1. Introduction: Why Silicon Carbide Powder Is in High Demand

Silicon carbide (SiC) powder is one of the most versatile and high-performance materials used across various sectors, including automotive, aerospace, metallurgy, electronics, and additive manufacturing. With exceptional hardness, thermal conductivity, and chemical resistance, SiC is the material of choice for high-temperature and high-wear applications.

Key Benefits of Silicon Carbide Powder:

- High thermal conductivity (up to 490 W/m·K)

- Extreme hardness (Mohs 9.5)

- Excellent wear and chemical resistance

- High-temperature stability (>1,600°C)

- Electrical conductivity for semiconductor applications

B2B Relevance:

For B2B buyers, the demand for high-purity, consistent-grade silicon carbide powder has increased significantly for applications in:

- Powder metallurgy (PM)

- 3D 프린팅

- Semiconductor wafer production

- Abrasives and cutting tools

- 구조용 세라믹

With the rise in industrial automation and electric vehicles, the SiC powder market is expected to grow at a CAGR of 16.3% through 2030.

2. Industrial Applications of Silicon Carbide Powder

Silicon carbide powder’s unique properties make it ideal for a wide range of industrial applications. Below is a breakdown of major sectors that rely on SiC powders in bulk quantities:

| 산업 | 애플리케이션 | Function of SiC Powder |

|---|---|---|

| 자동차 | Electric vehicle inverters, brake systems | Heat dissipation, strength, wear resistance |

| 항공우주 | 엔진 부품 | 고온 내성 |

| 야금학 | Furnace linings, foundry materials | 열 충격 저항 |

| 전자 제품 | Power devices, semiconductors | 전기 전도성 |

| 세라믹 | Kiln furniture, wear parts | 구조적 무결성 |

| 적층 제조 | 3D printed parts | 높은 중량 대비 강도 비율 |

Why B2B Buyers Prefer SiC for Additive Manufacturing:

- Enables production of lightweight, high-strength components

- Increased demand for heat-resistant materials in aerospace and automotive

- Compatible with binder jetting and selective laser sintering (SLS) technologies

🔗 자세한 정보는 powder metallurgy materials and solutions on our dedicated product page.

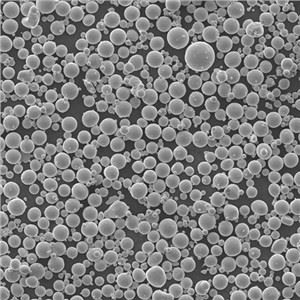

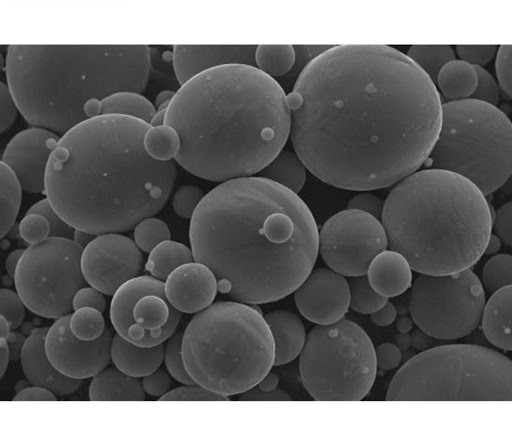

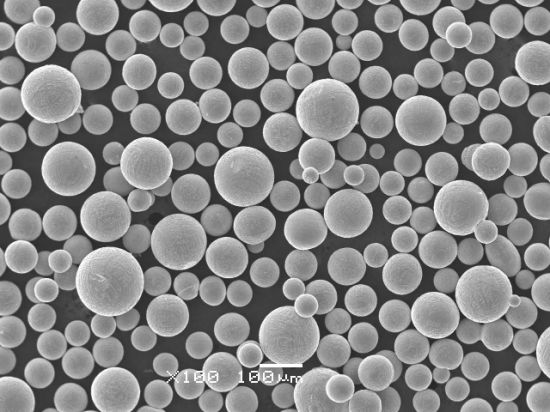

3. Grades and Types of Silicon Carbide Powder

When sourcing SiC powder in bulk, it’s essential to understand the different grades and particle sizes available, which affect performance, sintering behavior, and end-use applications.

Common Grades of Silicon Carbide for B2B Applications:

| 등급 | 설명 | 일반적인 사용 |

|---|---|---|

| Black SiC | Produced via Acheson process, contains impurities | Abrasives, refractories |

| Green SiC | Higher purity (>99%), friable | Ceramics, semiconductors |

| Ultra-fine SiC | Submicron/nanoparticles | 3D printing, high-tech coatings |

| Recrystallized SiC | High porosity, thermal stability | Kiln furniture, heat exchangers |

Particle Size Options:

- Coarse: 200–600 mesh (used in abrasives, cutting)

- Fine: <1 µm (used in semiconductors, PM parts)

- Nano: <100 nm (used in coatings, advanced ceramics)

Key Specifications B2B Buyers Should Consider:

- Purity (typically 98% to 99.9%)

- 입자 크기 분포

- Surface area (BET analysis)

- Flowability for AM and PM processes

- 벌크 밀도

👉 Tip: Always request the technical data sheet (TDS) and material safety data sheet (MSDS) when evaluating a SiC powder supplier.

