1. Introduction: What Is FeNiMo Spherical Powder and Why It Matters in Industry

FeNiMo spherical powder is a high-performance metal powder composed of iron (Fe), nickel (Ni), and molybdenum (Mo), widely used in powder metallurgy (PM) and additive manufacturing (AM) applications. Its spherical morphology, high purity, and excellent flowability make it ideal for sintering, 3D 프린팅, and thermal spraying.

Why FeNiMo Stands Out in Industrial Applications:

- 뛰어난 내마모성: Thanks to the molybdenum content

- 향상된 내식성: Provided by nickel

- 높은 온도 안정성: Suitable for demanding operating conditions

- 우수한 자기적 특성: Beneficial in electric and electronic components

Common Industrial Users:

| 산업 | 사용 사례 | 혜택 |

|---|---|---|

| 자동차 | Gears, bushings, magnetic components | Durable & cost-effective |

| 항공우주 | Engine parts, structural brackets | 높은 중량 대비 강도 비율 |

| 전자 제품 | Soft magnetic cores, EMI shielding | Superior magnetic properties |

| 석유 및 가스 | Valve components, connectors | Corrosion & heat resistance |

FeNiMo alloys are engineered to provide performance where traditional materials fall short. Especially in the B2B landscape, where manufacturers, OEMs, and distributors seek consistent quality and scalable supply, FeNiMo spherical powder is a go-to choice.

2. Applications of FeNiMo Spherical Powder in Powder Metallurgy & 3D Printing

FeNiMo powders are extensively used in both conventional and advanced manufacturing processes. These include:

분말 야금(PM)

In PM, FeNiMo is utilized to produce high-strength components with complex geometries. Its spherical shape enhances compaction and sintering efficiency.

PM Applications:

- 구조 부품

- 자성 코어

- 기어 및 부싱

- Hydraulic components

금속 사출 성형(MIM)

FeNiMo powder’s fine particle size distribution and high compressibility make it suitable for MIM, especially in electronics and medical tools.

MIM Benefits:

- 높은 치수 정확도

- Enhanced surface finish

- Cost-effective for small complex parts

적층 제조(3D 프린팅)

FeNiMo powder is an excellent material for 선택적 레이저 용융(SLM) 그리고 전자 빔 용융(EBM) due to its:

- Superior flowability

- 높은 포장 밀도

- Uniform microstructure after printing

AM Use Cases:

- Aerospace brackets

- Customized energy components

- Tooling inserts

For more information on other high-quality 3D printing powders, visit our PM powder catalog.

3. Key Properties and Advantages of FeNiMo Spherical Powder

FeNiMo powder is engineered for high-performance applications. The following properties make it especially attractive for B2B buyers:

