1. Introduction: Why Spherical Iron Powder Matters in Modern Manufacturing

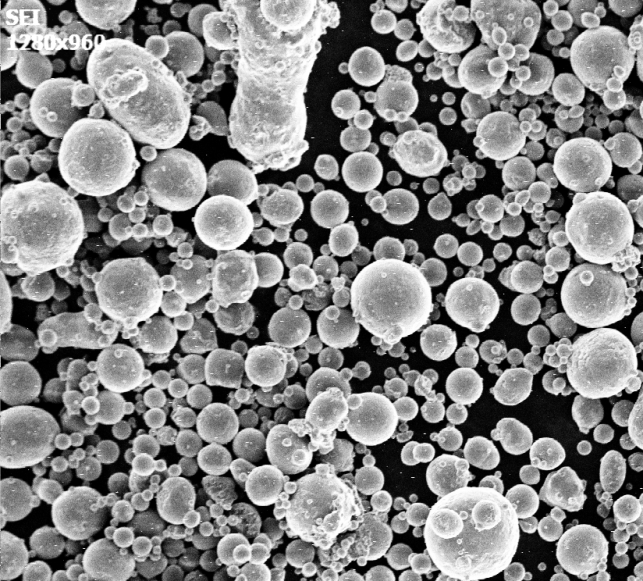

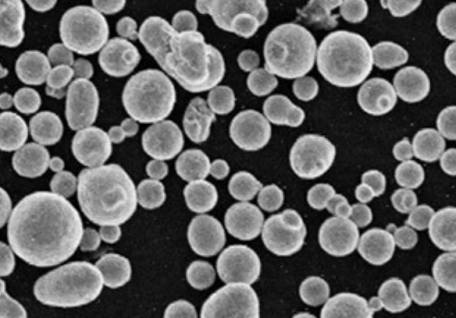

Spherical iron powder has become a cornerstone material in industries ranging from additive manufacturing and powder metallurgy (PM) to magnetic materials and soft magnetic composites. Its spherical morphology provides excellent flowability, uniform packing density, and exceptional sintering behavior—key factors for achieving high-quality finished parts.

For B2B buyers—including wholesale distributors, e-commerce sellers, and industrial procurement managers—understanding the full potential of spherical iron powder is critical for sourcing the right materials at scale. With increasing demand in sectors such as automotive, aerospace, and electronics, the global market for spherical iron powder continues to grow rapidly.

Key B2B Benefits

- Consistent particle shape and size distribution

- 자동화된 공정을 위한 뛰어난 유동성

- High tap density and packing efficiency

- Excellent magnetic and mechanical properties

- Ideal for 3D 프린팅 and powder metallurgy applications

2. Industrial Applications of Spherical Iron Powder

Spherical iron powder is widely used across multiple high-demand industries. Its versatility and performance characteristics make it a preferred material for precision manufacturing processes.

Major Application Areas

| 산업 | 애플리케이션 | Benefits of Spherical Iron Powder |

|---|---|---|

| 적층 제조 | Metal 3D printing (Binder Jetting, SLM, DMLS) | Superior flow, uniform melting, high-density parts |

| 분말 야금 | Structural parts, sintered components | Improved compaction, reduced friction, uniform microstructure |

| 자동차 | Brake pads, gears, camshafts | 높은 내마모성, 치수 안정성 |

| 전자 제품 | EMI shielding, inductors, magnetic cores | High permeability, low coercivity |

| 항공우주 | Lightweight yet strong structural components | 높은 중량 대비 강도, 내산화성 |

Additive Manufacturing Spotlight

The rise of additive manufacturing has created new demand for high-quality spherical iron powder. Its uniform particle shape ensures consistent layer deposition and melting behavior in laser-based 3D printing systems. For businesses scaling up their AM operations, sourcing high-purity, spherical iron powder is key to producing strong, dense, and defect-free parts.

3. Properties and Types of Spherical Iron Powder

The performance of spherical iron powder depends largely on its chemical composition, particle size distribution, and production method. Understanding these variables helps B2B buyers make informed purchasing decisions.

Common Properties of High-Quality Spherical Iron Powder

- Purity: ≥ 99% Fe

- Particle Size: 15–150 µm (customizable based on application)

- Shape: Near-perfect spherical morphology

- Density: Apparent density 2.5–3.0 g/cm³; Tap density 3.5–4.5 g/cm³

- Flowability: Highly flowable (Hall flow rate ≤ 30 s/50g)

- Oxygen Content: Low (< 0.2%) for high sintering efficiency

Types of Spherical Iron Powder by Production Method

| 생산 방법 | 설명 | Suitable Applications |

|---|---|---|

| 물 분무 | High-pressure water breaks molten metal | Cost-effective, good for general PM parts |

| 가스 분무 | Inert gas used for atomization | High purity, ideal for AM and magnetic applications |

| Carbonyl Process | Chemical decomposition of iron carbonyl | Ultra-fine particles, high purity, used in electronics |

| 하이브리드 분무 | 가스 및 수분무의 조합 | Balanced cost and performance |

Particle Size Distribution Options

| 애플리케이션 유형 | Recommended Particle Size (µm) |

|---|---|

| 분말 야금 | 50–150 µm |

| 적층 제조 | 15–63 µm |

| Magnetic Applications | 45–106 µm |

| 금속 사출 성형 | 5–25 µm |

Shanghai Truer Technology Co., Ltd offers a full range of spherical iron powders through water, gas, or hybrid atomization methods. Their powders are engineered for performance and compatibility with leading industrial processes. You can explore their full PM powder offerings on their product overview page.

