1. Introduction: Why Laser Cladding Powder Matters in Modern Manufacturing

Laser cladding is a revolutionary surface modification technique that enhances the surface properties of a component by depositing a layer of material using a laser. At the heart of this process lies laser cladding powder—high-performance metal powders engineered to deliver superior wear resistance, corrosion protection, and repair capabilities.

Importance in B2B Manufacturing

- Cost-effective repairs: Extends the life of expensive machinery parts.

- Customizable materials: Tailored compositions for specific industrial applications.

- Minimal dilution: Ensures high purity and bonding strength.

- Low heat input: Reduces thermal distortion and cracking.

Laser cladding is widely adopted across industries like:

- 항공우주

- 석유 및 가스

- 전력 생산

- 자동차

- Tool & Die Manufacturing

As a result, the demand for reliable, high-purity laser cladding powders is rising globally. Suppliers aiming to serve B2B customers need to meet advanced material specifications and consistent quality standards.

2. Key Applications of Laser Cladding Powder in Industry

Laser cladding powder is used for both preventive and reparative applications in heavy-duty environments. Below are key industry verticals and how B2B buyers are leveraging laser cladding for performance optimization.

| 산업 | 적용 분야 | 혜택 |

|---|---|---|

| 석유 및 가스 | Drill bits, pump shafts, valves | Wear resistance, corrosion protection |

| 항공우주 | 터빈 블레이드, 랜딩 기어 | High-temperature resistance, fatigue life |

| 자동차 | 엔진 부품, 변속기 부품 | Friction reduction, surface hardening |

| Mining & Construction | Excavator arms, crushers | 내마모성, 수명 연장 |

| 전력 생산 | Steam turbine parts, nuclear components | Heat resistance, structural integrity |

| 도구 및 다이 | Molds, dies, forming tools | Precision restoration, anti-galling layers |

Benefits for OEMs and Distributors

- Reduced downtime: Parts can be repaired in-situ or off-site with quick turnaround.

- Inventory management: Enhanced part longevity reduces replacement frequency.

- 사용자 지정: Powders can be precisely engineered for specific part geometries and functions.

3. Types of Laser Cladding Powders and Their Properties

The performance of laser cladding depends heavily on the powder’s composition and morphology. Here’s a breakdown of common types of laser cladding powders available in the wholesale market:

| 파우더 유형 | 구성 | 주요 속성 | 애플리케이션 |

|---|---|---|---|

| Nickel-based alloys | Ni-Cr-B-Si, Ni-WC | Corrosion and wear resistance, high toughness | 항공우주, 석유 및 가스 |

| Cobalt-based alloys | Co-Cr-W | High temperature resistance, biocompatibility | Medical, Nuclear |

| Iron-based alloys | Fe-Cr, Fe-Ni, Fe-Mo | Cost-effective, abrasion resistance | Mining, Power Plants |

| Carbide-reinforced powders | Ni-WC, Co-WC, Fe-WC | Extreme hardness, erosion resistance | Construction, Tooling |

| 스테인리스 스틸 파우더 | 316L, 420, 430 | 내식성, 연성 | Marine, Food Processing |

| Aluminum-bronze powders | Cu-Al-Ni | Anti-friction, cavitation resistance | Shipbuilding, Pumps |

