パウダーの概要 マルチレーザー印刷

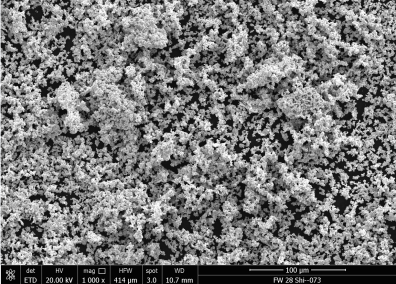

進化し続ける製造業の世界で、マルチレーザープリンティングは最先端技術として登場し、積層造形で可能なことの限界を押し広げている。しかし、この技術の原動力は何だろうか?その答えは 金属粉 これらの高度な機械に使用される。綿密に設計され製造されたこれらのパウダーは、複雑で耐久性のある高精度の部品を製造するための基盤となっている。

マルチレーザー・プリンティング、特に金属積層造形の領域では、使用する粉末の品質と特性に大きく依存する。この記事では、マルチレーザー印刷用の金属粉末のさまざまな側面を深く掘り下げ、さまざまな種類、組成、特性、および用途を探ります。熟練した専門家であれ、好奇心旺盛な初心者であれ、十分な情報に基づいた決断ができるよう、技術的な複雑さをガイドし、比較を提供します。

マルチレーザー印刷用パウダーの組成

マルチレーザー印刷用の金属粉末について議論する場合、組成は極めて重要である。粉末の元素構成は、特定の用途への適合性、溶融挙動、そして最終的には印刷部品の品質を決定します。ここでは、マルチレーザー印刷で使用される一般的な金属粉末の組成について説明します:

| パウダータイプ | 主な構成 | 副次的要素 | 特筆すべき特徴 |

|---|---|---|---|

| ステンレススチール316L | Fe、Cr、Ni、Mo | C、Si、Mn | 高耐食性、優れた延性 |

| アルミニウム合金 AlSi10Mg | Al、Si、Mg | Fe、Cu、Mn | 軽量、優れた熱特性、高強度対重量比 |

| チタン合金 Ti-6Al-4V | Ti、Al、V | O、Fe | 高強度、生体適合性、耐食性 |

| Inconel 718 | Ni、Cr、Fe、Nb | Mo、Ti、Al、Co | 高温耐性、強度、靭性 |

| コバルトクロム(CoCr) | Co、Cr、Mo | W、Si | 優れた耐摩耗性、生体適合性 |

| マルエージング鋼 (18Ni300) | Fe、Ni、Co、Mo | Ti、Al | 高強度、高靭性、機械加工が容易 |

| 銅合金(CuCrZr) | Cu、Cr、Zr | 鉄、鉛 | 高い熱伝導性と電気伝導性 |

| Hastelloy X | Ni、Cr、Fe、Mo | Co、W、Si | 高温での耐酸化性と耐クリープ性 |

| 工具鋼(H13) | Fe、Cr、Mo、V | C、Si、Mn | 高い耐摩耗性、優れた靭性 |

| ニッケル合金 (Ni625) | Ni、Cr、Mo、Nb | Fe、Al、Ti | 高い耐食性と耐酸化性 |

これらの組成物は、航空宇宙から生物医学インプラントまで、多様な用途に必要な特定の特性を提供するために細かく調整されている。

マルチレーザー印刷用パウダーの特徴

金属粉末の特性は、その組成と同様に非常に重要である。これらの特性は、印刷プロセス、印刷部品の機械的特性、およびマルチレーザー印刷作業の全体的な成功に影響を与えます。

| 特徴 | 説明 |

|---|---|

| 粒度分布 | 均一な粒度分布により、レイヤー・バイ・レイヤー印刷に不可欠な安定した流動性と充填密度を実現します。 |

| 球形度 | 球状粒子は、より良い流動性とパッキングを促進し、印刷部品の欠陥の可能性を低減します。 |

| 純度 | 高純度は、最終部品の欠陥や性能低下につながるコンタミネーションを最小限に抑える。 |

| 見かけ密度 | 見掛け密度が高いと、ボイドや欠陥が少なくなるため、最終部品の機械的特性が向上する。 |

| 流動性 | 良好な流動性は、印刷工程で安定した粉体分布に不可欠であり、造形品質と信頼性に影響する。 |

| 含水率 | パウダーの性能を損なう可能性のある酸化やその他の反応を防ぐためには、含水率を低くすることが重要である。 |

| 酸素含有量 | 特にチタンのような反応性の高い材料では、高い酸素が脆化につながる可能性があるため、酸素レベルの管理は極めて重要である。 |

| 化学的均質性 | 印刷部品全体に均一な機械的特性を確保し、弱点や不整合を防ぎます。 |

| 表面の質感 | 滑らかな表面テクスチャーが粒子間の摩擦を低減し、印刷時の流動性と層の凝集力を高める。 |

これらの特性を理解することは、特定の用途に適したパウダーを選択し、最適な性能と品質を確保するための鍵となります。

金属粉末の種類 マルチレーザー印刷

用途によって必要とされる金属粉末の種類は異なります。ここでは、マルチレーザー印刷で最も一般的に使用される金属粉末について詳しく説明します:

