1. Introduction: The Growing Demand for Titanium Alloy Powder in Industry

Titanium alloy powders have become a cornerstone in the evolution of advanced manufacturing, particularly in aerospace, medical, automotive, and additive manufacturing industries. As global industries shift toward lightweight, high-strength, and corrosion-resistant materials, titanium alloy powder demand is experiencing exponential growth.

Why Titanium Alloy Powder Matters in B2B Manufacturing

- Rapport résistance/poids élevé – Ideal for aerospace and automotive applications.

- Résistance à la corrosion – Long-lasting performance in harsh environments.

- Biocompatibilité – Perfect for medical implants and surgical devices.

- Additive Manufacturing Compatibility – Optimized for Impression 3D and powder metallurgy processes.

B2B Benefits of Bulk Titanium Powder Purchasing

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| Bulk Pricing | Significant cost savings for large-volume buyers |

| Une qualité constante | Ensures uniformity in production runs |

| Custom Particle Sizes | Tailored for specific application needs |

| Global Logistics Support | Reliable supply chain for international customers |

For B2B buyers like aerospace OEMs, medical device manufacturers, and 3D printing service providers, titanium alloy powder is not just a material—it’s a strategic investment.

2. Key Industrial Applications of Titanium Alloy Powders

Titanium alloy powders are favored in industries that demand high-performance materials. Below are the core sectors utilizing bulk titanium powders:

Aérospatiale et défense

- Jet engine components

- Airframe structures

- Turbine blades

- Light armor systems

Medical & Dental

- Orthopedic implants (hips, knees, spinal rods)

- Dental bridges and crowns

- Outils chirurgicaux

Automotive & Motorsport

- Engine valves and connecting rods

- Suspension systems

- Lightweight frames

Additive Manufacturing & 3D Printing

- Prototyping and production parts

- Custom medical implants

- Complex aerospace parts with internal channels

Powder Metallurgy (PM) Applications

- High-performance sintered parts

- Structural components with superior fatigue resistance

- Oil and gas tools

Example Table: Titanium Alloy Powder Grades & Applications

| Nuance d'alliage | Utilisation courante | Propriétés |

|---|---|---|

| Ti-6Al-4V (grade 5) | Aérospatiale, Médical | Haute résistance, résistance à la corrosion |

| Ti-6Al-7Nb | Implants médicaux | Biocompatible, nickel-free |

| Ti CP Grade 2 | Chemical processing, 3D printing | Good formability, corrosion resistance |

| Ti-5553 | Motorsport, Aerospace | Haute résistance, résistance à la fatigue |

3. Types of Titanium Alloy Powders and Their Properties

Titanium alloy powders are classified based on their production method, particle size distribution, and composition.

Based on Manufacturing Method

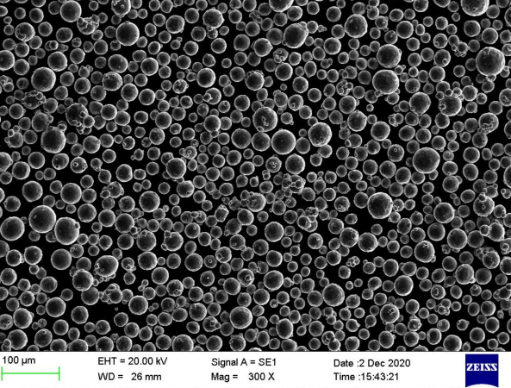

- Gas Atomized Titanium Powder

- Particules sphériques

- Excellente fluidité

- Ideal for metal 3D printing (SLM, EBM)

- Poudre atomisée par plasma

- Ultra-spherical and pure

- Medical-grade implants, aerospace parts

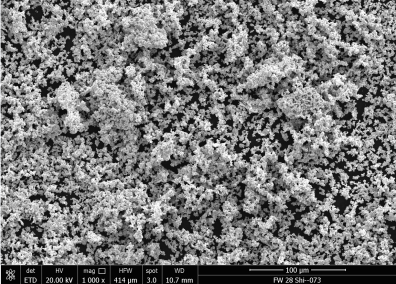

- Hydride-Dehydride (HDH) Powder

- Angular particles

- Rentabilité

- Suitable for PM and press-sinter applications

Based on Composition

- Alpha-Beta Alloys (e.g., Ti-6Al-4V)

