1. Introduction to 904L Powder in Industrial Manufacturing

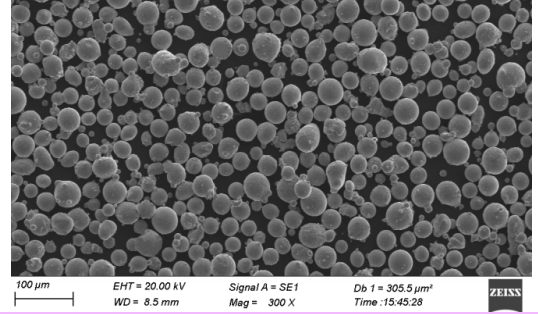

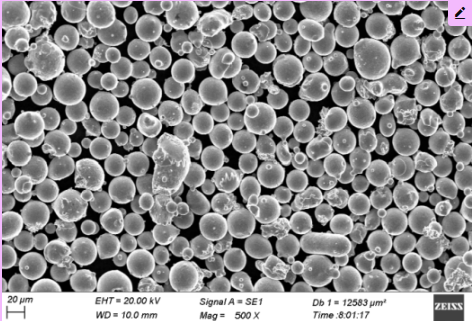

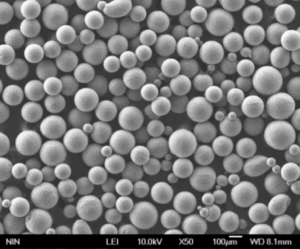

904L powder, a high-alloy austenitic stainless steel powder, is increasingly in demand across industries for its exceptional corrosion resistance and mechanical strength. It is primarily used in additive manufacturing (AM), powder metallurgy (PM), and metal injection molding (MIM) applications. The powder is typically produced using gas atomization or water atomization methods for optimized particle size distribution and flowability.

주요 B2B 이점:

- High resistance to corrosion in acidic and chloride environments.

- Excellent weldability and formability.

- Ideal for producing complex geometries in AM and PM processes.

- Competitive advantage for manufacturers in chemical, petrochemical, and marine sectors.

| 기능 | B2B 구매자를 위한 혜택 |

|---|---|

| High Nickel & Molybdenum | Superior resistance to pitting and crevice corrosion |

| Low Carbon Content | Prevents carbide precipitation in welding |

| Fine Powder Distribution | Enhances sintering and printing quality |

| Available in Bulk Quantities | Supports large-scale industrial manufacturing |

2. Key Applications of 904L Powder in Various Industries

904L stainless steel powder is used in a wide range of applications where corrosion resistance and high strength are critical. Below are key industries and specific use cases:

Industrial Applications:

- Chemical Processing Plants

Used in heat exchangers, acid tanks, and piping systems. - 석유 및 가스 산업

Ideal for offshore platforms, subsea equipment, and pressure vessels. - 자동차 부문

Utilized in high-performance engine components and exhaust systems. - 항공우주 산업

Employed in structural components requiring strength and corrosion resistance. - Additive Manufacturing (3D 프린팅)

Suitable for printing complex parts with high mechanical performance.

Benefits Across Industries:

- Extended service life in harsh environments.

- Reduced maintenance costs.

- Enhanced product reliability and safety.

| 산업 | 응용 분야 예시 | 혜택 |

|---|---|---|

| 화학 | Acid-resistant vessels | 내식성 |

| 석유 및 가스 | High-pressure valves | Strength in harsh environments |

| 자동차 | 배기 시스템 | Durability under thermal stress |

| 항공우주 | 구조 브래킷 | Lightweight and robust |

| 3D 프린팅 | Custom mechanical parts | Precision and material consistency |

3. Properties and Benefits of Using 904L Powder

904L powder offers a unique blend of chemical and physical properties that make it a preferred material for demanding applications.

화학 성분:

| 요소 | 함량(%) |

|---|---|

| 크롬(Cr) | 19.0 – 23.0 |

| 니켈(Ni) | 23.0 – 28.0 |

| Molybdenum(Mo) | 4.0 – 5.0 |

| 구리(Cu) | 1.0 – 2.0 |

| 탄소(C) | ≤ 0.02 |

| 철(Fe) | 잔액 |

기계적 속성:

| 속성 | 일반 값 |

|---|---|

| 인장 강도 | ≥ 490 MPa |

| 수율 강도 | ≥ 220 MPa |

| 신장 | ≥ 35% |

| Hardness (HB) | 150-190 |

B2B 구매자를 위한 주요 장점:

- 내식성: Performs well in reducing acids like sulfuric acid.

- Mechanical Integrity: High tensile and yield strength.

