1. Introduction: What is Diamond Catalyst Powder and Why It Matters

Diamond catalyst powder is a highly specialized material used primarily in the synthesis of industrial diamonds and in catalytic technologies. This ultra-fine powder, often composed of nanodiamond particles or synthetic diamond derivatives, acts as a facilitator in chemical reactions, especially in high-pressure, high-temperature (HPHT) environments.

Why It’s Important for B2B Buyers

- Critical for High-Performance Tools: Used in the production of cutting tools, drill bits, and wear-resistant components.

- Essential for Advanced Manufacturing: Plays a role in nanotechnology, electronics, and chemical catalysis.

- Growing Global Demand: With the rise in advanced manufacturing and energy-efficient industrial processes, B2B demand is increasing.

| 기능 | Value to B2B Buyers |

|---|---|

| 높은 열 전도성 | Ideal for heat-sensitive catalytic reactions |

| 화학적 불활성 | Stable under extreme environments |

| 높은 경도 | Useful in producing industrial diamond tools |

2. Industrial Applications of Diamond Catalyst Powder

Diamond catalyst powder is used across various industries due to its unique chemical and physical properties.

주요 적용 분야

A. Industrial Diamond Synthesis

- Acts as a seed or catalyst in HPHT and CVD (Chemical Vapor Deposition) diamond manufacturing processes.

- Enables the production of synthetic diamonds for cutting, grinding, and drilling applications.

B. Catalysis in Chemical Reactions

- Used in the oxidation of organic compounds.

- Supports catalytic converters in chemical plants.

C. Electronics and Semiconductor Industries

- Nanodiamond-based catalysts are used in semiconductors for heat dissipation.

- Aids in the fabrication of microelectronic components.

D. Biomedical Engineering

- Used in drug delivery systems due to its biocompatibility.

- Research on utilizing diamond powders in biosensors and implants.

| 산업 | 특정 용도 |

|---|---|

| 도구 제조 | Synthesis of industrial diamonds |

| Petrochemicals | High-temperature catalytic reactions |

| 전자 제품 | Fabrication of heat-resistant components |

| 의료 기기 | Drug delivery and biosensing research |

3. Properties and Use Cases in Catalyst Technologies

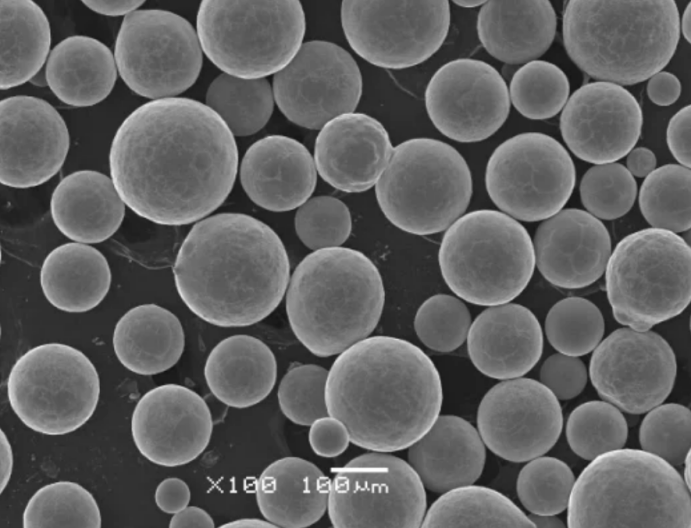

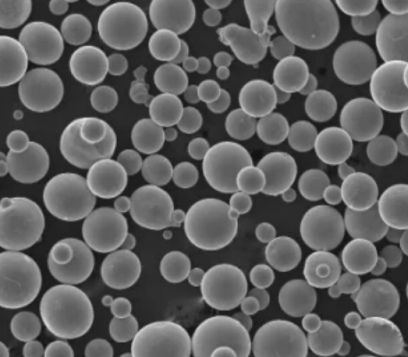

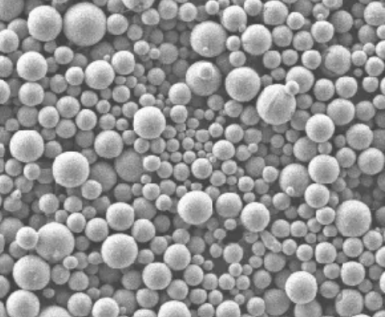

Diamond catalyst powders are engineered for high-performance chemical environments. These powders are often nano-structured to increase surface area, which enhances their catalytic efficiency.

