Introduction to HK30 Powder and Its Industrial Relevance

HK30 powder is a high-performance heat-resistant alloy composed primarily of iron, chromium, and 니켈. It is widely used in additive manufacturing, powder metallurgy (PM) processes, and high-temperature applications due to its excellent resistance to oxidation, carburization, and thermal fatigue.

What is HK30 Alloy?

HK30 is a cast austenitic stainless steel alloy classified under the heat-resistant steel category. Its typical composition includes:

| 요소 | Approximate Content (%) |

|---|---|

| 철(Fe) | 잔액 |

| 크롬(Cr) | 25–26 |

| 니켈(Ni) | 19–22 |

| 탄소(C) | 0.35–0.6 |

| 실리콘(Si) | 1–2 |

| 망간(Mn) | 1–2 |

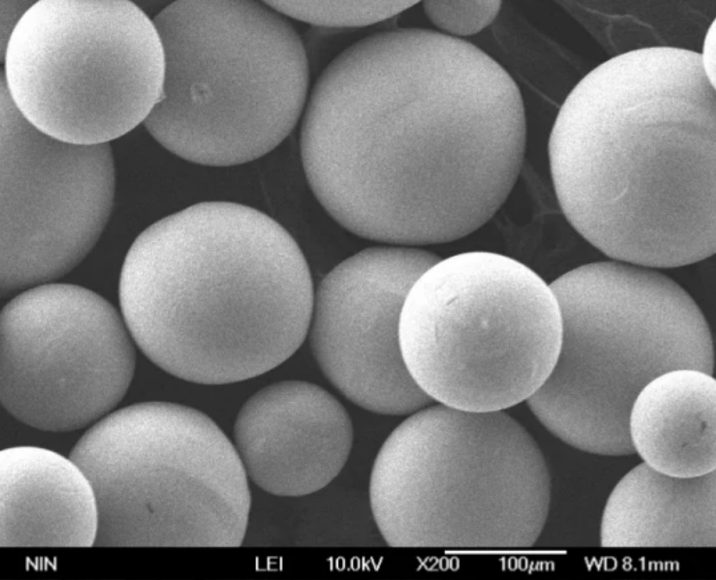

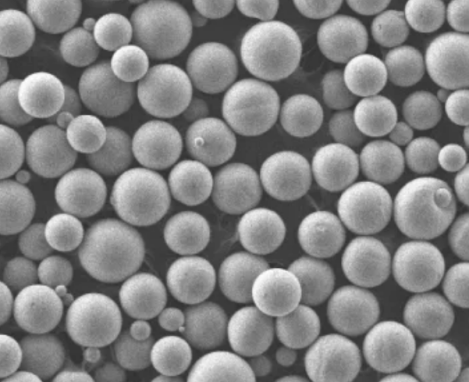

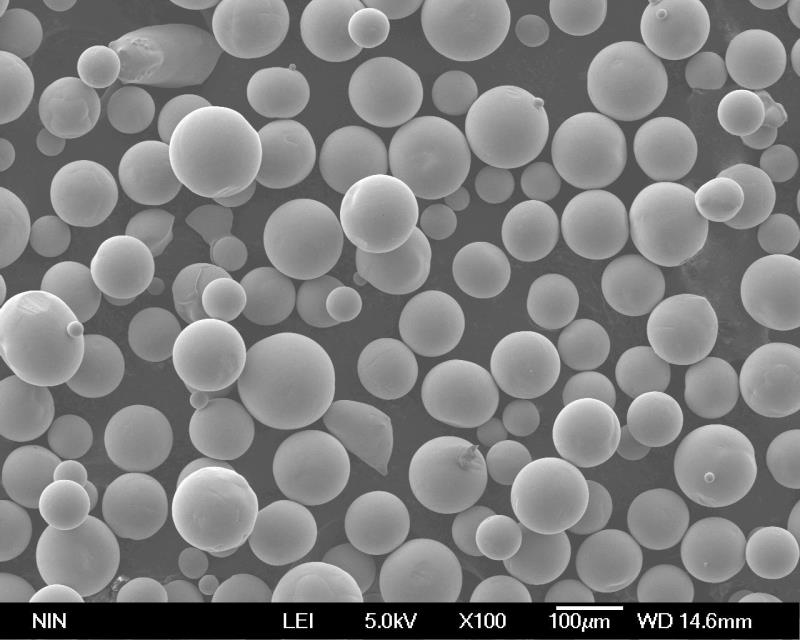

HK30 alloy powder is manufactured via gas atomization or water atomization methods to ensure spherical morphology and high flowability, which are critical for consistent part performance in metal injection molding (MIM) and additive manufacturing (AM) processes.

