1. Introduction: What Is Ni60 Powder and Why It Matters for Manufacturers

Ni60 powder is a nickel-based alloy powder widely recognized for its exceptional wear resistance, corrosion resistance, and high-temperature performance. It is primarily composed of nickel (Ni), chromium (Cr), boron (B), silicon (Si), iron (Fe), and carbon (C). This powder is particularly suitable for thermal spraying, laser cladding, and powder metallurgy (PM) processes.

In the B2B manufacturing space, Ni60 powder is a critical material for producing surface hardening coatings and wear-resistant parts, making it indispensable in sectors like:

- Automobile

- Aérospatiale

- L'énergie

- Pétrole et gaz

- Heavy machinery

Key Benefits for Industrial Buyers and Distributors

| Fonctionnalité | Bénéfice |

|---|---|

| Dureté élevée | Ideal for surface coatings subjected to abrasion |

| Self-fluxing | Excellent bonding during thermal spray processes |

| Résistance à la corrosion | Long life in harsh environments |

| Compatibilité | Suitable for laser cladding, PTA welding, and HVOF |

For wholesale buyers, having a reliable source of Ni60 powder ensures consistency in production quality and cost-efficiency in bulk orders.

2. Applications of Ni60 Powder in Industrial Sectors

Ni60 powder is extensively used in the following industrial applications:

✅ Thermal Spray Coatings

Ni60 powder is ideal for flame spraying and plasma spraying to create hard, wear-resistant coatings on substrates like steel and aluminum. These coatings are commonly used in:

- Hydraulic shafts

- Pump sleeves

- Valves and piston rods

✅ Laser Cladding & PTA Welding

Thanks to its high flowability and self-fluxing properties, Ni60 powder is perfect for laser cladding and plasma transferred arc (PTA) welding, providing:

- Metallurgically bonded layers

- Resistance to abrasive wear and oxidation

- Extended service life of components

✅ Powder Metallurgy (PM) Applications

In the PM industry, Ni60 is used to produce near-net-shape components with enhanced mechanical and surface properties.

| Domaine d'application | Component Example | Bénéfice |

|---|---|---|

| Pétrole et gaz | Outils de fond de puits | Corrosion and heat resistance |

| L'énergie | Turbine blades | Longue durée de vie |

| Automobile | Pièces de moteur | Reduced maintenance needs |

If you’re sourcing for high-performance wear-resistant materials, Ni60 powder is a strategic choice for your manufacturing line.

3. Properties and Use Cases of Ni60 Alloy Powder

Understanding the technical specifications of Ni60 powder is essential for OEM manufacturers, distributors, and procurement teams.

🔬 Chemical Composition (Typical)