주요 속성

- 표면적: Nano-diamond powders offer high surface areas, improving reactivity.

- Thermal and Chemical Stability: Maintains integrity under high temperatures and corrosive environments.

- 순도: High-purity powders ensure consistent catalytic behavior.

Use Cases in B2B Settings

Use Case 1: Diamond Powder in HPHT Synthesis

- Acts as a growth catalyst in the production of synthetic diamonds.

- Speeds up the crystallization process under extreme conditions.

Use Case 2: Oxidation Catalysts in Chemical Plants

- Used in oxidation reactions for producing fine chemicals.

- Offers a stable, reusable catalyst surface.

Use Case 3: Heat Dissipation in Electronics

- Nanodiamonds are embedded in thermal paste and adhesives.

- Improves heat conductivity in high-performance devices.

| 속성 | 사용 사례 | 혜택 |

|---|---|---|

| 높은 표면적 | Chemical catalysis | Faster reaction rates |

| 열 전도성 | 전자 제품 | Better heat management |

| 화학적 불활성 | Oxidation reactions | Longer catalyst life |

For a full list of powder metallurgy and additive manufacturing powders, you can explore the Truer PM Powder Product Page.

4. Market Trends and B2B Demand for Diamond Catalyst Materials

As industries shift toward more efficient, durable, and high-performance materials, the market for diamond catalyst powder is experiencing notable growth. This trend is especially evident in sectors like electronics, additive manufacturing, and petrochemicals.

Key B2B Trends Driving Demand

- Growth of Synthetic Diamond Production

The demand for synthetic diamonds, used in industrial cutting tools and semiconductors, is surging, requiring more high-purity diamond catalyst powders. - Nanotechnology Integration

Nanodiamond catalysts are being integrated into next-generation catalysts for cleaner, faster chemical reactions. - Green Catalysis

As environmental regulations tighten, industries are turning to diamond-based catalysts for cleaner, reusable alternatives.

글로벌 시장 통찰력

| 지역 | Growth Drivers | 시장 예측 (2024–2030) |

|---|---|---|

| 아시아 태평양 | Rapid industrialization, increased R&D in nanomaterials | CAGR of 8.2% |

| 북미 | Investment in green technologies and electronics | CAGR of 7.5% |

| 유럽 | Emphasis on sustainability and high-efficiency manufacturing | CAGR of 6.9% |

B2B Buying Signals

- Increase in bulk inquiries for HPHT-grade catalyst powders.

- Rising demand from tool manufacturers and R&D labs.

- Expansion of OEM contracts for nanodiamond-based materials.

5. Key Considerations When Choosing a Diamond Catalyst Powder Supplier

Selecting the right supplier is essential for maintaining quality, consistency, and cost-efficiency in B2B operations.

Critical Factors to Evaluate

1. Powder Purity and Particle Size Control

- Ensure the diamond catalyst powder has tight particle size distribution.

- Purity levels should exceed 99% for catalytic efficiency.

2. Manufacturing Methods

- Check if the supplier offers HPHT or CVD-compatible powders.

- Evaluate whether powders are surface-modified or coated for specific reactions.

3. Supply Chain Reliability

- Does the supplier offer consistent lead times?

- Are they capable of fulfilling bulk or repeat orders?

4. Technical Support and Customization

- Can they customize powders for specific catalytic reactions?

- Do they offer technical assistance for integration into your production?

5. Certifications and Quality Systems

- ISO-certified manufacturing processes.

- In-house lab testing and quality assurance.

