1. Introduction: Why Aluminum Nitride Powder Is in High Demand

Aluminum Nitride (AIN) powder is a high-performance ceramic material known for its excellent thermal conductivity, high electrical resistivity, and low thermal expansion. These properties make AIN powder a crucial material for electronic substrates, thermal management systems, and high-performance composites.

For B2B buyers in sectors like electronics, automotive, aerospace, and telecom, aluminum nitride powder offers a strategic advantage in manufacturing high-reliability components. With the global push towards miniaturization and high-speed electronics, the demand for aluminum nitride powder is accelerating at a significant pace.

Benefits of Aluminum Nitride Powder for B2B Applications:

| 속성 | Benefit for Industrial Use |

|---|---|

| 높은 열 전도성 | Efficient heat dissipation in electronic substrates |

| Low dielectric constant | Ideal for high-frequency semiconductor applications |

| High electrical resistivity | Excellent insulation for power modules and circuits |

| Thermal expansion matching | Reduces stress in multi-layer ceramic packages |

| Chemical stability | Resistance to molten metals and corrosive environments |

For companies sourcing materials for advanced manufacturing, quality and consistency of AIN powder are critical. That’s why partnering with a trusted supplier is essential for long-term success.

2. Key Applications of Aluminum Nitride Powder in Industry

Aluminum nitride powder serves as a core material in various high-end industrial applications. Its unique properties make it irreplaceable in some use cases, particularly where heat dissipation and electrical insulation are crucial.

Major Applications of Aluminum Nitride Powder:

- Electronic Substrates:

- AIN is widely used in substrates for high-power semiconductors and LEDs.

- Replaces alumina where higher thermal conductivity is required.

- Thermal Interface Materials (TIMs):

- Mixed with polymers or epoxies to create TIMs for computer processors and power electronics.

- Metal Matrix Composites (MMCs):

- Reinforces aluminum or magnesium alloys for automotive and aerospace lightweighting.

- Sputtering Targets:

- Used in thin-film deposition for semiconductor and optical devices.

- Ceramic Heaters and Crucibles:

- Withstands high temperatures and corrosive environments in CVD and PVD processes.

B2B Buyers That Frequently Use AIN Powder:

| 산업 | 사용 사례 |

|---|---|

| 전자 제품 | Substrates, heat sinks, circuit boards |

| 자동차 | EV power modules, high-performance composites |

| 항공우주 | Lightweight structural parts with thermal control |

| Telecom | RF modules, base station hardware |

| Semiconductor | Sputtering targets, packaging components |

If you’re sourcing aluminum nitride powder for any of the above applications, it’s essential to evaluate the supplier’s production method, material purity, and thermal conductivities to ensure compatibility with your manufacturing needs.

3. Types and Grades of Aluminum Nitride Powder

Aluminum nitride powder comes in various purities, particle sizes, and surface treatments, each tailored to specific industrial applications. Selecting the right type is key to ensuring optimal performance in your end product.

Common Types of Aluminum Nitride Powder:

| 유형 | 설명 |

|---|---|

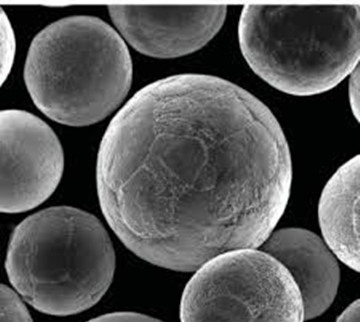

| High-Purity AIN Powder (≥99.9%) | Used in high-end electronics and semiconductor applications |

| Standard-Grade AIN Powder (≥98%) | Suitable for general thermal interface materials and ceramic substrates |

| Surface-Treated AIN Powder | Modified for better dispersion in polymers and resins |

| Nano-Scale AIN Powder | Used in advanced composites with ultra-thin layers or films |

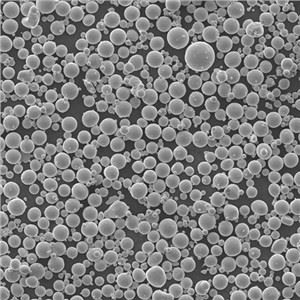

입자 크기 분포:

| 크기 범위 | 적용 분야 |

|---|---|

| 0.5–1 μm | Polishing materials, thin films |

| 1–3 μm | Ceramic substrates, thermal pastes |

| 5–10 μm | Metal matrix composites, injection molding |

Key Parameters to Consider:

- 열 전도성: Higher values (>170 W/m·K) are needed for heat sinks.