- Most widely used

- Balanced properties

- Beta Alloys (e.g., Ti-10V-2Fe-3Al)

- High strength, good formability

- Used in high-performance aerospace and motorsport applications

- Commercially Pure Titanium (CP)

- Grades 1–4

- Excellente résistance à la corrosion

- Used in chemical and marine environments

Particle Size Distribution Table

| Type de poudre | Taille des particules (µm) | application |

|---|---|---|

| Fine (<15 µm) | Binder Jetting, Coatings | |

| Medium (15–45 µm) | Laser Powder Bed Fusion (LPBF) | |

| Coarse (45–150 µm) | Direct Energy Deposition (DED), PM Press & Sinter |

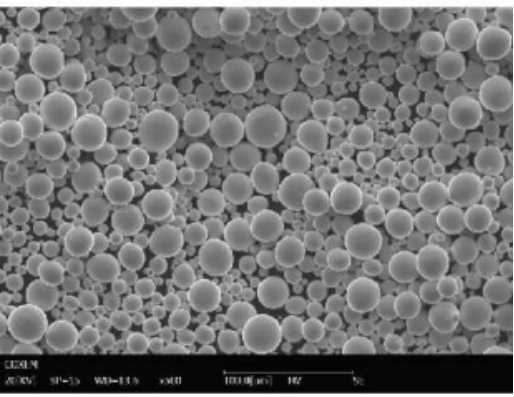

Shanghai Truer Technology Co., Ltd offers titanium alloy powders produced via gas and plasma atomization, ensuring high sphericity and flowability. These powders are optimized for both additive manufacturing and traditional powder metallurgy applications.

Discover more about our powder metallurgy materials including titanium, bronze, and nickel-based solutions tailored to your needs.

4. Market Trends and Future Growth Potential

Titanium alloy powder is rapidly becoming a strategic material across multiple industries due to its unique mechanical and chemical properties. The global market for titanium powder is projected to exceed USD $1.5 billion by 2030, driven by increased adoption in aerospace, medical, and additive manufacturing sectors.

Principaux moteurs du marché

- Surge in Additive Manufacturing

The expansion of 3D printing in aerospace and healthcare is fueling demand for high-purity, spherical titanium powders. - Lightweight Material Demand

Automotive and aerospace OEMs are replacing steel/aluminum parts with titanium to meet fuel efficiency and emissions targets. - Medical Implant Innovation

Custom implants using titanium alloy powder via electron beam melting (EBM) or selective laser melting (SLM) are gaining traction. - Defense Industry Investment

Governments are investing in titanium-based armor systems and aerospace components due to their superior ballistic and fatigue properties.

Market Projections by Region

| Région | 2023 Market Size (USD) | CAGR (2024-2030) | Key Sectors |

|---|---|---|---|

| Amérique du Nord | $410M | 8.4% | Aerospace, Defense, Medical |

| L'Europe | $350M | 7.9% | Automotive, 3D Printing |

| Asie-Pacifique | $500M | 9.5% | Electronics, Medical, Automotive |

| Moyen-Orient et Afrique | $90M | 6.0% | Oil & Gas, Military |

As the titanium powder market matures, companies looking to stay competitive must secure reliable, high-quality suppliers that can scale with demand.

5. Choosing the Right Titanium Alloy Powder Supplier

For B2B buyers, selecting the right titanium alloy powder supplier is critical. Factors such as consistency, traceability, technical support, and logistics capabilities can make or break your production efficiency.

Key Evaluation Criteria for B2B Buyers

| Facteur | Importance for Distributors & OEMs |

|---|---|

| Pureté des poudres | Directly affects mechanical performance |

| Contrôle de la taille des particules | Ensures compatibility with specific AM or PM processes |

| Spherical Morphology | Improves packing density and flowability |

| Cohérence des lots | Reduces production variability |

| Fiabilité de la chaîne d'approvisionnement | Guarantees on-time delivery |

| Capacités de personnalisation | Supports diverse industry applications |

Checklist for Vetting Suppliers

- Does the supplier offer both gas and plasma atomized titanium powders?