| 金属粉タイプ | 用途 | メリット | デメリット |

|---|---|---|---|

| ステンレススチール316L | 医療機器、食品加工機器 | 高耐食性、生体適合性 | 他の合金に比べて強度が低い |

| アルミニウム合金 AlSi10Mg | 航空宇宙、自動車部品 | 軽量、高強度対重量比 | 疲労強度に限界 |

| チタン合金 Ti-6Al-4V | 航空宇宙、医療用インプラント | 高強度、生体適合性 | 高価で加工が難しい |

| Inconel 718 | タービンブレード、高温部品 | 優れた耐熱性、強度 | 機械加工が難しい |

| コバルトクロム(CoCr) | 歯科インプラント、整形外科インプラント | 耐摩耗性、耐食性、生体適合性 | 高コスト |

| マルエージング鋼 (18Ni300) | 工具、高強度部品 | 高強度、靭性、機械加工が容易 | 高い |

| 銅合金(CuCrZr) | 熱交換器、電気部品 | 優れた熱伝導性と電気伝導性 | 酸化しやすい |

| Hastelloy X | 化学処理、航空宇宙 | 高温強度、耐酸化性 | 非常に高価、溶接が難しい |

| 工具鋼(H13) | 射出成形、ダイカスト | 高い耐摩耗性、靭性 | 熱処理中に割れやすい |

| ニッケル合金 (Ni625) | 海洋、化学処理 | 耐食性、良好な溶接性 | 高コスト、限られた利用可能性 |

これらのパウダーにはそれぞれ長所と短所があり、特定の用途には適しているが、他の用途では問題となる可能性がある。例えば チタン合金 Ti-6Al-4V は、比類のない強度と生体適合性を提供するが、それに比べて高価で加工が難しい。 ステンレススチール316L.

マルチレーザー印刷用パウダーの用途

マルチレーザー印刷は様々な産業で使用されており、それぞれが独自の要求を満たす特定の金属粉末を必要としています。ここでは、いくつかの用途について詳しく見てみよう:

| 産業 | 用途 | 好ましい金属粉末 |

|---|---|---|

| 航空宇宙 | タービンブレード、構造部品 | インコネル718、チタン合金Ti-6Al-4V、アルミニウム合金AlSi10Mg |

| メディカル | インプラント、手術器具 | ステンレス鋼316L、コバルトクロム(CoCr)、チタン合金Ti-6Al-4V |

| 自動車 | 軽量部品、エンジン部品 | アルミニウム合金AlSi10Mg、マルエージング鋼(18Ni300)、ステンレス鋼316L |

| 工具 | 金型、ダイ、高強度部品 | 工具鋼(H13)、マルエージング鋼(18Ni300)、インコネル718 |

| エネルギー | 熱交換器、発電部品 | 銅合金(CuCrZr)、ニッケル合金(Ni625)、ハステロイX |

| マリン | 耐食部品、構造部品 | ニッケル合金(Ni625)、ステンレス鋼316L、インコネル718 |

各業界にはそれぞれ異なる要件があり、最適な性能と費用対効果を確保するためには、適切な金属粉末を選択することが極めて重要です。

仕様、サイズ、等級、規格

マルチレーザー印刷用の金属粉末を選択する際には、特定の用途に必要な仕様、サイズ、グレード、および規格を考慮することが重要です。ここに、これらの側面をまとめた詳細な表を示します:

| 金属粉タイプ | 粒子径範囲 (µm) | グレード | 規格 | 純度 |

|---|---|---|---|---|

| ステンレススチール316L | 15-45 | AMシリーズ | ASTM F3184、ISO 5832-1 | 99.9% |

| アルミニウム合金 AlSi10Mg | 20-63 | AMシリーズ | ISO 9001、ASM F3318 | 99.8% |

| チタン合金 Ti-6Al-4V | 15-45 | AMシリーズ | ASTM F2924、ISO 5832-3 | 99.5% |

| Inconel 718 | 15-53 | AMシリーズ | ASMB637、ISO6362 | 99.8% |

コバルトクロム(CoCr) | 20-45 | AMシリーズ | ASTM F75、ISO 5832-12 | 99.5% |

| マルエージング鋼 (18Ni300) | 15-53 | AMシリーズ | A709, ISO 683-17 | 99.9% |

| 銅合金(CuCrZr) | 10-45 | AMシリーズ | ASMB192、ISO5414 | 99.9% |

| Hastelloy X | 15-53 | AMシリーズ | ASTM B333、ISO 18286 | 99.8% |

| 工具鋼(H13) | 15-45 | AMシリーズ | A681, ISO 4957 | 99.7% |

| ニッケル合金 (Ni625) | 15-53 | AMシリーズ | ASTM B443、ISO 6206 | 99.8% |

これらの仕様により、パウダーは性能と品質に関する業界標準を満たし、最終的な印刷部品に一貫性がもたらされる。

サプライヤーと価格詳細

適切なサプライヤーを選ぶことは、適切な粉末を選ぶことと同じくらい重要です。以下は、様々な金属粉末の評判の良いサプライヤーと一般的な価格詳細をまとめたものです:

