1. What Is Ni15 Powder & Why It Matters in B2B Manufacturing

Ni15 powder is a specialized nickel alloy powder containing approximately 15% nickel, optimized for use in powder metallurgy (PM), additive manufacturing (AM), and other high-performance engineering applications. In the B2B manufacturing landscape, it plays a critical role due to its:

- 뛰어난 내식성

- 높은 열 전도성

- 뛰어난 기계적 강도

- Compatibility with sintering and additive processes

Key B2B Markets That Use Ni15 Powder

| 산업 | 사용 사례 |

|---|---|

| 자동차 | Gears, bushings, and exhaust components |

| 항공우주 | Structural parts requiring high heat resistance |

| 전자 제품 | EMI shielding, contacts, and connectors |

| 석유 및 가스 | High-performance valves and pump parts |

| 산업 기계 | Wear-resistant components and sliding mechanisms |

Ni15 is especially attractive to manufacturers and distributors seeking a balance of performance and cost-efficiency, making it a preferred material in bulk purchasing.

2. Industrial Applications of Ni15 Powder

Ni15 powder is widely utilized across various sectors due to its adaptable properties and compatibility with multiple production techniques, including:

- 물 분무

- 가스 분무

- Reduction methods

- Hybrid (water + gas) atomization

Common Applications in Powder Metallurgy (PM)

- High-strength PM parts: Used in automotive and industrial machinery

- Infiltrated components: For enhanced mechanical properties

- 자성 어셈블리: Due to its magnetic characteristics

Additive Manufacturing (AM) Applications

- 3D printing of functional prototypes

- Tooling and jigs for industrial use

- Custom components for low-volume production

Typical Use Cases in Bulk Manufacturing

| 애플리케이션 | Benefits for B2B Buyers |

|---|---|

| Gears & Bearings | Long lifespan, reduced friction, cost-efficient |

| 열 차폐 | High temp resistance, corrosion protection |

| 전기 부품 | Stable conductivity, oxidation resistance |

| Structural Supports | 경량 및 내구성 |

For wholesale buyers, Ni15 powder provides an ideal balance of performance and affordability, reducing lifecycle costs and improving product quality.

3. Physical Properties and Use Cases of Ni15 for Professionals

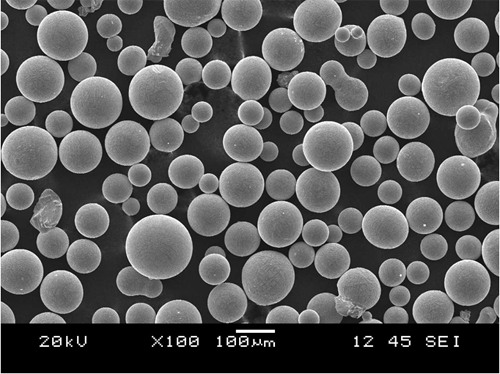

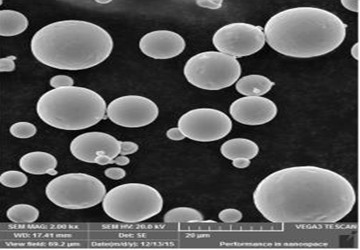

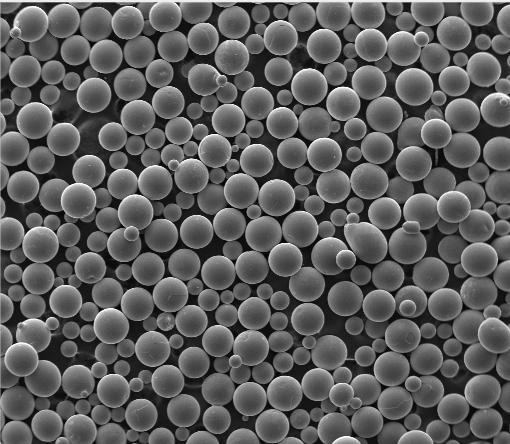

Ni15 powder exhibits a unique set of physical and mechanical properties that make it ideal for demanding industrial applications.

