紹介 球状チタン粉

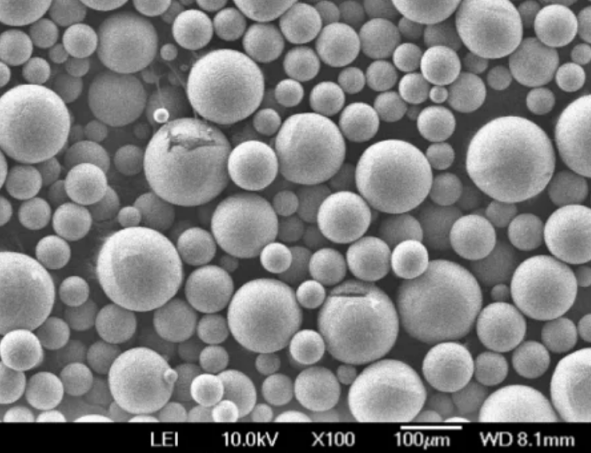

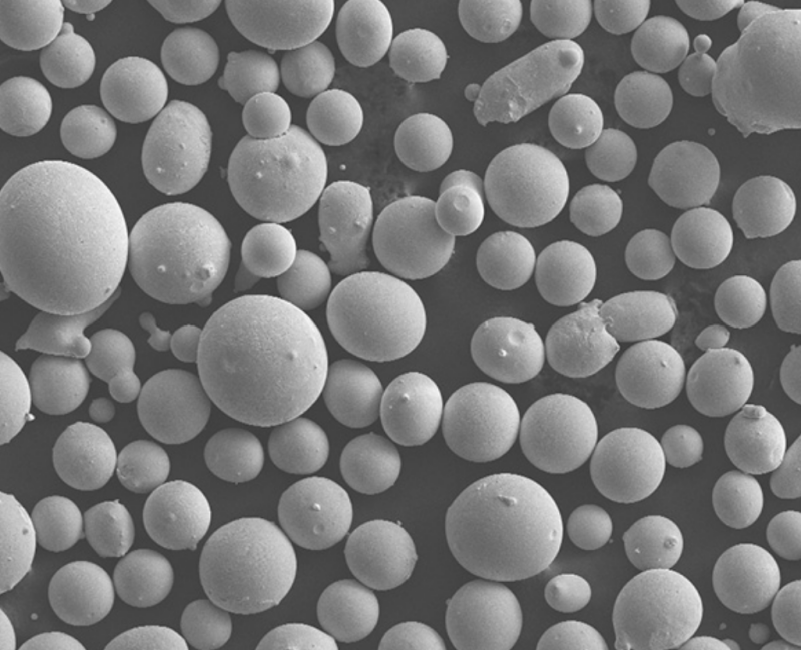

球状チタン粉末は、球状の形態と制御された粒度分布を持つ純チタン粉末の一形態です。優れた流動性、混合性、一貫性を提供し、各産業の高度な金属製造工程に適しています。

構成と特徴

表1: 球状チタン粉末の組成と主要特性

| パラメータ | 詳細 |

|---|---|

| 化学組成 | 99%チタン。窒素、酸素、炭素、水素のような残りの微量元素。 |

| 粒子形状 | 高い球状形態 |

| 粒子径範囲 | 通常15~45ミクロン |

| 流動性 | 球形で優れている |

| 見かけ密度 | 約2.7g/cm3 |

| タップ密度 | 固体チタン密度最大73%、すなわち~4 g/cm3 |

正確な粒度分布、酸素と窒素の含有量、流量、タップ密度は、用途に応じてカスタマイズできる。

製造工程

球状チタン粉末は、チタン原料を溶融し、噴霧化し、液滴を急速に凝固させて高度に球状の粉末粒子にする高度な方法によって製造されます:

- プラズマ霧化 高エネルギー・プラズマ・トーチと不活性ガス・ジェットを使用

- 電極誘導ガスアトマイズ(EIGA) 誘導溶融電極に頼る

- 回転電極プロセス(REP) 回転するチタン電極の先端から溶融金属ストリームを生成する

重要なのは、不活性雰囲気中での迅速な凝固であり、これによって純度と球状の形態が得られる。製造後のふるい分けと分級により、厳密な分別が行われる。

球状チタン粉末 用途と使用例

球状チタンパウダーのユニークな特性は、チタンパウダーの用途に適している:

表2:球状チタン粉末の主な用途

| エリア | 用途 |

|---|---|

| 付加製造 | DMLS、SLM、EBMによるインプラント、航空宇宙部品の3Dプリント |

| 粉末冶金 | プレスと焼結によるチタン製自動車・航空機部品の製造 |

| インベストメント鋳造 | 射出成形金型および金型製造 |

| バイオメディカル | 骨移植用多孔質構造体 |

| 顔料と触媒 | 化学・プラスチック産業 |

高純度、流動性、混合性、粒度分布の一貫性により、金属3Dプリンティングのような粉末ベースの製造工程全体で、信頼性の高い高性能の使用が可能になる。

仕様

球状チタンはASTM B988やASTM F3049などの規格に適合しています。代表的な値は以下の通りです:

表3: 球状チタン粉末の標準仕様

| パラメータ | 仕様 |

|---|---|

| 粒子サイズ | 15-45ミクロン |

| 酸素含有量 | 0.20% |

| 窒素含有量 | 0.05 |

| 水素含有量 | 0.015 |

| タップ密度 | 最大4 g/cm3 |

| 流量 | 25秒/50g |

| 粒度分布 | D10 > 20ミクロン; D90 < 63ミクロン |

タップ密度、流量、酸素・窒素含有量などの特性は、用途に応じてカスタマイズが可能です。

価格 球状チタン粉

表4: 球状チタン粉末 主要サプライヤーの価格帯

| サプライヤー | 価格/Kg |

|---|---|

| 先端パウダー&コーティング | $100-$200 |

| AP&C | $90-$180 |

| TLS Technik GmbH & Co. | $120-$250 |

| サンドビック・オスプレイ | $80-$220 |

価格は注文量、グレード、カスタマイズの必要性によって異なる。医療用の高純度グレードはプレミアム価格となる。リサイクル・パウダーは50%安価ですが、品質が安定しません。

代替案との比較

表5: 球状チタン粉末の長所と短所

| 長所 | 短所 |

|---|---|

| 優れた流動性と展延性 | 合金製より高価 |

| 分離のないミックス | グローバル・サプライヤーが限られ、供給が乏しい |

| 高密度のAMプリント部品が可能 | 反応性があり、不活性な取り扱いが必要 |

| 等方性 | HIPのような後処理は必須 |

| 最高の強度対重量比 | ニッチな合金特性を欠く |

より高いコストにもかかわらず、球状チタン粉末は、航空宇宙、自動車、医療、および一般的なエンジニアリングの領域において、より軽く、より強いチタンコンポーネントを可能にします。

よくある質問

金属AMプロセスにおいて粒子形状が果たす役割とは?

球状の形状は、SLMやDMLSのような積層造形法において、均一で高密度の粉末層となり、印刷されたチタン部品の気孔率を最小限に抑えます。その結果、機械的強度が向上します。

チタン焼結部品の完全密度はどのようにして達成されるのですか?

焼結チタンコンパクトの熱間静水圧プレス(HIP)後処理は、内部の気孔や空隙を除去し、完全な理論密度を達成するために不可欠です。これは強度を最大化します。

チタンパウダーの取り扱いによる健康被害はありますか?

チタンパウダーは反応性、爆発性、皮膚/呼吸器感作性を引き起こす可能性があるため、他の微細金属パウダーと同様、取り扱い上の注意が不可欠である。アルゴン手袋、保護具の使用を推奨する。

Frequently Asked Questions (FAQ)

1) What particle size distribution is best for Spherical Titanium Powder in AM vs. PM?

- AM (LPBF/SLM/EBM): typically 15–45 μm (sometimes 20–63 μm depending on OEM). PM press-and-sinter often prefers finer cuts (5–25 μm) to improve green density.

2) How do oxygen and nitrogen contents impact mechanical properties?

- Higher O/N increase strength/hardness but reduce ductility and fatigue life. For Ti-6Al-4V AM powders, many specs target O ≤0.15–0.20 wt% and N ≤0.05 wt% to balance elongation and toughness.

3) Gas atomization vs. plasma atomization vs. EIGA: which yields better Spherical Titanium Powder?

- Plasma atomization and EIGA typically deliver the highest sphericity and lowest satellite content, ideal for LPBF spreadability. Close-coupled gas atomization can be cost-effective but may require additional spheroidization/sieving.

4) Can Spherical Titanium Powder be reused in AM without compromising quality?

- Yes, with controlled sieving, oxygen monitoring (ASTM E1409/E1447), and blend-back rules. Many workflows achieve 5–10 cycles before blending with virgin powder; track PSD shift and flow (ASTM B213) to maintain consistency.

