Vue d'ensemble Poudre de CuAlFe

La poudre de cuivre-aluminium-fer (CuAlFe) est une poudre métallique haute performance réputée pour sa résistance, sa durabilité et sa polyvalence dans les applications industrielles. Cet alliage combine le cuivre (Cu), l'aluminium (Al) et le fer (Fe) pour créer un matériau adapté à une gamme d'applications de pointe, de la fabrication additive à la projection thermique. Sa composition unique en fait un candidat idéal pour une utilisation dans des environnements exigeants, offrant une excellente résistance à l'usure, une conductivité thermique et une résistance à la corrosion.

Dans cet article, nous allons vous présenter tout ce que vous devez savoir sur la poudre de CuAlFe : de ses types et propriétés à ses applications et avantages. En outre, nous explorerons des modèles spécifiques de poudre de CuAlFe, nous comparerons leurs caractéristiques et nous discuterons des éléments clés à prendre en compte pour sélectionner le produit le mieux adapté à vos besoins.

Qu'est-ce que la poudre de CuAlFe ?

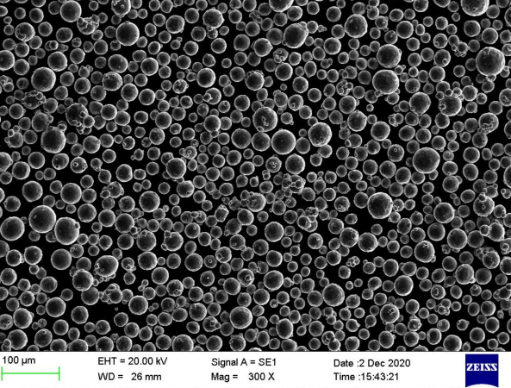

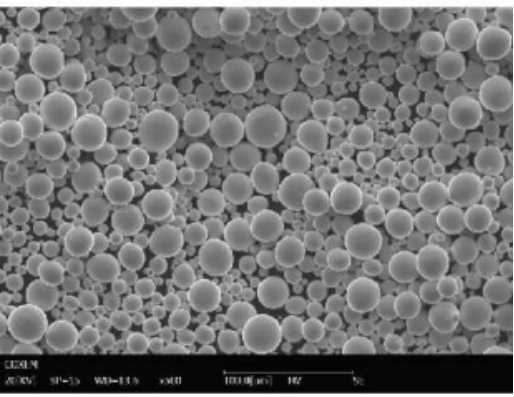

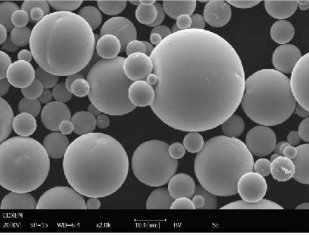

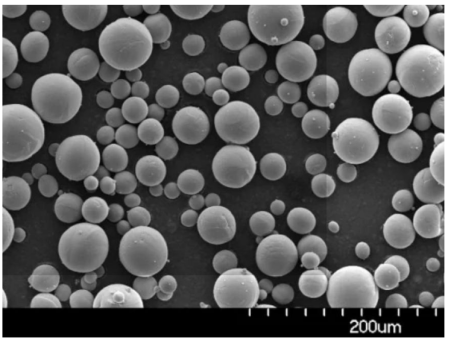

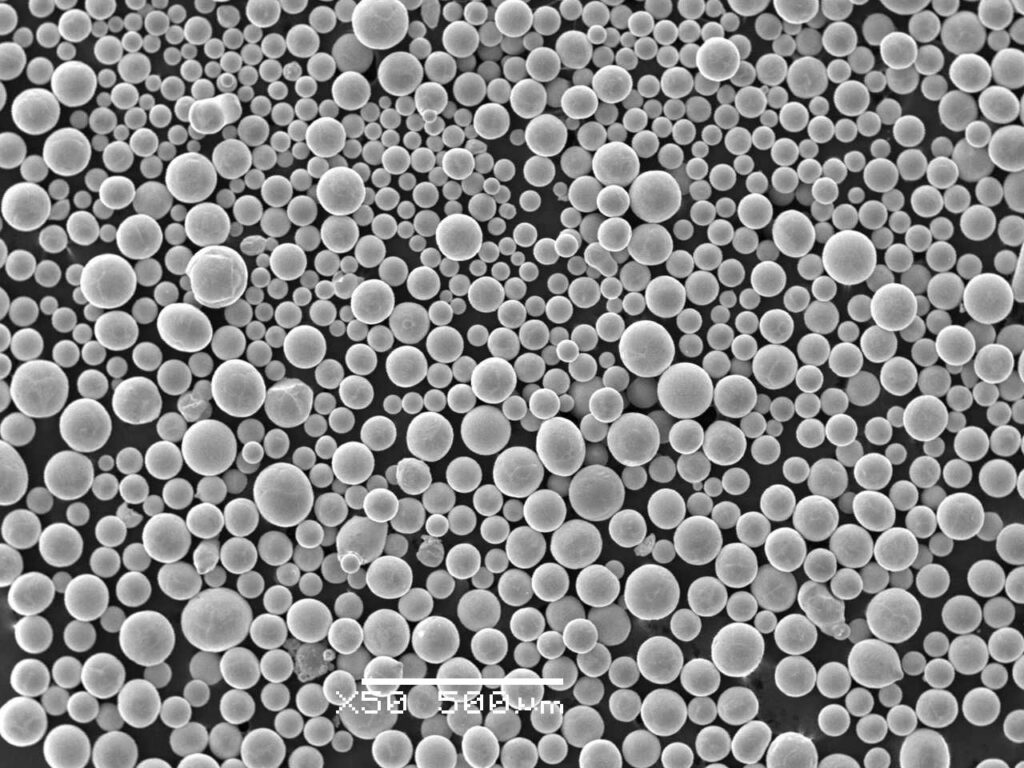

La poudre CuAlFe est une poudre d'alliage métallique créée en combinant le cuivre, l'aluminium et le fer dans des proportions précises. Cette poudre est produite par atomisation, par alliage mécanique ou par réduction, ce qui garantit une distribution uniforme et fine de la taille des particules. Sa composition la rend idéale pour les applications nécessitant une grande solidité, une stabilité thermique et une résistance à la dégradation de l'environnement.

Composition de la poudre de CuAlFe

Il est essentiel de comprendre la composition de la poudre de CuAlFe pour déterminer si elle convient à diverses applications. Voici un aperçu de sa composition typique :

| Élément | Gamme (% en poids) |

|---|---|

| Cuivre (Cu) | 50-70 |

| Aluminium (Al) | 15-35 |

| Fer (Fe) | 10-20 |

| Autres éléments | <1 (par exemple, Mn, Si) |

Les proportions spécifiques varient en fonction de l'utilisation prévue, et les fabricants peuvent ajuster la composition pour optimiser certaines propriétés telles que la résistance ou la conductivité thermique.

Caractéristiques de la poudre de CuAlFe