- Can they support custom particle size distribution?

- Do they have in-house testing and quality assurance protocols?

- Are they experienced in serving aerospace/medical clients?

- Do they provide technical support for additive manufacturing applications?

Shanghai Truer Technology Co., Ltd meets all the above criteria and more, making it a trusted powder supplier for engineering-grade applications worldwide.

6. Top 5 Global Titanium Alloy Powder Manufacturers

Here’s a look at the leading players in the titanium alloy powder industry, each known for their unique capabilities:

| Entreprise | Pays | Spécialisation | Key Advantage |

|---|---|---|---|

| AP&C (GE Additive) | Canada | Plasma atomized powders | Industry leader in medical/aerospace-grade powders |

| Tekna | Canada | Gas & plasma atomization | High-purity, spherical powders for AM |

| Praxair Surface Technologies | ÉTATS-UNIS | atomisation du gaz | Reliable supply for large-scale AM users |

| TLS Technik | Allemagne | Titanium & refractory powders | Advanced R&D for custom alloys |

| Shanghai Truer Technology Co. | Chine | 3D printing & PM powders | Integrated equipment + powder solution provider |

Qu'est-ce qui définit Shanghai Truer apart is its end-to-end integration. Unlike conventional suppliers, Truer not only produces titanium alloy powder but also provides powder-making equipment and consulting services for additive manufacturing.

Truer’s Competitive Advantages

- ✅ In-house atomization technology (gas, water, hybrid)

- ✅ Broad portfolio of PM and AM titanium alloy powders

- ✅ Support for custom alloy development

- ✅ Local and international logistics support

- ✅ ISO-certified quality control

Whether you’re a distributor seeking consistent quality or a manufacturer exploring new AM applications, Truer offers unmatched flexibility and technical support.

7. Why More Buyers Are Sourcing from Chinese Titanium Powder Suppliers

China is rapidly becoming a global hub for high-quality metal powders, including titanium alloys. Cost-effectiveness, improved quality standards, and scalability are key reasons international buyers are shifting to Chinese suppliers.

Advantages of Sourcing Titanium Alloy Powder from China

- Rentabilité

Lower production and labor costs allow for competitive pricing without compromising on quality. - Échelle de production

Suppliers like Truer can fulfill large-volume orders with short lead times. - Innovation in Atomization Technology

Chinese firms are now producing powders with sphericity and purity levels on par with Western competitors. - Personnalisation et flexibilité

Buyers can request custom compositions, particle sizes, and packaging. - Government Support & Infrastructure

National policies supporting AM and powder metallurgy innovation provide a robust manufacturing environment.

Comparison Table: Western vs. Chinese Suppliers

| Critères | Fournisseurs occidentaux | Fournisseurs chinois |

|---|---|---|

| Prix | Haut | Compétitif |

| Qualité | Haut | Increasingly high |

| Personnalisation | Limitée | Flexible |

| Délai d'exécution | Modéré | Court |

| MOQ | Modéré à élevé | Low to high |

With the rise of companies like Truer, Chinese suppliers are no longer just low-cost alternatives—they are strategic partners offering world-class quality, scalability, and service.

Contactez Truer aujourd'hui to learn how their titanium alloy powder solutions can elevate your production outcomes.

8. How to Order Wholesale Titanium Alloy Powder from Shanghai Truer

When sourcing titanium alloy powder in bulk, a streamlined and transparent procurement process is crucial for industrial buyers, distributors, and OEMs. Shanghai Truer Technology Co., Ltd has developed a B2B-friendly ordering system that supports both domestic and international buyers through every stage of the supply chain.