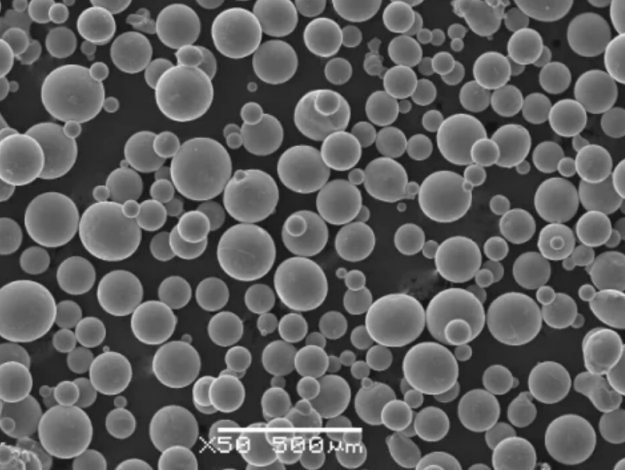

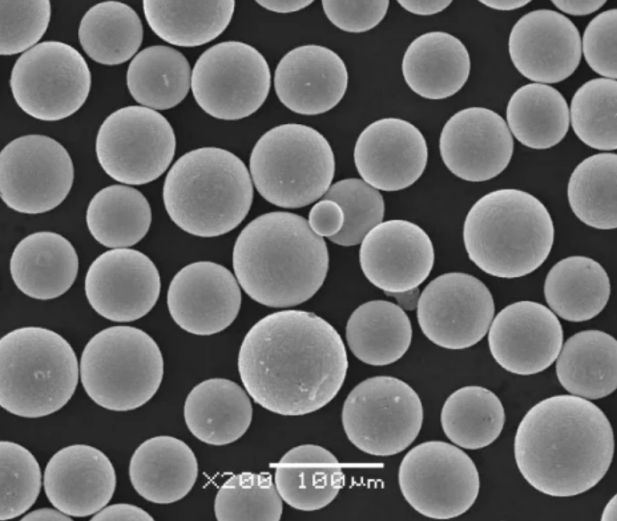

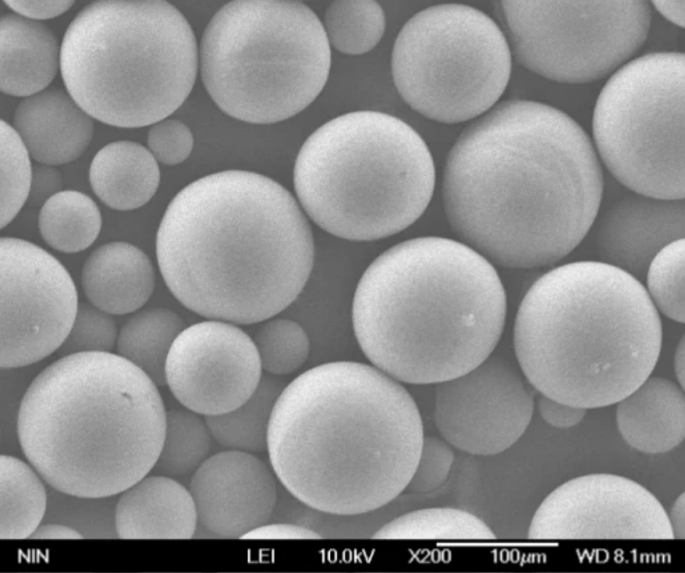

분말 특성

- 입자 크기 분포: Typically 45–150 μm for laser cladding.

- 구형성: High flowability and packing density.

- 순도: Low oxygen and carbon content.

- Production methods: Gas atomization is preferred for laser cladding due to superior morphology and cleanliness.

Shanghai Truer Technology Co., Ltd offers a wide range of water and gas atomized laser cladding powders including nickel alloys, cobalt alloys, and stainless steels, tailored for additive manufacturing and surface engineering.

4. Market Trends and Growth Potential of Laser Cladding Technology

The laser cladding market is experiencing rapid growth, driven by the increasing need for high-performance surface treatments in heavy industries. Manufacturers and distributors are prioritizing laser cladding powders in their procurement strategies due to the expanding adoption of Industry 4.0 and additive manufacturing.

Global Market Overview

| Metric | 가치 |

|---|---|

| 시장 규모(2023년) | USD 875 million |

| Projected CAGR (2024–2030) | 9.2% |

| 주요 성장 지역 | China, USA, Germany, India |

| Top End-Use Sectors | Oil & Gas, Aerospace, Automotive |

주요 시장 동인

- Lifecycle cost savings: Extending service life of components reduces replacement costs.

- 지속 가능성: Reduces waste by enabling part refurbishment instead of disposal.

- Digital manufacturing: Integration with CNC and robotic arms for automated cladding.

- Material innovation: Development of hybrid alloys and composite powders.

Market Opportunities for B2B Buyers

- OEM partnerships: Custom alloy development and co-engineered solutions.

