1. 소개: 현대 제조에서 스펀지 철 분말이 중요한 이유

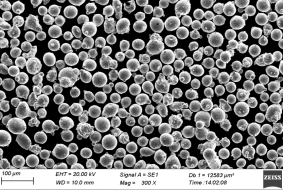

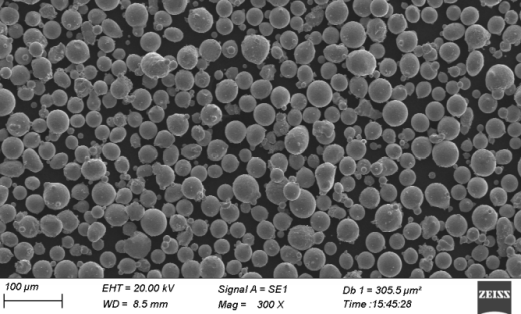

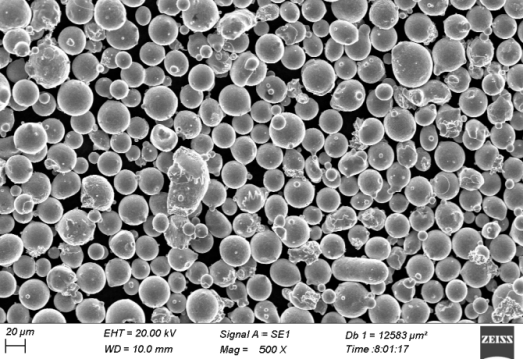

Sponge iron powder, also known as direct reduced iron (DRI) powder, is a highly porous form of iron produced through the reduction of iron ore without melting it. This powder is widely used across various industries, including powder metallurgy, automotive manufacturing, magnetic materials, and additive manufacturing. For B2B buyers, especially those in manufacturing and industrial sectors, sponge iron powder offers a versatile, cost-effective, and recyclable material source.

B2B 구매자를 위한 주요 혜택:

- ✅ High compressibility for powder metallurgy (PM) applications

- ✅ Excellent sintering properties

- ✅ Cost-effective raw material for producing structural PM parts

- ✅ Superior machinability when alloyed

- ✅ Recyclable and environmentally friendly

As demand for lightweight and high-strength components grows, sponge iron powder is being increasingly adopted by industries looking to optimize performance and reduce costs.

2. 스펀지 철 분말의 산업 응용

Sponge iron powder serves as a core material in the fabrication of sintered components, used across a wide range of industrial applications. Here’s a breakdown of the primary sectors utilizing sponge iron powder in bulk:

| 산업 | 애플리케이션 | 주요 이점 |

|---|---|---|

| 자동차 | Engine parts, gears, sprockets | Lightweight, durable, cost-efficient |

| 전기 및 전자 | Magnetic cores, inductors | High permeability, soft magnetic properties |

| 건설 | 구조 부품, 패스너 | 고강도, 내식성 |

| 적층 제조 | 3D 프린팅 metal parts | High porosity and sinterability |

| 석유 및 가스 | Valve parts, wear-resistant components | High-temperature stability |

Common Components Manufactured:

- 부싱

- 베어링

- 기어

- Camshafts

- 전기 접점

These applications highlight how sponge iron powder supports high-volume manufacturing with reliable mechanical performance.

3. Types of Sponge Iron Powder & Their Unique Properties

Sponge iron powder comes in various grades, depending on particle size, purity, and production method. The most common production methods include carbonyl, water atomization, and reduction.

Key Types of Sponge Iron Powder:

| 유형 | 입자 크기 | 생산 방법 | 애플리케이션 |

|---|---|---|---|

| Pure Iron Powder | <150 μm | Hydrogen/Carbon Reduction | PM structural parts |

| Pre-alloyed Powder | 다양 | 물 분무 | Automotive, tooling |

| 확산 합금 | 100–180 μm | Mixed & Sintered | Bearings, gears |

| Soft Magnetic Iron | Fine | 가스 분무 | 자기 부품 |

Shanghai Truer’s Sponge Iron Powder Portfolio

Shanghai Truer Technology Co., Ltd, a trusted supplier since 2009, offers a wide range of PM 분말 포함:

- PM iron

- PM infiltrated iron

- PM phosphorus iron

- PM hybrid low-alloy steel (FD-0208, FL-4605)

Truer’s sponge iron powder offers excellent compressibility and sinterability, making it ideal for high-precision manufacturing. Truer also supports custom formulations tailored to specific B2B requirements. Their powders are manufactured using advanced water and gas atomization techniques, ensuring consistency and superior metallurgical properties.

4. 글로벌 시장 동향 및 성장 기회

The global sponge iron powder market is experiencing steady growth, driven by rising demand for powder metallurgy components in automotive, industrial machinery, and 3D printing applications. According to industry reports, the powder metallurgy market—including sponge iron powder—is projected to reach over USD 10 billion by 2030, with a CAGR of 6-7%.