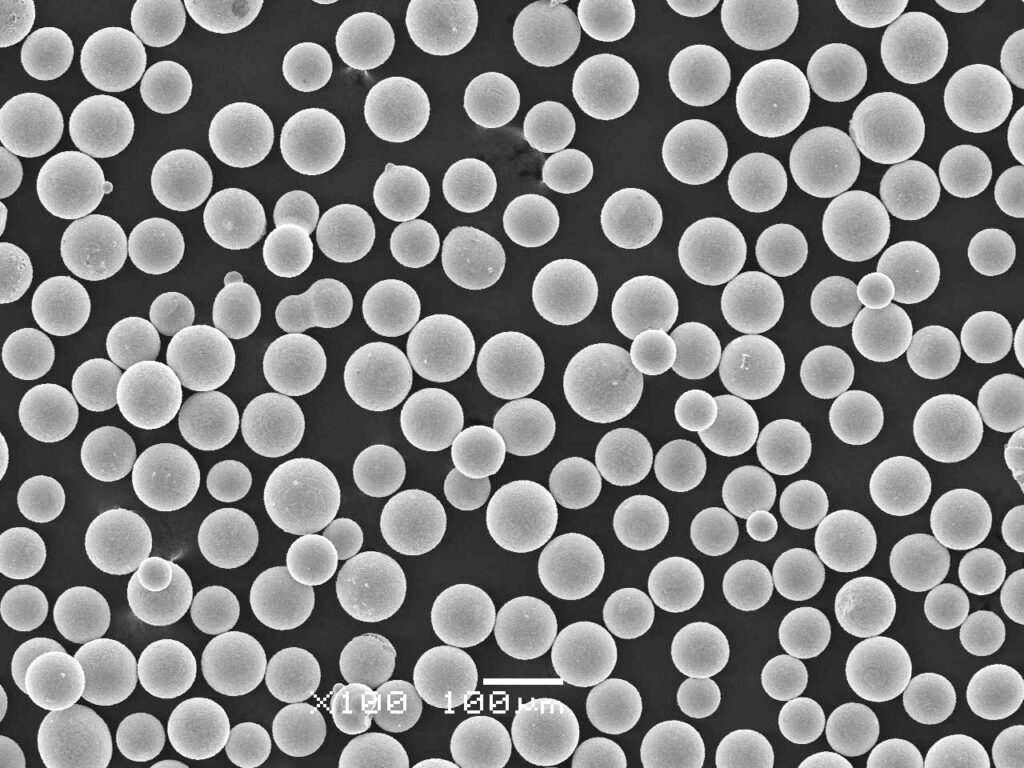

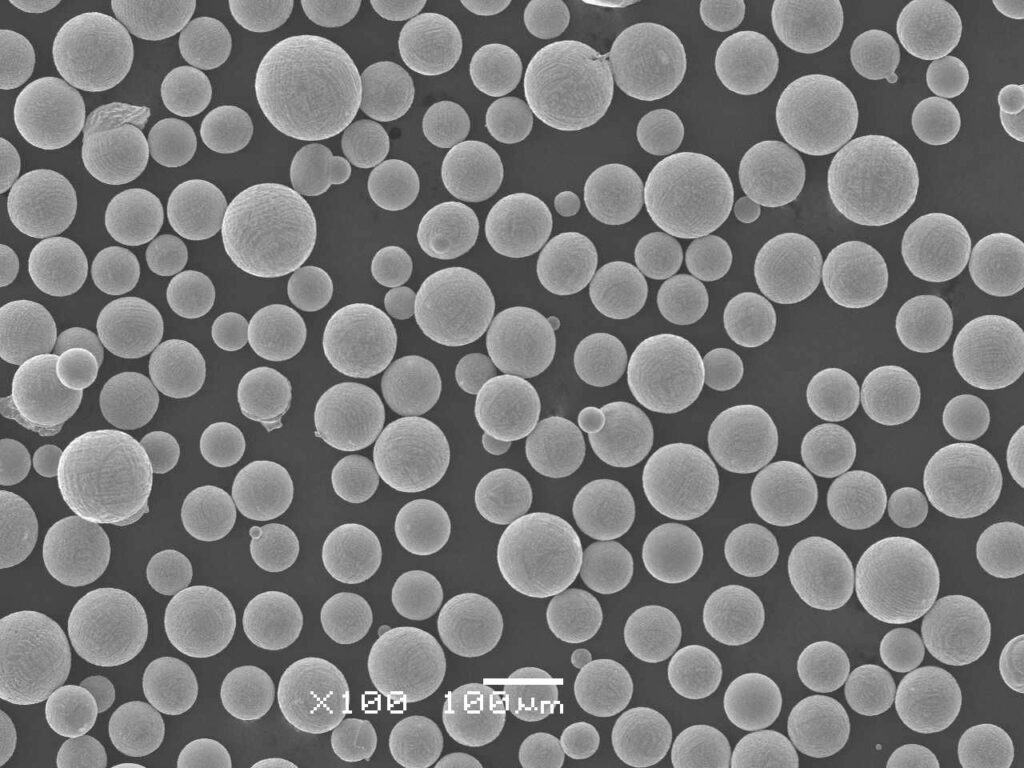

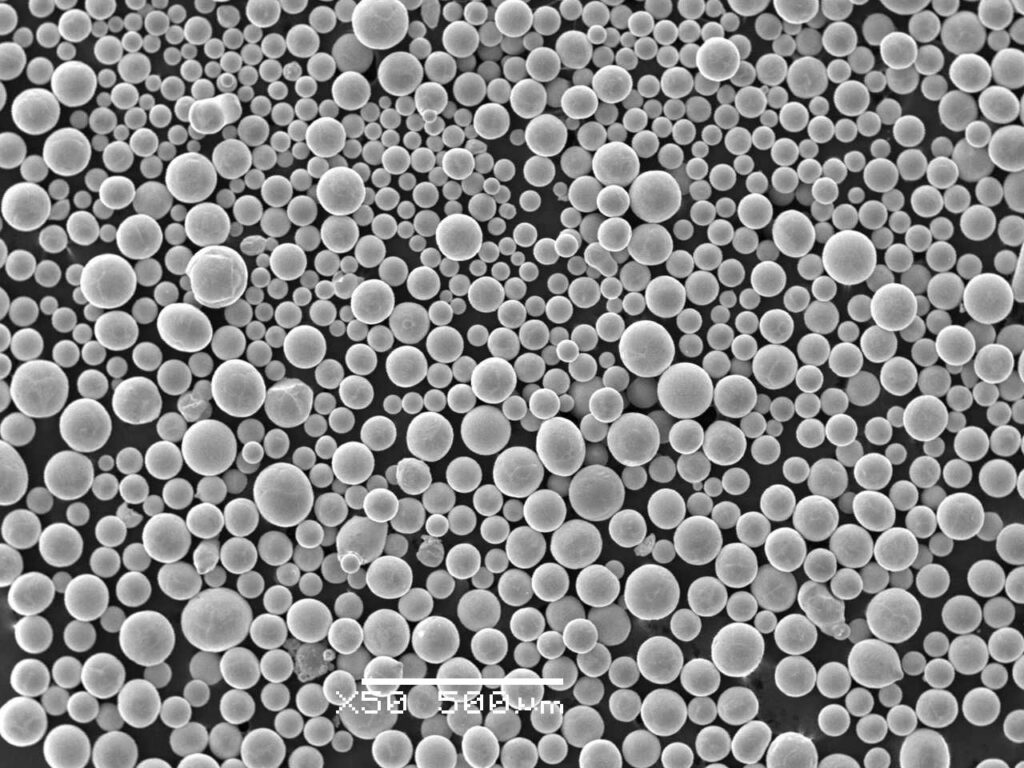

물리 및 화학적 특성

| 속성 | 값(일반) |

|---|---|

| 파티클 모양 | 구형 |

| 순도 | ≥ 99.5% |

| 입자 크기 | 15–53 µm (customizable) |

| 흐름성 | 높음 |

| 겉보기 밀도 | 4.5–5.5 g/cm³ |

| 산소 함량 | ≤ 0.1% |

Technical Advantages

- Excellent Sphericity: Improves flow and layer deposition in AM

- 낮은 산소 함량: Reduces oxidation during processing

- 우수한 소결성: Reduces processing time and energy

- Compatible with Multiple Techniques: Including MIM, SLM, and Cold Spray

Performance Benefits for B2B Buyers

- ✅ Improves production yield

- ✅ Reduces waste and post-processing cost

- ✅ Enhances mechanical integrity of finished parts

- ✅ Supports tight tolerance specifications

Ideal for Bulk and Custom Orders

FeNiMo powder is available in various batch sizes, supporting both prototyping and mass production needs. Shanghai Truer Technology offers tailored solutions for:

- OEMs

- Contract manufacturers

- R&D institutions

- 유통업체

To learn more about Shanghai Truer’s additive manufacturing capabilities and history, explore our company profile.

4. Global Market Trends and Growth Potential for FeNiMo Alloys

