1. Introduction: Why 410 Powder Is Crucial for Industrial Manufacturing

410 stainless steel powder is a martensitic, hardenable stainless steel that offers a balance of strength, hardness, and corrosion resistance. It is widely used in powder metallurgy (PM), additive manufacturing (AM), and metal injection molding (MIM) by industries such as aerospace, automotive, medical device, and industrial tooling.

For B2B buyers—including manufacturers, wholesalers, and distributors—410 powder presents an attractive combination of mechanical performance and cost-efficiency. The powdered form allows for complex geometries, reduced waste, and scalable production, which are essential for high-precision industrial applications.

Key B2B Benefits of 410 Powder:

- High tensile strength and wear resistance

- Good corrosion resistance in mild environments

- Suitable for heat treatment and machining

- Ideal for PM, AM, and MIM production lines

- Cost-effective for high-volume manufacturing

2. Applications of 410 Stainless Steel Powder in B2B Sectors

The versatility of 410 powder makes it a top choice for enterprises across various sectors:

Applications industrielles

| L'industrie | Cas d'utilisation | Bénéfice |

|---|---|---|

| Automobile | Valve components, pumps, gears | Résistance à l'usure, durabilité |

| Aérospatiale | Fasteners, structural parts | Strength-to-weight ratio |

| Pétrole et gaz | Tools, downhole equipment | Résistance à la corrosion |

| Médical | Instruments chirurgicaux | Biocompatibility, sterilization |

| Fabrication additive | Custom prototypes, tooling | Complex geometries, rapid production |

Fabrication additive (AM)

In the AM sector, 410 powder is used extensively for metal Impression 3D processes such as:

- Fusion sélective par laser (SLM)

- Fusion par faisceau d'électrons (EBM)

- Jetting de liant

Its martensitic nature allows post-build heat treatment to achieve high hardness and strength, making it ideal for tooling inserts and functional prototypes.

Key B2B Keywords to Target:

- 410 stainless steel powder supplier

- 410 powder for 3D printing

- wholesale 410 stainless steel powder

- 410 stainless steel additive manufacturing

- stainless steel powder for MIM

3. Key Properties and Technical Specifications of 410 Powder

Understanding the material properties of 410 powder is essential for engineers, procurement teams, and production managers. Below are the core specifications of 410 stainless steel powder provided by leading manufacturers like Shanghai Truer Technology Co..

Composition chimique (typique)

| Élément | Contenu (%) |

|---|---|

| Chrome (Cr) | 11.5 – 13.5 |

| Carbone (C) | 0.15 max |

| Manganèse (Mn) | 1,0 max |

| Silicium (Si) | 1,0 max |

| Phosphore (P) | 0.04 max |

| Soufre (S) | 0,03 max |

| Fer (Fe) | Balance |

Mechanical Properties (After Heat Treatment)

| Propriété | Valeur |

|---|---|

| Dureté | Up to 50 HRC |

| Résistance à la traction | 1000 MPa – 1200 MPa |

| Limite d'élasticité | ~700 MPa |

| Élongation | 10 – 15% |

| Densité | ~7.75 g/cm³ |

Particle Size Distribution (Typical)

- D10: ~10 µm

- D50: ~30 µm

- D90: ~50 µm

Particle sizes can be tailored for specific manufacturing processes like AM and PM.

