El polvo de tungsteno es una forma de polvo elemental puro de metal de tungsteno que se utiliza en aplicaciones industriales que requieren propiedades de alta densidad, fuerza y resistencia al calor. Esta guía proporciona una visión general de la composición del polvo de tungsteno, métodos de producción, aplicaciones, proveedor de polvo de tungstenoprecios y comparaciones.

Introducción al proveedor de polvo de tungsteno

El polvo de wolframio se compone de partículas microscópicas de metal elemental de wolframio relativamente puro. Propiedades clave de tungsteno por lo que es adecuado para aplicaciones de pulvimetalurgia son:

- Densidad extremadamente alta, similar a la del oro

- El punto de fusión más alto de todos los metales

- Bajo coeficiente de dilatación térmica

- Alta conductividad térmica y eléctrica

- Resistencia a la corrosión y a los ácidos

- Biocompatibilidad y no toxicidad

Con una densidad casi 20% superior a la del plomo, el tungsteno equilibra el rendimiento en cuanto a resistencia, conductividad y propiedades térmicas, lo que resulta ideal para su uso como partículas de polvo.

Características del polvo de wolframio

| Atributo | Detalles |

|---|---|

| Composición | 99,9% Tungsteno puro |

| Color | Gris oscuro con reflejo metálico |

| Estructura cristalina | Cúbico |

| Densidad | 19,3 g/cm3 |

| Punto de fusión | 6170°F (3422°C) |

| Dureza Mohs | 7-7.5 |

| Conductividad térmica | 163 W/m-K |

| Resistividad eléctrica | 5,5 μΩ-cm |

Estas propiedades intrínsecas del material permiten aplicaciones especializadas para el polvo de tungsteno en electrónica, aleaciones, pesaje, calefacción, etc.

Métodos de fabricación

El polvo de wolframio se produce a partir de concentrados de mineral de wolframio mediante técnicas metalúrgicas avanzadas:

1. Procesamiento del paratungstato de amonio

- Método de producción más común

- Implica extracción ácida, precipitación, secado, reducción de hidrógeno

- Crea polvos finos de gran pureza

2. Fresado mecánico

- Fresado de metal de tungsteno en partículas finas

- Tiende a producir formas irregulares

- Menor coste pero amplia distribución de tamaños

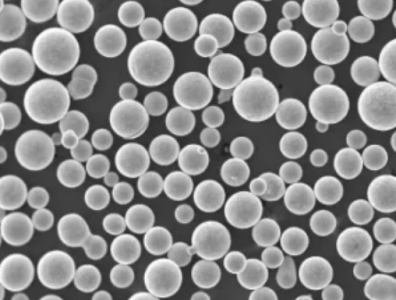

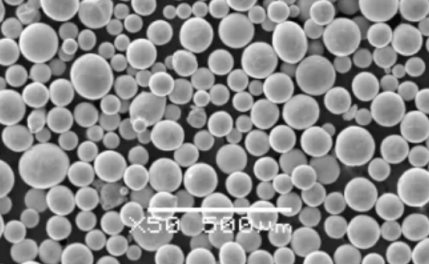

3. Procesamiento termoquímico

- Conversión en fase vapor de haluros de wolframio

- Obtención de polvos esféricos de gran pureza

- Producción especializada a pequeña escala

El método de fabricación determina la distribución del tamaño de las partículas de polvo, la forma, la densidad de la toma y la química de la superficie, que dictan la aplicabilidad.