- Oxygen Content: Lower oxygen (<1 wt%) improves thermal performance.

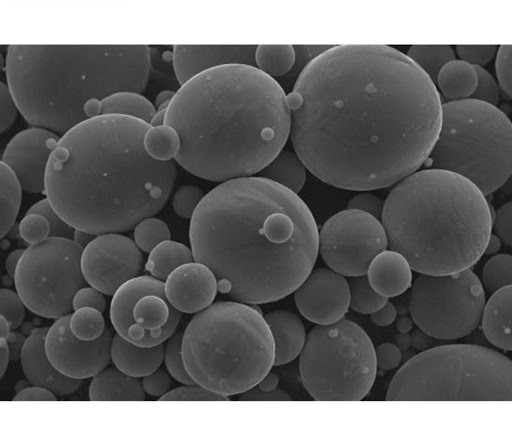

- 형태학: Spherical or irregular particles depending on application.

At 상하이 트루어 기술 유한공사, we understand the importance of performance characteristics in aluminum nitride powder selection. Our advanced powder processing technologies ensure consistent particle size, purity, and thermal performance for demanding industrial applications.

We welcome you to explore our PM powder offerings here for detailed specifications on our aluminum nitride and other metal powders.

4. Market Trends & Growth Potential in the AIN Sector

As industries rapidly advance in electronics, automotive electrification, and high-frequency communication, the aluminum nitride (AIN) powder market is experiencing unprecedented growth. B2B procurement professionals are increasingly seeking high-purity, thermally conductive materials to enhance product reliability and performance.

Global Market Overview

- The global aluminum nitride market was valued at over USD 100 million in 2023.

- Projected CAGR: 8–10% from 2024 to 2030.

- Asia-Pacific dominates the market, led by China, Japan, and South Korea.

- Demand is driven by:

- 5G infrastructure expansion

- Electric vehicles (EVs)

- Semiconductor miniaturization

Key B2B Market Drivers:

| Industry Segment | Growth Catalyst |

|---|---|

| Power Electronics | Need for efficient heat dissipation in IGBT and MOSFET modules |

| LED Manufacturing | Higher brightness and longer lifespan require thermal stability |

| 항공우주 및 방위 산업 | Lightweight and thermally stable materials for avionics |

| 통신 | High-frequency, low-loss materials for RF applications |

Technology Advancements:

- Surface functionalization to improve AIN dispersion in polymer composites.

- Development of nanoscale AIN for ultra-thin film applications.

- Hybrid composites blending AIN with boron nitride for enhanced performance.

With such dynamic growth, B2B buyers must stay ahead of material innovations and maintain strong supplier relationships to ensure a steady supply and technical support.

5. How to Choose a Reliable Aluminum Nitride Powder Supplier

Selecting a trustworthy supplier is critical to long-term success in product development and manufacturing efficiency. Below are key criteria B2B buyers should consider when sourcing aluminum nitride powder.