Qu'est-ce qui distingue la poudre de CuAlFe ? Examinons ses principales caractéristiques :

- Haute résistance et durabilité: Dotée d'excellentes propriétés mécaniques, cette poudre est parfaite pour les revêtements résistants à l'usure.

- Stabilité thermique: Il conserve son intégrité structurelle même à des températures élevées.

- Résistance à la corrosion: La teneur en aluminium améliore la résistance à l'oxydation et à la dégradation de l'environnement.

- Nature légère: Par rapport au cuivre pur, la poudre CuAlFe offre une alternative légère sans compromettre la résistance.

- Bonne usinabilité: Il peut être facilement transformé à l'aide de techniques conventionnelles telles que le frittage et le pressage à chaud.

Modèles spécifiques de poudre de CuAlFe

Voici un examen plus approfondi de dix modèles de poudres CuAlFe populaires disponibles sur le marché :

| Modèle | Description | Applications |

|---|---|---|

| CuAlFe-1 | Mélange de haute pureté avec 60 % de Cu, 25 % d'Al, 15 % de Fe ; idéal pour les applications aérospatiales. | Fabrication additive, composants aérospatiaux. |

| CuAlFe-2 | Optimisé pour la conductivité thermique avec 70 % de Cu et 20 % d'Al. | Échangeurs de chaleur, systèmes de refroidissement pour l'électronique. |

| CuAlFe-3 | Poudre à grain fin pour des applications de revêtement précises. | Pulvérisation thermique, couches anticorrosion. |

| CuAlFe-4 | Alliage résistant à l'usure avec une teneur élevée en Fe (20 %). | Outils de coupe, pièces résistantes à l'usure. |

| CuAlFe-5 | Formule légère avec 30 % d'aluminium, équilibrant la résistance et le poids. | Pièces automobiles, machines légères. |

| CuAlFe-6 | Conçu pour une stabilité à haute température avec une composition renforcée. | Fours à haute température, turbines. |

| CuAlFe-7 | Conception de particules sphériques pour un écoulement uniforme pendant la fabrication additive. | impression 3D, moulage de précision. |

| CuAlFe-8 | Formulation respectueuse de l'environnement avec un impact réduit sur l'environnement. | Fabrication durable, technologie des énergies vertes. |

| CuAlFe-9 | Particules extra-fines pour un meilleur comportement au frittage. | Métallurgie des poudres, densification des composants. |

| CuAlFe-10 | Propriétés de finition de surface améliorées pour les applications esthétiques. | Revêtements décoratifs à usage architectural. |