4. Top 5 Trusted Spherical Iron Powder Suppliers Worldwide

Selecting a reliable supplier is crucial for maintaining consistency, quality, and cost-efficiency in your manufacturing operations. Here are five globally recognized suppliers of spherical iron powder for B2B buyers, OEMs, and industrial distributors.

1. 상하이 트루어 기술 유한공사(중국)

- 설립: 2009 (Additive division since 2019)

- 스페셜티: Water atomized, gas atomized, and hybrid spherical iron powders

- Key Grades: CT-1000, F-0000, F0008, FC-0208, FD-0208, FN-0205, FL-4605

- Value Proposition: Vertical integration of powder production and 3D printing services

- 대상 고객: Powder metallurgy factories, additive manufacturing firms, global distributors

- 웹사이트: Truer Technology

2. Höganäs AB (Sweden)

- 스페셜티: High-performance metal powders for automotive, AM, and soft magnetic parts

- 글로벌 도달 범위: Production facilities in Europe, Asia, and the Americas

- 힘: Proprietary production technologies and global distribution

3. Rio Tinto Metal Powders (Canada)

- Focus: Press-ready iron powders for PM manufacturing

- 힘: Integration with iron ore mining and metal refining

- Clients: Automotive Tier 1 suppliers, PM part producers

4. CNPC Powder (China)

- 스페셜티: Metal powders for automotive, aerospace, and electronics

- 범위: Iron, copper, nickel, alloy powders

- 생산 방법: Water and gas atomization

5. GKN Hoeganaes (USA)

- Division of: GKN Powder Metallurgy

- 애플리케이션: Structural parts, soft magnetic components

- Research Focus: High-density and high-performance PM powders

These companies serve as essential links in the global B2B supply chain for powder-based manufacturing. Buyers should evaluate each supplier’s capabilities, certifications, and regional logistics support.

5. Why More Distributors Are Sourcing from Chinese Manufacturers

In recent years, Chinese manufacturers have become dominant players in the global powder metallurgy and additive manufacturing markets. This shift is driven by several key factors that make China a preferred sourcing destination for spherical iron powder.

중국에서 소싱하는 장점

| 기능 | Benefit for International B2B Buyers |

|---|---|

| 규모의 경제 | Lower costs due to large-scale production |

| Advanced Atomization Tech | High-spec powders through gas/water hybrid |

| 사용자 지정 유연성 | Tailor-made particle size, purity, and packaging |

| 리드 타임 단축 | Fast turnaround for bulk and repeat orders |

| 통합 서비스 | Powder + Equipment + Engineering Support |

Case in Point: Shanghai Truer

Shanghai Truer’s in-house R&D team and full-service manufacturing capabilities give global buyers access to high-quality powders at competitive pricing. Their hybrid atomization technology ensures a balance between cost and performance—perfect for businesses scaling up production.

Distributors and wholesalers looking to expand their product lines can benefit from Truer’s customizable powder solutions, which are optimized for PM, additive manufacturing, and magnetic applications.

6. Why Choose Shanghai Truer as Your Trusted Powder Supplier

Shanghai Truer Technology Co., Ltd is one of China’s leading suppliers of spherical metal powders, including iron, steel, bronze, copper, and specialty PM blends. Here’s why they stand out in the B2B market:

1. Full Vertical Integration

- 파우더 생산: Water, gas, carbonyl, and hybrid atomization

- Equipment Manufacturing: In-house production of powder atomization systems

- Application Engineering: Support for AM, PM, and sintered part development

2. Extensive Product Portfolio

- 제공되는 성적: CT-1000, F-0000, FC-0208, FD-0200, FN-5000, FX-2008

- Additives Division: Lubricants, cutting agents, graphite, soft magnetic additives

- 특수 분말: Phosphorus iron, infiltrated steel, hybrid low-alloy powders

3. Quality Assurance & Certifications

- 품질 관리: Advanced particle analysis, flow rate testing, tap density measurement

- 인증: ISO 9001:2015, RoHS, REACH compliant

- 추적 가능성: Batch-level documentation and material traceability

4. International Support & Logistics

- 수출 경험: Serving clients in 40+ countries

- 패키징 옵션: Bulk bags, sealed drums, vacuum packaging

- 고객 지원: English-speaking sales engineers and global shipping

5. Innovation & Collaboration

- R&D Partnerships: Collaboration with universities and PM associations

- 맞춤형 솔루션: Co-develop custom powders for unique applications

For buyers looking for a dependable, innovative, and cost-effective powder supplier, Shanghai Truer combines the best of Chinese manufacturing efficiency with global-quality standards. Learn more about their history and capabilities on the 회사 소개 페이지.