- Private labeling: Distributors can brand high-quality powders from trusted manufacturers.

- Regional warehousing: Reduced lead times and supply chain resilience.

B2B buyers, especially distributors and wholesalers, can capitalize on this growth by forging partnerships with vertically integrated suppliers like 상하이 트루어 기술 유한공사, which not only manufactures powders but also offers cladding process support.

5. Factors to Consider When Choosing a Laser Cladding Powder Supplier

Selecting the right B2B supplier for laser cladding powders involves evaluating multiple technical and commercial criteria. Below are essential factors wholesale buyers and procurement managers should consider:

Technical Considerations

- 분말 형태: Spherical, uniform particles for consistent flow and deposition.

- 화학적 순도: Low contamination levels (O, C, N, S) to avoid defects.

- Grain size distribution: Matches laser cladding system requirements (typically 45–150 μm).

- 생산 방법: Gas atomization preferred for high-end applications.

Commercial Considerations

| 기준 | B2B 구매자를 위한 중요성 |

|---|---|

| MOQ flexibility | Ideal for both small-batch and bulk orders |

| Pricing transparency | Helps in margin calculation for resellers |

| Lead time & logistics support | Essential for global distributors |

| Certification & testing | ISO, material certificates, lot traceability |

| 기술 지원 | Post-sale support for application engineering |

적층 제조 고객에 대한 경험 없음

- Lack of documentation or inconsistent particle sizing

- Poor packaging leading to oxidation or contamination during transit

- Inconsistent batch quality, affecting cladding performance

Shanghai Truer addresses these challenges by offering tightly controlled production batches, certified quality, and full technical documentation. Their powders are used in both additive manufacturing and laser cladding, giving distributors a dual-market advantage.

6. Top 5 Global Suppliers of Laser Cladding Powder

Here’s a curated list of leading global suppliers of laser cladding powders, ranked based on their product range, quality certifications, and global reach.

| 회사 이름 | 본사 | 특수 분말 | B2B Strengths |

|---|---|---|---|

| 올리콘 메트코 | 스위스 | Ni, Co, Fe, Carbides | Global distribution, R&D support |

| 호가나스 AB | 스웨덴 | Fe, Ni, stainless steel | Custom alloy design, strong logistics |

| 프렉스에어 표면 기술 | 미국 | Ni-based, ceramic blends | Aerospace-grade powders, ISO certified |

| 상하이 트루어 기술 유한공사 | 중국 | Ni, Co, Fe, stainless, hybrids | Custom solutions, OEM support, wholesale powder supply |

| AMETEK Surface Technologies | 미국 | NiCr, CoCr, tungsten blends | Strong in thermal spray and laser cladding |

Why B2B Buyers Should Consider Truer

- Established manufacturing since 2009 with 3D 프린팅 specialization launched in 2019.

- Integrated services: From powder production to cladding process support.

- Wide powder portfolio: Over 20+ PM and additive powder grades.

- Advanced atomization: Offers both gas and hybrid atomization methods.

Shanghai Truer not only competes on quality but also enables distributors to scale efficiently by offering consistent availability and technical guidance throughout the sales cycle.

7. Why More Buyers Are Sourcing from Chinese Manufacturers

China has become a dominant player in the global advanced materials supply chain, and the laser cladding powder segment is no exception. Increasingly, OEMs, distributors, and e-commerce industrial suppliers are turning to Chinese manufacturers for high-quality, cost-effective laser cladding powders.

Key Benefits for B2B Buyers Sourcing from China

- 비용 효율성: Lower production and labor costs translate into competitive wholesale pricing.

- 첨단 제조: Many Chinese suppliers now use state-of-the-art atomization technologies (gas and water hybrid).

- 확장성: Ability to fulfill large-volume orders with short lead times.

- 사용자 지정 기능: Tailored powder compositions for specialized industry needs.

- Global Shipping Infrastructure: Well-established export logistics and documentation processes.