FeNiMo alloys have been gaining significant traction in global markets thanks to their superior performance in high-stress and high-temperature environments. As industries continue to shift towards lightweight and corrosion-resistant materials, FeNiMo spherical powder is emerging as a preferred solution in sectors like automotive, aerospace, and energy.

주요 시장 동인

- Rising Demand for Additive Manufacturing (AM): The global 3D printing market is expected to exceed $50 billion by 2030, and FeNiMo alloy powders are vital to high-performance AM applications.

- Growth in Electric Vehicles (EVs): FeNiMo’s magnetic and thermal properties make it ideal for EV components.

- Expansion of Aerospace Applications: The aerospace industry increasingly requires lightweight yet durable metal powders for structural and engine components.

- Focus on Energy Efficiency: FeNiMo alloys help reduce energy losses in motors and transformers due to superior magnetic properties.

시장 예측

| 지역 | CAGR(2024-2030년) | Market Focus |

|---|---|---|

| 아시아 태평양 | 8.6% | Automotive, Electronics |

| 북미 | 7.9% | 항공우주, 국방 |

| 유럽 | 7.5% | 산업 기계 |

| 중동 | 6.8% | Energy, Oil & Gas |

Opportunities for B2B Buyers

- Bulk procurement contracts

- OEM partnerships for specialized components

- Private-label powder supply for distributors

- Custom powder formulations for advanced R&D

As supply chains stabilize post-COVID-19, wholesale buyers, distributors, and manufacturers are increasingly looking for long-term partners with reliable powder quality and flexible supply terms.