| サプライヤー | 金属粉タイプ | おおよその価格(1kgあたり) | 所在地 | ウェブサイト |

|---|---|---|---|---|

| サンドビック積層造形 | ステンレススチール316L | $150 – $250 | スウェーデン | サンドビック・ドットコム |

| イーオーエス | アルミニウム合金 AlSi10Mg | $200 – $300 | ドイツ | eos.info |

| アルカム(GEアディティブ) | チタン合金 Ti-6Al-4V | $400 – $600 | スウェーデン | アーカム・ドットコム |

| ケナメタル | Inconel 718 | $350 – $500 | アメリカ | kennametal.com |

| デスクトップ・メタル | コバルトクロム(CoCr) | $500 – $700 | アメリカ | デスクトップ・メタル・ドット・コム |

| LPWテクノロジー | マルエージング鋼 (18Ni300) | $300 – $450 | 英国 | lpwtechnology.com |

| GKNアディティブ | 銅合金(CuCrZr) | $250 – $350 | ドイツ | gknpowder.com |

| ハステロイ | Hastelloy X | $600 – $800 | アメリカ | ヘイネシントル・ドットコム |

| シスマ | 工具鋼(H13) | $220 – $320 | イタリア | シスマ・ドット・コム |

| ベロ3D | ニッケル合金 (Ni625) | $500 – $700 | アメリカ | ベロ3Dドットコム |

価格は注文数量、送料、市場の変動により異なる場合があります。最新の価格と在庫については、常にサプライヤーにお問い合わせください。

金属粉末の利点と限界 マルチレーザー印刷

適切な金属粉末を選択するには、その利点と限界を天秤にかける必要があります。ここでは、その比較の概要を説明する:

| パウダータイプ | メリット | 制限事項 |

|---|---|---|

| ステンレススチール316L | 耐食性、優れた機械的特性 | いくつかの合金に比べて強度が低い |

| アルミニウム合金 AlSi10Mg | 軽量、高強度対重量比 | 疲労強度が低く、加工コストが高い |

| チタン合金 Ti-6Al-4V | 高強度、優れた耐食性、生体適合性 | 高価で加工が難しい |

| Inconel 718 | 優れた耐熱性、高強度 | 機械加工が難しく、コストが高い |

| コバルトクロム(CoCr) | 耐摩耗性、生体適合性 | 高コスト、複雑な処理要件 |

| マルエージング鋼 (18Ni300) | 高強度、優れた靭性 | 高価、精密な熱処理が必要 |

| 銅合金(CuCrZr) | 優れた熱伝導性と電気伝導性 | 酸化しやすく、処理が複雑 |

| Hastelloy X | 高温強度、耐酸化性 | 非常に高価、溶接が難しい |

| 工具鋼(H13) | 高い耐摩耗性、優れた靭性 | 熱処理中に割れやすい |

| ニッケル合金 (Ni625) | 耐食性、良好な溶接性 | 高コスト、限られた利用可能性 |

粉末の種類はそれぞれ、特定の用途に適したユニークな利点を提供するが、同時に独自の課題も伴う。例えば チタン合金 Ti-6Al-4V は、その強度と生体適合性から非常に望ましいが、コストが高く、複雑な加工が必要なため、すべてのプロジェクトに適しているとは限らない。

よくある質問

| 質問 | 回答 |

|---|---|

| マルチレーザー印刷における金属粉末の役割とは? | 金属粉末は、マルチレーザープリンティングの材料原料として機能し、複雑なパーツを層ごとに作成することを可能にする。 |

| 金属粉末の違いは最終製品にどのような影響を与えるのか? | パウダーの選択は、強度、耐久性、様々な条件に対する耐性など、最終的な印刷部品の機械的特性、外観、性能に影響を与える。 |

| なぜ金属粉の粒径が重要なのか? | 粒子径はパウダーの流動性と充填密度に影響し、ひいては印刷層の一貫性と品質に影響する。 |

| 金属粉はリサイクルできますか? | はい、多くの金属粉末はリサイクルできますが、そのプロセスや効率は、使用する粉末やリサイクル技術によって異なります。 |

| マルチレーザー印刷用の金属粉末の一般的なコストは? | コストは、粉末の種類、純度、供給元によって大きく異なる。価格は一般的に1キログラムあたり150ドルから800ドルである。 |

| 純度は金属粉末にどのような影響を与えるのか? | 純度の高いパウダーはコンタミが少なく、最終的な印刷部品の機械的特性と信頼性の向上につながる。 |

| 金属粉の環境に対する懸念はありますか? | 金属粉は、適切に取り扱われないと、粉塵の危険や汚染など、環境上の問題を引き起こす可能性がある。適切な安全対策と廃棄方法が重要です。 |

| マルチレーザー印刷用の金属粉末はどのような基準を満たすべきか? | 一般的な規格にはASTMやISO仕様があり、積層造形に使用される粉末の品質と一貫性を保証している。 |