1. Introduction to Copper Nickel Tin Powder in Modern Manufacturing

Copper Nickel Tin (Cu-Ni-Sn) powder is a high-performance alloy powder widely used in the automotive, aerospace, electronics, and defense industries. Known for its exceptional strength, corrosion resistance, and wear resistance, this powder has become a critical material for advanced powder metallurgy (PM) and additive manufacturing (AM) applications.

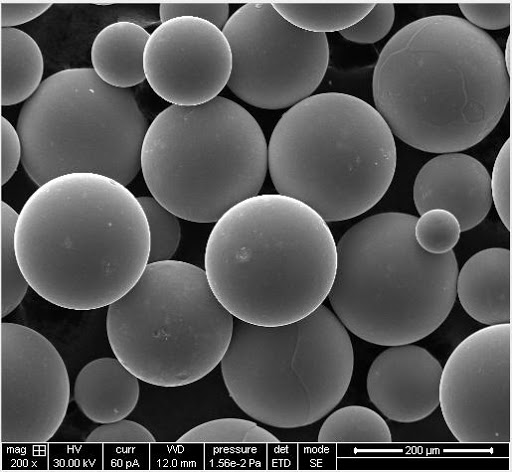

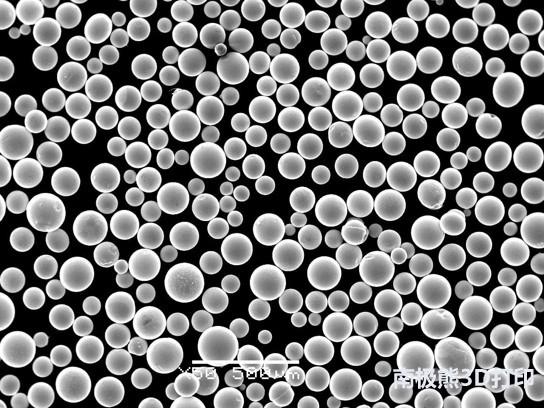

As industries continue their transition to lightweight, high-strength components, copper nickel tin powders offer a unique combination of mechanical properties and processing flexibility. These powders are typically produced through atomization processes such as water atomization, gas atomization, or a hybrid of both, ensuring high purity and homogeneity.

Why Cu-Ni-Sn Matters in B2B Supply Chains:

- High demand from OEMs, tier-1 suppliers, and defense contractors

- Critical for sintered parts, precision components, and bearing materials

- A preferred alternative to toxic beryllium copper alloys

- Compatible with both PM and Impression 3D applications

For enterprise buyers, distributors, and e-commerce sellers, sourcing high-quality copper nickel tin powder is essential for maintaining production consistency and achieving cost-effective results.

2. Industrial Applications of Copper Nickel Tin Alloy Powder

Copper nickel tin alloy powders are versatile and serve across various B2B sectors. These powders are particularly valued in industries that require non-magnetic, high-strength, and corrosion-resistant materials.

Principaux domaines d'application

| L'industrie | application | Avantages |

|---|---|---|

| Automobile | Synchronizer rings, valve guides | Wear resistance, fatigue strength |

| Aérospatiale | Bushings, fasteners, structural components | Léger, très résistant |

| Électronique | Connectors, springs, contacts | Conductivity, fatigue endurance |

| Defense & Military | Ammunition casings, radar components | Non-magnetic, high precision |

| Watchmaking | Precision gears, springs | Aesthetic finish, high wear resistance |

| Marine | Propellers, shafts, pump components | Excellente résistance à la corrosion |

Advantages in Powder Metallurgy:

- Net-shape manufacturing reduces waste

- Shorter production cycles

- Enables high-volume, low-cost component production

- Customizable compositions for specific applications

Many of these applications are transitioning from traditional materials to copper nickel tin powders due to environmental compliance, particularly in replacing beryllium copper alloys.

3. Properties and Grades of Copper Nickel Tin Powder

Understanding the material properties and available grades is crucial for procurement teams, R&D engineers, and product designers in B2B markets.