5. How to Choose the Right FeNiMo Powder Supplier

Selecting a high-quality FeNiMo powder supplier is critical for ensuring product performance, cost efficiency, and production consistency. Below are the most important considerations for B2B buyers, OEMs, and industrial purchasers:

Essential Factors to Consider

| 요인 | 중요성 | 세부 정보 |

|---|---|---|

| Purity & Composition | 높음 | Look for ≥ 99.5% purity with controlled Mo/Ni ratios |

| 입자 크기 분포 | 높음 | Critical for flowability and sintering |

| Spherical Morphology | 높음 | Improves packing density and AM performance |

| 생산 방법 | Medium | Atomization method (gas or water) affects quality |

| 재료 최적화 및 문제 해결에 필수적입니다. | 높음 | Ensures repeatable results in production |

| 인증 | 높음 | ISO 9001, RoHS, REACH compliance are must-haves |

| 사용자 지정 옵션 | Medium | Flexibility in size, shape, and packaging |

| 기술 지원 | 높음 | Application-specific guidance is essential |

Questions to Ask Your Supplier

- Can you provide third-party test reports?

- What atomization method is used for FeNiMo powders?

- Do you support custom blends or particle size ranges?

- What is your MOQ (Minimum Order Quantity)?

- Are you open to long-term supply agreements?

Need expert guidance on choosing the right powder? Contact the Truer team today for technical consultation.

6. Top 5 FeNiMo Spherical Powder Suppliers in Asia-Pacific

Asia-Pacific is a major hub for advanced powder metallurgy, with several companies offering FeNiMo spherical powders. Here’s a comparative analysis of the top suppliers in the region:

Comparison Table: FeNiMo Powder Suppliers in APAC

| 공급업체 | 국가 | 주요 강점 | 인증 | MOQ 유연성 |

|---|---|---|---|---|

| 상하이 트루어 기술 | 중국 | Full-range FeNiMo PM & AM powders, custom solutions, R&D support | ISO 9001, SGS | ✅ |

| 샌드빅 오스프리 | 싱가포르 | Premium AM powders, specialty alloys | ISO 9001 | ❌ (High MOQ) |

| CNPC 파우더 | 중국 | Competitive pricing, water atomized powders | ISO 9001 | ✅ |

| JGAM Powder Tech | 일본 | High-purity spherical powders | ISO 13485 | ❌ |

| GKN 회가나에스 | Korea | Global distribution, hybrid alloy powders | ISO 9001 | ✅ |

Why Shanghai Truer Leads the Market

- ✅ One of China’s most professional additive suppliers

- ✅ Offers both gas and water atomized powders

- ✅ Supplies over 20 FeNiMo-related PM grades

- ✅ In-house R&D and custom blending capabilities

- ✅ Flexible MOQs and global shipping

Explore our full product range of PM and AM powders in our online catalog.

Shanghai Truer Technology Co., Ltd, established in 2009, has become a trusted leader in the Chinese powder metallurgy market. Since launching its additive manufacturing division in 2019, Truer has rapidly expanded its capabilities to include FeNiMo spherical powders suitable for both PM and AM applications. Their powder metallurgy additives division also offers a complete solution, including lubricants, soft magnetic additives, and graphite.

Learn more about Shanghai Truer’s history and innovation-driven mission by visiting our 회사 소개 페이지.

7. Why More Buyers Are Turning to China for FeNiMo Powder Supply

In recent years, China has emerged as a global powerhouse in the production and export of high-performance metal powders, including FeNiMo spherical powder. For B2B buyers such as OEMs, distributors, and contract manufacturers, sourcing from Chinese suppliers offers a strategic advantage in cost, scalability, and technical innovation.

Key Reasons B2B Buyers Prefer Chinese Suppliers

1. 경쟁력 있는 가격

Chinese manufacturers benefit from:

- 낮은 인건비 및 운영 비용

- 규모의 경제

- Localized raw material sourcing

This translates into more attractive pricing for international buyers.