Why Chinese Manufacturers Are Gaining Trust

| 요인 | What It Means for Buyers |

|---|---|

| ISO and quality systems | International-grade reliability and consistency |

| R&D investment | Continuous improvement in alloy and powder design |

| Bilingual support teams | Easier communication for global B2B buyers |

| 유연한 최소 주문 수량(MOQ) | Supports both large distributors and small OEMs |

Shanghai Truer Technology Co., Ltd is a prime example of a Chinese manufacturer that has gained global recognition for quality and innovation. With over a decade of experience and a dedicated additive manufacturing division, Truer has become a preferred partner for international buyers seeking PM and AM powders.

8. Why Choose Shanghai Truer Technology Co., Ltd for Laser Cladding Powder

Shanghai Truer Technology Co., Ltd stands out in the Chinese powder metallurgy market by delivering unmatched expertise, quality, and customer-centric services. Truer is not just a powder supplier—it’s a partner for long-term B2B success.

트루어를 차별화하는 요소

- ✅ 확립된 전문 지식: Founded in 2009, with a full additive manufacturing division added in 2019.

- ✅ 포괄적인 제품 범위:

- PM Bronze, Brass, Nickel Silver, Iron, Steel

- Gas Atomized Stainless Powders (e.g., 316L, 304, 420)

- Hybrid Water/Gas Atomized Powders

- Custom diffusion-bonded and infiltrated grades

- ✅ Industry-Specific Solutions: Powders suitable for oil & gas, aerospace, tooling, and more.

- ✅ Advanced Equipment: In-house powder production lines with carbonyl, reduction, and atomization technologies.

- ✅ 품질 보증:

- ISO 인증 프로세스

- Full chemical analysis and particle size distribution reports

- Batch traceability and technical datasheets

Specialized Powder Grades for Laser Cladding

| Grade Name | 합금 유형 | 적용 분야 |

|---|---|---|

| FL-4605 | Low-alloy Steel | Tool wear resistance |

| FX-2008 | Hybrid Alloy | Surface repair for valves & gears |

| FD-0208 | 확산 합금 | Long-life coatings in aerospace |

| SBF2218 | 스테인리스 스틸 | Corrosion-resistant marine parts |

Truer also provides a range of additives and lubricants such as SUW-5000B and QH-150, which improve powder flow and deposition quality in laser cladding applications.

📌 Ready to explore Truer’s full product line? Visit the laser cladding powder catalog for technical specifications and ordering options.

9. FAQs: Common Questions About Buying Wholesale Laser Cladding Powder

Q1: What is the minimum order quantity (MOQ) for laser cladding powders?

A: MOQs vary by powder type but typically start at 25 kg. Truer offers flexible MOQs to accommodate both small and large buyers.

Q2: How do I ensure the powder is compatible with my laser cladding system?

A: Truer provides full technical datasheets, including particle size, flow rate, and chemical composition, to ensure compatibility. Custom sizing is also available upon request.

Q3: Does Shanghai Truer support international shipping?

A: Yes, Truer ships globally and provides all necessary export documentation, including MSDS, COA, and customs clearance support.

Q4: Can I request custom alloy compositions?

A: Absolutely. Truer specializes in developing tailored powder compositions based on your performance requirements and cladding method.

Q5: How do I get in touch for a quote or technical consultation?

A: You can reach out via the 연락처 페이지 to speak with a technical sales consultant or request a custom quote.

🔗 Internal Link Summary for SEO Optimization

Here are the embedded anchor links included throughout the article for improved user navigation and SEO:

- Laser cladding powders – Truer’s product catalog

- 상하이 트루어 기술 유한공사 – About the company

- International buyers seeking PM and AM powders – Homepage

- Laser cladding powder catalog – Detailed specs & ordering

- 연락처 페이지를 통해 직접 문의하세요. – Quote requests and consultations

This comprehensive guide is designed to help B2B buyers, procurement teams, and industrial distributors make informed decisions when sourcing laser cladding powders. Whether you’re restoring turbine blades or increasing wear resistance on mining tools, Shanghai Truer Technology offers trusted solutions backed by materials science and industry experience.

📞 Ready to request a quote or sample? Visit the 연락처 페이지 to speak with a specialist today.