Key B2B Market Drivers:

- 자동차 경량화: Car manufacturers are increasingly using PM parts to reduce vehicle weight and improve fuel efficiency.

- Electrification & E-Mobility: Electric motors require soft magnetic materials, where sponge iron powder plays a key role.

- 적층 제조: The rise of metal 3D printing is increasing demand for customized iron-based powders.

- 지속 가능한 제조: Recyclable and energy-efficient production methods are pushing industries toward sponge iron powder.

지역 시장 통찰력:

| 지역 | Key Trends | Buyer Focus |

|---|---|---|

| 아시아 태평양 | Largest producer & consumer | Cost-efficiency, scalability |

| 유럽 | Advanced PM applications | Quality, innovation |

| 북미 | Automotive & aerospace | High-performance materials |

With the shift toward sustainable manufacturing and the growth of precision industries, B2B buyers are prioritizing suppliers that offer both quality and versatility in sponge iron powder solutions.

5. Choosing the Right Sponge Iron Powder Supplier

For B2B buyers, selecting the ideal sponge iron powder supplier is a strategic decision that impacts production quality, cost, and supply chain stability.

Key Considerations When Evaluating a Supplier:

- 프로덕션 기능: Check if the supplier uses reduction, water atomization, or gas atomization methods.

- Powder Grades Available: Ensure the supplier offers the required grades such as FD-0208, FN-0205, FL-4605.

- 사용자 지정 옵션: Can the supplier tailor powder properties to your specific application?

- 인증 및 표준: ISO9001, RoHS, REACH compliance, etc.

- 물류 및 리드 타임: Evaluate delivery timelines and global distribution support.

- 기술 지원: Look for suppliers who offer metallurgical advice, testing, and co-development services.

Sample Supplier Evaluation Checklist:

| 기준 | 중요성 | Shanghai Truer’s Advantage |

|---|---|---|

| 파우더 품질 | ⭐⭐⭐⭐⭐ | High purity, consistent sizing |

| 제품 범위 | ⭐⭐⭐⭐ | Over 10 types of PM powders |

| 사용자 지정 | ⭐⭐⭐⭐⭐ | Tailored blends & grades |

| 배달 | ⭐⭐⭐⭐ | Global shipping, fast lead time |

| Industry Support | ⭐⭐⭐⭐⭐ | Expert technical support & R&D |

B2B buyers should prioritize suppliers like Shanghai Truer who not only deliver material but also offer complete powder metallurgy solutions. Learn more about Shanghai Truer’s background and technical capabilities.

6. Top Wholesale Sponge Iron Powder Suppliers in Asia

Asia is the world’s leading hub for sponge iron powder production due to its cost-efficiency, technological advancements, and large-scale manufacturing infrastructure. Here are some of the top suppliers in the region catering to B2B distributors and industrial buyers:

Top 5 Sponge Iron Powder Suppliers in Asia:

| 공급업체 | 국가 | 전문화 | B2B 서비스 |

|---|---|---|---|

| 상하이 트루어 기술 유한공사 | 중국 | PM powders, 3D printing powders, additives | OEM/ODM, bulk orders, technical support |

| Hoganas India Pvt Ltd | 인도 | Iron-based powders for PM & welding | Wide distribution network |

| JFE 스틸 코퍼레이션 | 일본 | Alloyed & non-alloyed iron powders | 자동차 등급 소재 |

| 키메라 인터내셔널 | China & Korea | Specialty metal powders | 맞춤형 파우더 개발 |

| Pometon S.p.A (Asia division) | 이탈리아/아시아 | Atomized iron, copper powders | High-volume industrial supply |

상하이 트루어가 돋보이는 이유:

- ✅ Offers both traditional and advanced powder types like diffusion alloyed and hybrid PM steels.

- ✅ One of China’s most professional PM additive suppliers.

- ✅ Supplies to industries like automotive, tool manufacturing, and additive manufacturing.

- ✅ Provides 지원팀에 문의 for global distributors and OEMs.

Thanks to its integrated R&D, production, and logistics capabilities, Shanghai Truer is increasingly becoming the preferred partner for B2B buyers seeking quality and scale.

7. Why More Distributors Are Sourcing from Chinese Manufacturers

In recent years, global wholesalers, distributors, and OEMs have increasingly turned to Chinese suppliers for sourcing sponge iron powder. This shift is not only driven by pricing advantages but also by improvements in quality, innovation, and supply chain reliability.

Key Reasons Why B2B Buyers Prefer Chinese Sponge Iron Powder Suppliers:

- 비용 효율성: Chinese manufacturers offer highly competitive pricing due to economies of scale and local raw material access.

- 첨단 제조: Many Chinese suppliers now use state-of-the-art equipment like water atomization and hybrid atomization.

- Product Diversity: From basic sponge iron to prealloyed and diffusion-alloyed powders, China offers a wide product range.

- 사용자 지정 기능: Suppliers like Shanghai Truer offer tailored solutions for specific industrial applications.