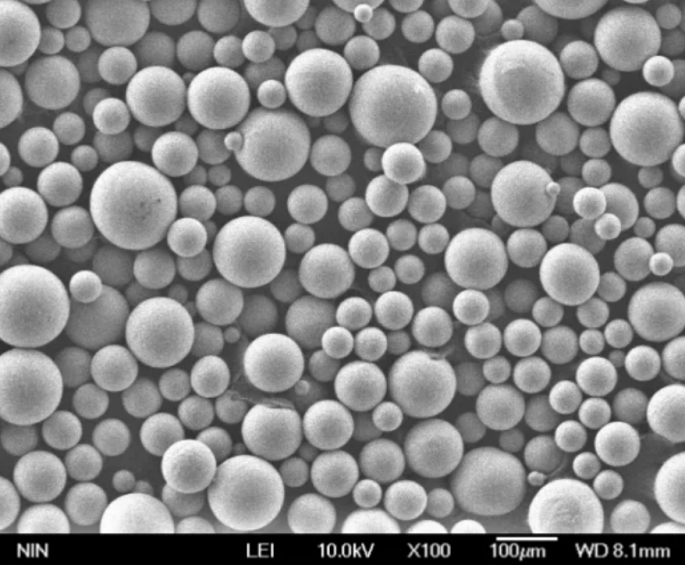

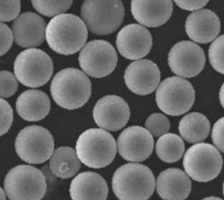

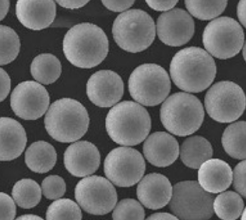

Available Atomization Methods

Shanghai Truer provides 410 stainless steel powder using the following atomization processes:

- Eau pulvérisée

- Gaz Atomisé

- Hybrid Atomization (Water + Gas)

Each type serves different application needs. For example, gas-atomized powders are ideal for high-precision AM due to their spherical shape and flowability.

Product Grades Available

Shanghai Truer offers 410 powder in grades suitable for:

- Métallurgie des poudres (PM)

- Fabrication additive (AM)

- Moulage par injection de métal (MIM)

You can explore a full list of available PM powders on the Page des produits PM Powder.

4. Global Market Trends and Demand Forecast for 410 Powder

The global market for stainless steel powders, including 410-grade, is experiencing steady growth due to the rising demand from additive manufacturing (AM), automotive, aerospace, and medical sectors. As Industry 4.0 and smart manufacturing continue to evolve, more enterprises are shifting toward powder metallurgy and 3D printing for precision parts manufacturing.

Principaux moteurs du marché

- Growth in Additive Manufacturing: The global metal AM market is projected to reach over $20 billion by 2030. 410 stainless steel powder is a preferred material due to its heat-treatability and corrosion resistance.

- Sustainability Initiatives: Powder metallurgy supports near-net-shape production, reducing material waste and energy consumption.

- Allègement automobile : 410 powder is increasingly used for lightweight, strong components in electric and hybrid vehicles.

- Medical Sector Expansion: 410 stainless steel’s biocompatibility and strength make it suitable for surgical tools and implants.

Global Market Forecast (2024–2030)

| Année | Estimated Market Value (USD Billion) | CAGR |

|---|---|---|

| 2024 | 1.6 | - |

| 2025 | 1.9 | 7.5% |

| 2026 | 2.2 | 8.0% |

| 2030 | 3.5+ | 9.2% |

High-Intent Keywords to Integrate:

- 410 stainless steel powder market size

- 410 powder demand forecast

- stainless steel powder for additive manufacturing

- AM powder supplier China

- powder metallurgy stainless steel trends

5. How to Choose a Reliable 410 Powder Supplier

Choosing the right supplier is critical for business buyers, OEMs, and manufacturing teams. Whether you’re sourcing for AM, MIM, or conventional PM processes, ensure the supplier has technical expertise, consistent quality, and scalable production.

Key Factors to Evaluate Suppliers

| Critères | Importance | Pourquoi c'est important |

|---|---|---|

| Expertise technique | ★★★★★ | Knowledge of atomization methods, AM compatibility |

| Cohérence du produit | ★★★★★ | Ensures batch-to-batch uniformity |

| Options de personnalisation | ★★★★☆ | Tailored particle sizes and grades |

| Certifications (ISO, RoHS) | ★★★★☆ | Validates quality and compliance |

| Délais et logistique | ★★★★☆ | Impacts your production scheduling |

| Support après-vente | ★★★★☆ | Critical for large-volume or technical buyers |

Checklist for Wholesale Buyers

- Does the supplier offer both gas and water atomized options?