Aplicaciones del polvo de wolframio

Las propiedades únicas de alta densidad del polvo de tungsteno lo hacen adecuado para:

Tabla: Aplicaciones del polvo de wolframio

| Solicitud | Descripción |

|---|---|

| Contrapesos | Contrapesos de alta densidad para equipos sensibles a las vibraciones |

| Blindaje contra la radiación | Aleaciones de tungsteno utilizadas como material de blindaje contra rayos gamma |

| Lastre | Alternativa a los pesos de plomo en las quillas de los yates para aumentar la estabilidad |

| Equipos rotativos | Tungsteno metal pesado utilizado en giroscopios y centrifugadoras |

| Gestión térmica | Disipadores de calor de wolframio por su alta conductividad térmica |

| Polvos portadores | Matriz aglutinante para catalizadores que requieren resistencia química |

| Contactos eléctricos | Aleaciones de wolframio y plata utilizadas en interruptores y relés |

| Polvos de impresión 3D | Tungsteno de alta densidad utilizado en la fabricación aditiva |

La idoneidad del wolframio para la emisión termoiónica a alta temperatura también lo hace útil para emisores de electrones en equipos de soldadura eléctrica y tubos de vacío como polvo prensado en frío en electrodos.

Especificaciones

El polvo de wolframio para uso industrial y comercial se clasifica por:

Tabla: Especificaciones del polvo de wolframio

| Parámetro | Detalles |

|---|---|

| Grados de pureza | 99,9%, 99,95%, 99,99% wolframio puro |

| Tamaño de partícula | 0,5 a 150 micras |

| Morfología | Irregular, esférica |

| Densidad del grifo | 2 a 12 g/cm3 |

| Superficie | 0,5 a 10 m2/g |

| Apariencia | Polvo gris oscuro |

| Embalaje | Botellas de 1 lb a cubos de 55 lb |

Otras especificaciones técnicas específicas de la aplicación pueden incluir coeficientes de expansión térmica, compresibilidad, contenido de hidrógeno, análisis de oxígeno y valores de resistencia en verde.

Dónde comprar polvo de wolframio

Como el wolframio es relativamente raro, se puede adquirir a través de fabricantes y proveedores especializados:

Mesa: proveedor de polvo de tungsteno

| Proveedor | Ubicación | Grados del producto |

|---|---|---|

| Midwest Tungsten Service | EE.UU. | Aleaciones de tungsteno, tungsteno puro |

| Tungsteno Buffalo | EE.UU. | Polvos, varillas, alambres |

| Polvo pesado de wolframio | China | 99,995% (5N) pureza polvo |

| Xiamen Tungsteno | China | Polvo 5N, 5N5, 6N |

| Aleaciones Beck | REINO UNIDO | Tungsteno elemental y aleado |

| HC Starck | Alemania | Metales refractarios de gran pureza |

| Nanjing Tungsteno | China | Polvo de wolframio puro |

| Japón Nuevo metal | Japón | Polvo de tungsteno de nano a grueso |

Dado que tanto la extracción como el refinado del wolframio requieren un procesamiento especializado, la disponibilidad económica procede principalmente de China, seguida de Rusia, Canadá, Bolivia y Portugal. Los fabricantes establecidos ofrecen diferentes niveles de pureza adecuados para aplicaciones médicas, industriales y de investigación.

Precio del tungsteno en polvo

Al ser relativamente raro, el polvo de wolframio es más caro que los metales comunes: su precio oscila entre $50 y $500 por kilogramo, en función de:

Tabla: Precios del polvo de wolframio

| Factor | Descripción |

|---|---|

| Pureza | 99,9% cuesta ~$50/kg; 99,999% cuesta ~$500/kg |

| Tamaño de partícula | El nanopolvo es más caro que los tamaños micrométricos |

| Cantidad | Los pedidos al por mayor de más de 25 kg permiten descuentos por volumen |

| Método de fabricación | Proceso químico frente a proceso mecánico |

| Forma del grano | El polvo esférico es más caro |

Los precios exactos varían en función del tiempo y la geografía. Póngase en contacto con proveedores de confianza para solicitar el último presupuesto con gastos de envío. Considere descuentos por cantidades superiores a 25 kg para ahorrar costes en polvos de gran pureza.