- 더 빠른 리드 타임: With better logistics infrastructure and production planning, Chinese manufacturers are shortening delivery cycles.

What to Look for When Sourcing from China:

| 기준 | 중요성 | What to Expect from Shanghai Truer |

|---|---|---|

| 기술 지원 | 매우 높음 | Dedicated R&D and PM experts |

| 수출 경험 | 높음 | 14+ years in international trade |

| 재료 일관성 | 높음 | Stable quality across batches |

| 사용자 지정 | Essential | Tailored powder solutions |

| 인증 | 필수 | ISO, RoHS, and other industry standards |

When choosing a Chinese supplier, it’s critical to work with a company that not only delivers materials but also provides long-term strategic support. Shanghai Truer is a standout in this regard, offering a full suite of powder metallurgy products and services, including PM 분말 솔루션 and technical assistance.

8. 상하이 Truer Technology Co., Ltd를 공급업체로 선택해야 하는 이유

Shanghai Truer Technology Co., Ltd is one of China’s most trusted names in the powder metallurgy industry. Established in 2009 and entering the additive manufacturing space in 2019, Truer has grown into a full-service provider of high-quality sponge iron powder and related PM materials.

Core Advantages of Partnering with Truer:

- 포괄적인 제품 라인:

- PM Bronze, PM Iron, PM Steel, PM Stainless Steel, PM Infiltrated Iron, and more.

- Advanced sponge iron grades like FD-0208, FN-0205, FL-4605, and FX-2008.

- Modern Production Methods:

- Water atomization, gas atomization, carbonyl, and reduction processes.

- Combined atomization for specialty applications.

- Professional Additive Division:

- Cutting agents (SME-100, TD-8)

- Lubricants (Lube-W, SUW-5000B)

- 연자성 첨가제(QH-150, QHP-330)

- Graphite additives (TBC-400, TBC-1000)

- Customization & R&D Collaboration:

- Tailor-made powder compositions for specific industrial requirements.

- Technical guidance on sintering parameters and part design.

- Global Logistics & Support:

- Fast delivery to Asia, Europe, and North America.

- Responsive customer service in English and Chinese.

- 오늘 Truer의 팀에 문의하여 고성능 PM 분말의 다음 배치를 시작하십시오. for technical consultation or a quote.

Why Truer Is a Strategic B2B Partner:

| 기능 | 구매자에게 이점 |

|---|---|

| 14+ years of experience | Proven track record in PM supply |

| 사내 R&D | Better customization and innovation |

| Full range of PM materials | One-stop sourcing for manufacturers |

| Export-ready logistics | Fast, reliable international shipping |

| Industry certifications | Confidence in compliance and quality |

With a reputation for reliability, customization, and technical excellence, Shanghai Truer is not just a powder supplier—it’s a strategic B2B partner for manufacturers, wholesalers, and distributors worldwide.

9. FAQs: Everything B2B Buyers Need to Know About Sponge Iron Powder

Here are some of the most frequently asked questions from OEMs, wholesalers, and industrial buyers:

Q1: What’s the difference between sponge iron powder and atomized iron powder?

A: Sponge iron powder is made by reducing iron ore without melting, resulting in a porous structure. Atomized powder is produced by spraying molten metal into fine droplets, which solidify into powder. Sponge iron is often used in PM applications requiring high compressibility, while atomized powder is preferred for more precise applications.

Q2: What is the typical particle size range of sponge iron powder?

A: Particle sizes typically range from 45 μm to 180 μm, depending on the production method and grade. Truer offers customizable particle sizing based on application needs.

Q3: Can I order a custom blend of sponge iron powder for my application?

A: Yes, suppliers like Shanghai Truer specialize in custom formulations for automotive, additive manufacturing, and tooling industries. You can learn more about the company’s capabilities here.

Q4: What is the minimum order quantity (MOQ) for wholesale sponge iron powder?

A: MOQs vary by product and grade but typically start from 500 kg for standard grades. Custom orders may require a higher MOQ depending on specifications.

Q5: How do I ensure consistent quality across batches?

A: Partner with suppliers like Truer, who offer batch testing, COAs (certificates of analysis), and ISO-certified quality systems. This guarantees consistency and traceability.

Q6: How long does international delivery take?

A: Standard lead times range from 2 to 4 weeks depending on order volume and destination. Truer provides real-time shipping updates and flexible delivery options.

Q7: Is sponge iron powder suitable for additive manufacturing?

A: Yes. Sponge iron powder is increasingly used in binder jetting and other AM technologies due to its sinterability and porosity. Truer provides high-purity PM powders optimized for AM—check out their main product page 에서 자세한 내용을 확인하세요.

With this complete guide, B2B buyers can make informed decisions about sourcing sponge iron powder for their manufacturing needs. Whether you’re an OEM in automotive, a distributor in industrial components, or a 3D printing specialist, Shanghai Truer Technology Co., Ltd provides the quality, flexibility, and service you need to scale confidently.

For more information or to place a wholesale order, contact us today.