Bienvenue dans notre guide complet sur Electrode Fusion par induction Gaz inerte (EIMIG), une technique sophistiquée utilisée dans la production de poudres métalliques de haute qualité. Que vous soyez ingénieur en matériaux, chercheur ou simplement curieux des processus métallurgiques avancés, cet article est conçu pour vous donner une compréhension détaillée de l'EIMIG. Nous nous pencherons sur ses mécanismes, explorerons des modèles de poudres métalliques spécifiques et mettrons en lumière ses diverses applications. Alors, c'est parti !

Vue d'ensemble de la fusion par induction d'électrodes sous gaz inerte

Le procédé EIMIG (Electrode Induction Melting Inert Gas) est un procédé métallurgique de pointe qui consiste à fondre des métaux à l'aide d'un arc électrique généré entre des électrodes dans un environnement de gaz inerte. Cette méthode est particulièrement avantageuse pour la production de poudres métalliques de haute pureté, qui sont essentielles dans des industries allant de l'aérospatiale à l'ingénierie biomédicale.

Qu'est-ce qui fait la spécificité de l'EIMIG ?

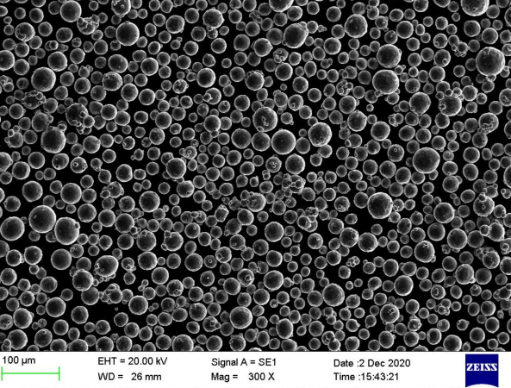

L'EIMIG se distingue par sa capacité à produire des poudres métalliques d'une pureté supérieure et de tailles de particules contrôlées. L'utilisation d'une atmosphère de gaz inerte, généralement de l'argon ou de l'hélium, permet de minimiser l'oxydation et la contamination, ce qui garantit la production de poudres métalliques de haute qualité. Ce procédé est également très polyvalent, car il permet de fondre une large gamme de métaux et d'alliages.

Composantes essentielles du MIEG

- Électrodes: Généralement en graphite ou en tungstène, ils génèrent l'arc électrique nécessaire à la fusion.

- Environnement de gaz inerte: L'argon ou l'hélium sont couramment utilisés pour prévenir l'oxydation.

- Système de chauffage par induction: Fournit l'énergie nécessaire pour soutenir le processus de fusion.

- Creuset: Maintient le métal pendant qu'il fond et se refroidit sous forme de poudre.

Types de poudres métalliques produites par EIMIG

L'EIMIG peut produire une grande variété de poudres métalliques, chacune ayant des propriétés uniques adaptées à différentes applications. Voici dix modèles spécifiques :

1. Alliage de titane (Ti-6Al-4V)

Composition: Titane, aluminium, vanadium

Propriétés: Rapport résistance/poids élevé, excellente résistance à la corrosion

Applications: Composants aérospatiaux, implants médicaux

2. Superalliage de nickel (Inconel 718)

Composition: Nickel, chrome, fer, niobium

Propriétés: Résistance aux températures élevées, excellentes propriétés mécaniques

Applications: Aubes de turbines, moteurs à réaction

3. Acier inoxydable (316L)

Composition: Fer, chrome, nickel, molybdène

Propriétés: Haute résistance à la corrosion, bonne aptitude à la mise en forme

Applications: Dispositifs biomédicaux, équipements de transformation des aliments