7. How to Order Wholesale Spherical Iron Powder from China

Procuring spherical iron powder in bulk from a trusted Chinese supplier like Shanghai Truer is a streamlined process, especially for international B2B buyers. Whether you’re a distributor, OEM, or additive manufacturing company, understanding the step-by-step process will help you save time, reduce costs, and ensure quality compliance.

단계별 주문 프로세스

| 단계 | 작업 | 세부 정보 |

|---|---|---|

| 1 | Inquiry & Specification Submission | Provide technical specs (particle size, purity, atomization method), quantity, and application details. Use the 문의 양식 직접 이메일을 보내세요. |

| 2 | Quotation & Sample Offer | Truer’s sales team will provide a formal quotation including pricing, lead time, and logistics options. Samples for testing can be shipped upon request. |

| 3 | Sample Evaluation (Optional) | Evaluate flowability, tap density, and sintering performance in your lab or pilot production. |

| 4 | Purchase Order & Contract | Confirm PO and sign supply agreement. OEM and private labeling options available. |

| 5 | Mass Production & Quality Assurance | Truer manufactures the powder according to ISO-certified QC standards. Batch reports and COAs are provided. |

| 6 | Packaging & Logistics Arrangement | Choose packaging (25 kg bags, 500 kg drums, vacuum sealed). Truer handles customs and shipping. FOB, CIF, and DDP terms available. |

| 7 | 배송 및 A/S 지원 | Receive your shipment on time. Technical support is ongoing for application optimization and reorders. |

제공된 문서

- 분석 인증서(COA)

- 물질 안전 보건 자료(MSDS)

- Quality Inspection Report

- Customs and Export Documentation

결제 조건

- Flexible options for long-term partners

- Standard terms: 30% deposit, 70% before shipment

- L/C, T/T, and PayPal for sample orders

To begin your wholesale inquiry, visit the contact page here.

8. FAQs: Buying Wholesale Spherical Iron Powder

Below are answers to some of the most common questions from B2B buyers, procurement managers, and engineering teams.

Q1: What is the minimum order quantity (MOQ) for bulk orders?

A: Shanghai Truer typically accepts a minimum order of 100 kg for standard grades. Custom grades may require higher MOQs (500–1000 kg), depending on the production batch size.

Q2: Can I request a custom particle size or blend?

A: Yes. Truer can tailor the particle size distribution, purity, and even produce pre-alloyed or diffusion-alloyed powders to meet your specific application needs.

Q3: What is the typical lead time?

A: For standard grades, lead time is 7–10 working days. For custom powders, allow 15–20 days. Express air shipments are available for urgent orders.

Q4: Do you offer technical support or application guidance?

A: Absolutely. Truer provides end-to-end support including powder selection, process compatibility, and post-processing optimization. You can also consult their PM expertise for more insights.

Q5: Is Truer’s powder compatible with additive manufacturing (3D printing)?

A: Yes. Their spherical iron powders are suitable for binder jetting, laser sintering (SLM), and direct metal laser sintering (DMLS). Gas atomized and hybrid powders are particularly suitable for AM.

Q6: How is the powder packaged?

A: 옵션은 다음과 같습니다.

- 25 kg polyethylene-lined paper bags

- 500 kg steel drums with moisture barrier

- Vacuum-sealed foil bags for lab-grade powders

Custom packaging and labeling are available for OEM partners.

Q7: Can I get a free sample for testing?

A: Yes. Small samples (1–2 kg) are available for free or at nominal cost. Shipping charges may apply depending on the destination.

9. Get Started with Shanghai Truer Today

If you’re a B2B buyer looking for a reliable source of high-quality spherical iron powder, Shanghai Truer Technology Co., Ltd should be at the top of your list. With over a decade of experience, proprietary atomization technologies, and a strong commitment to powder metallurgy innovation, Truer is the ideal partner for your next project.

Why Choose Shanghai Truer?

- ✅ ISO-certified production and quality control

- ✅ Full range of powder metallurgy and additive powders

- ✅ Customization and OEM services

- ✅ Fast delivery and global shipping

- ✅ Expert technical support

Start by exploring their metal powder product catalog, or reach out directly via their 문의 양식 에 문의하여 견적 또는 샘플을 요청하십시오.

🔗 기사에서 사용된 내부 앵커 텍스트 링크:

By following this guide, procurement specialists, distributors, and OEMs can make informed decisions when sourcing spherical iron powder for industrial-scale applications. Shanghai Truer stands ready to deliver both quality and value—at scale.