CuSn20 분말 개요

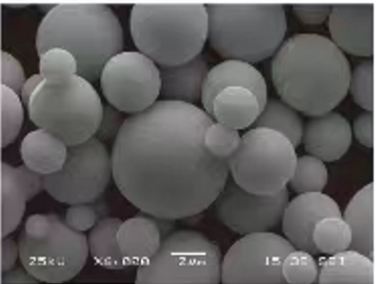

CuSn20 분말은 일반적으로 주석 함량이 높은 청동 분말로 알려져 있으며, 야금, 엔지니어링 및 제조 분야에서 매우 가치 있는 특수 합금 분말입니다. 구리 80%와 주석 20%로 구성된 CuSn20 분말은 내식성, 내구성 및 고마모 응용 분야에 적합하다는 점으로 유명합니다. 이러한 특성으로 인해 자동차, 전자 제품 및 기계 생산을 포함한 다양한 산업 분야에 이상적입니다.

이 가이드에서는 CuSn20 분말의 구성, 특성, 응용 분야 및 장점에 대해 자세히 살펴보겠습니다. 다양한 금속 분말 모델을 살펴보고 사용법과 특성을 비교하고 CuSn20이 다른 분말 유형과 어떻게 비교되는지 논의할 것입니다.

CuSn20 분말의 구성

CuSn20은 구리 80%와 나머지 20%가 주석으로 구성된 이원 구리-주석 합금 분말입니다. 이러한 구성은 인성과 변형 저항성이 모두 필요한 응용 분야에 CuSn20을 적합하게 만드는 물리적 및 기계적 특성에 필수적입니다.

| 요소 | 조성(중량 %) |

|---|---|

| 구리(Cu) | 80% |

| 주석(Sn) | 20% |

CuSn20 분말의 특성

CuSn20 분말의 특성은 조성과 밀접하게 관련되어 있습니다. 구리와 주석의 조합은 연성과 강도 사이의 균형을 제공하며, 가혹한 환경에서 일반적으로 사용되는 높은 내식성과 함께 제공됩니다.

| 속성 | 설명 |

|---|---|

| 내식성 | 특히 해양 및 습한 환경에서 탁월합니다. |

| 내마모성 | 내마모성이 뛰어나 부싱 및 베어링에 이상적입니다. |

| 연성 | 우수하여 합금을 쉽게 성형하고 형성할 수 있습니다. |

| 전기 전도성 | 중간 정도이며 순수 구리보다 낮지만 특정 전기 응용 분야에 충분합니다. |

| 열 전도성 | 우수한 열전도율로 기계 시스템의 열 발산을 돕습니다. |

| 밀도 | 약 8.9g/cm³로 상당한 질량과 안정성이 필요한 부품에 적합합니다. |

CuSn20 금속 분말의 주요 모델

1. CuSn20 모델 A

- 설명: 베어링 부품에 일반적으로 사용되는 고밀도 응용 분야에 최적화된 이 변형체입니다.

- 속성: 향상된 열 및 내마모성.

- 애플리케이션: 자동차 및 항공 우주 분야의 베어링, 부싱.

2. CuSn20 모델 B

- 설명: 최상위 전도성이 필요한 응용 분야에 적합한 불순물이 최소화된 고순도 버전의 CuSn20입니다.

- 속성: 뛰어난 전도성과 연성.

- 애플리케이션: 전기 커넥터, 고급 부싱.

3. CuSn20 모델 C

- 설명: 정밀한 응용 분야에 이상적인 미세 입자 CuSn20 분말.

- 속성: 고강도, 소형 부품에 적합합니다.

- 애플리케이션: 소규모 부싱, 복잡한 기계 부품.

4. CuSn20 고주석 변형체

- 설명: 기존 CuSn20보다 주석 함량이 약간 높아 내식성이 추가되었습니다.

- 속성: 향상된 내식성.

- 애플리케이션: 해양 응용 분야, 바닷물에 노출된 부품.

5. CuSn20 저주석 변형체

- 설명: 경도를 높이기 위해 주석 함량이 낮은 상태로 수정되었습니다.

- 속성: 더 높은 경도, 감소된 연성.

- 애플리케이션: 구조 부품, 산업 기계.

6. CuSn20 합금 분말 X

- 설명: 가공성을 향상시키기 위해 합금 원소를 추가한 CuSn20 변형체입니다.

- 속성: 향상된 가공성, 낮은 마찰.

