Las máquinas VIGA (atomización de gas inerte al vacío) se han convertido en fundamentales para la producción de polvos metálicos de alta calidad. Estas máquinas se utilizan ampliamente en diversas industrias, como la aeroespacial, la médica y la de automoción, gracias a su capacidad para producir polvos metálicos finos y uniformes. En esta guía detallada, exploraremos todos los aspectos de Máquinas VIGAdesde su visión general hasta los modelos específicos de polvo metálico, sus aplicaciones y mucho más. Prepárese para conocer a fondo el mundo de las máquinas VIGA

Visión general de las máquinas VIGA

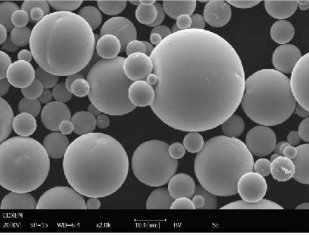

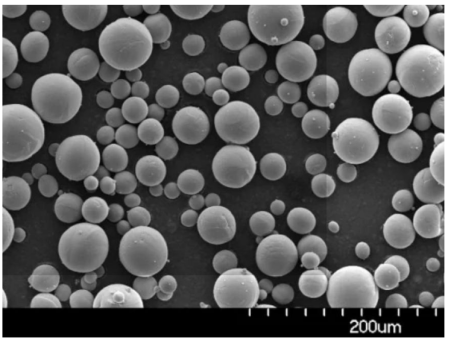

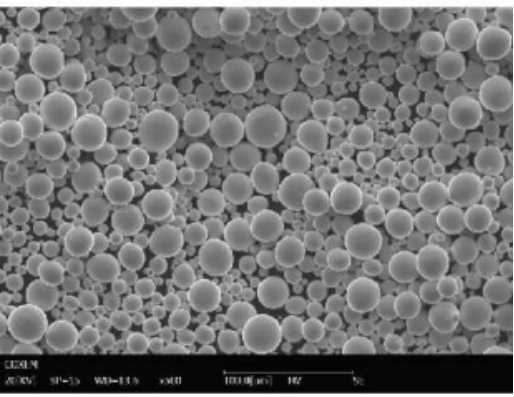

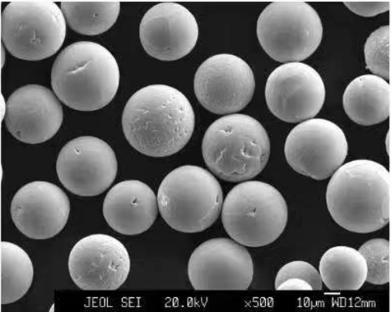

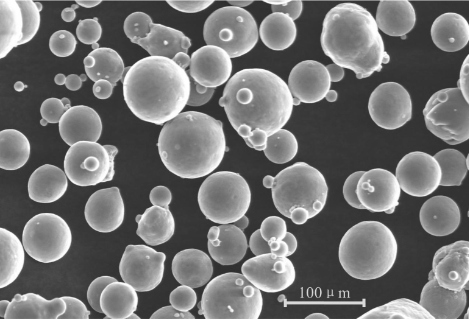

La atomización con gas inerte al vacío (VIGA) es un método utilizado para producir polvos metálicos atomizando metal fundido en un entorno controlado. El proceso consiste en fundir el metal en el vacío y atomizarlo con un gas inerte como el argón o el nitrógeno. De este modo se obtienen polvos metálicos de gran pureza y excelentes propiedades, lo que los hace adecuados para diversos procesos de fabricación avanzados.

Detalles clave de VIGA Machines

- Proceso: Fusión y atomización en un entorno de vacío/gas inerte

- Salida: Polvos metálicos esféricos de gran pureza

- Aplicaciones: Fabricación aditiva, metalurgia, pulvimetalurgia, tecnologías de revestimiento

Tipos de polvos metálicos producidos por las máquinas VIGA

La versatilidad de las máquinas VIGA les permite producir una amplia gama de polvos metálicos. A continuación encontrará una lista de modelos específicos de polvo metálico producidos con tecnología VIGA, junto con descripciones detalladas.