Key Supplier Evaluation Checklist:

| 요인 | 확인해야 할 사항 |

|---|---|

| Purity and Consistency | ≥99% purity; consistent particle morphology and size |

| 기술 지원 | R&D assistance, documentation, and customization options |

| 생산 능력 | Ability to fulfill large-volume or recurring bulk orders |

| 품질 인증 | ISO 9001, RoHS, REACH, and other compliance documentation |

| 배송 신뢰성 | Stable lead times and robust logistics network |

| 사용자 지정 기능 | Tailored grades for specific thermal or electrical applications |

Common Pitfalls to Avoid:

- Sourcing from brokers without manufacturing oversight

- Lack of technical data (TDS, SDS, COA)

- Inconsistent batch quality leading to product failures

To mitigate these risks, it is advisable to work directly with reputable manufacturers like 상하이 트루어 기술 유한공사, which offers full traceability, technical expertise, and customizable solutions for industrial buyers across the globe.

6. Top 5 Global and Chinese Suppliers for Aluminum Nitride Powder

Here is a curated list of leading aluminum nitride powder suppliers with strong reputations in quality, capacity, and global delivery.

Top Global Suppliers:

| 회사 이름 | 국가 | 강점 |

|---|---|---|

| Tokuyama Corporation | 일본 | Ultra-high-purity AIN for semiconductors and LEDs |

| Surmet Corporation | 미국 | Advanced ceramics, including AIN for defense |

| 생고뱅 | 프랑스 | Thermal management materials and composites |

Top Chinese Suppliers:

| 회사 이름 | 하이라이트 |

|---|---|

| Henan Yuxing Sino-Crystal | AIN ceramics for LED and microelectronics |

| Advanced Technology & Materials Co., Ltd. (AT&M) | Integrated R&D and manufacturing |

| 상하이 트루어 기술 유한공사 | Full-spectrum PM powders, including AIN |

Shanghai Truer stands out not only for its high-quality AIN powders but also for its comprehensive additive manufacturing solutions. Having entered the additive manufacturing field in 2019, Truer has become one of the most respected suppliers in China’s powder metallurgy industry.

7. Why More Buyers Are Switching to Chinese Manufacturers

With rising material costs and tightening global supply chains, more international buyers are turning to Chinese suppliers for their aluminum nitride powder needs. Here’s why.

Advantages of Chinese AIN Powder Manufacturers:

- 비용 효율성: Lower labor and operational costs without compromising quality.

- Rapid Scaling: Quick capacity expansion to meet urgent or large-volume orders.

- Innovation in Processing: Advanced atomization and purification technologies.

- 사용자 지정: Flexible production tailored to client specifications.

Case Study: Truer’s Edge in the Global Market

Shanghai Truer Technology Co., Ltd demonstrates the strengths of Chinese manufacturing through:

- Diverse powder metallurgy products including AIN, PM steels, and CuSn alloys.

- In-house R&D and proprietary processing for particle size control and purity.

- Technical support for integration into additive manufacturing and PM applications.

Whether you’re sourcing AIN powder for thermal substrates or high-performance composites, Truer provides a competitive alternative to traditional Western suppliers—without sacrificing quality.

Explore how Truer’s PM powders support advanced engineering applications by visiting their PM 분말 포트폴리오.

8. How to Order Wholesale Aluminum Nitride Powder from China

Sourcing aluminum nitride (AIN) powder in bulk from China can be a cost-effective and efficient solution for B2B buyers—if done correctly. Here’s a step-by-step guide to streamline your procurement process and secure consistent, high-quality supply from trusted manufacturers like Shanghai Truer Technology Co., Ltd.

Step-by-Step Wholesale Ordering Process:

| 단계 | 설명 |

|---|---|

| 1 | Product Specification Submission – Define purity, particle size, and quantity. |

| 2 | Quotation Request – Request a formal quote including MOQ, lead time, Incoterms. |

| 3 | Sample Testing – Request 100g–1kg sample for lab evaluation. |

| 4 | Contract Finalization – Sign PO, NDA, and quality agreement if necessary. |

| 5 | 생산 및 품질 관리 – Batch manufacturing with COA (Certificate of Analysis). |

| 6 | Packaging & Labeling – Standard: sealed vacuum bags in HDPE drums or custom. |

| 7 | 배송 및 물류 – FOB Shanghai or CIF global ports via air/sea freight. |

| 8 | 판매 후 지원 – Technical guidance, reorder planning, and feedback loop. |

Typical Documentation Provided:

