1. Introduction to 13-8PH Powder in Modern Manufacturing

13-8PH stainless steel powder is a martensitic precipitation-hardening alloy known for its superior strength, high hardness, excellent corrosion resistance, and good fracture toughness. As industries increasingly transition to additive manufacturing and powder metallurgy, the demand for high-performance powders like 13-8PH continues to rise.

This alloy is composed primarily of chromium, nickel, and aluminum, and is heat-treatable to achieve a wide range of strength levels. It’s especially useful in aerospace, medical, oil & gas, and defense sectors, where lightweight, high-strength, and corrosion-resistant materials are essential.

Key Technical Composition (Typical)

| 요소 | 무게 % |

|---|---|

| 크롬(Cr) | 12.25 – 13.25 |

| 니켈(Ni) | 7.5 – 8.5 |

| 알루미늄(Al) | 0.9 – 1.35 |

| 몰리브덴(Mo) | 2.0 – 2.5 |

| 탄소(C) | ≤ 0.05 |

| 철(Fe) | 잔액 |

Common Manufacturing Methods for 13-8PH Powder:

- Gas Atomization (Preferred for AM applications)

- Water Atomization (Cost-effective for PM parts)

- Plasma Atomization (High sphericity, premium applications)

13-8PH powder is especially valuable in metal 3D 프린팅 (laser powder bed fusion, electron beam melting), as well as in traditional powder metallurgy (PM) and hot isostatic pressing (HIP).

2. Industrial Applications of 13-8PH Stainless Steel Powder

13-8PH powder is used across a wide array of industries that demand high strength, durability, and resistance to harsh environments. Below are the key sectors and application areas where this alloy powder performs exceptionally well:

항공우주 산업

- 구조적 구성 요소

- 엔진 부품

- Landing gear systems

- Actuator housings

의료 기기

- 수술 기구

- 정형외과 임플란트

- 치과용 도구

Oil & Gas Sector

- 다운홀 도구

- Valve components

- Pump shafts

- High-pressure fittings

Automotive & Motorsport

- Performance engine parts

- Turbocharger components

- Lightweight chassis supports

Defense & Firearms

- Weapon components

- Military-grade fasteners

- Armor-piercing projectile cores

Comparison: 13-8PH vs. Other Stainless Steel Alloys

| 속성 | 13-8PH | 17-4PH | 316L | 15-5PH |

|---|---|---|---|---|

| 수율 강도 | 우수 | 매우 좋음 | 보통 | 매우 좋음 |

| 내식성 | 높음 | 높음 | 매우 높음 | 높음 |

| Heat Treatable | 예 | 예 | 아니요 | 예 |

| AM Suitability | 우수 | 우수 | 우수 | 매우 좋음 |

With its balanced combination of properties, 13-8PH has emerged as a go-to material for critical parts where failure is not an option.