1. Polvo de acero inoxidable (316L)

Descripción: El polvo de acero inoxidable 316L es conocido por su excelente resistencia a la corrosión y sus propiedades mecánicas. Se utiliza ampliamente en las industrias médica y aeroespacial.

Caracteristicas:

- Composición: Hierro, cromo, níquel, molibdeno

- Propiedades: Alta resistencia a la corrosión, buena resistencia mecánica

2. Polvo de aleación de titanio (Ti-6Al-4V)

Descripción: Ti-6Al-4V es la aleación de titanio en polvo más utilizada, conocida por su elevada relación resistencia-peso y su excelente biocompatibilidad.

Caracteristicas:

- Composición: Titanio, aluminio, vanadio

- Propiedades: Alta resistencia, ligereza y biocompatibilidad

3. Polvo de Inconel (Inconel 718)

Descripción: El polvo de Inconel 718 es una aleación de níquel-cromo con una excelente resistencia a altas temperaturas y a la corrosión, ideal para aplicaciones aeroespaciales.

Caracteristicas:

- Composición: Níquel, cromo, hierro, niobio

- Propiedades: Estabilidad a altas temperaturas, resistencia a la corrosión

4. Polvo de aleación de aluminio (AlSi10Mg)

Descripción: El polvo de AlSi10Mg es una aleación de aluminio-silicio-magnesio con buena conductividad térmica y propiedades ligeras, lo que la hace adecuada para aplicaciones de automoción y aeroespaciales.

Caracteristicas:

- Composición: Aluminio, silicio, magnesio

- Propiedades: Ligero, buena conductividad térmica

5. Polvo de aleación de cobalto-cromo (CoCrMo)

Descripción: El polvo de aleación de CoCrMo es conocido por su excelente resistencia al desgaste y biocompatibilidad, y se utiliza ampliamente en implantes médicos.

Caracteristicas:

- Composición: Cobalto, cromo, molibdeno

- Propiedades: Alta resistencia al desgaste, biocompatibilidad

6. Polvo de aleación de cobre (CuCrZr)

Descripción: El polvo de CuCrZr es una aleación de cobre, cromo y circonio con una excelente conductividad eléctrica y térmica, adecuada para aplicaciones eléctricas y térmicas.

Caracteristicas:

- Composición: Cobre, cromo, circonio

- Propiedades: Alta conductividad, buena resistencia mecánica

7. Polvo de acero martensítico envejecido (18Ni300)

Descripción: El polvo de acero martensítico envejecido 18Ni300 es conocido por su gran resistencia y tenacidad, y se utiliza habitualmente en las industrias de utillaje y aeroespacial.

Caracteristicas:

- Composición: Hierro, níquel, cobalto, molibdeno

- Propiedades: Alta resistencia, tenacidad

8. Polvo de acero para herramientas (H13)

Descripción: El polvo de acero para herramientas H13 es famoso por su gran dureza y resistencia al calor, lo que lo hace adecuado para la fabricación de herramientas y moldes.

Caracteristicas:

- Composición: Hierro, cromo, molibdeno, vanadio

- Propiedades: Gran dureza, resistencia al calor

9. Polvo de aleación de níquel (NiCr8020)

Descripción: El polvo NiCr8020 es una aleación de níquel-cromo con una excelente resistencia a la oxidación y estabilidad a altas temperaturas, utilizada en elementos calefactores y hornos industriales.

Caracteristicas:

- Composición: Níquel, cromo

- Propiedades: Resistencia a la oxidación, estabilidad a altas temperaturas

10. Carburo de wolframio en polvo (WC-Co)

Descripción: El polvo de carburo de wolframio es conocido por su extrema dureza y resistencia al desgaste, y se utiliza ampliamente en herramientas de corte y revestimientos resistentes al desgaste.