4. 글로벌 시장 동향 및 수요 예측

The global silicon carbide powder market is experiencing unprecedented growth, driven by increasing demand in the automotive, electronics, and renewable energy sectors. For B2B buyers, understanding these trends is essential for planning long-term procurement strategies and ensuring supply chain stability.

주요 시장 동인:

- EV Boom: SiC is critical in electric vehicle (EV) power electronics due to its ability to handle high voltages and temperatures.

- 5G & Semiconductors: High-purity SiC is used in wide bandgap power devices, essential for next-gen electronics.

- 산업 자동화: Increased use of SiC components in wear-resistant machinery parts.

- Additive Manufacturing Growth: More manufacturers are adopting SiC for its lightweight, heat-resistant properties in 3D printing.

Market Forecast (2024–2030):

| 지역 | CAGR(%) | 주요 애플리케이션 |

|---|---|---|

| 아시아 태평양 | 18.5% | EVs, semiconductors, PM parts |

| 북미 | 14.2% | 항공우주, 전자 |

| 유럽 | 13.7% | Automotive, energy |

| 중동 및 아프리카 | 11.0% | Industrial refractories |

🔎 Insight: B2B buyers should consider long-term contracts and diversified sourcing strategies to secure a stable supply of high-quality SiC powder.

5. Key Considerations When Choosing a SiC Powder Supplier

Choosing the right silicon carbide powder supplier is critical for maintaining product consistency, minimizing production downtime, and ensuring regulatory compliance. Below are essential factors that wholesale buyers, distributors, and manufacturers should evaluate:

✅ 공급업체 평가 체크리스트:

| 기준 | 중요한 이유 |

|---|---|

| 순도 수준 | Impacts performance in electronic and additive applications |

| Particle Size Customization | Required for different manufacturing processes |

| 생산 기술 | Determines consistency and scalability |

| Delivery Capabilities | Affects lead times and inventory planning |

| 규정 준수 | Ensures safety and industry standards (e.g., RoHS, REACH) |

| 기술 지원 | Crucial for optimizing use in complex manufacturing |

Red Flags to Watch For:

- Inconsistent batch quality

- 분말부터 첨가제 및 장비까지 전체 스펙트럼 PM 솔루션을 제공합니다.

- 제한적인 맞춤형 옵션

- Poor customer service or delayed logistics

✨ Pro Tip: Request a sample batch and test it in your specific application before committing to a large order.

6. Top 5 Trusted Silicon Carbide Powder Suppliers in Asia

Asia-Pacific is the global hub for silicon carbide powder production, offering competitive pricing, technological innovation, and scalable capacity. Here are the top 5 suppliers B2B buyers should consider:

| 공급업체 | 지역 | 강점 | Customer Focus |

|---|---|---|---|

| 상하이 트루어 기술 유한공사 | 중국 | Wide range of PM & AM powders, customizable grades, strong R&D | Additive manufacturing and powder metallurgy industries |

| Washington Mills | USA (with Asia presence) | One of the oldest producers, high-purity SiC | Abrasives and refractories |

| 생고뱅 | 글로벌 | High-end SiC ceramics and powders | 항공우주, 에너지 |

| Fiven Norway | Norway/China | High-purity, high-tech SiC | Electronics and semiconductors |

| ESK-SIC GmbH | Germany/China | Ultra-pure, nano-grade SiC | Semiconductor and high-tech ceramics |

✅ Shanghai Truer stands out by offering both standard and customized SiC powder solutions for 3D printing and powder metallurgy, supported by full technical documentation and customer support.

Explore our company’s about page to learn why we’re trusted by clients across Asia and beyond.

7. Why More Buyers Are Shifting to Chinese Silicon Carbide Manufacturers

Over the last decade, Chinese manufacturers have become global leaders in silicon carbide powder production due to advancements in technology, cost efficiency, and scalable infrastructure.

Competitive Advantages of Chinese Suppliers:

- Lower Cost per KG: Up to 30% cheaper than Western counterparts

- Mass Production Capacity: Ability to meet bulk and urgent orders

- 맞춤화 서비스: Particle sizing, blending, and surface treatments

- Integrated Supply Chains: From raw materials to final delivery

- Investment in R&D: Continuous improvement in powder quality and grades

B2B Buyers Prefer China for:

- Cost-effective solutions without compromising quality

- Faster turnaround on large-volume orders

- Access to new materials and formulations (e.g., hybrid powders for PM and AM)

🌐 Shanghai Truer is a leading example of this trend, combining over a decade of powder metallurgy experience with cutting-edge additive manufacturing solutions.

저희 웹사이트를 방문하세요. 홈페이지 to explore our full range of SiC and PM powders.