Cómo seleccionar el polvo de wolframio

Factores que guían la selección del polvo de wolframio:

Tabla: Criterios de selección del polvo de wolframio

| Parámetro | Descripción |

|---|---|

| Requisitos de solicitud | Necesidades de densidad, temperaturas de funcionamiento, cargas, vida útil prevista, homologaciones necesarias |

| Especificaciones | Tamaño de las partículas, nivel de pureza, densidad de toma, superficie, etc. |

| Cualificaciones de los proveedores | Experiencia, sistemas de calidad y prácticas de control |

| Muestreo | Obtenga muestras de polvo para comprobar su idoneidad |

| Coste total | Comparar los precios de los proveedores preseleccionados, incluida la logística |

| Asistencia técnica | Evaluar el apoyo al diseño del proveedor frente a la mera venta |

| Certificaciones | Revise los informes de ensayo de materiales (MTR) para mayor tranquilidad |

Trabaje con proveedores cualificados para obtener su grado óptimo de polvo de tungsteno de forma rentable en función del método de producción previsto y de los criterios de rendimiento.

Ventajas e inconvenientes del uso de polvo de wolframio

Tabla: Ventajas y desventajas del polvo de wolframio

| Pros | Contras |

|---|---|

| Densidad extremadamente alta | Caro en comparación con los metales comunes |

| Punto de fusión más alto de los metales | Oferta y disponibilidad mundiales limitadas |

| Conductividad térmica/eléctrica | Requiere una manipulación cuidadosa dada su alta densidad |

| Flexibilidad de la aleación | Se considera material de transporte peligroso |

| Biocompatible para usos médicos | Necesidad de proveedores con experiencia |

| Permite mejorar el rendimiento | Posibilidad de falsificación de productos |

Para aplicaciones especiales que requieren alta densidad o conductividad térmica, el polvo de tungsteno ofrece ventajas significativas. El coste y la disponibilidad exigen una gestión cuidadosa.

Preguntas frecuentes

¿Cómo se manipula y almacena el polvo de wolframio de forma segura?

Siga las hojas de datos de seguridad - use equipo de protección personal, evite la inhalación usando respiradores, maneje los paquetes con cuidado dado su gran peso. Almacenar los envases sellados y debidamente etiquetados lejos de la humedad y de temperaturas extremas en ambientes frescos e inertes.

¿Qué industrias utilizan más el polvo de wolframio?

Entre las industrias que aprovechan las propiedades especiales del tungsteno se encuentran la aeroespacial, el blindaje contra la radiación, la automoción, las baterías y la medicina, además de áreas emergentes como la fabricación aditiva/impresión 3D.

¿Requiere el polvo de tungsteno controles especiales de envío o exportación?

Dado que el wolframio está clasificado como producto de doble uso, su exportación puede requerir licencias. Clasificado como mercancía peligrosa durante el transporte, necesita manipuladores competentes conscientes de los riesgos de densidad y combustión siguiendo la normativa aplicable.

¿Qué sustitutos existen para el polvo de wolframio?

Pocos materiales alternativos igualan la estabilidad térmica y la densidad del wolframio. El uranio empobrecido se aproxima a la densidad, pero plantea problemas de radiactividad. El plomo es más barato para algunas aplicaciones de pesaje, pero tóxico y carece de resistencia y comportamiento térmico.

¿Cuál es el tamaño típico del polvo de tungsteno utilizado para la impresión 3D?

La distribución del tamaño de las partículas, con una media de 20 micras, funciona bien en los procesos de impresión 3D por fusión de lecho de polvo que permiten la producción de piezas metálicas complejas y de alta densidad, utilizadas solas o mezcladas con otros polvos.

Conclusión

El polvo de tungsteno, que ofrece una densidad extraordinaria y resistencia a la temperatura, satisface requisitos de rendimiento especiales a pesar de su elevado coste. La selección cuidadosa de especificaciones como el tamaño de las partículas y la pureza, junto con proveedores de confianza, permite aprovechar las ventajas de la electrónica, el blindaje contra radiaciones y la fabricación aditiva de metales moderna. Como elemento puro impactante, el polvo de tungsteno facilita la superación de los límites de las aplicaciones cuando se diseña de forma creativa.