4. Alliage cobalt-chrome (Co-Cr-Mo)

Composition: Cobalt, chrome, molybdène

Propriétés: Haute résistance à l'usure, biocompatibilité

Applications: Implants dentaires, implants orthopédiques

5. Alliage d'aluminium (AlSi10Mg)

Composition: Aluminium, Silicium, Magnésium

Propriétés: Léger, bonne conductivité thermique

Applications: Pièces automobiles, structures aérospatiales

6. Alliage de cuivre (CuNi2SiCr)

Composition: Cuivre, Nickel, Silicium, Chrome

Propriétés: Conductivité électrique élevée, bonne résistance mécanique

Applications: Connecteurs électriques, échangeurs de chaleur

7. Acier à outils (H13)

Composition: Fer, chrome, molybdène, vanadium

Propriétés: Ténacité élevée, excellente résistance à la chaleur

Applications: Moules pour le moulage sous pression, outils d'extrusion

8. Acier maraging (18Ni300)

Composition: Fer, nickel, cobalt, molybdène

Propriétés: Haute résistance, bonne ténacité

Applications: Composants aérospatiaux, outillage

9. Carbure de tungstène (WC-Co)

Composition: Tungstène, Cobalt

Propriétés: Extrêmement dur, haute résistance à l'usure

Applications: Outils de coupe, équipement minier

10. Alliage de zirconium (Zr702)

Composition: Zirconium, Hafnium, Fer

Propriétés: Excellente résistance à la corrosion, bonnes propriétés mécaniques

Applications: Réacteurs nucléaires, équipements de traitement chimique

Caractéristiques des Electrode Fusion par induction Gaz inerte

L'EIMIG est connu pour plusieurs caractéristiques clés qui en font une option intéressante pour la production de poudres métalliques.

La pureté

L'environnement de gaz inerte réduit considérablement la contamination, ce qui permet d'obtenir des poudres métalliques d'une grande pureté.

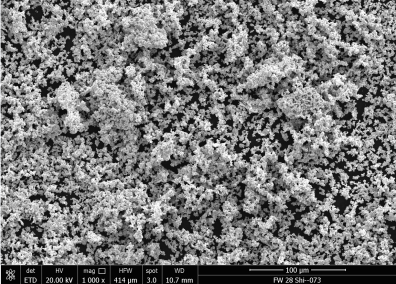

Contrôle de la taille des particules

L'EIMIG permet un contrôle précis de la distribution de la taille des particules, ce qui est crucial pour les applications nécessitant des caractéristiques de poudre spécifiques.

Polyvalence

Le procédé est adaptable à une large gamme de métaux et d'alliages, ce qui le rend approprié pour diverses applications industrielles.

Efficiency

L'EIMIG est un procédé économe en énergie, capable de produire de grandes quantités de poudre métallique avec un minimum de déchets.

Applications de la fusion par induction d'électrodes sous gaz inerte

Les poudres métalliques produites par EIMIG sont utilisées dans diverses industries de haute technologie en raison de leurs propriétés supérieures.

Industrie aérospatiale

Les alliages légers et à haute résistance comme le Ti-6Al-4V sont essentiels pour les composants aéronautiques, où les performances et la fiabilité sont primordiales.

Ingénierie biomédicale

Les matériaux biocompatibles tels que le Co-Cr-Mo sont utilisés dans les implants et les dispositifs médicaux, garantissant ainsi la sécurité et l'efficacité pour les patients.

Secteur automobile

Les alliages d'aluminium tels que l'AlSi10Mg sont utilisés dans les pièces automobiles pour réduire le poids et améliorer le rendement énergétique.

Électronique

Les alliages de cuivre à haute conductivité électrique sont essentiels pour les connecteurs et autres composants électroniques.

Outillage et fabrication

Les aciers à outils et les poudres de carbure de tungstène sont utilisés pour créer des moules et des outils de coupe durables pour divers processus de fabrication.

Spécifications détaillées des poudres métalliques EIMIG

Propriétés et caractéristiques

| Poudre métallique | Densité (g/cm³) | Point de fusion (°C) | Dureté (HV) | Résistance à la traction (MPa) | Élongation (%) |