2. Advanced Manufacturing Technology

Top-tier Chinese suppliers now use:

- Gas atomization for high-purity spherical powders

- Hybrid and combined atomization technology

- In-house R&D to customize powder chemistry

3. Short Lead Times & Global Logistics

Many Chinese suppliers can ship globally within 1–2 weeks and manage customs efficiently.

4. Broad Product Range

Unlike some Western suppliers with limited options, Chinese manufacturers like 상하이 트루어 기술 offer:

- FeNiMo powders for both PM and AM

- Custom sizing and packaging

- Powder additives, lubricants, and soft magnetic materials

- Technical support for application-specific challenges

저희 웹사이트를 방문하세요. 홈페이지 to explore the full scope of solutions offered by Shanghai Truer Technology.

8. Why Choose Shanghai Truer Technology as Your FeNiMo Powder Supplier

Shanghai Truer Technology Co., Ltd. is one of the most trusted names in China’s powder metallurgy industry. With over a decade of experience and a dedicated additive manufacturing division established in 2019, Truer is a reliable partner for all your FeNiMo powder needs.

무엇이 트루를 차별화할까요?

✅ Full-Service Capabilities

- Powder production using gas, water, and combined atomization

- Custom alloy formulation

- Advanced testing and quality control

✅ Broad Product Portfolio

- PM FeNiMo powders with grades like FC-0208, FN-0205, FL-4605

- Spherical powders for AM with tight PSD control

- Additives like Lube-W, SUW-8000, soft magnetic QH-150

- Diffusion CuSn for diamond tools and sintered bearings

✅ Industry-Grade Certifications

- ISO 9001 certification

- RoHS and REACH compliance

- SGS testing available upon request

✅ Flexible B2B Solutions

- Low and high MOQ options

- Custom packaging (10kg, 25kg, 100kg)

- OEM branding available for distributors

- Global shipping with end-to-end logistics support

Customer Testimonials

“Shanghai Truer offered us not only high-quality FeNiMo powder but also technical guidance that helped us reduce print failures by 25%. We now source all our PM powders from them.”

— Procurement Manager, Aerospace Components OEM

“Their responsiveness and flexibility in customizing the powder size distribution made them our primary supplier for AM materials.”

— R&D Director, Electric Motor Manufacturer

To speak with our technical team or request a quote, contact us directly.

9. FAQs: Common Questions About Buying Wholesale FeNiMo Spherical Powder

Below are some of the most frequently asked questions from B2B buyers looking to source FeNiMo spherical powder for powder metallurgy and additive manufacturing applications.

❓ What atomization methods are used to produce FeNiMo powder at Shanghai Truer?

Shanghai Truer uses:

- 가스 분무: for high-purity, spherical AM powders

- 물 분무: for cost-effective PM powders

- Combined method: when both flowability and cost-efficiency are required

❓ Can I request custom particle size distribution (PSD)?

Yes. Truer offers customizable PSD ranges such as:

- 15–45 µm

- 20–53 µm

- 45–105 µm

Custom sizing is available upon request for both PM and AM applications.

❓ Do you support OEM or white-label packaging?

Yes, Truer supports OEM branding and can supply powders in sealed jars, vacuum packs, or steel drums depending on your requirements.

❓ What is the typical MOQ for FeNiMo spherical powder?

Minimum Order Quantity (MOQ) starts at:

- 5–10kg for R&D and sample orders

- 100kg for production batches

Larger quantities are eligible for volume discounts.

❓ Are technical data sheets and certifications available?

Yes. Truer provides:

- 기술 데이터 시트(TDS)

- 물질안전보건자료(MSDS)

- Third-party lab reports (SGS, ROHS)

Upon request.

❓ How do I place an order?

You can place an order by:

- Contacting our sales team

- Requesting a quote via our 연락처 페이지

- Confirming product specifications and delivery terms

- Finalizing payment and shipping

❓ What industries are best suited for FeNiMo spherical powder?

FeNiMo powder is ideal for:

- 항공우주 (engine parts, brackets)

- 자동차 (Gears, bushings)

- 전자 제품 (magnetic cores)

- 석유 및 가스 (valve parts, connectors)

- 에너지 (motor components)

❓ Does Shanghai Truer offer support for international buyers?

Absolutely. Truer ships globally and provides:

- 다국어 지원

- Logistics coordination

- After-sales technical assistance

For in-depth specifications and to browse more metal powders, explore our PM product catalog.