Why HK30 Powder Matters in B2B Supply Chains

For B2B buyers, especially those sourcing for:

- High-temperature industrial furnaces

- Petrochemical plant components

- Heat treatment fixtures

- Additive manufacturing feedstock

…HK30 powder provides a reliable solution with high mechanical integrity and thermal stability. Its demand is growing within 분말 야금 and additive manufacturing industries, particularly in regions emphasizing energy and heavy-duty manufacturing.

Applications of HK30 Powder in High-Temperature Industries

HK30 alloy powder’s unique chemical composition makes it suitable for a wide range of high-temperature and corrosive environments. Below are some of the most common industrial applications.

1. Heat Treatment and Furnace Components

- Retorts

- Furnace racks and fixtures

- Radiant tubes

- Muffles

Key Benefits:

HK30 offers excellent oxidation resistance up to 1150°C, making it ideal for continuous operation in industrial furnaces.

2. Petrochemical and Refinery Equipment

- Reformer tubes

- Catalyst support grids

- Transfer lines

Why HK30 Is Preferred:

Its nickel-chromium base provides resistance to carburization and sulfidation, commonly found in petrochemical processes.

3. Additive Manufacturing (AM)

- Customized components for aerospace and energy

- Complex geometries for heat exchangers

- Wear-resistant parts in high-load environments

AM Advantages with HK30 Powder:

| 기능 | 혜택 |

|---|---|

| 구형 입자 | Improved flowability and build consistency |

| 낮은 산소 함량 | 향상된 기계적 특성 |

| 고순도 | Suitable for aerospace-grade applications |

Shanghai Truer Technology Co., Ltd offers HK30 powder specifically optimized for AM applications, ensuring consistent quality and batch-to-batch reliability.

4. Automotive and Transportation

- Turbocharger parts

- Exhaust system components

- EGR (Exhaust Gas Recirculation) valves

HK30’s ability to withstand thermal cycling and oxidation makes it ideal for automotive parts exposed to extreme temperatures.

Properties and Technical Specifications of HK30 Alloy Powder

Understanding the key properties of HK30 alloy powder helps B2B decision-makers evaluate its suitability for their specific applications.

Mechanical and Physical Properties

| 속성 | 일반 값 |

|---|---|

| Tensile Strength (at 20°C) | 580–620 MPa |

| Yield Strength (0.2% offset) | 280–300 MPa |

| 신장 | 20-30% |

| Hardness (HBW) | 160–180 |

| 최대 작동 온도 | Up to 1150°C |

내식성 및 내산화성

- Excellent oxidation resistance at high temperatures

- Good resistance to thermal fatigue

- Withstands carburizing environments

- Resistant to intergranular corrosion

Powder Characteristics for AM and PM

| 특징 | 설명 |

|---|---|

| 입자 크기 분포 | D10: 15 μm, D50: 35 μm, D90: 50 μm |

| 형태학 | Near-spherical (gas atomized) |

| 유량 | < 25 seconds/50g |

| 겉보기 밀도 | 4.2–4.5 g/cm³ |

| 탭 밀도 | 5.0–5.4 g/cm³ |

Shanghai Truer provides HK30 powder in multiple particle size ranges, suitable for both loose PM compaction and AM laser powder bed fusion (L-PBF) techniques.

Their powders are developed under strict quality standards, ensuring traceability and lot-to-lot consistency demanded by industrial buyers. You can learn more about their capabilities on their 회사 소개 페이지로 이동합니다.

Market Demand and Growth Trends in HK30 Powder Supply

The global demand for HK30 alloy powder has been steadily increasing, driven by the rapid growth of high-temperature industries and the expansion of additive manufacturing (AM) across various sectors. For B2B buyers, understanding these trends is critical when planning procurement strategies and managing long-term supply chains.

Global Market Drivers

1. Expansion of Additive Manufacturing (AM):

Metal AM technologies, particularly laser powder bed fusion (L-PBF) and directed energy deposition (DED), have increased the use of HK30 alloy powder in aerospace, energy, and automotive applications.

2. Growth in Petrochemical and Refining Sectors:

As countries invest in refining capacity and energy infrastructure, the need for high-performance heat- and corrosion-resistant components is fueling HK30 powder demand.

3. Heat Treatment and Furnace Manufacturing:

Manufacturers of industrial furnaces, heat treatment fixtures, and thermal processing equipment are major consumers of HK30 powder due to its durability at elevated temperatures.

Regional Analysis

| 지역 | Market Trend |

|---|---|

| 북미 | Growing adoption of AM in aerospace and defense |

| 유럽 | Strong demand in energy and petrochemical sectors |

| 아시아 태평양 | Rapid industrialization and expansion of PM manufacturing |

| 중동 | High investments in oil & gas processing infrastructure |

Forecasted Market Growth

According to internal industry data and market research:

- The global high-temperature alloy powder market is projected to grow at a CAGR of 6.5% through 2030.