|---|---|---|---|---|---|

| ti-6al-4v | 4.43 | 1660 | 349 | 895 | 10 |

| Inconel 718 | 8.19 | 1350 | 330 | 1240 | 12 |

| Acier inoxydable 316L | 7.99 | 1375 | 217 | 620 | 40 |

| Co-Cr-Mo | 8.29 | 1330 | 450 | 900 | 8 |

| AlSi10Mg | 2.68 | 570 | 85 | 310 | 7 |

| CuNi2SiCr | 8.78 | 1083 | 100 | 450 | 20 |

| Acier à outils H13 | 7.80 | 1427 | 750 | 1450 | 12 |

| Acier maraging 18Ni300 | 8.00 | 1413 | 340 | 2000 | 10 |

| WC-Co | 15.60 | 2870 | 1600 | – | – |

| Zr702 | 6.50 | 1855 | 250 | 550 | 30 |

Applications et utilisations

| Poudre métallique | Applications primaires | Utilisations supplémentaires |

|---|---|---|

| ti-6al-4v | Composants aérospatiaux, implants médicaux | Articles de sport, applications marines |

| Inconel 718 | Aubes de turbines, moteurs à réaction | Réacteurs nucléaires, véhicules spatiaux |

| Acier inoxydable 316L | Dispositifs biomédicaux, transformation des aliments | Traitement chimique, applications marines |

| Co-Cr-Mo | Implants dentaires, implants orthopédiques | Composants horlogers, roulements industriels |

| AlSi10Mg | Pièces automobiles, structures aérospatiales | Électronique grand public, bicyclettes |

| CuNi2SiCr | Connecteurs électriques, échangeurs de chaleur | Applications marines, monnaies |

| Acier à outils H13 | Moules pour le moulage sous pression, outils d'extrusion | Moules d'injection, matrices de forgeage |

| Acier maraging 18Ni300 | Composants aérospatiaux, outillage | Engrenages et arbres à haute performance |

| WC-Co | Outils de coupe, équipement minier | Pièces résistantes à l'usure, outils de forage |

| Zr702 | Réacteurs nucléaires, traitement chimique | Dispositifs médicaux, composants aérospatiaux |

Spécifications, tailles, qualités, normes

| Poudre métallique | Grade | Gamme de tailles (µm) | Standard |

|---|---|---|---|

| ti-6al-4v | 5e année | 15-45 | ASTM B348 |

| Inconel 718 | UNS N07718 | 15-53 | AMS 5662 |

| Acier inoxydable 316L | 316L | 10-45 | ASTM F138 |

| Co-Cr-Mo | ASTM F75 | 20-63 | ISO 5832-4 |

| AlSi10Mg | – | 15-45 | DIN EN 1706 |

| CuNi2SiCr | – | 20-50 | ASTM B422 |

| Acier à outils H13 | H13 | 20-63 | ASTM A681 |

| Acier maraging 18Ni300 | 18ni300 | 10-45 | AMS 6514 |

| WC-Co | 1-20 | ISO 4499-1 | |

| Zr702 | R60702 | 15-45 | ASTM B551 |

Fournisseurs et détails des prix

| Fournisseur | Poudre métallique | Prix (par kg) | Disponibilité |

|---|---|---|---|

| Advanced Powders Inc. | ti-6al-4v | $150 | En stock |

| Métaux spéciaux Co. | Inconel 718 | $200 | Stock limité |

| Medical Materials LLC | Acier inoxydable 316L | $120 | En stock |

| BioMetals Corp. | Co-Cr-Mo | $180 | Pré-commande nécessaire |

| Light Metals Inc. | AlSi10Mg | $100 | En stock |

| Electrical Alloys Ltd. | CuNi2SiCr | $160 | En stock |

| Tool Steel Supply Co. | Acier à outils H13 | $140 | Stock limité |

| Métaux à haute résistance | Acier maraging 18Ni300 | $220 | En stock |

| Groupe des métaux durs | WC-Co | $300 | Pré-commande nécessaire |

| Nuclear Materials Inc. | Zr702 | $250 | En stock |

Comparer le pour et le contre, les avantages et les limites

| Poudre métallique | Avantages | Limites |

|---|---|---|

| ti-6al-4v | Haute résistance, légèreté, résistance à la corrosion | Coûteux, difficile à usiner |

| Inconel 718 | Excellentes propriétés à haute température | Coût élevé, traitement complexe |

| Acier inoxydable 316L | Résistant à la corrosion, biocompatible | Résistance moindre par rapport à d'autres alliages |