3. Properties and Advantages of 13-8PH for Additive Manufacturing

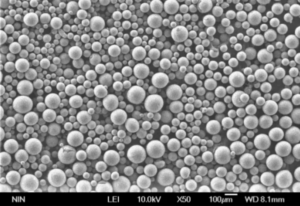

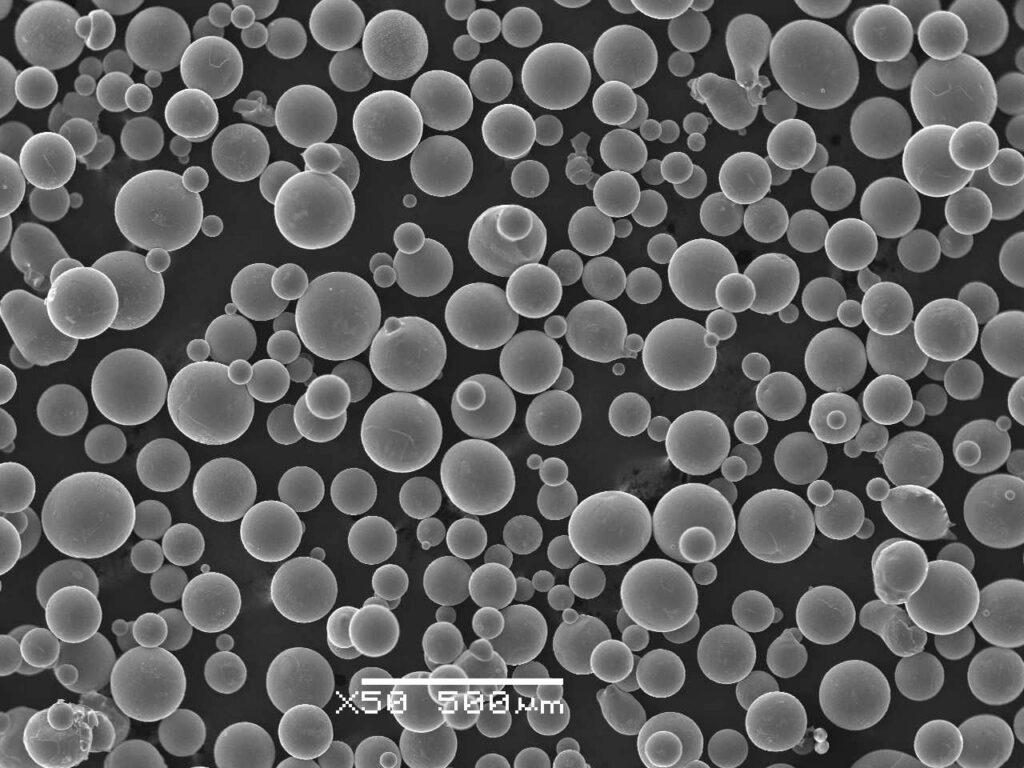

13-8PH powder is one of the most preferred materials for additive manufacturing (AM) due to its consistent microstructure and mechanical performance. The following characteristics make it ideal for 3D printing and sintering:

Mechanical Properties (After Heat Treatment)

| 조건 | UTS (MPa) | YS (MPa) | 연신율 (%) | 경도(HRC) |

|---|---|---|---|---|

| H950 | ~1450 | ~1350 | 10-12% | 45-47 |

| H1000 | ~1400 | ~1300 | 12-14% | 43-45 |

| H1050 | ~1350 | ~1250 | 14-16% | 41-43 |

Key Advantages for B2B Buyers

- ✅ Excellent isotropy in mechanical properties via AM

- ✅ High surface finish quality post-print

- ✅ Outstanding fatigue resistance

- ✅ Maintains strength at elevated temperatures

- ✅ Low gas content ensures consistent quality

Why 13-8PH is Ideal for Powder Bed Fusion (PBF)

| 기능 | 혜택 |

|---|---|

| High Sphericity | Better flowability, smoother recoating |

| Low Oxygen Levels | Enhanced ductility and fatigue strength |

| Tight PSD Control | Uniform layer thickness and fusion |

| 고순도 | Consistent and repeatable part quality |

Shanghai Truer Technology Co., Ltd.는 다음을 제공합니다. high-quality 13-8PH powder with excellent sphericity, low oxygen content, and superior flowability, ensuring optimal performance in both AM and PM applications.

4. Global Market Trends and Future Outlook for 13-8PH Powder

As industries like aerospace, medical, and energy continue to adopt additive manufacturing (AM) and advanced powder metallurgy (PM) methods, demand for high-performance powders such as 13-8PH is accelerating.

Key Global Trends

- Additive Manufacturing Growth: The global metal 3D printing market is projected to grow at a CAGR of over 25% through 2030. Alloys like 13-8PH are at the forefront due to their high strength-to-weight ratio and excellent fatigue resistance.

- Defense & Aerospace Demand: Increasing investments in next-gen aircraft and defense systems are driving the need for high-strength, corrosion-resistant alloys.

- 지역화된 공급망: Manufacturers are seeking regional powder suppliers for better lead times, cost control, and trade compliance.

- 커스터마이징 및 합금 개발: Demand for tailored powder solutions (custom particle size distribution, spherical morphology, specific mechanical properties) is rising.

Forecast: Global 13-8PH Powder Market Size

| 연도 | 예상 시장 가치(백만 달러) |

|---|---|

| 2022 | 72.1M |

| 2024 | 92.5M |

| 2026 | 121.3M |

| 2030 | 179.7M |

Key End-Use Growth Segments

- Aerospace & Defense: 36%

- Medical & Dental: 22%

- Energy & Oil: 18%

- Automotive: 14%

- Industrial Tooling: 10%

5. How to Choose a Reliable 13-8PH Powder Supplier

Choosing the right supplier for 13-8PH powder is critical to ensure consistent part quality, repeatable performance, and cost efficiency. Here are essential factors B2B buyers and procurement teams should evaluate:

1. Powder Morphology & Purity

- Look for gas atomized 또는 plasma atomized powder with high sphericity and minimal satellites.

- Ensure low oxygen and nitrogen content for optimal fatigue performance.

2. 입자 크기 분포(PSD)

- Common PSD ranges: 15–45 µm (PBF), 45–105 µm (DED), 0–20 µm (MIM).

- Suppliers should provide custom sieving and classification services.