- 애플리케이션: 가공 부품, 맞춤형 부품.

7. CuSn20 나노 분말

- 설명: 고급 적층 제조를 위해 설계된 나노 스케일 분말.

- 속성: 뛰어난 분말 유동성, 3D 프린팅에 적합합니다.

- 애플리케이션: 3D 프린팅 부품, 복잡한 형상.

8. CuSn20 모델 고정밀

- 설명: 고정밀 요구 사항을 위한 정밀 등급 분말.

- 속성: 고정밀 응용 분야를 위한 탁월한 유동성 및 분포.

- 애플리케이션: 의료 기기, 마이크로 가공 부품.

9. CuSn20 모델 향상된 전도성

- 설명: 구리의 자연적 특성의 균형을 맞추면서 더 높은 전도성을 위해 최적화되었습니다.

- 속성: 중간 정도의 전기 및 열 전도성.

- 애플리케이션: 전기 부품, 열 전달 시스템.

10. CuSn20 모델 맞춤형 합금

- 설명: 고객의 요구 사항에 따라 고유하고 특정 특성을 위해 맞춤화된 합금.

- 속성: 맞춤형 요구 사항에 따라 유연한 구성.

- 애플리케이션: 맞춤형 기계 및 전자 제품의 특수 응용 분야.

CuSn20 분말의 응용 분야

| 산업 | 애플리케이션 |

|---|---|

| 자동차 | 부싱, 베어링, 기어 |

| 전자 제품 | 커넥터, 전도성 부품 |

| 항공우주 | 고강도 부싱, 로터 |

| 해양 | 내식성 부품, 선체 |

| 산업 기계 | 구조 부품, 피스톤 |

| 의료 | 수술 기구, 임플란트 |

| 3D 프린팅 | 맞춤형 부품, 프로토타입 |

CuSn20 분말의 장점 및 단점

| 장점 | 단점 |

|---|---|

| 뛰어난 내식성 | 더 간단한 합금에 비해 더 높은 비용 |

| 강도와 연성의 균형 유지 | 중간 정도의 전기 전도성 |

| 가혹한 환경 설정에서 안정적임 | 순수 구리에 비해 연성 제한 |

| 고마모 응용 분야에 적합 | 주석은 일부 형태에서 취성을 유발할 수 있음 |

CuSn20 분말 모델의 사양

| 모델 | 평균 입자 크기 | 순도 | 밀도 | 전도성 |

|---|---|---|---|---|

| CuSn20 모델 A | 20 미크론 | 99.8% | 8.9g/cm³ | 보통 |

| CuSn20 모델 B | 25 미크론 | 99.5% | 8.9g/cm³ | 더 높음 |

| CuSn20 모델 C | 15 미크론 | 99.2% | 8.8 g/cm³ | 보통 |

| CuSn20 고주석 변형체 | 18 미크론 | 99.9% | 8.85 g/cm³ | 중간 정도, 내식성 |

| CuSn20 나노 분말 | <1 미크론 | 99.6% | 8.7g/cm³ | 나노 스케일 응용 분야에 맞게 향상됨 |

자주 묻는 질문

| 질문 | 답변 |

|---|---|

| CuSn20 분말은 무엇에 사용됩니까? | CuSn20 분말은 주로 부싱, 베어링 및 해양 부품과 같이 내마모성과 내식성이 높은 응용 분야에 사용됩니다. |

| CuSn20 분말을 3D 프린팅에 사용할 수 있습니까? | 예, CuSn20 나노 분말 및 미세 입자 변형체는 종종 적층 제조 및 3D 프린팅에 사용됩니다. |

| 어떤 산업이 CuSn20 분말에 가장 많이 의존합니까? | 자동차, 항공 우주, 전자 및 해양 공학과 같은 산업은 내구성과 환경 요인에 대한 저항성으로 인해 CuSn20을 많이 사용합니다. |

| CuSn20은 다른 청동 분말과 어떻게 비교됩니까? | CuSn20은 주석 함량으로 인해 다른 많은 청동 합금보다 높은 내식성을 제공하지만 순수 구리 또는 저주석 합금보다 연성이 떨어질 수 있습니다. |

| 기계에 CuSn20을 사용하면 어떤 주요 이점이 있습니까? | 높은 내마모성과 우수한 열전도율을 결합하여 마찰이 많은 부품에 적합하여 기계 수명을 연장합니다. |