- Can they provide technical data sheets (TDS) and material safety datasheets (MSDS)?

- Do they offer volume-based discounts or OEM partnerships?

- Are they ISO 9001 certified?

Shanghai Truer Technology Co., Ltd is a trusted supplier that checks all these boxes. You can contact Truer directly here pour demander un devis ou une consultation technique.

6. Top 5 Trusted 410 Powder Manufacturers and Distributors

If you’re looking for high-quality 410 stainless steel powder on a wholesale basis, here are five of the most reliable global suppliers based on industry reputation, product quality, and B2B services.

1. Shanghai Truer Technology Co. Ltd (Chine)

- ✅ Specializes in PM and AM powders

- ✅ Offers water, gas, and hybrid atomization

- ✅ Custom particle size and grade options

- ✅ Trusted by PM and AM manufacturers globally

- 🌐 Visit: À propos de Shanghai Truer

2. Hoganas AB (Sweden)

- ✅ Global leader in powder metallurgy

- ✅ Offers a wide range of stainless steel powders

- ✅ Strong sustainability focus

- ❌ Limited customization for Asian markets

3. GKN Powder Metallurgy (Germany/USA)

- ✅ High-volume capability for OEMs

- ✅ Strong R&D in binder jetting and MIM

- ❌ High minimum order quantities

4. Carpenter Additive (USA)

- ✅ Advanced AM powder portfolio

- ✅ Strong in aerospace certifications

- ❌ High cost for small-volume buyers

5. Sandvik Osprey (UK)

- ✅ Known for spherical, high-purity powders

- ✅ Ideal for SLM and EBM

- ❌ Long lead times outside Europe

| Fournisseur | Région | Type d'atomisation | Services B2B |

|---|---|---|---|

| Shanghai Truer | Chine | Eau, gaz, hybride | OEM, Custom Grades |

| Hoganas AB | Suède | Eau pulvérisée | Support technique |

| GKN | Germany/USA | Divers | High-Volume OEM |

| Charpentier | ÉTATS-UNIS | Gaz Atomisé | AM Focused |

| Sandvik | ROYAUME-UNI | Gaz Atomisé | Haute pureté |

Shanghai Truer stands out for its flexible supply options, custom material development, and support for both large and small buyers. Learn more about their PM product line on the official PM powder page.

7. Why More Buyers Are Sourcing 410 Powder from China

In recent years, a significant shift has been observed where international buyers are increasingly turning to Chinese suppliers for advanced materials like 410 stainless steel powder. This is due to a combination of cost, quality, and technological capability.

Avantages de l'approvisionnement en Chine

- Competitive Pricing: Lower labor and production costs allow for better wholesale pricing.

- Capacités de fabrication avancées : Chinese manufacturers like Shanghai Truer offer both traditional and innovative atomization methods.

- Flexibility in Custom Orders: Easier to get custom batches, tailored particle sizes, and specific grades.

- Faster Lead Times for APAC Buyers: Reduced shipping times for Asian customers and nearby markets.

Challenges (And How to Overcome Them)

| Défi | Solution |

|---|---|

| Assurance qualité | Work with ISO-certified suppliers like Truer |

| Communication barriers | Choose suppliers with English-speaking tech teams |

| Logistique | Use DDP or third-party logistics partners for smoother shipping |

Shanghai Truer has positioned itself as a trusted international partner, offering not just material, but also comprehensive technical support. With a professional team and growing global footprint, Truer is helping reshape the powder metallurgy landscape.

8. How to Order Wholesale 410 Powder from China

For enterprise buyers, OEMs, and distributors, placing a wholesale order for 410 stainless steel powder requires careful planning to ensure the right grade, quantity, and logistics setup. Below is a step-by-step guide to streamline your procurement process when sourcing from trusted suppliers like Shanghai Truer Technology Co..