8. Why Choose Shanghai Truer as Your SiC Powder Partner

Shanghai Truer Technology Co., Ltd. has emerged as one of the most professional and reliable suppliers of silicon carbide and powder metallurgy materials in China. Founded in 2009 and launching its additive manufacturing division in 2019, Truer has grown into a trusted partner for global B2B buyers.

What Sets Us Apart:

- ✅ Full Range of SiC Powders: Black, green, ultra-fine, nano-grade

- ✅ Multiple Atomization Techniques: Water, gas, carbonyl, reduction

- ✅ Custom Specifications: Tailored to your manufacturing process

- ✅ R&D Support: In-house technical team to assist your engineers

- ✅ Proven Track Record: Serving clients in Asia, Europe, and North America

Our Flagship SiC Powder Products:

- Green SiC ≥99.5% purity for electronics and semiconductors

- Black SiC 98% for abrasives and refractories

- Submicron SiC for binder jetting and metal AM

- Hybrid PM powders with SiC additives for enhanced wear resistance

🔗 Learn more about our contact process and get a technical consultation today.

9. How to Order Wholesale Silicon Carbide Powder from Shanghai Truer

For enterprise buyers, distributors, and manufacturers, ordering wholesale silicon carbide (SiC) powder from Shanghai Truer is a straightforward, transparent process designed to ensure quality, consistency, and timely delivery.

Here’s a step-by-step overview of how to place your first or repeat order with us.

🔄 Step-by-Step Ordering Process for B2B Buyers:

| 단계 | 작업 | 세부 정보 |

|---|---|---|

| 1 | Product Selection | Choose from various SiC grades (Black, Green, Ultrafine, Nano) and particle sizes. Custom blends available. |

| 2 | 기술 상담 | Our R&D team will assist with TDS, MSDS, and performance data for your application. |

| 3 | 샘플 테스트(선택 사항) | Request lab-scale or pilot batch samples for in-house validation. |

| 4 | Quotation & MOQ | We provide volume-based pricing. Minimum order quantity (MOQ): 25 kg to 500 kg, depending on grade. |

| 5 | 계약 및 결제 | Sign the supply contract. Payment terms include T/T, LC, or net-30 for verified accounts. |

| 6 | Production & QC | Orders undergo strict production and quality control under ISO standards. |

| 7 | 포장 및 물류 | Safe, moisture-proof packaging with global shipping via sea, air, or express. |

| 8 | 판매 후 지원 | Full support including reordering, technical troubleshooting, and logistics tracking. |

📦 포장 옵션:

- 25 kg fiber drums with inner PE liner

- 500 kg jumbo bags for bulk orders

- Customized labeling with batch numbers, specs, and safety instructions

🌍 Global Shipping:

- Air Freight: 5–7 days

- Sea Freight: 20–35 days

- Express (DHL, FedEx): 3–5 days for samples or urgent orders

🔗 Ready to place an order? Start by contacting us via our inquiry form and our team will assist you within 24 hours.

10. FAQs: Everything B2B Buyers Need to Know About Silicon Carbide Powder

Q1: What purity levels do you offer for silicon carbide powders?

We offer:

- Green SiC: ≥99.5%

- Black SiC: ≥98%

- Custom purities available for electronic and AM applications

Q2: Can I get customized particle sizes for my production line?

Absolutely. We can produce SiC powders in:

- Coarse: 200–600 mesh

- Fine: <1 µm

- Nano: <100 nm

We also offer narrow particle size distribution upon request.

Q3: What’s the typical lead time for bulk orders?

- Standard Grades: 7–10 business days

- Custom Grades: 10–20 business days

Lead time may vary depending on order volume and shipping method.

Q4: Do you supply SiC powder for additive manufacturing?

Yes. Shanghai Truer specializes in ultra-fine and nano-grade silicon carbide powders suitable for:

- 바인더 제팅

- 선택적 레이저 소결(SLS)

- Direct Ink Writing

Our powders are optimized for flowability, sintering temperature, and thermal conductivity.

Q5: What industries do you primarily serve?

- Automotive and EVs

- Aerospace and defense

- Metallurgy and sintering

- Semiconductors and electronics

- Abrasives manufacturers

- 3D printing and additive manufacturing companies

🔗 Want to explore other additive powders? Visit our powder metallurgy page 더 많은 옵션을 위해.

Final Call to Action: Partner with Shanghai Truer for Trusted SiC Supply

Shanghai Truer Technology Co., Ltd. is your one-stop solution for high-purity, performance-grade silicon carbide powders tailored to your industrial needs. Whether you’re in additive manufacturing, electronics, or powder metallurgy, we offer:

✅ Competitive wholesale pricing

✅ Custom formulations and particle sizes

✅ Technical support and documentation

✅ Global shipping and logistics support

✅ Consistent quality backed by over a decade of PM expertise

With our commitment to innovation and customer satisfaction, we’re proud to serve clients across Asia, Europe, and North America. Let us help you optimize your supply chain with high-quality silicon carbide powder.

📞 Reach out today via our contact portal and request a quote or technical consultation.