공급업체 평가 체크리스트

| 기준 | 설명 | 중요한 이유 |

|---|---|---|

| 순도 | 99%+ diamond content | Ensures reaction efficiency |

| 입자 크기 | 1–100 nm ranges | Tailored applications |

| MOQ 유연성 | Small and large batch options | Ideal for pilots and scaling |

| R&D Support | Custom blends and consultation | Faster product development |

| 물류 | Global shipping, warehousing | Reduces downtime |

6. Top 5 Global Suppliers of Diamond Catalyst Powder

Here’s a curated list of leading global suppliers, selected based on quality, B2B service, and market presence.

| 공급업체 | 국가 | 주요 강점 | B2B 서비스 |

|---|---|---|---|

| Element Six (De Beers Group) | UK | HPHT & CVD diamond catalysts | Technical support, global logistics |

| Advanced Abrasives Corp | 미국 | Nanodiamond slurry and powders | OEM supply, rapid delivery |

| Henan Huanghe Whirlwind | 중국 | Industrial diamonds and catalyst powders | Competitive pricing, bulk orders |

| NanoDiamond Products | Ireland | High-purity nanodiamond | Custom milling, R&D support |

| 상하이 트루어 기술 유한공사 | 중국 | PM & additive manufacturing powders | Integrated services, customization |

7. Why More Buyers Are Sourcing Directly from China

China has become a global hotspot for sourcing diamond catalyst powder, especially for B2B buyers seeking cost-effective, high-quality materials.

Key Reasons for This Shift

- Lower Manufacturing Costs

Competitive pricing due to streamlined production and abundant raw materials. - 확장 가능한 생산

Chinese suppliers offer flexibility — from small R&D batches to bulk industrial orders. - Advanced Powder Metallurgy Technology

Many suppliers, like 상하이 트루어 기술 유한공사, have invested in cutting-edge powder production methods including water atomization, gas atomization, and combined atomization.

China vs. Western Markets: A Comparison

| 기능 | China-Based Suppliers | 서구 공급업체 |

|---|---|---|

| kg당 가격 | ↓ Lower | ↑ Higher |

| MOQ 유연성 | 높음 | 보통 |

| 사용자 지정 | Advanced | 제한적 |

| Shipping Time (Asia) | 3–5 days | 10–15 days |

| 인증 | ISO, CE | ISO, ASTM |

8. Why Choose Shanghai Truer as Your Diamond Catalyst Powder Supplier

Shanghai Truer Technology Co., Ltd, a leading name in the Chinese powder metallurgy sector, offers a unique combination of technical expertise, advanced manufacturing, and exceptional B2B service.

회사 개요

- 설립: 2009

- Additive Manufacturing Division Created: 2019

- 전문화: 3D 프린팅 powders, PM materials, and catalyst-grade powders.

What Makes Truer a Reliable Supplier

A. Advanced Powder Production Technology

- Offers water atomized, gas atomized, and combined atomized powders.

- Maintains strict control over particle size, density, and purity.

B. Broad Product Portfolio

- Supplies PM copper, bronze, brass, iron, steel, and stainless powders.

- Offers specialized diffusion and infiltration powders for high-end applications.

C. Tailored Solutions for Catalytic Applications

- Customizes diamond catalyst powders for HPHT and chemical processes.

- Offers consultation on formulation and integration.

D. Trusted by B2B Buyers Worldwide

- Serving OEMs, tool manufacturers, and R&D institutions globally.

- Offers flexible MOQs, fast lead times, and responsive technical support.

| 혜택 | 설명 |

|---|---|

| 사용자 지정 | Tailored powder specs for catalytic efficiency |

| 글로벌 도달 범위 | Ships to North America, Europe, and Asia |

| R&D Support | Engineering assistance for new product development |

| 품질 보증 | In-house lab testing and consistent batch control |

🔗 Learn more about Truer’s capabilities on the 회사 소개 페이지.

9. How to Order Wholesale Diamond Catalyst Powder from Shanghai Truer

Ordering high-quality diamond catalyst powder from a trusted supplier such as Shanghai Truer is a streamlined process designed to accommodate both small-scale R&D labs and large-volume industrial buyers. Below is a step-by-step guide to help you navigate the B2B procurement process efficiently.

단계별 주문 프로세스

Step 1: Product Selection

Begin by identifying the specific diamond catalyst powder you need. Truer offers customizable options based on:

- 입자 크기 분포 (e.g., nano to micron)

- 순도 수준

- Application-specific needs (e.g., HPHT synthesis, chemical catalysis, electronics)

📌 Truer’s PM 분말 카탈로그 includes a range of base powders and additives that can complement your diamond catalyst applications.