| Co-Cr-Mo | Résistance élevée à l'usure, biocompatibilité | Fragilité, cherté |

| AlSi10Mg | Léger, bonnes propriétés thermiques | Résistance moindre par rapport aux alliages d'acier |

| CuNi2SiCr | Conductivité électrique élevée, résistance à la corrosion | Coûteux, résistance mécanique limitée |

| Acier à outils H13 | Ténacité élevée, résistance à la chaleur | Susceptible de se fissurer sous l'effet de la contrainte |

| Acier maraging 18Ni300 | Haute résistance, bonne ténacité | Traitement thermique complexe et coûteux |

| WC-Co | Extrêmement dur, haute résistance à l'usure | Fragilité, coût élevé |

| Zr702 | Excellente résistance à la corrosion, bonnes propriétés mécaniques | Coût élevé, disponibilité limitée |

FAQ

Qu'est-ce que Electrode Fusion par induction Gaz inerte (EIMIG) ?

L'EIMIG est un procédé dans lequel les métaux sont fondus à l'aide d'un arc électrique entre des électrodes dans une atmosphère de gaz inerte, produisant des poudres métalliques de haute pureté.

Pourquoi utiliser un gaz inerte dans l'EIMIG ?

Les gaz inertes comme l'argon ou l'hélium empêchent l'oxydation et la contamination pendant le processus de fusion, ce qui garantit des poudres métalliques de haute qualité.

Quels sont les métaux qui peuvent être fondus avec l'EIMIG ?

L'EIMIG est polyvalent et peut fondre une large gamme de métaux et d'alliages, notamment le titane, le nickel, l'acier inoxydable, le cobalt-chrome, etc.

Quelles sont les applications des poudres métalliques EIMIG ?

Les poudres métalliques EIMIG sont utilisées dans les secteurs de l'aérospatiale, de l'ingénierie biomédicale, de l'automobile, de l'électronique et de l'outillage en raison de leurs propriétés supérieures.

Comment l'EIMIG contrôle-t-il la taille des particules ?

Les paramètres du processus de l'EIMIG peuvent être finement ajustés pour contrôler la distribution de la taille des particules, ce qui garantit l'uniformité et la précision du produit final.

Les poudres métalliques EIMIG sont-elles chères ?

Le coût des poudres métalliques EIMIG varie en fonction du type et de la pureté du métal, mais tend généralement à être plus élevé en raison de la nature avancée du processus.

Quels sont les principaux avantages de l'EIMIG ?

L'EIMIG offre une grande pureté, un contrôle précis de la taille des particules, une grande variété de types de métaux et une production efficace, ce qui le rend très utile pour la production de poudres métalliques spécialisées.

En quoi l'EIMIG diffère-t-il des autres techniques de fusion ?

L'EIMIG utilise une atmosphère de gaz inerte et un chauffage par induction, ce qui réduit la contamination et permet un contrôle précis du processus de fusion, se distinguant ainsi d'autres techniques telles que la fusion à l'arc conventionnelle.

L'EIMIG peut-il être utilisé pour une production à grande échelle ?

Oui, l'EIMIG peut être mis à l'échelle pour la production industrielle, ce qui le rend adapté à la fois à la recherche à petite échelle et à la fabrication à grande échelle.

Quels sont les principaux fournisseurs de poudres métalliques EIMIG ?

Les principaux fournisseurs sont Advanced Powders Inc, Specialty Metals Co, Medical Materials LLC et BioMetals Corp, entre autres, qui proposent une variété de poudres métalliques pour différentes applications.

Conclusion

Le procédé EIMIG (Electrode Induction Melting Inert Gas) est une technologie transformatrice dans le domaine de la métallurgie, offrant une pureté et une précision inégalées dans la production de poudres métalliques. Ses applications s'étendent à des secteurs critiques, garantissant des performances et une fiabilité élevées dans des environnements exigeants. Qu'il s'agisse de composants aérospatiaux, d'appareils biomédicaux ou d'outillage de haute performance, l'EIMIG fournit les matériaux avancés nécessaires pour repousser les limites de l'innovation.