Caracteristicas:

- Composición: Carburo de tungsteno, cobalto

- Propiedades: Dureza extrema, resistencia al desgaste

Composición y características de los polvos metálicos VIGA

A continuación figura un cuadro en el que se resumen la composición y las características de los polvos metálicos producidos por Máquinas VIGA.

| Polvo metálico | Composición | Propiedades |

|---|---|---|

| Acero inoxidable 316L | Hierro, cromo, níquel, molibdeno | Alta resistencia a la corrosión, resistencia mecánica |

| Ti-6Al-4V | Titanio, aluminio, vanadio | Alta resistencia, ligereza y biocompatibilidad |

| Inconel 718 | Níquel, cromo, hierro, niobio | Estabilidad a altas temperaturas, resistencia a la corrosión |

| AlSi10Mg | Aluminio, silicio, magnesio | Ligero, buena conductividad térmica |

| CoCrMo | Cobalto, cromo, molibdeno | Alta resistencia al desgaste, biocompatibilidad |

| CuCrZr | Cobre, cromo, circonio | Alta conductividad, buena resistencia mecánica |

| 18Ni300 | Hierro, níquel, cobalto, molibdeno | Alta resistencia, tenacidad |

| H13 | Hierro, cromo, molibdeno, vanadio | Gran dureza, resistencia al calor |

| NiCr8020 | Níquel, cromo | Resistencia a la oxidación, estabilidad a altas temperaturas |

| WC-Co | Carburo de tungsteno, cobalto | Dureza extrema, resistencia al desgaste |

Aplicaciones de los polvos metálicos VIGA

Los polvos metálicos producidos por las máquinas VIGA tienen una amplia gama de aplicaciones en diversas industrias. En la siguiente tabla se destacan algunas de estas aplicaciones.

| Industria | Aplicaciones | Polvos metálicos utilizados |

|---|---|---|

| Aeroespacial | Componentes del motor, piezas estructurales | Ti-6Al-4V, Inconel 718, AlSi10Mg |

| Médico | Implantes, prótesis | Acero inoxidable 316L, CoCrMo, Ti-6Al-4V |

| Automotor | Piezas ligeras, gestión térmica | AlSi10Mg, CuCrZr |

| Herramientas | Moldes, herramientas de corte | H13, WC-Co, 18Ni300 |

| Eléctrico | Componentes conductores, gestión térmica | CuCrZr, NiCr8020 |

| Industrial | Elementos calefactores, revestimientos resistentes al desgaste | NiCr8020, WC-Co |

Especificaciones, tamaños, calidades y normas

La siguiente tabla proporciona especificaciones, tamaños, grados y normas para algunos polvos metálicos producidos comúnmente por las máquinas VIGA.

| Polvo metálico | Tamaños (µm) | Grado | Normas |

|---|---|---|---|

| Acero inoxidable 316L | 10-45 | AISI 316L | ASTM F138, ISO 5832-1 |

| Ti-6Al-4V | 15-45 | 5º curso | ASTM F136, ISO 5832-3 |

| Inconel 718 | 15-53 | AMS 5662 | ASTM B637 |

| AlSi10Mg | 20-63 | AlSi10Mg | EN AC-43400, ISO 3522 |

| CoCrMo | 10-45 | ASTM F75 | ASTM F75, ISO 5832-4 |

| CuCrZr | 20-63 | CuCrZr | ASTM B505, DIN 17670 |

| 18Ni300 | 10-53 | Acero martensítico envejecido 300 | AMS 6521 |

| H13 | 15-45 | H13 | ASTM A681 |

| NiCr8020 | 20-63 | NiCr8020 | ASTM B163, DIN 17742 |

| WC-Co | 10-45 | WC-Co | ISO 3327 |

Proveedores y precios

A continuación figura una tabla en la que se enumeran algunos de los proveedores y los precios aproximados de diversos polvos metálicos producidos por las máquinas VIGA.