- HK30 powder is expected to gain a larger share due to its balance of cost-effectiveness and high-temperature performance.

B2B buyers, especially procurement officers in manufacturing, should consider long-term contracts and diversified sourcing to mitigate supply chain risks as demand continues to rise.

How to Choose a Reliable HK30 Powder Supplier

For procurement specialists, distributors, and OEMs, choosing the right HK30 powder supplier is critical to ensure quality, consistency, and on-time delivery. Below are the key factors to consider when evaluating a supplier.

1. Manufacturing Capabilities

- Does the supplier have in-house atomization technology (gas or water)?

- Do they support both small-batch R&D and large-scale industrial production?

- What is their QC/QA process for powder certification?

Shanghai Truer Technology Co., Ltd utilizes both gas and water atomization techniques and offers customized particle size distributions, ensuring suitability for both PM and AM customers.

2. Product Quality Certifications

Make sure your supplier provides:

- Material Test Reports (MTR)

- Particle size analysis (Laser Diffraction)

- SEM/EDS microstructure verification

- ISO 9001 or equivalent quality management certifications

3. Logistics and Fulfillment Capabilities

- Can they provide international shipping?

- Do they maintain stock in multiple warehouses for faster turnaround?

- Are they experienced in handling bulk powder packaging and documentation?

4. Technical Support and Customization

A reliable supplier should offer:

- Metallurgical consulting for application-specific needs

- Capability to develop custom alloy blends

- Troubleshooting support for AM or PM processes

공급업체 비교 표

| 기준 | 상하이 트루어 | Generic Supplier A | Generic Supplier B |

|---|---|---|---|

| 사내 분무 | ✅ | ❌ | ✅ |

| Custom Particle Sizes | ✅ | 제한적 | ❌ |

| 기술 지원 | ✅ | 보통 | ❌ |

| MOQ 유연성 | ✅ | 높음 | 높음 |

| Global Shipping | ✅ | ✅ | ✅ |

To explore Shanghai Truer’s full catalog of powder metallurgy solutions, visit their PM 분말 제품 페이지.

Top HK30 Powder Manufacturers and Distributors Globally

Here’s a curated list for B2B buyers looking to evaluate top suppliers of HK30 alloy powder worldwide.

1. 상하이 트루어 기술 유한공사(중국)

- Founded: 2009

- Specialization: Additive manufacturing and powder metallurgy

- Products: HK30, PM stainless steels, nickel alloys, copper-based powders

- 제조: Gas and water atomization

- 웹사이트: am-material.com

Shanghai Truer is recognized in China’s powder metallurgy industry for its advanced powder production capabilities and extensive range of alloy options. Their in-house R&D ensures top-tier powder quality suitable for both PM and AM applications.

2. Carpenter Additive (USA)

- Offers high-performance alloy powders for aerospace and energy sectors

- Specializes in AM feedstock with tight particle size control

- High pricing for small and mid-volume buyers

3. Sandvik Osprey (UK)

- Long-standing reputation in metal powder production

- Strong presence in Europe and North America

- May require large minimum order quantities (MOQ)

4. EOS GmbH (Germany)

- Primarily focused on AM powders for EOS printer platforms

- High-quality powders but limited customization options

- Premium pricing model

5. Heraeus Additive Manufacturing (Germany)

- Offers customized alloy development and powder production

- Suitable for R&D and small-batch production

- Lead times may be longer for bulk orders

Supplier Comparison Summary

| 회사 | 지역 | AM Capability | MOQ 유연성 | 맞춤형 합금 개발 |

|---|---|---|---|---|

| 상하이 트루어 | 중국 | ✅ | ✅ | ✅ |

| 목수 첨가제 | 미국 | ✅ | ❌ | ❌ |

| 샌드빅 오스프리 | UK | ✅ | ❌ | ✅ |

| EOS GmbH | 독일 | ✅ | ❌ | ❌ |

| 헤레우스 | 독일 | ✅ | ✅ | ✅ |

Shanghai Truer stands out for its balance of technical capabilities, flexibility, and customer support—especially attractive to SMEs and mid-sized manufacturers.

Why More Buyers Are Sourcing HK30 Powder from China

In recent years, a growing number of international B2B buyers—including OEMs, distributors, and additive manufacturing service providers—have shifted their HK30 alloy powder sourcing to China. This trend is fueled by multiple factors that combine cost-effectiveness with rapid innovation and improved quality standards.

: 특히 아시아 및 아세안 시장의 경우

1. 경쟁력 있는 가격

- 낮은 인건비 및 운영 비용 reduce the base price of raw materials.

- Many Chinese manufacturers, like Shanghai Truer, offer volume discounts 그리고 bulk packaging options for industrial buyers.