Processus de commande étape par étape

| Étape | Description | Avantages |

|---|---|---|

| 1. Demande de renseignements | Contact Truer via their website or email with your powder specifications | Fast response within 24 hours |

| 2. Consultation technique | Work with Truer’s engineers to select the right alloy, particle size, and packaging | Tailored powder solutions |

| 3. Quotation & Lead Time | Receive a detailed quotation including pricing, MOQ, delivery schedule, and logistics options | Transparent terms |

| 4. Sample Testing (optional) | Request small-batch samples for testing in your production process | Minimize production risk |

| 5. Contract & Payment | Confirm purchase order and initiate payment (L/C, T/T, other terms available) | Secure and flexible terms |

| 6. Production & QA | Truer produces your order with full quality control and traceability | Consistent, certified quality |

| 7. Expédition et livraison | Global logistics support via air, sea, or express | On-time delivery worldwide |

Customization Available in Bulk Orders

- Particle size distribution (15–45 µm, 45–150 µm, etc.)

- Custom titanium alloy grades (Ti-6Al-4V, Ti-6Al-7Nb, CP Grades)

- Packaging (vacuum-sealed, nitrogen-filled, anti-static bags)

- Documentation (COA, SDS, RoHS, Reach, ISO certifications)

For detailed ordering assistance and to explore Truer’s full catalog of titanium and PM metal powders, their customer service team is available via web, email, and phone.

9. FAQs: Common Questions About Buying Titanium Alloy Powder

Q1: What’s the minimum order quantity (MOQ) for wholesale buyers?

Truer offers flexible MOQs depending on the alloy and production method. Standard MOQ is typically 50 kg, but smaller trial batches can be arranged for new customers or R&D applications.

Q2: Can I request custom titanium alloy compositions?

Yes. Truer specializes in custom alloy development for advanced applications, including beta titanium alloys, hybrid compositions, and biocompatible blends.

Q3: How is the powder packaged for international shipping?

Powders are vacuum-sealed in moisture-proof, anti-static packaging. For air or sea freight, materials are packed in industrial-grade drums or boxes with full export documentation.

Q4: Is Truer’s titanium alloy powder suitable for 3D printing?

Absolutely. Truer provides gas atomized and plasma atomized titanium powders with spherical morphology, low oxygen content, and controlled PSD—ideal for SLM, DMLS, and EBM.

Q5: Are quality certifications available?

Yes. Truer’s powders come with ISO 9001:2015 certification, and additional documentation such as Material Safety Data Sheets (MSDS), Certificate of Analysis (COA), and third-party lab reports can be provided upon request.

Q6: Can I visit Truer’s facility or audit their production process?

Yes, Truer welcomes partners and clients to visit their facility in Shanghai. Virtual audits and video tours are also available for international clients who cannot travel.

Why Choose Shanghai Truer Technology Co., Ltd as Your Titanium Powder Supplier

Shanghai Truer Technology Co., Ltd is not just a powder supplier—it’s a complete additive manufacturing and powder metallurgy solution provider. Since launching its AM division in 2019, Truer has become one of China’s most respected names in 3D printing materials and PM powders.

Qu'est-ce qui distingue Truer ?

- ✅ Full-spectrum titanium powder portfolio (gas/plasma atomized)

- ✅ Advanced atomization equipment and in-house R&D

- ✅ Support for PM and additive manufacturing applications

- ✅ Competitive pricing for bulk orders

- ✅ Fast delivery and reliable global logistics

- ✅ Proven track record with aerospace, medical, and industrial clients

Truer’s Titanium Powder Product Highlights

| Grade | Type d'alliage | application | Atomisation |

|---|---|---|---|

| ti-6al-4v | Alpha-Beta | Aerospace, Implants, AM | Gas/Plasma |

| Ti-6Al-7Nb | Alpha-Beta | Médical | Gaz |

| CP Grade 2 | Commercially Pure | Chemical, Marine | Gas/Hybrid |

| Custom Beta Alloys | Beta | Motorsport, High-strength parts | Gaz |

Whether you’re a metal AM service provider, automotive OEM, or distributor looking for reliable titanium powder sources, Truer offers a complete B2B solution. You can learn more about Truer’s company and values on their official website.