Processus de commande en gros, étape par étape

| Étape | Détails | Conseils |

|---|---|---|

| 1. Define Product Requirements | Identify particle size, atomization method (gas/water/hybrid), and quantity required. | Consult with your engineering or R&D team for technical specs. |

| 2. Request Technical Data Sheets (TDS) | Ask the supplier for chemical composition, mechanical properties, and particle size distribution. | Ensure the grade matches your application (e.g., AM, PM, or MIM). |

| 3. Get a Quote | Request a formal quotation including pricing, MOQ, delivery time, and payment terms. | Shanghai Truer offers volume-based discounts for bulk orders. |

| 4. Place a Trial Order (Optional) | Before large-scale procurement, consider a trial batch for internal testing. | This helps verify compatibility with your production process. |

| 5. Confirm Order & Sign Agreement | Finalize purchase contracts or supply agreements. Include terms for delivery, quality assurance, and return policy. | For recurring orders, consider a long-term procurement contract. |

| 6. Arrange Logistics | Choose between FOB, CIF, or DDP shipping terms. | Shanghai Truer supports international logistics and can assist with customs documentation. |

| 7. Quality Inspection & Delivery | Upon receipt, inspect the powder batch for consistency and conformance. | Maintain a quality control checklist for batch inspections. |

Shipping & Logistics Options

- FOB Shanghai Port – Cost-effective for experienced importers

- CIF (Cost, Insurance, Freight) – Good for mid-volume orders

- DDP (Delivered Duty Paid) – Recommended for first-time international buyers

When sourcing through Truer, you can also request technical support post-purchase to optimize powder usage in your equipment.

9. FAQs: Everything You Need to Know About Buying 410 Powder Wholesale

Here are the most frequently asked questions from B2B buyers considering 410 stainless steel powder for industrial use.

Q1: What is the minimum order quantity (MOQ) for wholesale 410 powder?

A : At Shanghai Truer, the MOQ typically starts at 100kg, but custom arrangements can be made for trial batches or R&D purposes.

Q2: Which atomization method is best for additive manufacturing?

A : Gas atomization is ideal for AM due to the spherical particle morphology and excellent flowability. Truer offers high-purity gas atomized 410 powder for this purpose.

Q3: Can I get custom particle sizes or blends?

A : Yes. Shanghai Truer offers flexible customization based on the application—whether it’s AM, PM, or MIM. Custom blends and particle size distributions can be requested during the quotation stage.

Q4: Does 410 powder require post-processing?

A : Yes. 410 stainless steel is martensitic and typically requires heat treatment to achieve optimal hardness and mechanical properties after forming or printing.

Q5: How do I ensure powder quality and batch consistency?

A : Always request a Certificate of Analysis (CoA) and TDS with each batch. Truer provides full documentation, and their powders conform to international standards.

Q6: Is technical support available after purchase?

A : Yes. Shanghai Truer offers post-sale technical support to help with powder handling, processing parameters, and troubleshooting.

Q7: Where can I learn more about Truer’s PM and AM powder products?

A : Visit their Poudre PM page produit to explore the full range of available metal powders, including 410 stainless steel, nickel alloys, copper steels, and hybrid grades.

🔍 Why Choose Shanghai Truer Technology Co., Ltd?

Shanghai Truer is not just a powder supplier—they are a complete solutions provider for the additive manufacturing and powder metallurgy industries. With over a decade of experience and a dedicated AM division launched in 2019, Truer offers:

- ✅ A complete portfolio of stainless steel powders including 410, 316L, 420, and more

- ✅ Multiple atomization methods (gas, water, hybrid)

- ✅ Customization capabilities for industrial applications

- ✅ ISO-compliant production and quality assurance

- ✅ Responsive B2B support for OEMs, distributors, and engineers

- ✅ Competitive global pricing and fast logistics

Whether you’re in automotive, aerospace, tool manufacturing, or medical device production, Shanghai Truer is equipped to meet your 410 stainless steel powder needs at scale.

📞 Ready to get started? Contactez Truer aujourd'hui for a free consultation or quotation tailored to your business.