| Polvo metálico | Proveedor | Precio (por kg) | Notas |

|---|---|---|---|

| Acero inoxidable 316L | Tecnología Carpenter | $50 – $70 | Descuentos por volumen |

| Ti-6Al-4V | AP&C | $200 – $250 | Calidad superior, grado aeroespacial |

| Inconel 718 | Tecnologías de superficie Praxair | $150 – $200 | Aplicaciones de alta temperatura |

| AlSi10Mg | ECKART | $30 – $50 | Común en la fabricación aditiva |

| CoCrMo | Arcam AB | $300 – $350 | Grado de implante médico |

| CuCrZr | Aditivos GKN | $40 – $60 | Alta conductividad |

| 18Ni300 | Höganäs AB | $80 – $100 | Alta resistencia, aplicaciones de utillaje |

| H13 | Tecnología Carpenter | $70 – $90 | Herramientas resistentes al calor |

| NiCr8020 | Oerlikon Metco | $100 – $130 | Hornos industriales |

| WC-Co | Kennametal | $250 – $300 | Dureza extrema, herramientas de corte |

Comparación de ventajas e inconvenientes de los polvos metálicos VIGA

En la tabla siguiente se comparan los pros y los contras de los distintos polvos metálicos producidos por las máquinas VIGA.

| Polvo metálico | Ventajas | Limitaciones |

|---|---|---|

| Acero inoxidable 316L | Excelente resistencia a la corrosión y resistencia mecánica | Mayor coste que el acero normal |

| Ti-6Al-4V | Elevada relación resistencia/peso, biocompatibilidad | Caro, difícil de mecanizar |

| Inconel 718 | Resistencia a altas temperaturas y a la corrosión | Caro, maquinabilidad limitada |

| AlSi10Mg | Ligero, buenas propiedades térmicas | Menor resistencia en comparación con otras aleaciones |

| CoCrMo | Resistencia al desgaste, biocompatibilidad | Caro, disponibilidad limitada |

| CuCrZr | Excelente conductividad eléctrica y térmica | Menor resistencia mecánica |

| 18Ni300 | Alta resistencia, tenacidad | Caro, requiere un manejo especial |

| H13 | Gran dureza, resistencia al calor | Propenso a agrietarse |

| NiCr8020 | Resistencia a la oxidación, estabilidad a altas temperaturas | Caro, disponibilidad limitada |

| WC-Co | Dureza extrema, resistencia al desgaste | Muy caro, fragilidad |

Preguntas más frecuentes

¿Qué es el proceso VIGA?

El proceso VIGA consiste en fundir metal en el vacío y atomizarlo con gas inerte para producir polvos metálicos finos.

¿Qué industrias utilizan los polvos metálicos de VIGA?

Industrias como la aeroespacial, médica, automovilística, de herramientas y eléctrica utilizan los polvos metálicos de VIGA.

¿Cuáles son las ventajas de utilizar polvos metálicos VIGA?

Los polvos metálicos VIGA ofrecen alta pureza, tamaño de partícula uniforme y excelentes propiedades adecuadas para procesos de fabricación avanzados.

¿Cómo se comparan las máquinas VIGA con otros métodos de atomización?

Las máquinas VIGA proporcionan un mejor control de la calidad y pureza del polvo en comparación con otros métodos como la atomización con agua o con gas.

¿Son caros los polvos metálicos VIGA?

El coste de los polvos metálicos VIGA puede ser más elevado debido a la avanzada tecnología y a la alta calidad del producto, pero las ventajas suelen compensar los costes.

¿Qué polvos metálicos suelen producir las máquinas VIGA?

Los polvos más comunes son el acero inoxidable 316L, Ti-6Al-4V, Inconel 718, AlSi10Mg, CoCrMo, CuCrZr, 18Ni300, H13, NiCr8020 y WC-Co.

Conclusión

Máquinas VIGA representan una cumbre en el campo de la producción de polvo metálico, ya que proporcionan materiales de alta calidad para una amplia gama de industrias. Su capacidad para producir polvos con un control preciso de la composición y el tamaño de las partículas los hace indispensables en la fabricación moderna. Ya se trate de componentes aeroespaciales, implantes médicos o herramientas industriales, la versatilidad y fiabilidad de los polvos producidos por VIGA garantizan que sigan siendo un recurso fundamental en las aplicaciones de materiales avanzados.