- 다용도성: Suitable for both AM and PM methods.

- 표면 마감: Excellent finish for end-use parts.

B2B buyers sourcing 904L powder from reliable manufacturers benefit from consistent quality and customized sizing for specific applications. Companies like Shanghai Truer Technology Co., Ltd offer 904L powder produced using advanced atomization techniques to ensure optimal performance in engineering applications.

Learn more about Truer’s powder metallurgy solutions for industrial use.

4. Global Market Trends and Demand for 904L Powder

The demand for 904L stainless steel powder has grown significantly due to the rise of additive manufacturing and the need for corrosion-resistant materials in high-performance industries. B2B buyers, especially those in aerospace, medical devices, and energy infrastructure, are driving this growth.

주요 시장 동인:

- Expansion of Additive Manufacturing (AM):

The global 3D printing market is projected to reach $44.5 billion by 2026. 904L powder is favored for 3D printing due to its high corrosion resistance and mechanical properties. - Stringent Industry Regulations:

Industries like pharmaceuticals and petrochemicals require materials that comply with high safety and corrosion standards—904L fits that need. - Shift Toward Sustainable Manufacturing:

904L’s long lifecycle reduces material waste and maintenance costs, aligning with sustainability goals.

Regional Demand Highlights:

| 지역 | 시장 동향 |

|---|---|

| 북미 | High adoption in aerospace and oil & gas sectors |

| 유럽 | Demand from renewable energy and medical equipment markets |

| 아시아 태평양 | Rapid industrialization and infrastructure development |

| 중동 | Investment in desalination plants and offshore facilities |

Market Growth Projections:

- CAGR: Estimated at 8.5% from 2023 to 2030.

- Key Sectors: Medical implants, defense, aerospace, automotive performance parts.

B2B enterprises are now prioritizing suppliers that can offer consistent supply, quick lead times, and technical support—factors that make companies like Shanghai Truer Technology Co., Ltd a strategic partner.

5. How to Select a Reliable 904L Powder Supplier

Choosing the right supplier is critical for B2B success, especially when dealing with high-performance alloys like 904L. Below are the key factors to consider:

1. Powder Production Method:

- 가스 분무: Produces spherical powders ideal for AM.

- 물 분무: More cost-effective for PM.

- Hybrid Atomization: Offers a balance between cost and quality.

2. Quality Certifications:

Ensure the supplier provides:

- ISO 9001:2015 certification

- Material traceability

- 일관된 입자 크기 분포

- 배치 간 균일성

3. Customization & Technical Support:

- Ability to customize particle size and composition

- On-site technical consultation

- Application-specific recommendations

4. Logistics & Supply Chain:

- Warehousing capabilities

- Prompt international shipping

- Reliable after-sales support

공급업체 평가 체크리스트:

| 기준 | 중요한 이유 |

|---|---|

| 생산 능력 | Ensures adequate volume for bulk orders |

| R&D 역량 | Supports innovation and material tailoring |

| 업계 경험 | Reduces risks and ensures compliance |

| Customer Reviews | Provides insight into reliability and service |

Shanghai Truer Technology Co., Ltd checks all these boxes. With over a decade of experience and a strong focus on powder metallurgy innovation, Truer is a trusted source for high-performance metal powders.

자세히 알아보기 about Shanghai Truer’s company background.

6. Top 904L Powder Manufacturers and Distributors

Finding a reputable manufacturer or distributor is essential for wholesale buyers looking to secure high-quality 904L powder. Below are the leading global suppliers:

Top Global Suppliers:

| 회사 이름 | 국가 | 전문화 |

|---|---|---|

| 상하이 트루어 기술 유한공사 | 중국 | PM and AM powders, custom alloys, technical service |

| 샌드빅 적층 제조 | 스웨덴 | High-performance AM powders, including 904L |

| 목수 첨가제 | 미국 | Aerospace-grade stainless steel powders |

| 호가나스 AB | 스웨덴 | Water-atomized PM powders, including stainless steels |

| 아메텍 특수 금속 제품 | 미국 | Gas atomized powders for aerospace and medical use |

상하이 트루어가 돋보이는 이유:

- Diverse Powder Portfolio:

Offers PM bronze, PM stainless steel, PM iron, infiltrated steel, and 904L powder. - Advanced Atomization Technology:

Combines gas and water atomization for optimal results. - Application Support:

Provides industry-specific additives and lubricants for enhanced performance. - Location Advantage:

Based in China, offering competitive pricing and scalable production for global orders.

Contact Truer directly for bulk inquiries and customized powder solutions.

