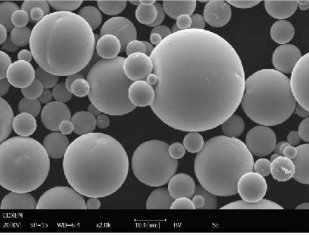

Aperçu de la poudre de FeCoNiCrMn

Poudre de FeCoNiCrMnsouvent appelé alliage à haute entropie (HEA), représente une avancée révolutionnaire dans la science des matériaux. Connue pour ses remarquables propriétés mécaniques, chimiques et thermiques, cette poudre métallique est largement utilisée dans des applications exigeant solidité, résistance à la corrosion et polyvalence. Les HEA, y compris le FeCoNiCrMn, ont gagné en popularité grâce à leur conception unique à éléments principaux multiples, s'écartant des alliages traditionnels dominés par un ou deux éléments clés.

Dans ce guide complet, nous allons nous plonger dans la poudre de FeCoNiCrMn, en explorant sa composition, ses caractéristiques, ses modèles et ses applications. Nous aborderons également les avantages, les limites et les principaux fournisseurs, afin de vous donner une vue d'ensemble qui vous permettra de prendre des décisions en toute connaissance de cause.

Qu'est-ce que la poudre de FeCoNiCrMn ?

La poudre FeCoNiCrMn est une poudre d'alliage à cinq éléments combinant le fer (Fe), le cobalt (Co), le nickel (Ni), le chrome (Cr) et le manganèse (Mn) dans des proportions presque égales. Cette composition équilibrée est à la base de ses caractéristiques de haute entropie, qui se traduisent par d'excellentes propriétés structurelles et fonctionnelles.

Faits marquants

- Résistance et dureté élevées : Propriétés mécaniques exceptionnelles grâce à son arrangement atomique unique.

- Stabilité thermique : Idéal pour les applications à haute température.

- Résistance à la corrosion : Résistant à l'oxydation et à la dégradation chimique.

- Polyvalence : Largement utilisé dans les secteurs de la fabrication additive, de l'aérospatiale et de la biomédecine.

Composition des Poudre de FeCoNiCrMn

Il est essentiel de comprendre la composition pour comprendre pourquoi cette poudre est si performante. En voici la composition :

| Élément | Pourcentage (plage typique) | Rôle dans Alloy |

|---|---|---|

| Fer (Fe) | 19-23% | Améliore les propriétés magnétiques et la résistance. |

| Cobalt (Co) | 19-23% | Assure la solidité et la résistance thermique. |

| Nickel (Ni) | 19-23% | Améliore la résistance à la corrosion et la ductilité. |

| Chrome (Cr) | 19-23% | Résistance à la corrosion et dureté. |

| Manganèse (Mn) | 19-23% | Contribue à l'ouvrabilité et aux propriétés anti-usure. |

Cette distribution quasi équiatomique minimise la distorsion du réseau cristallin, ce qui permet d'obtenir des performances supérieures dans des conditions difficiles.

Caractéristiques de la poudre de FeCoNiCrMn

Les propriétés de ce matériau en font un choix de premier ordre dans tous les secteurs d'activité. Examinons ces caractéristiques de plus près :

| Propriété | Détails |

|---|---|

| Entropie élevée | Arrangement atomique unique dû à une répartition égale des éléments. |

| Stabilité thermique | Structure et performances stables à des températures élevées (jusqu'à 1000°C et au-delà). |

| Résistance à la corrosion | Excellente résistance à l'oxydation et aux attaques chimiques, même dans des environnements difficiles. |

| Résistance mécanique | Résistance élevée à la traction, ductilité et résistance à l'usure. |

| Propriétés magnétiques | Conserve le comportement magnétique utile dans l'électronique et les machines spécialisées. |

Ces propriétés permettent au FeCoNiCrMn d'être performant dans des scénarios exigeants tels que les moteurs à réaction, l'impression 3D et les environnements marins.

Applications de la Poudre de FeCoNiCrMn

La poudre de FeCoNiCrMn fait partie intégrante de plusieurs industries de haute technologie. Pour plus de clarté, nous présentons ci-dessous une matrice d'application :

| L'industrie | Applications | Principaux avantages |

|---|---|---|

| Aérospatiale | Composants de moteurs à réaction, aubes de turbines. | Résistance à la chaleur et résistance aux contraintes. |

| Fabrication additive | Impression 3D de structures complexes. | Polyvalence et finitions de haute qualité. |

| Biomédical | Instruments chirurgicaux, implants. | Biocompatibilité et résistance à la corrosion. |

| Marine | Pièces détachées de navires, machines sous-marines. | Résistance à la corrosion et à l'usure. |

| L'énergie | Centrales électriques, réacteurs nucléaires. | Stabilité à des températures et des pressions élevées. |