3. Certifications & Quality Assurance

- ISO 9001, AS9100, and material test reports (MTRs) are essential.

- Request third-party lab testing or in-house quality control documentation.

4. Supply Capacity & Lead Time

- Can the supplier fulfill bulk orders consistently?

- What are the average lead times for new orders?

5. 기술 지원 및 R&D

- Does the supplier offer technical guidance, application support, or alloy customization?

- Do they have an R&D team for developing new alloy grades?

Evaluation Checklist for B2B Procurement Teams

| 평가 기준 | 중요성 | Shanghai Truer Score |

|---|---|---|

| Sphericity & Flowability | ★★★★★ | ★★★★★ |

| Purity & Traceability | ★★★★★ | ★★★★★ |

| Custom PSD Options | ★★★★☆ | ★★★★★ |

| Certifications & QA | ★★★★☆ | ★★★★★ |

| 기술 지원 | ★★★★☆ | ★★★★★ |

| Lead Time & Capacity | ★★★★☆ | ★★★★☆ |

Shanghai Truer Technology meets or exceeds industry standards in every category, making them a top choice for high-performance 13-8PH powder supply.

6. Top 5 Trusted 13-8PH Powder Suppliers in Asia

Asia is emerging as a powerhouse in metal powder manufacturing, offering cost-effective, high-quality solutions for global OEMs and AM service bureaus. Below are five trusted suppliers that provide 13-8PH powder:

| 공급업체 | 국가 | 주요 기능 | 일반적인 클라이언트 |

|---|---|---|---|

| 상하이 트루어 기술 유한공사 | 중국 | High sphericity gas-atomized powder, full traceability, custom PSD, technical support | Aerospace, PM, 3D printing bureaus |

| AP&C (Arcam/GE Additive) | China (Facility) | Plasma-atomized powder, premium quality | Medical, aerospace, defense |

| TLS 기술 | Germany (Asia distribution) | Ultra-pure powder, tight PSD, EU compliance | Tier-1 aerospace |

| 샌드빅 오스프리 | India/Japan | High-volume capabilities, ISO 9001 certified | Industrial & automotive |

| CNPC 파우더 | 중국 | Cost-effective options, wide alloy range | General industry, tooling |

상하이 트루어가 돋보이는 이유:

- 둘 다 제공합니다. gas atomized 그리고 hybrid atomized options

- In-house R&D for additive manufacturing materials

- Strong focus on powder metallurgy and engineering-grade alloys

- Full suite of value-added additives for PM parts (e.g., Lube-W, SME-100, TD-8)

If you’re looking for a supplier that combines technical expertise, flexible customization, and consistent quality, Shanghai Truer is an ideal partner—especially for OEMs, contract manufacturers, and powder distributors.

7. Why Manufacturers Are Switching to Chinese Powder Sources

Driven by cost pressures, supply chain diversification, and improved quality standards, many OEMs and powder buyers are turning to Chinese suppliers for their metal powder needs—including 13-8PH.

전환의 주요 이유

- 비용 효율성: Chinese suppliers can offer competitive pricing without compromising quality.

- Improved Quality Standards: Many Chinese manufacturers, such as Shanghai Truer, now operate under ISO 9001 and meet international quality benchmarks.

- 더 빠른 리드 타임: Regional sourcing in Asia improves time-to-market compared to EU or US suppliers.

- Technical Customization: Chinese suppliers are more flexible in developing custom grades, PSD ranges, and packaging.

Case Study: Shanghai Truer Technology

Shanghai Truer has become a go-to supplier of 13-8PH powder for customers in Japan, South Korea, Germany, and the US. Their additive manufacturing division, launched in 2019, focuses on:

- Custom AM powder solutions for LPBF, DED, and HIP

- Advanced atomization technologies (gas, water, hybrid)

- Full additive packages including lubricants, graphite, and cutting agents for PM

상하이 트루어 둘러보기 engineering powder portfolio and see how they can support your manufacturing goals.

8. Why Choose Shanghai Truer Technology as Your 13-8PH Powder Partner

Shanghai Truer Technology Co., Ltd has positioned itself as one of the most professional and reliable partners in the Chinese powder metallurgy industry. Since launching its additive manufacturing division in 2019, Truer has been serving B2B customers worldwide with high-quality metal powders—including 13-8PH—for various AM and PM applications.