Applications de la poudre de CuAlFe

Où la poudre de CuAlFe brille-t-elle ? Sa polyvalence lui permet de s'adapter à un large éventail d'industries et d'applications :

| Domaine d'application | Cas d'utilisation |

|---|---|

| Fabrication additive | Production de géométries complexes pour les industries aérospatiale et automobile. |

| Pulvérisation thermique | Revêtements pour la résistance à l'usure et la protection thermique. |

| Électronique | Composants conducteurs, dissipateurs thermiques et connecteurs. |

| Automobile | Pièces légères, composants de moteur et engrenages. |

| Aérospatiale | Composants à haute résistance pour les avions et les engins spatiaux. |

| Machines industrielles | Roulements, bagues et revêtements résistants à l'usure. |

| L'énergie | Composants pour éoliennes, panneaux solaires et centrales électriques. |

Spécifications, tailles et normes

Voici un tableau résumant les principales spécifications et normes pour la poudre de CuAlFe :

| Paramètres | Détails |

|---|---|

| Gamme de taille des particules | 10-100 microns (réglable en fonction de l'application). |

| La pureté | >99% pour la plupart des modèles. |

| Respect des normes | ASTM B212, ISO 9001, DIN EN 10204. |

| Tailles d'emballage | 1 kg, 5 kg, 25 kg et emballages en vrac personnalisés. |

| Morphologie des poudres | Formes sphériques, irrégulières ou dendritiques selon le procédé de fabrication. |

Avantages de la Poudre de CuAlFe

- Renforcement de la force: Les poudres CuAlFe offrent une résistance et une durabilité exceptionnelles pour les applications exigeantes.

- Léger: L'aluminium contribue à réduire le poids, ce qui est idéal pour l'aérospatiale et l'automobile.

- Coût-efficacité: Offre une alternative économique aux alliages plus coûteux comme le titane.

- Performance thermique: L'excellente dissipation de la chaleur en fait un excellent choix pour les composants électroniques.

- Respect de l'environnement: Certains modèles sont conçus dans une optique de développement durable.

Limites de la Poudre de CuAlFe

Si la poudre de CuAlFe est impressionnante, elle n'est pas sans inconvénients :

- Résistance limitée à la corrosion: Bien qu'il soit meilleur que certains matériaux, il ne peut rivaliser avec l'aluminium pur ou l'acier inoxydable dans les environnements hautement corrosifs.

- Défis en matière de traitement: Pour obtenir des résultats optimaux, il est nécessaire de disposer d'un équipement et de techniques précis.

- Variabilité des coûts: Le coût peut fluctuer en fonction des prix des matières premières et des méthodes de transformation.

Comparaison des avantages et des inconvénients

| Aspect | Pour | Cons |

|---|---|---|

| Solidité et durabilité | Propriétés mécaniques supérieures. | Peut nécessiter un post-traitement spécialisé. |

| Propriétés thermiques | Haute conductivité pour la dissipation de la chaleur. | Il n'est pas idéal pour les températures très élevées. |

| Résistance à la corrosion | Résistance modérée avec renforcement de l'aluminium. | Ne convient pas aux environnements extrêmement corrosifs. |

| Polyvalence | Applicable à tous les secteurs d'activité. | Les performances peuvent varier en fonction de la composition. |

Fournisseurs et prix

| Fournisseur | Gamme de produits | Prix moyen (USD/kg) | Coordonnées |

|---|---|---|---|

| PowderTech Inc. | Modèles CuAlFe-1 à CuAlFe-10. | $50-$80 | www.powdertech.com |

| AlloyWorks Ltd. | Formulations personnalisées disponibles. | $45-$75 | [email protected] |

| Solutions MetalForm | Poudres préemballées et en vrac. | $55-$90 | www.metalformsolutions.com |

| Industrial Alloys Co. | Poudres CuAlFe de haute pureté. | $60-$85 | [email protected] |

FAQ

| Question | Réponse |

|---|---|

| Quelles sont les industries qui utilisent couramment la poudre de CuAlFe ? | Les secteurs de l'aérospatiale, de l'automobile, de l'électronique et de l'énergie. |

| Comment la poudre de CuAlFe est-elle fabriquée ? | Il est généralement produit par atomisation ou par des procédés d'alliage mécanique. |

| La poudre de CuAlFe peut-elle être réutilisée ? | Oui, dans des conditions contrôlées, la poudre inutilisée issue de la fabrication additive peut souvent être recyclée. |

| La poudre de CuAlFe est-elle respectueuse de l'environnement ? | Certains modèles sont conçus dans un souci d'écocompatibilité, ce qui permet de réduire leur impact sur l'environnement. |

| Quelles sont les tailles de particules disponibles ? | Les tailles courantes vont de 10 à 100 microns, en fonction de l'application. |