138、ISO 5832-1 |

| インコネル | 5666, N06625 | 15-45µm、20-60µm | IN625、IN718 | ASMB443、AMS5662 |

| アルミニウム合金 | ASMB209、AMS4225 | 20-63µm、10-50µm | AlSi10Mg, AlSi12 | ASTM B918、ISO 3522 |

| 工具鋼 | A681, AISI H13 | 15-45µm、20-60µm | H13, D2 | A681, DIN 1.2344 |

| コバルト・クロム | ASTM F75、ISO 5832-12 | 15-45µm、10-50µm | CoCrMo、CoCrW | ASTM F75、ISO 5832-12 |

| 銅合金 | アストムB152、C18150 | 10~50μm、15~45μm | CuCr1Zr、C18150 | ASMB187、AMS4980 |

| マレージング鋼 | AMS 6514, AISI 18Ni(300) | 10~45µm、20~60µm | 1.2709、18Ni(300) | AMS 6520、DIN 1.6358 |

| ニッケル合金 | ASMB435、UNS N06002 | 10~45µm、20~60µm | ハステロイX、N06002 | ASMB435、AMS5754 |

| 炭化タングステン | ISO 9001、ASM B777 | 5~20µm、10~45µm | WC-Co、コバルトボンド | ISO 9001、ASM B777 |

サプライヤーと価格詳細

ここでは、金属粉末の主要サプライヤーとその価格詳細を見てみよう:

| サプライヤー | 金属粉末 | 価格帯(kgあたり) |

|---|---|---|

| ヘガネスAB | ステンレス鋼、工具鋼 | $50 – $200 |

| カーペンター・テクノロジー | チタン合金、インコネル | $300 – $600 |

| サンドビック | ステンレス鋼、マレージング鋼 | $100 – $400 |

| LPWテクノロジー | コバルトクロム、インコネル | $250 – $700 |

| GKNアディティブ | アルミニウム合金、チタン合金 | $150 – $500 |

| AP&C(GEアディティブ) | チタン合金、アルミニウム合金 | $200 – $800 |

| スタルクHC | タングステンカーバイド、コバルトクロム | $100 – $300 |

| アルカムAB | チタン合金、ステンレス鋼 | $200 – $600 |

| エラスティール | 工具鋼、マルエージング鋼 | $150 – $400 |

| オベール&デュバル | ニッケル合金、工具鋼 | $200 – $500 |

の利点と限界 AMマシン

他のテクノロジーと同様、AMマシンにも長所と短所がある:

メリット

| メリット | 説明 |

|---|---|

| デザインの自由 | 複雑なジオメトリと複雑なデザインを作成します。 |

| 材料効率 | 材料は層ごとに追加されるため、廃棄物は最小限に抑えられる。 |

| カスタマイズ | パーソナライズされた製品のデザインを簡単に変更できます。 |

| ラピッドプロトタイピング | デザインから完成品までの納期が早い。 |

| オンデマンド制作 | 必要に応じて部品を生産し、在庫コストを削減。 |

制限事項

| 制限 | 説明 |

|---|---|

| 材料の制限 | すべての材料がAMプロセスに適しているわけではない。 |

| 表面仕上げ | 希望する表面品質を得るためには、後処理が必要な場合がある。 |

| サイズの制約 | 従来の製造方法に比べ、製造量が限られている。 |

| コスト | 設備や材料への初期投資が高い。 |

| スピード | 大規模生産のためのいくつかの伝統的な製造方法よりも遅い。 |

AMマシンの構成と特徴

AMマシンの構成と特性を理解することは、ニーズに合ったマシンを選択する上で極めて重要である。

AMマシンの種類と特徴

| タイプ | 素材 | 特徴 |

|---|---|---|

| エスエルエー | フォトポリマー樹脂 | 高精度で滑らかな表面仕上げ、プロトタイプに最適 |

| SLS | ナイロン、ポリアミド、金属 | 丈夫で耐久性があり、機能的なプロトタイプに適しています。 |

| 多重伝送装置 | 熱可塑性フィラメント | 手頃な価格で、ラピッドプロトタイピングやホビイストに最適。 |

| DMLS | 金属粉(Ti、Al、SS) | 航空宇宙、医療で使用される高強度、複雑な金属部品 |

| EBM | 金属粉(Ti、CoCr) | 重要産業で使用される高温、高強度部品 |

AMマシンの特性

| プロパティ | 説明 |

|---|---|

| ビルド・ボリューム | 印刷可能なオブジェクトの最大サイズ。 |

| レイヤー解像度 | 各層の厚さは、表面仕上げと細部に影響する。 |

| 素材適合性 | マシンが使用できる材料の範囲。 |

| 印刷速度 | 機械が印刷できる速度で、生産時間に影響する。 |

| 精密 | 高精度のアプリケーションに不可欠なプリント部品の精度。 |

AMマシンの用途と使用例

AMマシンは、さまざまな産業で使用されている汎用性の高いツールです。一般的な用途をいくつか見てみよう:

航空宇宙

AMマシンは、エンジン部品や構造部品など、軽量で高強度の部品を作るために使用される。複雑な形状を製造できるため、航空宇宙部品の重量が軽減され、効率が向上する。

メディカル

医療分野では、AMマシンはカスタムインプラント、補綴物、手術器具を製造する。精度とカスタマイズ能力により、医療器具が患者に完璧にフィットし、転帰と快適性が向上する。

自動車

自動車業界では、軽量部品、カスタム部品、プロトタイプの作成にAMマシンを使用している。この技術は、新しい設計の迅速な試作とテストを可能にし、開発プロセスを加速させる。

消費財

AMマシンは、宝飾品から眼鏡に至るまで、カスタムデザインの消費財の生産を可能にする。製品をパーソナライズする能力は、ユニークでオーダーメイドの商品を求める消費者にアピールする。

エレクトロニクス

エレクトロニクス分野では、AMマシンがハウジング、ヒートシンク、コネクターを製造する。AMの精度と材料能力は、電子部品が性能と耐久性の要求仕様を満たすことを保証します。

工具

AMマシンは、複雑な形状と高い精度を持つ金型、ダイ、切削工具を作成するために使用されます。このアプリケーションは、従来の金型製作方法に関連するリードタイムとコストを削減します。

金属粉末の比較 AMマシン

AM用の金属粉末を選択する際には、その特性と特定の用途への適合性を比較することが不可欠である。

チタン合金とステンレス鋼の比較

チタン合金 は高い強度対重量比と生体適合性で知られ、航空宇宙や医療用途に理想的である。 ステンレス鋼一方、耐食性と強度に優れ、幅広い産業用途に適している。

インコネルとアルミニウム合金の比較

インコネル は、高温強度と耐酸化性で知られるニッケル・クロム超合金で、航空宇宙や発電に最適です。 アルミニウム合金 は軽量で熱特性に優れているため、自動車や家電の用途に適している。

工具鋼とコバルト・クロムの比較

工具鋼 は、その硬度と耐摩耗性が評価され、工具用途に最適です。 コバルト・クロム は高い耐摩耗性と生体適合性を持ち、医療用インプラントや歯科補綴物に適している。

銅合金とマルエージング鋼の比較

銅合金 は優れた熱伝導性と電気伝導性を持ち、電気部品や熱交換器に適している。 マレージング鋼 は高い強度と靭性を備えており、航空宇宙および高性能エンジニアリング用途に最適です。

よくある質問

| 質問 | 回答 |

|---|---|

| 積層造形とは何か? | アディティブ・マニュファクチャリング(AM)は、材料を層ごとに追加することで物体を作成するプロセスである。 |

| AM機の仕組みは? | AMマシンは、デジタル設計を使用して材料を層ごとに追加し、物理的なオブジェクトを作成します。 |

| AMマシンに使用できる素材は? | AMマシンは、金属、ポリマー、セラミックなど、さまざまな材料を使用することができる。 |

| AMマシンの利点は何ですか? | 利点としては、設計の自由度、材料効率、カスタマイズ、ラピッドプロトタイピング、オンデマンド生産などが挙げられる。 |

| AMマシンの限界とは? | 制限には、材料の制約、表面仕上げの品質、サイズの制約、コスト、速度などがある。 |

| AMマシンはどのような産業で使用されているのか? | 航空宇宙、医療、自動車、エレクトロニクス、消費財、工具などの産業が含まれる。 |

| AM用金属粉末の正しい選び方は? | アプリケーションの要件、材料の特性、AMマシンとの互換性などの要因を考慮してください。 |

| AMに使用される一般的な金属粉末にはどのようなものがありますか? | 一般的な金属粉末には、チタン合金、ステンレス鋼、インコネル、アルミニウム合金、工具鋼、コバルトクロムなどがある。 |

| AMマシンは機能的な部品を製造できるか? | そう、AMマシンは高精度で耐久性のある機能部品を製造できる。 |

| AMマシンの未来は? | AMマシンの将来は有望で、材料、プロセス、アプリケーションの進歩が成長を牽引している。 |