Key Physical Properties of Ni15 Powder

| 속성 | 값 범위 | Industry Relevance |

|---|---|---|

| 니켈 함량 | ~15% | Enhances corrosion and heat resistance |

| 입자 크기 분포 | 15–75 μm (typical) | Optimized for sintering and AM |

| Density (Apparent) | 3.5–5.0 g/cm³ | Suitable for compacted PM parts |

| 흐름성 | Good (depending on atomization) | Ensures smooth processing in AM and PM |

| 산소 함량 | 0.5% | Critical for achieving desired sinter quality |

Use Cases in High-Volume B2B Manufacturing

- Bulk sintered parts for automotive and industrial applications

- 3D printed tooling for rapid prototyping and short-run manufacturing

- High-wear components such as bushings, sleeves, and washers

- Additive infiltration to boost hardness and tensile strength

Key Advantages for B2B Buyers

- 일관된 품질 across large batches

- High compatibility with standard PM and AM equipment

- Reduced lead times when sourced from reliable suppliers like Shanghai Truer

- Customizable grades to meet specific application requirements

Shanghai Truer Technology Co., Ltd excels in producing premium Ni15 and other PM powders through advanced atomization methods (water, gas, or hybrid), ensuring high flowability and purity levels tailored for industrial applications.

4. Market Demand & Trends in Nickel Alloy Powders

The global demand for nickel-based powders like Ni15 has surged over the past five years, driven by the expansion of powder metallurgy (PM), additive manufacturing (AM), and the increasing need for high-strength, corrosion-resistant components across industries.

Major Market Drivers

- Electrification in Automotive: Demand for nickel-containing components in EV motors and battery casings.

- Aerospace Lightweighting: Use of Ni15 in high-strength, lightweight structural parts.

- 산업 자동화: Growing need for precision components made via PM and AM.

- 3D 프린팅 Boom: Widespread adoption of metal AM in prototyping and tooling.

Global Ni15 Powder Market Outlook (2024–2029)

| 지역 | CAGR(%) | Growth Drivers |

|---|---|---|

| 아시아 태평양 | 9.8% | China’s PM production, EV manufacturing, cost advantage |

| 유럽 | 7.5% | Aerospace and automotive demand |

| 북미 | 6.9% | Industrial automation, MIM & AM growth |

| 중동 | 5.1% | Oil & gas component manufacturing |

Key Trends Impacting B2B Buyers

- 📦 Bulk Purchasing Growth: Large-scale manufacturers increasingly favor long-term contracts with Ni15 suppliers to reduce volatility in pricing and supply chain risks.

- 🔄 Shift to Hybrid Atomization: More buyers prefer powders made with combined water and gas atomization for better flowability and sintering performance.

- 🌍 Sourcing from China: Competitive pricing, improved quality standards, and shorter lead times make China a strategic hub for Ni15 procurement.

5. How to Choose the Right Ni15 Powder Supplier

For B2B buyers, selecting a credible Ni15 supplier impacts not only the quality of the final product but also operational efficiency and cost competitiveness.

Key Selection Criteria for Wholesale Ni15 Powder

| 요인 | 비용 효율성: |

|---|---|

| Purity & Composition | Directly affects sintering quality and mechanical output |

| 입자 크기 분포 | Influences part density and surface finish in AM & PM |

| 분무 방법 | Determines flowability, porosity, and uniformity |

| 기술 지원 | Assists with formulation, troubleshooting, and optimization |

| 리드 타임 및 물류 | Critical for uninterrupted production and inventory flow |

| 인증 | ISO, REACH, RoHS compliance builds buyer confidence |

Checklist for Vetting Ni15 Suppliers

- ✔️ Do they offer both gas and water atomized options?

- ✔️ Are they capable of producing custom grades or blends?

- ✔️ Can they deliver consistent quality across large volumes?

- ✔️ Do they provide technical documentation and COAs?

- ✔️ Are they a direct manufacturer or just a reseller?