Modèles de poudres FeCoNiCrMn

Examinons les modèles de poudres FeCoNiCrMn spécifiques afin de mieux comprendre les variations et leurs applications spécifiques :

| Nom du modèle | Description |

|---|---|

| FeCoNiCrMn-101 | Qualité standard pour la fabrication additive et les revêtements à usage général. |

| FeCoNiCrMn-202 | Formulation améliorée résistante à la corrosion pour les applications marines et biomédicales. |

| FeCoNiCrMn-HT100 | Variante haute température optimisée pour l'aérospatiale et la production d'énergie. |

| FeCoNiCrMn-WR | Modèle résistant à l'usure, idéal pour les machines industrielles et les outils miniers. |

| FeCoNiCrMn-BM | Version biocompatible spécialement conçue pour les implants et instruments médicaux. |

| FeCoNiCrMn-AM | Qualité avancée pour les applications d'impression 3D, garantissant des finitions plus lisses et des détails complexes. |

| FeCoNiCrMn-Plus | Mélange d'alliages de première qualité avec une résistance à la traction et une ductilité supérieures pour les conditions extrêmes. |

| FeCoNiCrMn-Céramix | Formulation hybride incorporant des propriétés de type céramique pour une dureté et une résistance à l'usure accrues. |

| FeCoNiCrMn-Light | Version légère pour les applications aérospatiales et automobiles nécessitant un rapport résistance/poids élevé. |

| Hybride FeCoNiCrMn | Modèle polyvalent conçu pour les applications hybrides impliquant des défis thermiques et de corrosion. |

Spécifications et normes

Lors de l'approvisionnement en poudre de FeCoNiCrMn, il est essentiel de comprendre les spécifications :

| Paramètres | Range | Notes |

|---|---|---|

| Taille des particules | 15-150 microns | Optimisé pour l'impression 3D et le frittage laser. |

| La pureté | ≥99.5% | Garantit des performances et une fiabilité élevées. |

| Densité | 7,5-8,0 g/cm³ | Reflet de son entropie et de sa composition élevées. |

| Point de fusion | ~1350°C | Offre une excellente stabilité thermique. |

| Respect des normes | ISO 9001, ASTM E-8 | Assurer la qualité et la cohérence des lots. |

Avantages et inconvénients de la Poudre de FeCoNiCrMn

Chaque matériau a ses avantages et ses inconvénients, et la poudre de FeCoNiCrMn ne fait pas exception. Voici une comparaison :

| Avantages | Inconvénients |

|---|---|

| Propriétés mécaniques exceptionnelles | Coût plus élevé que celui des alliages conventionnels. |

| Polyvalent pour diverses applications | Fournisseurs limités et difficultés d'approvisionnement. |

| Résistance exceptionnelle à la corrosion et à l'oxydation | Nécessite des machines de pointe pour la transformation. |

| Stabilité thermique à des températures extrêmes | Limites potentielles dans les applications légères. |

Fournisseurs et prix

Il est essentiel de trouver des fournisseurs fiables pour garantir la qualité. En voici une liste restreinte :

| Nom du fournisseur | Localisation | Prix (USD/Kg) | Spécialisation |

|---|---|---|---|

| AlloyTech Solutions | ÉTATS-UNIS | $250-$300 | Poudres de qualité aérospatiale. |

| PowderMasters Inc. | Allemagne | $220-$280 | Taille des particules personnalisée. |

| Fournisseurs de GlobalHEA | Chine | $200-$240 | Commandes en gros et qualités standard. |

| MetalMatrix Co. | Inde | $180-$220 | Options rentables pour un usage général. |

| Dynamique HEA | Japon | $270-$320 | Alliages haut de gamme. |

FAQ

| Question | Réponse |

|---|---|

| Quelle est l'utilisation principale de la poudre de FeCoNiCrMn ? | Il est utilisé dans l'aérospatiale, la fabrication additive et les applications biomédicales en raison de sa polyvalence. |

| Le FeCoNiCrMn est-il biocompatible ? | Oui, des modèles spécifiques comme le FeCoNiCrMn-BM sont conçus pour des utilisations biomédicales. |

| Qu'est-ce qui en fait un alliage à haute entropie ? | La proportion presque égale des cinq éléments principaux crée une configuration stable et à forte entropie. |

| Quelle est la différence avec les alliages conventionnels ? | Il offre une meilleure résistance à la corrosion, une meilleure stabilité thermique et une meilleure résistance mécanique. |

| Le FeCoNiCrMn peut-il être utilisé dans l'impression 3D ? | Absolument, il est largement utilisé dans la fabrication additive en raison de sa distribution de poudre fine. |