2. 첨단 제조 역량

- Leading Chinese suppliers have embraced 가스 분무, 수분무및 vacuum melting technologies to produce high-performance powders.

- Facilities are now on par with Western counterparts in terms of 순도, particle size control및 spheroidization.

3. Government Support & Infrastructure

- National policies in China support the additive manufacturing and powder metallurgy sectors, offering tax incentives and R&D grants to top companies.

- Export-oriented logistics infrastructure ensures faster international shipping via sea, air, and rail freight.

4. Customization and Technical Support

- Chinese suppliers like Shanghai Truer provide tailored HK30 powders based on specific customer requirements.

- 더 빠르게 prototyping cycles 그리고 유연한 MOQ make it easier for buyers to test and transition into full-scale production.

Case Study: Shanghai Truer’s Export Capability

Shanghai Truer Technology Co., Ltd has successfully exported HK30 powder to buyers in Europe, North America, and Southeast Asia. Their product quality, paired with multilingual support 그리고 transparent documentation, has strengthened their reputation as a premium Chinese supplier.

Buyers can learn more about the company’s international presence and certifications through their 회사 소개 페이지.

Why Choose Shanghai Truer Technology Co., Ltd for HK30 Powder

Shanghai Truer is not only one of China’s leading powder metallurgy and additive manufacturing powder providers—it’s also a trusted partner for global B2B buyers looking for high-performance HK30 powder.

회사 개요

- 설립: 2009

- AM Business Started: 2019

- Headquarters: 상하이, 중국

- Specialization: Powder metallurgy powder, AM powders, powder-making equipment

- 웹사이트: AM-material.com

무엇이 트루를 차별화할까요?

1. Comprehensive Product Range

Shanghai Truer offers an extensive portfolio including:

- HK30 alloy powder

- PM stainless steel (e.g., 304L, 316L)

- PM nickel-based and copper-based alloys

- Hybrid and diffusion-alloyed PM steels

- Additives and lubricants for sintering, pressing, and machining

This allows buyers to source multiple materials from one trusted supplier, reducing administrative costs and freight complexity.

2. In-House Manufacturing and R&D

- Equipped with 가스 분무, 수분무및 결합된 분무 systems.

- Dedicated R&D teams develop 맞춤형 분말 혼합물 그리고 tailor-made solutions for AM and PM buyers.

- Powder grades such as FD-0208, FL-4605, FN-5000 meet both Chinese GB and international ASTM standards.

3. Quality Assurance and Traceability

- All powders undergo rigorous chemical analysis, SEM 이미징및 flowability testing.

- Detailed batch reports and COAs (Certificates of Analysis) are provided with every shipment.

- ISO-compliant documentation ensures traceability 그리고 process control.

4. B2B-Focused Service Model

| 기능 | 상하이 트루어 어드밴티지 |

|---|---|

| MOQ 유연성 | Orders starting from 25kg |

| 수출 경험 | 50+ countries served |

| Technical Consulting | Yes (powder selection, process matching) |

| 물류 지원 | Sea, air, express delivery available |

| Language Support | English, Chinese, technical documentation |

5. Custom Packaging & Labeling

- Packaging options include sealed drums, vacuum bags, moisture-barrier packs, suitable for export.

- Custom labeling with barcodes, lot numbers, and safety data ensures compliance with global standards.

If you’re a distributor or OEM looking for a reliable HK30 powder supplier, Shanghai Truer에 문의하십시오. 에 문의하여 견적 또는 샘플을 요청하십시오.

FAQs: Common Questions About Buying HK30 Powder Wholesale

Below are some of the most commonly asked questions from B2B buyers interested in purchasing HK30 alloy powder.

1. What is the minimum order quantity (MOQ) for HK30 powder?

Shanghai Truer offers flexible MOQs starting from as low as 25kg, making it suitable for both prototyping and bulk orders.

2. What is the typical lead time for international orders?

- Standard stock items: 5~7일

- Custom grades/sizes: 10–15 business days

- Shipping time: Varies by location (Air: 5–10 days, Sea: 20–35 days)

3. Can I request a specific particle size distribution?

Yes. Truer provides customized particle size ranges for AM, MIM, and PM applications. Options include:

- D10: 15μm / D50: 35μm / D90: 50μm

- D10: 20μm / D50: 40μm / D90: 60μm

- Custom mesh cuts available upon request

4. Does the powder come with certifications?

Yes. Each batch is shipped with:

- 분석 인증서(COA)

- Material Test Report (MTR)

- SDS(안전 데이터 시트)

- SEM micrograph and flowability data (on request)

5. How do I place an order?

You can submit an inquiry via the HK30 Powder Product Page or directly through the 문의 페이지. A sales engineer will assist with pricing, availability, and technical documentation.