Shanghai Truer Technology Co., Ltd meets all the above criteria, offering end-to-end solutions for Ni15 and other PM powders with in-house atomization facilities, strict quality control, and one of the widest product ranges in China.

6. Top Global & Chinese Suppliers of Ni15 Powder

Here’s a curated list of some of the most reliable Ni15 suppliers globally, with a focus on those catering to wholesale buyers and distributors.

Leading Ni15 Powder Suppliers (B2B Focus)

| 공급업체 이름 | 지역 | 강점 |

|---|---|---|

| 상하이 트루어 기술 | 중국 | Custom grades, hybrid atomization, large-scale production |

| 호가나스 AB | 스웨덴 | Global leader in PM powders, high consistency |

| 샌드빅 적층 제조 | 스웨덴 | Specializes in AM powders, strong R&D support |

| GKN 회가나에스 | 미국 | High-performance PM materials, extensive global distribution |

| CNPC 파우더 | 중국 | Competitive pricing, broad product catalog |

상하이 트루어가 돋보이는 이유

- 🏭 확립된 전문 지식: Since 2009 in PM, and since 2019 in additive manufacturing

- 🔬 고급 기술: Offers water, gas, and hybrid atomized Ni15 powders

- 📦 Wholesale Ready: Supports bulk orders with consistent batch quality

- 🧪 Diverse Grades: Offers standard and custom Ni15 blends suitable for specific B2B needs

For buyers looking to source directly from a trusted Chinese manufacturer, Shanghai Truer offers a strategic combination of price, quality, and service.

7. Why More Buyers Are Sourcing Ni15 from China

China has become a global hub for powder metallurgy materials, including high-quality nickel alloy powders like Ni15. For B2B buyers, sourcing from China offers several compelling advantages.

Cost, Capacity, and Customization

| 혜택 | How It Helps B2B Buyers |

|---|---|

| 경쟁력 있는 가격 | Lower material cost without compromising quality |

| High Production Volume | Supports large-scale manufacturing and long-term contracts |

| 맞춤형 제형 | Tailored Ni15 compositions for specific industrial needs |

| Integrated Supply Chains | Faster lead times and better logistics management |

Strategic Reasons to Choose China for Ni15 Powder

- 📈 Mass Production Expertise: Chinese suppliers have deep experience in scaling production efficiently.

- 🧪 Materials Innovation: Increasing R&D investments in powder metallurgy and additive manufacturing.

- 🌐 Export-Oriented: Many suppliers specialize in international B2B supply contracts and logistics.

Shanghai Truer’s Value Proposition

Shanghai Truer is one of China’s most professional additive suppliers, offering more than just powder — it provides complete additive solutions. Its PM Powder Division supports customers with:

- Full range of PM nickel-based powders including Ni15

- Custom particle size and alloy adjustments

- Technical support from experienced powder metallurgy engineers

- Reliable shipping to North America, Europe, and Asia-Pacific

8. How to Order Wholesale Ni15 Powder from China

For international buyers, ordering Ni15 powder in bulk from a trusted supplier such as Shanghai Truer is a straightforward process — when handled professionally, it can save time, reduce costs, and improve supply chain reliability.

Step-by-Step Ordering Process with Shanghai Truer

| 단계 | 설명 |

|---|---|

| 1. Inquiry & Quotation | Submit your Ni15 powder specs (grade, quantity, PSD, etc.) through the 연락처 페이지. |

| 2. Sample Evaluation | Receive a sample batch for testing and quality validation. |

| 3. Contract & Pricing | Agree on pricing, lead time, and delivery terms (FOB, CIF, etc.). |

| 4. Production | Truer schedules production with strict quality control. |

| 5. Quality Inspection | Certificate of Analysis (COA) and technical documentation provided. |

| 6. 포장 및 배송 | Export-compliant packaging, support for sea/air freight. |

| 7. 애프터 서비스 지원 | Ongoing tech support and reorder services available. |

Customization Options Available

- Tailored particle size distribution (PSD)

- Specific alloying elements or base mixtures

- Surface treatment or coating (if necessary)

- Special packaging (vacuum sealed, nitrogen flushed, etc.)