| Élément | Contenu (%) |

|---|---|

| Ni | >60 |

| Cr | 14–18 |

| B | 2–3 |

| Si | 3–5 |

| Fe | <5 |

| C | 0.5–1.2 |

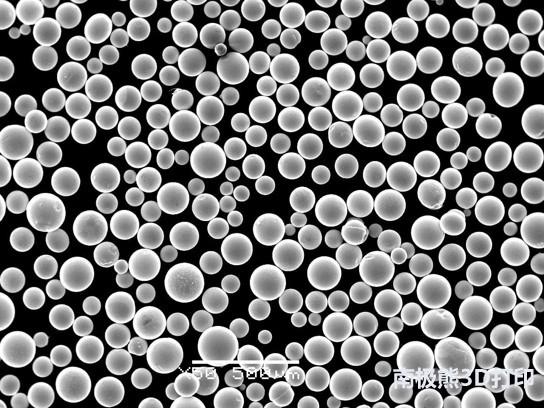

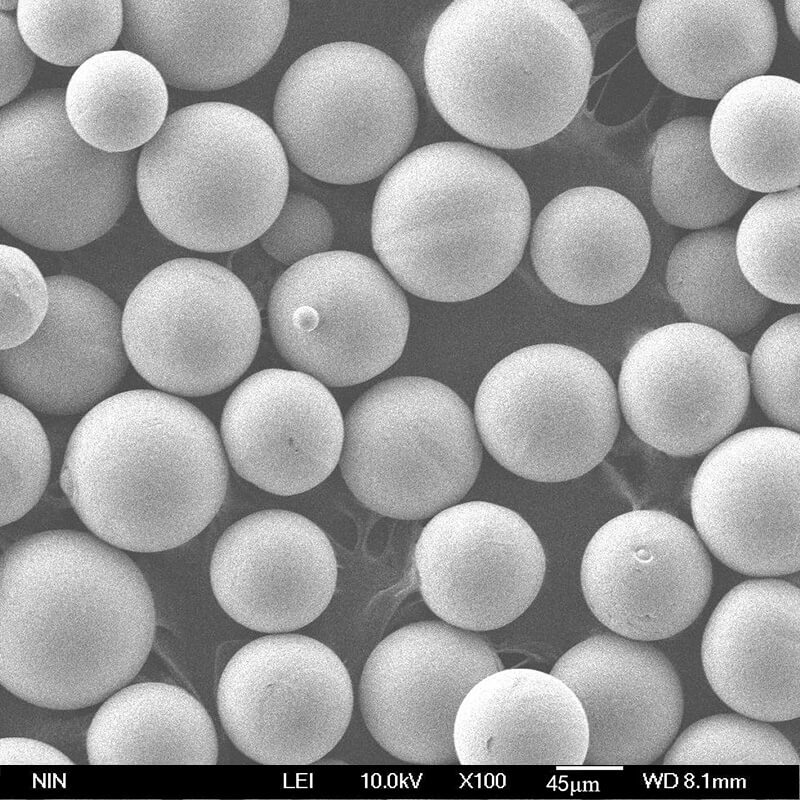

🧪 Physical Properties

- Particle Size: -45μm, -75μm (customizable)

- Flowability: High

- Melting Point: ~1020°C

- Hardness of Coating: ~58–62 HRC after thermal spraying

🌍 Use Cases and Benefits

- Entretien et réparation: Ideal for rebuilding worn components.

- OEM Manufacturing: Used in new parts for heavy-duty equipment.

- Fabrication additive: Emerging use in metal Impression 3D des applications.

By using Ni60 powder, manufacturers can achieve superior surface performance, reduce component failures, and extend maintenance intervals—key benefits for industrial clients focused on total cost of ownership (TCO).

Shanghai Truer Technology Co., Ltd, as a premier supplier of Poudres PM, offers high-quality Ni60 powder suitable for a wide range of industrial applications. The company utilizes advanced atomization techniques to ensure consistent particle distribution, high purity, and excellent fluidity, making it an ideal partner for global distributors and OEMs.

4. Market Trends and Global Demand for Ni60 Powder

The global demand for Ni60 powder has seen significant growth in recent years, driven by the expanding needs of the aerospace, oil & gas, and automotive industries. As industries demand longer-lasting and high-performance materials, nickel-based alloy powders like Ni60 are becoming central to advanced manufacturing techniques.

🔍 Global Market Insight

According to recent market research, the thermal spray powders market—including Ni60—is projected to grow at a CAGR of over 6% between 2024 and 2030. This growth is largely attributed to:

- Increasing demand for wear-resistant coatings

- Rapid adoption of laser cladding and PTA welding in manufacturing

- Growth of 3D printing technologies in metal fabrication

🌍 Regional Demand Breakdown

| Région | Demand Drivers | Industries clés |

|---|---|---|

| Amérique du Nord | Aérospatiale, Pétrole et gaz | Turbine manufacturing, pipeline repair |

| L'Europe | Automotive, Energy | Engine wear parts, power generation |

| Asie-Pacifique | Infrastructure, Industrial Machinery | Construction equipment, mining tools |

🛒 High-Intent B2B Keywords (for SEO)

- Ni60 powder wholesale

- Ni60 thermal spray powder supplier

- Nickel alloy powder for wear resistance

- Ni60 powder manufacturer China

- Buy Ni60 powder bulk

As these trends continue, B2B buyers are increasingly seeking reliable, cost-effective sources—particularly in Asia—to meet growing demands at scale.