Propriétés principales

- High Yield Strength: Up to 1200 MPa (post heat treatment)

- Excellent Fatigue Resistance: Suitable for dynamic load applications

- Résistance supérieure à l'usure: Outperforms many bronze and brass alloys

- Non-Magnetic: Ideal for defense and electronic use

- Résistance à la corrosion: Comparable to stainless steels in marine environments

- Bonne usinabilité: Especially with optimized cutting agents

Typical Grades Available

| Grade | Cu (%) | Ni (%) | Sn (%) | Caractéristiques |

|---|---|---|---|---|

| CN7 | 85 | 7 | 8 | Balanced strength and conductivity |

| CN10 | 80 | 10 | 10 | Higher strength, reduced conductivity |

| CN12-8 | 80 | 12 | 8 | Résistance accrue à la corrosion |

| Custom Blend | Sur mesure | Sur mesure | Sur mesure | Tailored to specific mechanical requirements |

At Shanghai Truer Technology Co., we offer custom-grade Cu-Ni-Sn powders for PM and AM applications. Our powders are produced using advanced atomization technologies, ensuring excellent flowability, compressibility, and uniform performance across batches.

Powder Characteristics Table

| Attribut | Spécifications |

|---|---|

| Particle Size (D50) | 15–75 µm (adjustable by request) |

| Densité apparente | 2.8 – 4.5 g/cm³ |

| Débit (débit de Hall) | <35 s/50g |

| La pureté | >99.5% |

| Teneur en oxygène | <0.1% (depending on production method) |

| Méthode de production | Water atomized / Gas atomized |

These powders are ideal for pressing and sintering operations, metal injection molding (MIM), and binder jetting. We also offer diffusion-alloyed and pre-alloyed variants depending on customer requirements.

Click to explore our complete powder metallurgy product range to see what else we offer.

4. Global Market Trends and Growth Potential for Cu-Ni-Sn Powder

The global copper nickel tin (Cu-Ni-Sn) alloy powder market is experiencing steady growth, driven by the increasing demand for high-performance materials in automotive, electronics, defense, and additive manufacturing sectors. As industries seek sustainable and high-strength alternatives to traditional copper alloys, Cu-Ni-Sn powders are becoming a material of choice due to their mechanical superiority and eco-friendly profile.

Market Drivers

- Beryllium Replacement: Stringent regulations regarding beryllium use are pushing industries to adopt Cu-Ni-Sn alloys as a safer, high-performance alternative.

- Additive Manufacturing Growth: Cu-Ni-Sn powders are gaining traction in metal 3D printing due to their excellent flowability and sintering characteristics.

- Miniaturization in Electronics: The demand for wear-resistant, non-magnetic materials in micro-components is fueling interest in Cu-Ni-Sn.

- Expansion of EV Industry: As electric vehicles require highly durable and conductive components, Cu-Ni-Sn alloys are being integrated into motor and battery modules.

Prévisions de marché (2024-2030)

| Région | 2024 Market Value (USD Million) | CAGR (2024-2030) | Key Sectors |

|---|---|---|---|

| Asie-Pacifique | 110 | 8.9% | Automotive, Electronics, Defense |

| Amérique du Nord | 78 | 7.2% | Aérospatiale, défense |

| L'Europe | 65 | 6.8% | Automotive, Energy Sector |

| Moyen-Orient | 22 | 5.4% | Marine, Industrial Components |

| South America | 18 | 4.9% | Mining Equipment, Heavy Industries |

With its corrosion resistance and fatigue performance, Cu-Ni-Sn powder is poised to replace multiple traditional alloys in PM and AM applications.

5. Key Considerations When Choosing a Copper Nickel Tin Powder Supplier

Selecting the right Cu-Ni-Sn powder supplier is critical for manufacturers, distributors, and OEMs to ensure product consistency, cost-efficiency, and scalability.

Liste de contrôle pour l'évaluation des fournisseurs

- ✅ Powder Quality Certifications: ISO 9001, RoHS, REACH compliance

- ✅ Capacités de production: Atomization method (water/gas), capacity, consistency

- ✅ Options de personnalisation: Custom alloy blends, particle size distribution

- ✅ Fiabilité de la chaîne d'approvisionnement: On-time delivery, inventory management, global logistics

- ✅ Support technique: Application engineering, R&D collaboration

- ✅ Transparence des prix: Competitive bulk pricing, MOQ flexibility

Drapeaux rouges à éviter

- ❌ No third-party testing or material traceability

- ❌ Inconsistent particle size or high oxygen levels

- ❌ Poor flowability affecting press and sintering quality

- ❌ Limited technical documentation

At Shanghai Truer Technology Co., Ltd, we meet all industry standards and offer technical support through a dedicated R&D team to help optimize your Cu-Ni-Sn powder usage. We also provide detailed testing sheets with every shipment, ensuring transparency and trust.