7. Why More Buyers Are Sourcing 904L Powder from China

In recent years, China has emerged as a global leader in the production and export of metal powders, including high-performance stainless steels like 904L. B2B buyers, from small component manufacturers to large-scale OEMs, are turning to Chinese suppliers for competitive pricing, technological advancement, and flexible supply capabilities.

Key Reasons to Source 904L Powder from China:

- Cost Efficiency at Scale

- Lower labor and operational costs result in more competitive pricing.

- Ideal for bulk orders and recurring production cycles.

- 고급 제조 기능

- Rapid adoption of atomization technologies (gas, water, hybrid).

- High R&D investment in AM and PM powders.

- 다양한 제품군

- Suppliers like Shanghai Truer offer stainless steels, bronze, brass, iron-copper blends, and more.

- Custom particle sizes and alloy compositions available.

- Logistics & Export Readiness

- Dedicated export teams and international certifications.

- Strong global distribution networks.

Comparison Table: Sourcing from China vs. Other Regions

| 기준 | China (e.g., Truer) | USA/Europe |

|---|---|---|

| Price per kg (est.) | $30–$50 | $50-$80 |

| 사용자 지정 옵션 | 높음 | Medium |

| 리드 타임 | 1–2 weeks | 3~5주 |

| AM/PM Compatibility | ✔ Comprehensive | ✔ Standard |

| MOQ 유연성 | Low to High | 중간 ~ 높음 |

For buyers seeking high-purity, scalable, and cost-effective 904L powder solutions, China—especially suppliers like Shanghai Truer—is a smart sourcing destination.

8. 상하이 Truer Technology Co., Ltd를 공급업체로 선택해야 하는 이유

Shanghai Truer Technology Co., Ltd has become a preferred partner for global B2B buyers seeking advanced powder metallurgy materials. Since entering the additive manufacturing market in 2019, Truer has invested heavily in developing a vertically integrated supply chain—from powder production to additive solutions.

Truer’s Core Advantages:

- ✅ Comprehensive Powder Offering:

Including PM 904L, PM steels (FD-0200, FN-0205, FL-4605), and special additives like graphite and cutting agents. - ✅ 첨단 분무 방법:

Truer uses gas atomization, water atomization, and hybrid methods to meet diverse application needs. - ✅ Custom Engineering Support:

Truer’s engineering team provides application consultation, powder customization, and process optimization advice. - ✅ Proven Industry Experience:

Trusted by clients in automotive, aerospace, electronics, and oil & gas sectors. - ✅ Dedicated Export Team:

Ensures fast response times, documentation compliance, and global shipping reliability.

Featured 904L Powder Specs from Truer:

| 사양 | 가치 |

|---|---|

| 입자 크기 범위 | 15–45µm / 45–105µm |

| 생산 방법 | Gas Atomized / Water Atomized |

| 순도 수준 | ≥ 99.9% |

| Customization Available | Yes (size, shape, packaging) |

Truer also offers a full suite of powder metallurgy products, in addition to stainless steel 904L powder, making it a one-stop supplier for integrated PM and AM solutions.

9. FAQ: Buying 904L Powder in Bulk

Q1: What is the minimum order quantity (MOQ) for 904L powder?

A: Truer offers flexible MOQs to support both prototyping and mass production. Typical MOQ starts at 10kg but can be adjusted based on customer needs.

Q2: Can I request a custom particle size distribution?

A: Yes, Shanghai Truer can customize particle size ranges such as 15–45µm for LPBF or 45–105µm for binder jetting and PM applications.

Q3: Does Truer provide technical support for additive manufacturing?

A: Absolutely. Truer’s team includes experts in powder behavior, sintering, and 3D printing processes. They offer process optimization and material selection guidance.

Q4: What certifications do Truer’s powders comply with?

A: Truer’s powders meet international standards including ISO 9001:2015, and can be tailored to meet ASTM or DIN specifications upon request.

Q5: 도매 주문은 어떻게 하나요?

A: 다음을 수행할 수 있습니다. Truer에 직접 문의하십시오. via their website or email their sales team with your specifications, quantity, and delivery timeline.

Q6: Are samples available for testing?

A: Yes, Truer offers sample quantities for lab or pilot-scale testing before placing bulk orders.

✅ Ready to Source Premium 904L Powder?

Shanghai Truer Technology Co., Ltd is your trusted partner for high-purity, application-specific 904L stainless steel powder. With scalable production, technical expertise, and global delivery capabilities, Truer is the ideal supplier for industries pushing the boundaries of performance and innovation.

👉 Explore all of Truer’s additive manufacturing powder solutions