5. Top Ni60 Powder Suppliers in Asia and Globally

For procurement officers and supply chain managers, choosing the right Ni60 powder supplier is essential to maintaining quality and operational efficiency. Below is a list of top-tier global and Asian suppliers of Ni60 powder, evaluated based on quality, production capability, certifications, and client base.

🌟 Global Ni60 Powder Suppliers

| Fournisseur | Pays | Principaux points forts |

|---|---|---|

| Hoganas AB | Suède | High-purity PM powders, global distribution |

| Oerlikon Metco | Suisse | Advanced thermal spray materials |

| Praxair Surface Technologies | ÉTATS-UNIS | PTA and laser cladding powders |

🌏 Leading Asian Suppliers

| Fournisseur | Pays | Principaux points forts |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Full range of PM and additive powders, in-house R&D |

| Sandvik Asia | Inde | Specialized in alloy powders and wear-resistant materials |

| Toho Titanium | Japon | High-quality alloy powders for aerospace |

Shanghai Truer Technology is recognized for its wide range of high-performance PM powders, including Ni60, and has provided materials for industrial applications across Asia, the EU, and North America. With a strong focus on quality control and vertical integration, Truer offers consistent particle sizing, chemical homogeneity, and excellent flowability.

6. Why More Distributors Are Turning to Chinese Manufacturers

Over the past decade, China has emerged as a global powerhouse in powder metallurgy and advanced materials manufacturing. Distributors and OEMs from Europe, the U.S., and Southeast Asia are increasingly sourcing Ni60 powder directly from Chinese producers—and for good reason.

✅ Key Advantages of Sourcing from China

- Rentabilité: Competitive pricing due to mature supply chains and large-scale production

- Expertise technique: Rapid advancements in atomization and metallurgy

- Personnalisation: Ability to tailor specs, particle sizes, and packaging for B2B clients

- Logistique et soutien à l'exportation: Dedicated international sales teams and shipping networks

🏭 Case Study: Shanghai Truer Technology

Shanghai Truer Technology Co., Ltd, founded in 2009, has become a trusted name in the Chinese powder metallurgy industry. Since launching its additive manufacturing division in 2019, Truer has provided high-quality Ni60 powder for:

- Laser cladding systems

- Thermal spray coating companies

- Fabricants de composants PM

The company offers powders using gas atomization, water atomization, and combined methods, ensuring flexibility in meeting diverse industrial requirements. Its proprietary additive solutions and lubricant systems further enhance its position as a one-stop supplier for powder metallurgy.

Visitez Truer's A propos de nous to learn more about the company’s history and technical capabilities.

7. Why Choose Shanghai Truer Technology as Your Ni60 Powder Supplier

When selecting a wholesale supplier for Ni60 powder, industrial buyers must evaluate not only product quality but also technical support, consistency in supply, and the ability to meet custom specifications. Shanghai Truer Technology Co., Ltd. stands out as one of the most reliable and professional suppliers in the Chinese powder metallurgy market.

🏆 What Makes Truer a Preferred Ni60 Powder Partner?

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| Established expertise since 2009 | Over 14 years of metallurgy and materials R&D |

| Advanced atomization technologies | Gas, water, and hybrid atomization for tailored powder performance |

| Custom particle sizing | -45μm, -75μm, or as specified by client needs |

| Production certifiée ISO | Ensures quality, traceability, and compliance |

| Dedicated export services | Full support for international logistics and documentation |

| Wide product range | Offers not just Ni60, but bronze, iron, steel, brass, and specialty PM powders |

As one of the most trusted PM additive suppliers in China, Truer is not only a Ni60 powder provider but also a complete additive solutions partner. Their in-house R&D team continues to innovate in powder metallurgy lubricants, cutting agents, and graphite additives.