6. Top 5 Reliable Copper Nickel Tin Powder Suppliers in Asia

For B2B buyers, especially in the Asia-Pacific region, sourcing from reputable suppliers is essential to ensure consistent quality and delivery. Below are five of the most trusted suppliers of Cu-Ni-Sn powder.

| Entreprise | Pays | Points forts |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Wide alloy portfolio, customizable grades, advanced atomization tech |

| JX Nippon Mining & Metals | Japon | High-purity Cu-based powders, strict quality control |

| Korea Zinc Co., Ltd | Corée du Sud | Large-scale production, strong logistics network |

| Matériaux Mitsubishi | Japon | Extensive R&D capabilities, global distribution |

| Groupe des poudres CNPC | Chine | Competitive pricing, diversified metal powder product lines |

Parmi ces derniers, Shanghai Truer Technology Co. stands out for its flexible manufacturing, fast lead times, and commitment to powder metallurgy innovation. With in-house powder development, Truer offers both standard and custom Cu-Ni-Sn powder grades for pressing, sintering, and additive manufacturing.

7. Why More Buyers Are Turning to Chinese Suppliers for Cu-Ni-Sn Powder

Chinese suppliers are rapidly becoming the go-to sourcing partners for copper nickel tin powder due to a combination of cost-efficiency, innovation, and robust supply chains.

Key Advantages of Chinese Suppliers

- Lower Manufacturing Costs: Reduced overheads allow for more competitive pricing without compromising quality

- Advanced Production Facilities: Many Chinese companies operate atomization lines comparable to global standards

- Customizable Solutions: Suppliers like Truer offer tailored grades and particle size distributions based on application needs

- Délais d'exécution rapides: Strategic logistics and domestic sourcing of raw materials enable shorter delivery cycles

- Strong R&D Focus: Investment in powder metallurgy R&D ensures cutting-edge material performance

Why Choose Truer from China?

Shanghai Truer Technology Co., Ltd is a leading name in the Chinese PM industry. Since launching its additive manufacturing division in 2019, Truer has expanded its powder portfolio to include high-performance Cu-Ni-Sn powders for both PM and AM applications.

Unique Selling Points of Truer:

- Over 10 years of experience in powder metallurgy

- Expertise dans l'atomisation de l'eau et du gaz

- Custom powder development based on customer specifications

- Dedicated product support team for B2B clients

- Stable monthly production capacity for bulk orders

Explore Truer’s full product line to see available copper nickel tin and other PM-grade powders.

8. Why Choose Shanghai Truer Technology as Your Cu-Ni-Sn Powder Partner

As a trusted additive materials partner, Shanghai Truer Technology Co., Ltd offers unmatched value, quality, and support to industrial buyers, OEMs, and distributors.

Full-Service Supplier Capabilities

| Service Area | Truer Offering |

|---|---|

| Powder Manufacturing | Water atomized, gas atomized, hybrid atomized Cu-Ni-Sn powders |

| Alloy Customization | Tailored compositions and particle size grading for specific applications |

| Technical Consulting | Application engineering, sintering optimization, and product development support |

| Assurance qualité | ISO-certified production, third-party testing, batch traceability |

| Logistique mondiale | Livraison rapide vers l'Asie, l'Europe et l'Amérique du Nord |

| Service à la clientèle | Fast inquiry response, post-sales support, reorder assistance |

Product Examples

| Nom du produit | Grade | Cas d'utilisation |

|---|---|---|

| CuNiSn-WA75 | CN7 | Automotive synchronizer rings |

| CuNiSn-GA60 | CN10 | Aerospace fasteners |

| CuNiSn-CustomBlend | Sur mesure | Defense and marine components |

Truer’s Cu-Ni-Sn powders are widely used in producing sintered parts, bearing materials, and 3D printed components. For product details or to request a datasheet, visit our homepage ou contact us directly.

9. How to Order Wholesale Copper Nickel Tin Powder from Truer

For OEMs, distributors, and industrial buyers looking to streamline their procurement process, Shanghai Truer Technology Co., Ltd offers a seamless and transparent ordering experience for wholesale copper nickel tin (Cu-Ni-Sn) powder.