최소 주문 수량(MOQ)

Shanghai Truer typically supports both small test batches and full container loads. MOQ may vary based on:

- Customization level

- Atomization method

- Destination country regulations

제공된 문서

- 분석 인증서(COA)

- 안전 데이터 시트(SDS)

- Packing List & Commercial Invoice

- Origin Certificate (if required)

Logistics and Delivery

| 배송 방법 | 예상 배송 시간 | 참고 |

|---|---|---|

| Air Freight | 5–10 business days | Quicker but costlier |

| Sea Freight | 20–35 business days | Economical for bulk orders |

| Express Courier | 3–7 business days | Ideal for samples or urgent orders |

For all logistics, Shanghai Truer can work with your freight forwarder or manage end-to-end delivery.

9. FAQs: Buying Ni15 Powder in Bulk for Manufacturing

Here are some of the most common questions we receive from distributors, wholesale buyers, and industrial manufacturers regarding Ni15 powder:

❓ What is the typical composition of Ni15 powder?

Ni15 powder contains approximately 15% nickel, with the balance being primarily iron and trace alloying elements. The exact formulation can be customized based on application requirements.

❓ Is Ni15 powder suitable for 3D printing?

Yes. Ni15 powder produced via gas or hybrid atomization offers excellent flowability and particle morphology, making it suitable for additive manufacturing, including binder jetting and laser powder bed fusion.

❓ Can I request a custom particle size distribution (PSD)?

Absolutely. Shanghai Truer offers tailored PSD ranging from <15μm to >75μm based on your production process — whether sintering, MIM, or AM.

❓ What quality assurance measures are in place?

Shanghai Truer applies rigorous QA/QC protocols, including:

- ISO-certified production systems

- In-house chemical analysis and morphology inspection

- Batch-to-batch consistency checks

- Third-party testing (on request)

❓ Do you support long-term supply agreements?

Yes. We work with many OEMs and distributors on annual contracts to secure pricing, volume, and delivery timelines — ideal for high-volume manufacturers and procurement teams.

❓ How can I get started?

Click here to contact our technical sales team and submit your specifications. Our engineers will provide guidance, samples, and pricing tailored to your needs.

Why Shanghai Truer Is Your Trusted Ni15 Powder Partner

With over a decade of experience in powder metallurgy and additive manufacturing, Shanghai Truer Technology Co., Ltd is a recognized leader in producing and supplying high-performance powders for industrial applications.

Shanghai Truer at a Glance

- 🏢 Established in 2009, additive manufacturing division launched in 2019

- 🧪 Full range of Ni-based, Fe-based, Cu-based, and hybrid alloy PM powders

- ⚙️ Advanced production methods: water, gas, and hybrid atomization

- 🌐 Export-ready: Serving global clients across North America, EU, and Asia

- 🔗 Integrated solutions: Additive materials, powder tech, and PM expertise

Product Range Snapshot

| 파우더 유형 | Methods Available | 사용 사례 |

|---|---|---|

| Ni15 Powder | Water, Gas, Hybrid Atomization | AM, PM, Infiltration, Tooling |

| PM 스테인리스강 | 수분무 또는 가스 분무 | Automotive, Aerospace, Medical |

| PM 4600 / 4200 Steel | 사전 합금 / 하이브리드 | 구조적 PM 부품 |

| Diffusion CuSn Powder | Cu-Sn Sintering Applications | Diamond Tools, Oil Bearings |

| Cutting Additives (SME-100, TD-8) | Composite Agents | Machinability Enhancement |

Whether you are a large-scale OEM, a regional distributor, or a specialized AM service provider, Truer has the capacity, expertise, and materials to fuel your manufacturing success.

Want to Learn More?

👉 Visit our homepage for product categories and case studies

📧 Submit an inquiry via our 문의 양식

🧪 Explore our full range of PM powders and additive materials

Shanghai Truer — Your Strategic Partner in Powder Metallurgy Innovation.