🌐 Learn More

Explore Truer’s full range of PM powders and additive solutions tailored for industrial manufacturing, 3D printing, and thermal spraying.

8. How to Order Wholesale Ni60 Powder from China

For B2B procurement teams, ordering Ni60 powder wholesale should be straightforward, transparent, and efficient. Shanghai Truer Technology has streamlined its ordering process to support buyers from initial inquiry to final delivery.

📝 Step-by-Step Ordering Process

| Étape | Description |

|---|---|

| 1. Demande de renseignements | Contact Truer via their Page de contact with your specifications and volume requirements. |

| 2. Consultation technique | Truer’s sales engineers will guide you on particle size options, purity, and best practices for your application. |

| 3. Quotation & Lead Time | Receive a detailed quotation including lead time, pricing, packaging, and shipping terms. |

| 4. Sample Testing (Optional) | Request a sample batch for testing coating performance or PM compatibility. |

| 5. Purchase Order Confirmation | Once specs are approved, issue a PO and initiate the order. |

| 6. Production & Quality Control | Truer manufactures and inspects the batch per ISO standards. |

| 7. Expédition et livraison | Global delivery via sea, air, or express based on urgency and volume. |

📦 Options d'emballage

- 5kg / 10kg foil bags (vacuum-sealed)

- 25kg drums

- Custom bulk packaging available upon request

📌 Pro Tips for First-Time Buyers

- Clearly define your particle size and application use (e.g., laser cladding, HVOF spray, PM part production)

- Ask for a Certificate of Analysis (CoA) for every batch

- Confirm Incoterms (FOB, CIF, EXW) for international shipping

With a robust export infrastructure, Truer ensures timely and safe delivery to clients in North America, Europe, Southeast Asia, and the Middle East.

9. FAQs: Buying Wholesale Ni60 Powder for Industrial Use

Here are some of the most common questions we receive from industrial buyers and distributors:

❓ What is the typical hardness of Ni60 coatings?

The hardness of coatings made using Ni60 powder is approximately 58–62 HRC, depending on spraying method and heat treatment.

❓ What manufacturing methods are compatible with Ni60 powder?

Ni60 is ideal for:

- Revêtement par laser

- Plasma Transferred Arc (PTA) welding

- Flame spraying

- Powder Metallurgy (PM) sintering

❓ Does Shanghai Truer offer custom blends of Ni-based powders?

Yes. Truer can customize compositions and particle size distributions to meet specific requirements for wear resistance, corrosion resistance, or flowability.

❓ Can I get technical support for using Ni60 in my process?

Absolutely. Truer provides engineering consultations to help optimize performance in your application, whether it’s thermal spraying or PM part production.

❓ Is Truer’s Ni60 powder suitable for additive manufacturing (3D printing)?

Yes, Truer’s gas-atomized Ni60 powders with controlled spherical morphology are suitable for selective laser melting (SLM) and direct energy deposition (DED) processes.

❓ Where can I see the full product portfolio?

You can view Truer’s complete line of metal powders and additives on their site officiel.

✅ Final Internal Links Summary

- Poudres PM – Linked under Section 1 and 5

- À propos de Truer Technology – Linked under Section 6

- Page de contact – Linked under Section 8

- Truer Product Catalog – Linked in FAQ section

- PM Additive Solutions – Linked under Section 7

By partnering with Shanghai Truer Technology Co., Ltd., industrial buyers can ensure a reliable, consistent, and technically supported supply of Ni60 powder for high-performance applications. Whether you’re an OEM, distributor, or contract manufacturer, Truer delivers quality at scale.

Ready to request a quote or sample?

📩 Reach out via Truer’s Page de contact today for custom pricing and technical consultation.