Step-by-Step Procurement Workflow

- Enquête initiale

- Contact Truer via notre formulaire de contact or email to specify:

- Desired grade or chemical composition

- Volume (kg or tons)

- Distribution de la taille des particules

- Application (PM or AM)

- Shipping destination and timeline

- Contact Truer via notre formulaire de contact or email to specify:

- Consultation technique

- Our technical team assists with:

- Grade selection (e.g., CN7, CN10, CN12-8)

- Custom blending requirements

- Performance optimization based on your application

- Our technical team assists with:

- Quotation & Sampling

- Receive a formal quotation within 24–48 hours

- Optional: Request a free sample (typically 500g–1kg) for testing and validation

- Confirmation de commande

- Sign commercial invoice or purchase order

- Confirm payment terms (T/T, LC, etc.) and Incoterms (FOB, CIF, DDP)

- Production et assurance qualité

- Powder is produced per your specifications

- Batch undergoes quality testing (size analysis, flow rate, chemical analysis)

- Expédition et livraison

- Packaging: Vacuum-sealed or nitrogen-filled bags in drums or cartons

- Shipping: Air freight, sea freight, or express courier depending on urgency

- Lead time: 7–15 working days depending on volume

- Service après-vente

- Assistance technique permanente

- Reorder management and batch consistency assurance

Minimum Order Quantities (MOQ)

| Type de produit | MOQ |

|---|---|

| Standard Cu-Ni-Sn powder | 100 kg |

| Custom alloy formulations | 300 kg |

| Additive Manufacturing grade | 50 kg |

Payment & Shipping Info

- Paiements acceptés: T/T, L/C, PayPal (for samples)

- Ports de navigation: Shanghai, Ningbo, Shenzhen

- Options d'emballage:

- 25kg drum

- 500kg big bag

- Custom packaging upon request

To ensure a smooth transaction, visit our Page de contact to connect with our sales engineers.

10. FAQs: Buying Wholesale Copper Nickel Tin Powder

Here are some of the most frequently asked questions from our B2B buyers:

Q1: What is the difference between gas atomized and water atomized Cu-Ni-Sn powder?

- Gaz Atomisé: Spherical particles, better flowability, ideal for additive manufacturing.

- Eau pulvérisée: Irregular particles, cost-effective, suitable for pressing and sintering.

Q2: Can Truer provide custom alloy ratios?

Yes. We support custom Cu/Ni/Sn ratios based on your mechanical and corrosion resistance requirements. Customization is available with a minimum order of 300kg.

Q3: What is the shelf life of Cu-Ni-Sn powders?

Properly stored in sealed, moisture-proof packaging, the shelf life is 12–24 months depending on the environment.

Q4: Are your powders suitable for metal injection molding (MIM)?

Yes. We offer fine-grade Cu-Ni-Sn powders with narrow particle size distributions suitable for MIM applications.

Q5: What quality certifications do you offer?

- ISO 9001-certified production

- RoHS and REACH compliance

- Full chemical composition and particle size test reports provided

Q6: How can I ensure batch consistency?

We maintain batch traceability and consistent process parameters. Batch samples are archived for reference, and we offer repeat order matching.

Q7: What industries typically buy your Cu-Ni-Sn powder?

- Automotive component manufacturers

- Aerospace and defense contractors

- Bearing and bushing producers

- 3D printing service bureaus

- Electronics and watchmaking firms

Final Thoughts & Call to Action

As the global demand for high-strength, corrosion-resistant, and environmentally friendly materials increases, copper nickel tin powder is securing its place as a top-tier alloy in multiple industries. With its excellent mechanical properties, non-magnetic behavior, and adaptability to both powder metallurgy and additive manufacturing, Cu-Ni-Sn powder is the strategic choice for forward-thinking manufacturers.

For companies looking to scale production, reduce material costs, and stay ahead of compliance requirements, partnering with a reliable supplier is key.

Why You Should Choose Shanghai Truer Technology:

✅ Over a decade of metallurgy experience

✅ Full customization and technical support

✅ Certified quality assurance and fast lead times

✅ Affordable pricing for bulk orders

✅ Dedicated export services for global buyers

Whether you’re sourcing for a new project or optimizing an existing supply chain, Shanghai Truer Technology Co. is committed to delivering value-driven, high-performance Cu-Ni-Sn powders.

👉 Ready to discuss your requirements? Get in touch with us here or explore our Catalogue de poudres PM for more information.

🧪 Looking for samples? Bulk pricing? Custom alloy configurations?

📞 Contact our sales team today and get a quote within 24 hours.