Step 2: Request for Quotation (RFQ)

Submit an RFQ including the following information:

- Desired quantity (kg or tons)

- Specification requirements (purity, particle size, etc.)

- End-use industry/application

- Destination and shipping preferences

💡 Tip: Use the 문의 양식 for faster response times.

Step 3: Technical Consultation

Truer’s engineering and R&D team will review your requirements and offer:

- Suggestions on suitable powder grades

- Custom blending or surface modifications if needed

- Sample testing options for performance verification

Step 4: Quotation and Lead Time Confirmation

Once requirements are confirmed, Truer provides:

- A formal quotation (EXW, FOB, or CIF terms)

- Estimated lead time (typically 7–15 business days for standard orders)

- Logistics options (air freight, sea freight, express)

Step 5: Order Confirmation and Payment

Upon quotation approval:

- A Proforma Invoice (PI) is issued

- Payment terms are discussed (T/T, LC, etc.)

- Production begins upon receipt of payment or deposit

Step 6: Shipping and Delivery

Truer offers global delivery with real-time tracking:

- Packaging is moisture-proof and vacuum-sealed

- Each batch is labeled with lot number, date, and specifications

- Certificate of Analysis (COA) included with shipment

| 단계 | 작업 | 세부 정보 |

|---|---|---|

| 1 | Product Selection | Choose powder grade & specs |

| 2 | Submit RFQ | Quantity, purity, usage |

| 3 | Technical Review | Customization & consultation |

| 4 | 견적 수신 | Delivery terms & pricing |

| 5 | Payment & Production | Start manufacturing |

| 6 | Global Delivery | Secure packaging & COA |

10. FAQs: Common Questions About Buying Diamond Catalyst Powder

Below are answers to frequently asked questions from wholesale buyers, distributors, and industrial procurement teams.

Q1: What is the minimum order quantity (MOQ)?

A: Truer offers flexible MOQs starting from as low as 1 kg for R&D and up to several metric tons for industrial-scale buyers.

Q2: Can I request a custom particle size or surface treatment?

A: Yes. Truer specializes in customization and can tailor diamond catalyst powders to meet your specific application, including nano-sizing and chemical surface modifications.

Q3: Is Truer certified to international quality standards?

A: Yes. Truer’s manufacturing plant complies with ISO standards and each batch undergoes rigorous in-house quality testing to ensure purity, consistency, and performance.

Q4: How do I evaluate powder compatibility with my existing process?

A: Truer offers technical support and can provide small sample batches along with COA (Certificate of Analysis) and SDS (Safety Data Sheet) for lab-scale testing.

Q5: Do you ship internationally?

A: Absolutely. Truer has a strong global logistics network and ships to over 30 countries across North America, Europe, Southeast Asia, and the Middle East.

Q6: Can I visit Truer’s facility?

A: Yes. Visits can be arranged for serious B2B partners. Contact Truer via the 공식 웹사이트 to schedule a factory tour or virtual walkthrough.

Q7: What other additives or powders does Truer offer?

A: In addition to diamond catalyst powders, Truer supplies:

- Lubricants (e.g., Lube-W, SUW-5000B)

- Cutting agents (e.g., manganese sulfide, sulfur-free SME-100)

- Soft magnetic additives (e.g., QH-150, QHP-330)

- Prealloyed and hybrid PM steels (e.g., FL-4605, FD-0208)

Explore the full range of products on the Truer 소개 페이지.

Q8: Can I get a sample before placing a bulk order?

A: Yes. Truer offers sample testing for most powder grades. Samples are typically shipped within 3–5 working days after technical confirmation.

🔗 For more information or to initiate a wholesale inquiry, visit the 문의 페이지.

Internal Anchor Link Summary

To enhance user navigation and SEO optimization, we’ve embedded the following internal links:

- Truer PM Powder Product Page

- About Truer Technology Co., Ltd

- Official Website Homepage

- 문의 페이지

- PM Product Overview

This concludes the comprehensive B2B guide on sourcing Diamond Catalyst Powder. With its advanced manufacturing capabilities, customizable solutions, and global logistics support, Shanghai Truer Technology Co., Ltd is your trusted partner in the powder metallurgy supply chain.