Core Advantages for Wholesale Buyers

| 기능 | Benefit to Distributors & OEMs |

|---|---|

| 🎯 Industry Experience | Over 14 years in powder metallurgy, 5+ years in AM |

| 🧪 In-House R&D | Custom alloy development and process optimization |

| 🌐 Export Capabilities | Global shipping with full material traceability |

| 🛠️ Broad Product Range | Over 20+ powder alloys including 13-8PH, 17-4PH, PM steels |

| ⚙️ Customization | Controlled PSD, spherical morphology, low oxygen levels |

| 💡 Additive Packages | Lubricants, graphite, cutting agents for PM integration |

Technical Capabilities at Shanghai Truer

- 제작 방법: Gas atomization, water atomization, hybrid methods

- Supported Grades: CT-1000, FN-0205, FD-0208, FL-4605, and many more

- 첨가제 솔루션: Lube-W, SUW-5000B, QH-150, SME-100, TD-8, TBC-400

- 적용 분야: Aerospace, oil & gas, tools, medical, sintered parts

Explore more on how Truer supports high-performance manufacturing across industries.

9. How to Order Wholesale 13-8PH Powder from China

If you’re a procurement manager, distributor, or OEM looking to source 13-8PH powder in bulk, Shanghai Truer offers a streamlined, B2B-friendly ordering process.

단계별 도매 주문 프로세스

- Submit Inquiry or RFQ

- 다음을 통해 Truer에 문의하십시오. 문의 양식 or email their sales team directly.

- Provide details like quantity, preferred PSD, alloy grade, and intended application.

- Receive Technical Datasheets & Quotation

- Truer’s sales engineers will send you:

- Product specification sheet

- SDS (safety data sheet)

- MOQ breakdown and tiered pricing

- Truer’s sales engineers will send you:

- Sampling & Qualification (Optional)

- For first-time buyers, Truer offers small-batch sampling.

- You can test powder in your AM or PM processes before scaling.

- Place Purchase Order

- Confirm order details, lead times, and shipping terms.

- Choose between EXW, FOB, CIF based on your supply chain needs.

- Quality Control & Packaging

- Powder is double-bagged in nitrogen-purged containers.

- Each shipment includes MTRs and QA certifications.

- 배송 및 물류

- Truer ships globally via air or sea.

- Typical lead times: 2–4 weeks for standard orders, 4–6 weeks for custom powders.

- 판매 후 지원

- Truer provides technical assistance, reordering support, and performance feedback integration for continuous improvement.

Minimum Order Quantities (MOQ)

| 제품 유형 | MOQ |

|---|---|

| 13-8PH Powder (Standard PSD) | 20kg |

| Custom PSD or Blend | 50kg |

| Additive Packages (Lube, Graphite, MSM, etc.) | 10kg |

The team at Shanghai Truer is committed to building long-term B2B partnerships by offering flexible order quantities and scalable supply capabilities.

10. FAQs: Buying 13-8PH Powder in Bulk for Industrial Use

Q1: What is the typical shelf life of 13-8PH powder?

A: When stored in a dry, inert atmosphere (original packaging), the shelf life is 12–24 months. Truer uses nitrogen-sealed containers to maintain powder integrity.

Q2: Can Truer customize the particle size distribution (PSD)?

A: Yes. Truer offers custom sieving and classification services to meet specific AM and PM needs—such as 15–45 µm for PBF or 45–105 µm for DED.

Q3: What packaging options are available?

A: 표준 포장에는 다음이 포함됩니다:

- 5 kg aluminum foil bags (for samples)

- 20 kg or 50 kg drums

- Nitrogen-purged containers

Q4: Is there technical support for new customers?

A: Absolutely. Truer provides metallurgical consulting, printability testing support, and application guidance to help customers qualify powders for production.

Q5: How does Truer ensure powder consistency?

A: Each batch undergoes:

- Chemical composition analysis (ICP-OES)

- Flow rate and tap density testing (Hall Flowmeter)

- Oxygen/nitrogen analysis (LECO)

- Particle morphology (SEM analysis)

Q6: Can I integrate other PM additives with 13-8PH?

A: Yes. Truer also supplies a full suite of PM additives like Lube-W, SME-100, and QHP-330 graphite for sintered metal parts.

Q7: What industries are currently using Truer’s 13-8PH powder?

A: Truer’s customers span:

- 항공우주 부품 제조업체

- Oil & gas toolmakers

- Defense contractors

- Medical device OEMs

- Metal 3D printing service providers

Ready to Partner with Shanghai Truer?

Shanghai Truer Technology is more than just a powder supplier—they are a strategic partner in your additive manufacturing and powder metallurgy journey. With top-tier 13-8PH stainless steel powder, dedicated technical support, and global logistics capabilities, Truer is a trusted supplier for B2B buyers across industries.

📩 Contact Truer today to request a datasheet or quote for 13-8PH powder:

👉 Get in touch with our sales team →