5) What post-processing is common for AM parts made from Spherical Titanium Powder?

- Stress relief, HIP to close porosity, and heat treatments per alloy (e.g., Ti‑6Al‑4V). Surface finishing (machining, shot peen, electropolish) and NDT (CT, dye penetrant) are used for critical components.

2025 Industry Trends: Spherical Titanium Powder

- Digital powder passports: Lot-level traceability for PSD (D10/D50/D90), O/N/H, flow, tap density, and reuse count accelerating cross-site qualifications.

- Sustainability gains: Inert gas recovery (Ar) and higher recycled feed content disclosures (5–20%) without compromising O/N specs.

- Higher throughput AM: Multi-laser systems and path optimization improving LPBF build rates by 20–50% for Ti‑6Al‑4V.

- Medical and aerospace focus: Tighter bioburden/EO sterilization workflows for medical-grade powders and stricter inclusion control for flight hardware.

- Coarse-cut growth: Expanded 45–106 μm cuts for EBM and cold spray, improving application reach beyond LPBF.

2025 KPI Snapshot for Spherical Titanium Powder (indicative ranges)

| メートル | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| Sphericity (AM grade) | 0.92–0.95 | 0.94–0.97 | Plasma/EIGA improvements |

| Oxygen (wt%, Ti‑6Al‑4V AM grade) | 0.10–0.20 | 0.08–0.18 | Better inert handling |

| Hall flow (spherical 15–45 μm) | 25–32 s/50 g | 22–28 s/50 g | ASTM B213 |

| Tap density (g/cm³, 15–45 μm) | 3.6–4.0 | 3.8–4.2 | Depends on PSD |

| LPBF build rate (cm³/h per laser) | 25–40 | 35–60 | OEM notes, multi‑laser |

| Reuse cycles before blend | 3–6 | 5-10 | With digital passports |

References: ASTM B213/B212/B703; ASTM E1409 (O/N), E1447 (H); ISO/ASTM 52907; OEM application notes (EOS, SLM Solutions, GE Additive); NIST AM‑Bench

Latest Research Cases

Case Study 1: Improving LPBF Yield with Low‑Oxygen Spherical Titanium Powder (2025)

Background: An orthopedic OEM experienced variable elongation in Ti‑6Al‑4V ELI acetabular cups due to powder reuse.

Solution: Implemented digital powder passports, tightened O spec from 0.18 to 0.13 wt% max, added inline oxygen monitoring and tighter sieving (20–63 μm). Post‑HIP and surface finishing standardized.

Results: Elongation Cpk improved 0.9 → 1.5; CT‑detected porosity reduced by 35%; first‑pass yield +12%; no change in build rate.

Case Study 2: EIGA Spherical Titanium Powder for Thin‑Wall Aerospace Brackets (2024)

Background: An aero supplier needed consistent layer spread for 0.8–1.2 mm walls in Ti‑6Al‑4V.

Solution: Switched to EIGA powder (D50 ≈ 35 μm, sphericity >0.96), optimized recoater speed and stripe rotation, applied HIP and machining.

Results: Lack‑of‑fusion defects −42%; as‑built density +0.4% absolute; bracket mass −9% via topology optimization; lead time −30% vs prior workflow.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “For Spherical Titanium Powder, oxygen and hydrogen control verified by standardized methods is pivotal to predictable fatigue life in AM parts.” https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “In 2025 we see parameter portability and digital material passports making titanium AM scalable for serial aerospace and medical production.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Closer alignment with ISO/ASTM 52907 and harmonized COAs is shortening qualification cycles for Ti‑6Al‑4V and related medical/aerospace grades.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: General principles for metal powder feedstock characterization

https://www.iso.org/standard/78974.html - ASTM E1409/E1447: Determination of O/N and H in titanium

https://www.astm.org/ - ASTM F2924/F3301/F3571: AM process and material standards for titanium alloys

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for AM process validation

https://www.nist.gov/ambench - Senvol Database: Machine/material data for Spherical Titanium Powder applications

https://senvol.com/database - HSE ATEX/DSEAR: Guidance on combustible metal powders and inert gas handling

https://www.hse.gov.uk/fireandexplosion/atex.htm

Last updated: 2025-08-27

Changelog: Added five focused FAQs, 2025 KPI/trend table, two case studies (medical and aerospace), expert viewpoints, and curated standards/resources for Spherical Titanium Powder.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, OEMs release new Ti AM parameter sets, or significant changes occur in oxygen control/reuse best practices.