- COA (Certificate of Analysis)

- MSDS / SDS

- RoHS / REACH Certification

- Export License & Customs Declarations

- Packing List & Commercial Invoice

Accepted Payment Terms:

- T/T (30% deposit, 70% before shipment)

- 대량 주문의 경우 L/C

- Negotiable payment plans for long-term buyers

Shanghai Truer ensures a transparent and efficient procurement process. With over a decade of experience in powder metallurgy and additive manufacturing, Truer provides not only high-quality AIN powder but also full support during the procurement and application process. Visit 문의 페이지를 방문하십시오. to request a quote or product consultation.

9. FAQs: Buying Aluminum Nitride Powder in Bulk

Q1: What is the MOQ for aluminum nitride powder from Shanghai Truer?

A: The minimum order quantity typically starts at 25kg. For new clients or testing purposes, smaller quantities can be arranged upon request.

Q2: How is the powder packaged?

A: 표준 포장에는 다음이 포함됩니다.

- Vacuum-sealed polyethylene bags

- Contained in 25kg drums with moisture protection

- Custom packaging available for large-volume clients

Q3: Can I request a custom particle size or purity?

A: Yes. Truer specializes in producing tailored AIN powders based on:

- Purity levels (from 98% to 99.9%)

- Particle size distribution (0.5 μm to 10 μm)

- Surface modification treatments for polymer dispersion

Q4: How long does it take to receive the goods?

A: Lead time ranges from 7–15 business days depending on order volume and customization requirements. Air freight typically takes 5–7 working days internationally.

Q5: Is technical support available for integrating AIN powder into my product?

A: Absolutely. The Truer technical team offers expert guidance for:

- Powder selection based on end-use

- Dispersion and blending techniques

- Compatibility with injection molding, sintering, or extrusion

Q6: What industries does Truer currently serve?

A: Truer supplies AIN powder and other PM materials to:

- 전자 제품

- Automotive (especially EVs)

- 항공우주

- LED and lighting systems

- 반도체 제조

Q7: Can I visit the Truer facility for a factory audit?

A: Yes. Truer welcomes factory audits and technical evaluations by procurement teams. They also offer virtual tours and live video inspections for international clients.

Why Choose Shanghai Truer Technology Co., Ltd as Your AIN Supplier

Shanghai Truer Technology Co., Ltd is one of China’s most recognized names in powder metallurgy and additive manufacturing materials. Since expanding into 3D 프린팅 and advanced powders in 2019, Truer has become the go-to partner for B2B buyers seeking consistent quality, technical innovation, and reliable service.

Truer’s Distinct Advantages:

- ✅ Over 15 years of PM manufacturing experience

- ✅ Specialized in high-performance powders including AIN, PM alloys, and CuSn

- ✅ Advanced atomization techniques: water, gas or hybrid

- ✅ Customizable grades for electronics, thermal management, and composites

- ✅ Full documentation, rapid delivery, and responsive support

Whether you’re developing cutting-edge electronics or scaling up EV production, Truer’s aluminum nitride powders offer the thermal and electrical performance your application demands.

Explore the full range of powders, including AIN, steel, copper, and customized PM materials, by visiting our products page.

Internal Links Summary (Anchor Text + URLs)

- 상하이 트루어 기술 유한공사 - https://am-material.com/about/

- PM 분말 포트폴리오 - https://am-material.com/pm-powder/

- 연락처 페이지를 통해 직접 문의하세요. - https://am-material.com/contact-us/

- Aluminum nitride powder offerings - https://am-material.com/pm-powder/

- Truer’s homepage - https://am-material.com/

📩 Ready to place your first bulk order or request a technical consultation?

👉 Contact Truer’s team today to get started with high-quality aluminum nitride powder tailored for your industrial needs.

Let Truer be your trusted partner in advanced powder metallurgy.